repair sun damaged lcd screen made in china

Ive not had big problems with bubbles and screen replacements have you done these types of repairs before and keep having that problem? It may sound ghetto but when doing window tinting you can use a hairdryer to heat it up a bit and it will stretch out then use a kind of scraping tool to get the bubble out. Should work the same with a phone i wouldnt see why not. As far as the business goes i wouldn"t reccomend doign a glass only type of thing, i would highly reccomend if you"re going to do it repair all phone problems and if you can"t fix it or its totally shot thats fine just tell the customer and dont charge them. Im starting a game console and phone repair business where i am now and for someone your age i would reccomend you try that out unless you live somewhere that you have plenty of clients and opportunity to make money where i am theres not a lot of money going around so game consoles are pretty trendy along with the smartphones. One last thing don"t worry about spending hundreds or thousands of dollars on anything for a business until you already have the business going trust me you"ll get discouraged spending a thousand dollars on something and then finding out you can only make a hundred dollars a week or less on average so pace yourself and start with simple repairs work your way up to complex things and build a large understanding of what you want to work with. As a young person your biggest problem will be people not taking you seriously or trusting you have the knowledge to do something so work on speaking and knowledge and you should be able to get over that hurdle. Hope some of that us helpful.

Well if you have a demand for that in your area then i would say go for it. I have honestly not heard of the things you"re talking about but i have not done many phone repairs just a couple and i didnt have any specific issues. Maybe some of the newer stuff is like that but i cant say i know anything about it. The best i can figure from a google search is that its cured by a screen/digitzer replacement and it could be caused from internal pressure or heat causing weird things to happen. Did you replace a screen on a phone and have problems with bubbles or something this is the first ive really heard of issues like this.

If you press a bit more than a little, but not too much, some of the warmed crystal can squeeze out. Both time and varying electric current twisting the crystal might cause it to return to it"s correct location - not something you would want to test on a new screen.

"The characteristic of liquid crystals that makes them ideal to be used in display screens is that they align themselves when an external electric field is applied to them. To be more technically specific, these liquid crystals are sandwiched between two pieces of polarized glass ...".

"... several people have had good luck simply applying a small amount of pressure to the affected pixel with your finger or a pen through a folded paper towel or piece of cloth (to keep said pen from scratching the screen). While applying pressure, turn the screen on and off several times.".

Smartphones are the opium of the people. If you need proof, just watch the average person’s reaction when they break “their precious”. Repairing smartphones has become a huge business. The most often broken item on phones is of course the front glass. In most cases, the screen itself doesn’t break. On newer smartphones, even the touchscreen is safe. The front glass is only a protective lens.

The easiest way to repair a broken front glass is to swap the entire LCD assembly. For an iPhone 6 plus, this will run upwards of $120 USD. However, the glass lens alone is just $10. The problem is that the LCD, digitizer and front glass are a laminated package. Removing them without breaking the wafer thin LCD glass requires great care. The hardest part is breaking down the optical glue securing the glass to the LCD. In the past that has been done with heat. More recently, companies from China have been selling liquid-nitrogen-based machines that cool the assembly. Now immersing a phone screen in -196° C liquid nitrogen would probably destroy the LCD. However, these machines use a temperature controller to keep a surface at -140° C. Just enough to cause the glue to become brittle, but not kill the LCD.

[JerryRigEverything] doesn’t have several thousand dollars for a liquid nitrogen machine, but he does have a $5 block of dry ice. Dry ice runs at -78.5°C. Balmy compared to liquid nitrogen, but still plenty cold. After laying the phone screens down on the ice for a few minutes, [Jerry] was able to chip away the glass. It definitely takes more work than the nitrogen method. Still, if you’re not opening your own phone repair shop, we think this is the way to go.

Broken phones are a cheap and easy way to get high-resolution LCD screens for your projects. The problem is driving them.[Twl] has an awesome project on Hackaday.io for driving phone screens using an FPGA. We haven’t seen it done with iPhone 6 yet though. Anyone up for the challenge?

The original Game Boy is a classic. Sure, it had no backlight, but there is something special about playing on that classic green screen. Unfortunately, some of these older systems are suffering a terrible fate — screen burn. Game Boy’s played best with lots of light — especially out in the sun. But that same sun did terrible things to the screen. A black splotch in the center of the LCD is the telltale sign of a burned Game Boy. You might think that screen replacement is the only option, but[The Retro Future] shows us how to repair this issue.

A reflective LCD is a layer cake made up of polarizers, two panes of glass, and a reflector. The burns often seen on Game Boy screens usually are in the polarizer and the optically clear glue which attaches the plastic polarizer to the glass. We’re guessing these burns happen when someone leaves their Game Boy out in the sun. Between the sun rays directly striking the top polarizer and the rays bounced back from the reflector at the rear of the screen, that poor polarizer doesn’t stand a chance.

Repairing the burn is a delicate operation, as one false move could crack the thin LCD glass. The first step is to carefully peel off the burned polarizer. This leaves a mess of dried glue, which can be scraped off or dissolved with alcohol. A new linear polarizer can then be placed on the front of the screen. [The Retro Future] chose not to glue the polarizer, but we’re betting some UV cure LOCA (Liquid Optically Clear Adhesive) from a cell phone screen protector would do the trick.

I need to replace my cracked digitizer/glass on my OnePlus One and it seems changing only the digitizer is kinda hard so next thing is to get the full LCD to replace.

It seems logical that lcd + frame is easier but it seems it requires to move components/motherboard around which for me seems more prone to mistakes and problems then just buying an LCD and putting it into my old frame.

LOCA or Liquid Optically Clear Adhesive is kind of special UV glue or sealant used to bond display / LCD Screen and touch screen panels. It is also called UV Glue. Most technicians prefer to use LOCA Glue or UV Glue over other glue or sealants because it improves contrast by many times. It also prevents loss of light from the display and hence increases the life of Mobile Phone Battery.

In order to replace a faulty, broken or damaged glass / touch panel (PDA) of LCD Screen of a mobile phone or smartphone, you will need following Mobile Phone Repairing Tools:

Separating the glass from the LCD should be done very carefully to avoid any unwanted damage. Special care must be undertaken if the glass is cracked. Never try to take off the glass without the right tools and equipment. It can damage the LCD which can be very costly to replace.

The glass and LCD are strongly bonded together with LOCA glue. The glue must be heated to loosen the bond. It can be done using a Hot Air Gun / Heat Gun. Technicians with some practice can easily do it. However, in most authorized service centers and professional service centers, they use LCD separator machine.

Use a Hot Air Gun or LCD Separator Machine, to give heat to the LCD to Loosen the bond of the LOCA glue. In both cases, a temperature of 200-300 Degree C is OK.

Gradually and evenly heat the front side of the phone. Use the Infrared Thermometer to check the temperature before trying to remove the glass. Make sure there is neither too much heat nor too little heat. Too much heat will burn the LCD screen while too little heat might crack it.

Start removing the glass from the top of the screen where speaker is located. Use the metal spudger to carefully separate the glass from the LCD screen. Move the spudger along the top edge and make enough space for the putty knife to slip in.

Reheat the surface and using the putty knife, carefully pry the glass away. After removing the Glass, use the Goof Off or Hot Blade to remove existing melted LOCA glue and clean the LCD screen using lint-free wipes. Some service centers and technicians also use automated LOCA removing machine.

LOCA glue is available in the form of liquid. It is not as thick as other adhesives. Apply just enough glue on to the screen in a “X” pattern with a “-” in the middle of “X”. Make sure not to apply too much or too little glue and see that there is no air bubble.

The adhesive will gradually spread across the screen and to the edges on its own without you having to apply any pressure. If there is any bubble, apply gentle pressure on the LCD and guide the bubble to the edge.

Curing or Drying time of the Glue is generally 1 to 2 minutes. It also depends on the Wattage of the UV light source and the distance between the UV light source and the LCD Screen or Glass.

Hey folks, got an annoying problem with my instrument cluster KOMBI unit. My bottom lcd is screwed up badly, and it came that way when I got it. I just barely read my mileage and the temp info but it is super blurry throughout the center of it. I"ve been searching for any related threads but there seems to be few out there with this same issue.

So a few questions. Does anyone know if it"s possible to swap one of these displays from a cluster bought off eBay? And if so does it need to be coded? I assume since it"s just a screen I would assume it"s plug and play.

This question is important. Outdoor panels are usually seen from further distance, thus resolution will be lower. Outdoor led panels will likely be brighter because they are used in sunlight. Also outdoor panels will be more durable as they need to withstand weather conditions, dust, moisture and dirt. Indoor panels offer superior color, smaller pixels and a more refined picture. For the same pitch, indoor screens are cheaper. For all these reasons, we recommend indoor panels, unless you actually need to use an outdoor screen.

1) Ground Support Installation: This method system is a combination of a base-unit, connection bar and ladder truss that creates a very stable system to support your LED screens in various configurations and offers flexibility in height as well as width.

2) Flown Method (rigging): There are certain requirements that need to be in place in order to fly a screen. Most importantly, there needs to be ample structural support in the ceiling to hold the total weight of the screen. When someone says they want to “Fly” an LED screen, that means the screen will be rigged to either an overhead truss system, a ceiling grid, a crane, or some other support structure from above.

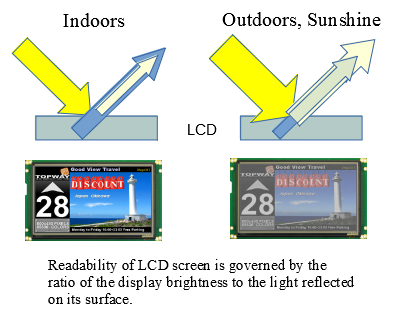

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

Watching your mobile screen with those white or black vertical/horizontal lines is annoying. In short, it’s tough to use a phone with these lines appearing on the screen. Typically, this issue is associated with the LCD, caused by a faulty hardware component in your device due to some accidental fall or water damage. Phones with such damages can only be fixed at a phone repair center.

If you are itel, TECNO or Infinix phone user and is troubled with vertical and horizontal line issues, make a reservation now without waiting time at the service shop. Carlcare Service will fix your phones easily. If your phone is under warranty, Carlcare can also save you repair costs. Check warranty now>>

In case you’re not sure about the process, it’s better to take help from a professional repair center. For Infinix, Itel, and TECNO users, Carlcare Service - being their official service center for these brands- is a recommended place to go.

If there’re white lines on the screen, this solution may prove effective. A battery cycle is when you charge a mobile to 100% and let it drain to 0% again. Usually, the lines will disappear soon as you charge the battery fully.

Suppose the lines are still visible. Then the issue is most likely due to some hardware failure- and the best option for you is to take your device to a reliable repair center.

If the horizontal or vertical lines still appear on your phone screen after trying all the above methods, you better take your device to a reliable mobile repair store near you. Most likely, it’s a faulty hardware component that needs to be repaired or replaced. Here, we would suggest you opt for only an authorized service center, as this will ensure flawless repair at a reasonable cost. Besides, if any of the components have to be replaced, they will be genuine and as per your specific requirements.

As the official service center part, we provide 100% original spare parts and various value-added services for Infinix, Itel, and TECNO users. Now with the online reservation service through Carlcare App, you don’t need to wait while your phone is repaired at our service centers.

A while back I was sitting around and wondering what to do with my dead laptop. I knew the mother board was fried but everything else was still in working condition. As a result, I decided to make an external monitor from my dead laptop and proceeded to do the research to find out if this was possible. Below is what I discovered. Unfortunately, there was no way to use the motherboard"s VGA connector. The VGA connector on a laptop is used to connect to an external monitor. In any case the VGA connector is output only and wouldn"t work for an external screen. As a result, I found that I needed to buy a controller board for the LCD screen, to make it work as an external monitor. This was the main cost but was still less than half the cost of buying an external monitor.

Step Two. To Remove the LCD screen from the laptop, you will need to remove the screws. There are rubber pads on the front of the LCD screen to protect it when the laptop lid is closed. Behind the rubber pads are the screws. Find and remove all the screws holding the front plastic frame on the laptop lid. Keep track of the pads and screws as you will need them to reassemble everything.

Step Three. Remove the plastic frame from the LCD screen. Here is where you need to be careful. The screws are not the only thing holding the plastic frame on the LCD screen! The plastic frame is snapped into place. Carefully pry loose the frame from the LCD screen. Pry it loose gently. Try to keep it as close as possible to the LCD panel while you are prying it loose because you may also find that you need to slide it to the left or right to completely remove it from the laptop. There is a small protrusion of the plastic frame where the hinge is. Because of this protrusion you need to slide the frame, in this case, to the right, to detach it from the laptop.

Step Four. Locate and remove the screws holding the LCD panel to the laptop. These are located on the bottom. The screws are attached to a small metal hinge. this is the component that is attached to the keyboard frame.

Next you will need to remove the LCD screen. Note that there is a cable attached. This is the LVDS cable. It is best to take apart the rest of the laptop and unplug it from the keyboard. However, the cable can be cut at the bottom. Take care not to cut the two wires going into the inverter (that"s the slim circuit board at the bottom.

Once the LCD panel is removed, you can remove the LVDS cable and unplug the inverter at the bottom. Unplug the inverter from both ends. Do not cut it. The LVDS cable is taped to the back of the LCD screen at the top. It is the flat cable running up the back. Remove the tape and slid the cable down. Since you need to buy an LCD controller board, you will no longer need the LVDS cable the laptop came with or the inverter. At this point you should just have an LCD screen with a pair of wires coming out of it.

Keep track of the plastic front frame and the plastic backing. You will need them to resemble the LCD screen. On the other hand, you have different fingers, just kidding. On the other hand, you can buy a picture frame and put the LCD screen in the picture frame.

Here is a picture of the LVDS cable and the inverter detached from the LCD screen. Since we will be buying an LCD control board these cables will not be needed again.

Next, once you have removed the LCD panel. Flip it over and look for a model number on the back. You will need this model number to order the correct LCD controller board. I went to E-Bay and found one for $42.00. I bought the LCD controller board and then received an email from the seller requesting the model number of the LCD screen and manufacturer. This is because each controller board is flashed, (programed to run a specific LCD) I gave him my model number, LP171WX2 A4K1 and told him it was made by LG Phillips. Since the board was coming from China, I received my order about 2 weeks later. Due note to buy one with a power cord! The LCD controller board has the VGA input connection which allows you to connect it to another computer and use it as a second monitor or as a back up in the event the one on your working computer goes out.

The LCD controller board is real easy to connect. It comes with all the required cables, except a VGA cable which you will need, in order to connect your LCD to another computer. You can buy a VGA cable from Best Buy or a computer parts store.

The LCD control Bard comes with all the cables except the VGA cable which you will have to buy. Once you have received your kit, proceed to connect it to the LCD screen. Plug the LVDS cable into the LCD panel where you removed the original from. The two wires at the bottom of the LCD screen that were connected to the inverter need to be unplugged from the old inverter and plugged into the new inverter below. Then, plug the power in. Make sure that the LCD control board is not sitting on anything conductive, like metal or it will short and fry. Next connect the VGA cable to the LCD control board and plug the other end of the VGA cable to another computer. Make sure the computer is on before you plug in the VGA cable. At this point you should have the same image that is on the computer you plugged the VGA cable into, on the LCD panel.

Next, I attached a 4 inch section of two by four on the outside back of the laptop lid. I needed this in order to attach my stand to the LCD screen. I used 5 screws and screwed them in place from the inside. I did splice and extend the cables going from the LCD controller to the inverter it came with just to have a little more room.

Originally, I built a nice wooden stand for my LCD panel but was not satisfied with it. So, I took a broken florescent desk lamp and dremeled off the section holding the florescent tubes, leaving enough metal to screw on to the two by four on the laptop lid. Before attaching the stand, I drilled four holes in the metal to make it easier to screw it on the two by four.

Next you will need to attach the LCD controller to the laptop lid. To do this, screw in a few sections of wood from the inside of the lid. Then on the outside of the lid attach the LCD control board. Place the wood in an area where the control board can reach.

Next you will need to find all those screws you have been saving and reassemble the LCD screen. I also added some surgical tubing to the top springs for added strength.

By the way a store bought swing arm half the size of this one, I found, cost around $400.00. If you choose to use a swing arm like this one, go with the one that has a magnifier on it and dremel off the magnifier leaving enough metal to attach to your LCD lid. You need one of this caliber to hold the LCD screen. Swing arms with the light attached are not strong enough.

Since I was asked about the web cam, I though Should add it to the instructable. There is a nice instructable here at this site showing how to convert a web cam from an LCD screen: http://rntmns.com/2011/02/rebirth-of-a-webcam/

Actually, you can do One better. You can salvage the RAM, the Wireless card, the Batteries, the charger, the hard drive, the DVD disk player and sell them to people that need them on E-bay and Still keep the LCD screen for yourself.

Genius! As an honorary "Red neck" (U.K. chapter, it"s a good thing, honest) I"m putting your application in the post. You have given me the three screens I need for my simpit plus a lot of peripherals that I hadn"t even considered. Thanks.0

Thanks for this instructable. I recently came upon some discarded laptops with either had bad screens or nonfunctioning everything else. I may be able to mix and match to get a usable machine out of the pile of junk!0

I checked ebay for the LCD control Board and all I did was punch in " LCD control Board for a LP154W01(A3)" , That"s my model number. You, of course, use your"s. ebay came up with the correct one for $25.00 and it has all the imputs you could want. This is good today, 2/11/19. Have fun folks!

i have a similar lcd panel to yours. infact 3 of them! they"re so easy to work with and doesn"t need a backlight controller LP154WH4 TLA1 except the lvds cable sold separately. I"ve build one and runs on

Nicely done and very informative!! However unfortunately, by the time you add the cost of the LCD Controller card, various parts and time you could have bought a new inexpensive monitor.

it really depends on what kind of display your laptop came with. I recently had a laptop that featured a 4k OLED screen and If I add the price up of the controller kit and materials (depending how you are going to make the stand) it would actually in my case be cheaper to make that an external monitor because, quite frankly 4k is pretty expensive and I don"t want to degrade to a lower resolution. in said laptop the motherboard died so I just scavenged everything including the LCD which I have just lying on my desk. so I might even consider trying this.0

Expansion was further pursued after a March 2012 acquisition of a 10-percent stake in the Japanese electronics company Sharp Corporation for US$806 million and to purchase up to 50 percent of the LCDs produced at Sharp"s plant in Sakai, Japan.Itu, Brazil, creating 10,000 jobs.

Following almost a year of public controversy regarding its COVID-19 vaccine shortage;TSMC, and negotiate purchasing COVID-19 vaccines on its behalf.BioNTech"s Chinese sales agent Fosun Pharma announced that Foxconn and TSMC had reached an agreement to purchase 10 million BioNTech COVID-19 vaccines from Germany for Taiwan.

Foxconn and Sharp Corporation jointly operate two manufacturing plants specializing in large-screen televisions in Sakai, Osaka. In August 2012, it was reported that Sharp, while doing corporate restructuring and downsizing, was considering selling the plants to Foxconn. The company was believed to be receptive to the plan. The acquisition was completed with a $3.8 billion deal in August 2016.

In January 2019, Foxconn said it was reconsidering its initial plans to manufacture LCD screens at the Wisconsin plant, citing high labour costs in the United States.

No third party iPhone repair shop uses “original” iPhone screens. Apple, in their infinite wisdom will not sell repair parts to third party repair shops. They are not like Ford that will sell Motorcraft alternators to O’Reillys Auto Parts. Apple prefers to keep their parts available only at Apple Stores or Authorized Apple Repair Centers.

As it stands right now, I have to use aftermarket parts, or refurbished screens that use original LCDs and touchscreens. Every time you order original screens from China you are taking a gamble with US Customs. Apple has a pretty tight grip on imports of Apple parts.

Aftermarket iPhone screens for instance are around a third of the price of even refurbished screens. If you went to an Apple store to replace the screen on your iPhone 7, you could expect to spend around $149. I can replace that screen with an aftermarket one for around $85. That is quite a savings, and that may make a difference to someone who doesn’t want to spend a ton of money getting their iPhone fixed.

When I say original quality, I mean a screen that has been refurbished by a company that has the proper equipment to do so. They buy cracked screens with working touchscreens and LCDs from companies like mine. They take these cracked screens and remove the glass, and replace it with new glass. This means that these screens have an original LCD and touchscreen on new glass. There is quite a bit of labor involved with refurbishing these screens so you will see that reflected in the prices.

Aftermarket iPhone screens tend to have a cooler, bluer hue. Let’s say you had your iPhone screen replaced. If you set your iPhone next to someone with an original screen, yours would have more blue tint.

At Hotshot Repair I tend to use screens that have a Tianma LCD. This is a middle ground between a super cheap screen and an original LCD. You can see the difference between a Tianma LCD and and original LCD in the photos above. You will notice that the whites are a little bluer and the greys are a little lighter. On the home screen you can see that the Tianma screen appears a little lighter.

Because aftermarket screens use a thicker LCD with more layers, the overall screen thickness is greater. It isn’t much but it will be noticeable. Overall aftermarket screens tend to be .42 mm thicker than original screens. This will manifest itself in a slight edge where your new screen meets the frame.

This is a rarer occurrence these days. In the beginning we had issues with the polarizer on some aftermarket screens. If you wear Ray-Ban sunglasses you may be familiar with the term. LCDs use a polarizer film to direct the light from the backlight forward throught the LCD. If this polarizer film is installed incorrectly it will make your screen hard to see through polarized sun glasses.

This isn’t much of a problem these days because the aftermarket screens are tested at the factory. Still, these screens are still assembled by humans so a bad one can slip through the test.

If you notice that your new screen doesn’t play well with your sun glasses, just let me know. I am more than happy to install another screen and we can re-test it to make sure that they play nice.

At Hotshot Repair, I try to be as open and honest with my customers as I can possibly be. Sometimes to my own detriment. I have talked plenty of people out of a possible repair, because it just wouldn’t make sense. To that end, I am writing this blog post. I feel that any potential customer should be made aware of the differences between aftermarket and original screens, and no other shop in Columbia seems to be stepping up to tell them.

If we look at the iPhone 6s for example. That phone with a good screen is still worth around $230 or so, depending on the capacity. An $85 repair to the screen makes a lot more sense than driving to an Apple Store in Kansas City or St. Louis, and spending $149.

I try to let every customer know about these differences when they are considering a repair, and I would say 95% to 98% of them don’t care. Seriously, I have had like 3 customers in my entire career who would rather have an original quality screen installed at the additional price.

If you are unsure about the quality of these aftermarket screens, just come by. If you have a cracked screen, I am more than happy to put a screen on it temporarily, so you can test it out. If you decide that you are happy with the quality, you will save some money. If you would rather have an original quality screen installed, no problem as I am happy to help you with that too.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey