wiki tft display factory

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

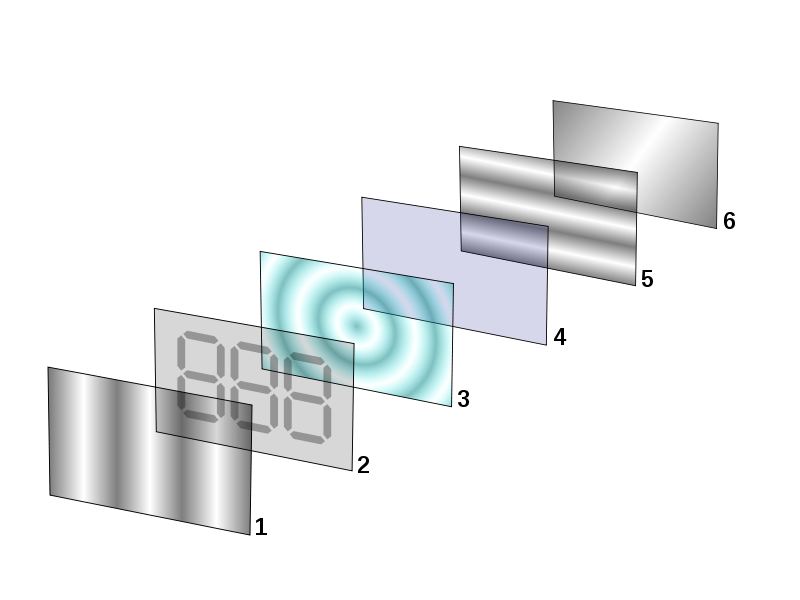

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

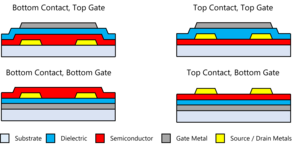

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

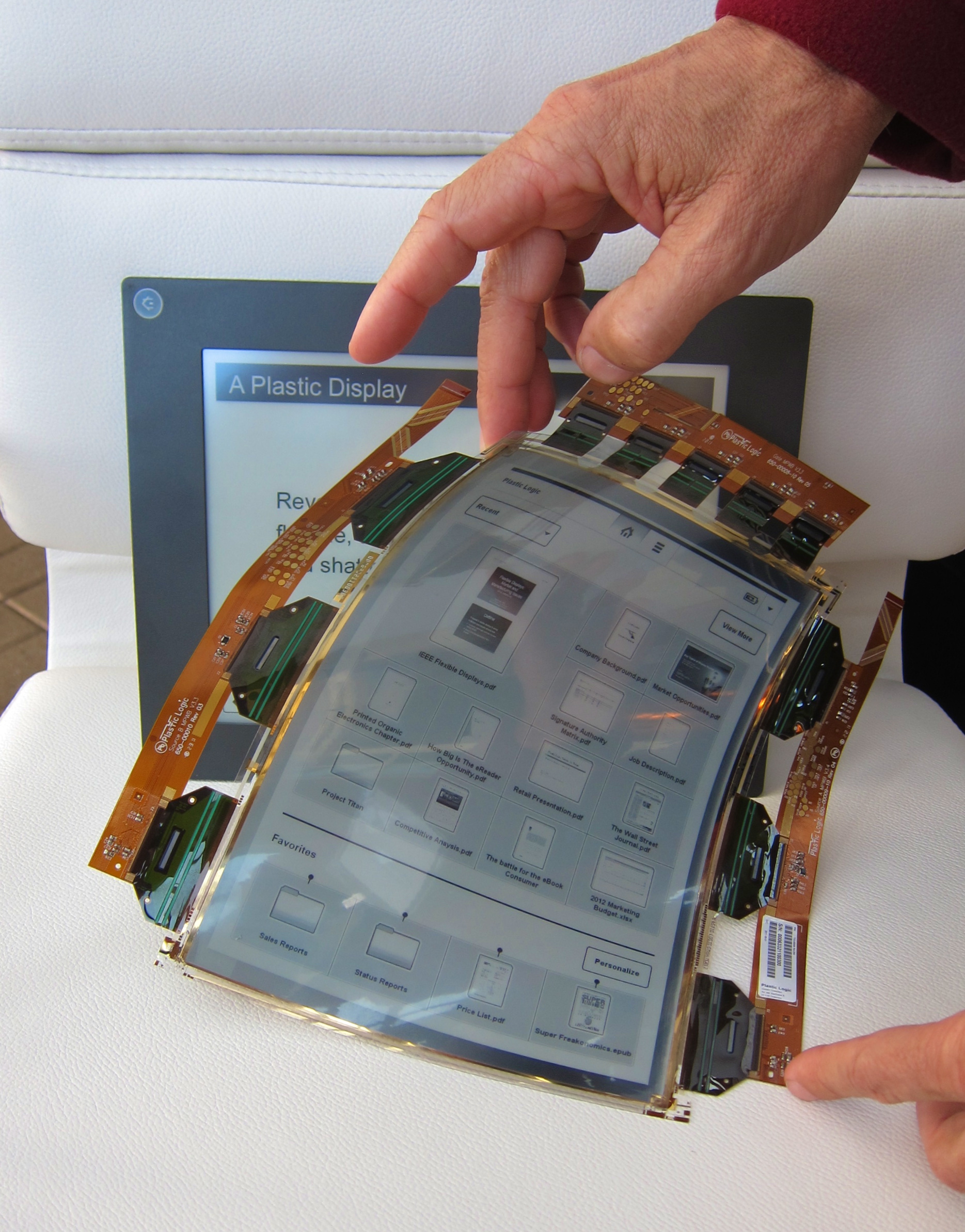

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

Nextion includes hardware part (a series of TFT boards) and software part (the Nextion editor). The Nextion TFT board uses only one serial port to communicate. It lets you avoid the hassle of wiring. We notice that most engineers spend much time in application development but get unsatisfactory results. In this situation, Nextion editor has mass components such as button, text, progress bar, slider, instrument panel etc. to enrich your interface design. And the drag-and-drop function ensures that you spend less time in programming, which will reduce 99% of your development workloads. With the help of this WYSIWYG editor, designing a GUI is a piece of cake.

Nextion Editor(Official Download) is a development software used for visual building of graphic interface for embedded GUI-intensive devices with various types of TFT displays and Touch Panels. Using this tool, users can start creating TFT based devices in a faster and easier way.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

6) Power on the Raspberry Pi and wait for a few seconds until the LCD displays normally. And the touch function can also work after the system starts.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

Nextion is a Human Machine Interface (HMI) solution combining an onboard processor and memory touch display with Nextion Editor software for HMI GUI project development.

Using the Nextion Editor software, you can quickly develop the HMI GUI by drag-and-drop components (graphics, text, button, slider, etc.) and ASCII text-based instructions for coding how components interact on the display side.

Nextion HMI display connects to peripheral MCU via TTL Serial (5V, TX, RX, GND) to provide event notifications that peripheral MCU can act on, the peripheral MCU can easily update progress, and status back to Nextion display utilizing simple ASCII text-based instructions.

Used TFT clocks DIM from S/V60, XC60, S80II, XC/V70III made in the years 2014 to 2017 (the unit from V40 series can only be used in V40 cars - it has different mechanical shape than x60, x70, x80)

make sure that you located the TFT DIM that matches the transmission type of the target car - Automatic (PRND display) or Manual (+ Gear -) on the right side of the display. Diesel/petrol fuel type of the donor car does NOT matter.

Then press DECODE CEM. We must warn you this process can take up to 24 hours(but on average it usually does not take more than 12 hours). During the whole process you can interrupt the decoding process and continue later. If you do the CEM PIN decoding then you no longer need to do it again. Thanks to this you can also make other changes in the vehicle configuration including the TFT retrofit. After this process is done you will receive an email to the account you put in in the beginning.

Then choose CAR CONFIGURATION and then “Car configuration wizard”. Then you only need to choose the “TFT retrofit” wizard. Make sure DIM is connected.

Connect DiCE again, turn the ignition key to position II and open VDASH again on your computer. Go to “Car configuration wizard” and choose TFT retrofit again.

VDASH will begin to look for the newly connected TFT DIM. If all wires are correctly plugged in, the update process will begin. If not then check the connecting of the wires again using the multimeter.

Your vehicle will restart itself many times during the process and at the end you will see a picture of the vehicle, the state of fuel and more. At the very beginning the incorrect measures can be displayed, but after a short trial run it should be fixed. The kilometres will also automatically reappear.

You can change and move the clock motivesonly when the engine is running (this does not have any specific explanation). The designated motive is Elegance(grey or brown). It is possible to reprogramme this motive to a blue version “R-design” (using car configuration > advanced settings > Advanced TFT DIM settings > Screen Skins > DIM: R-design menu), motives Ecoand Powerremain unchanged.

1. Temporarily disconnect newly connected cables from the white DIM connector, and connect the original DIM2. Start the engine (SCL the steering lock will now unlock)3. While the engine is running, disconnect the original DIM connector and reconnect the additional wiring, connect the TFT DIM4. Turn the engine off and lock the car5. SCL will NOT turn on again (unless you connect the original DIM). You will not observe any further immobilisation issues.

2. Face Learning: Point the “+” symbol at a face, short press the "learning button" to learn the face. If the same face is detected by HuskyLens, a blue frame with words "Face: ID1" will be displayed on the screen,which indicates that HuskyLens has learned the face and can recognize it now.

Keep pressing the “learning button”, point HuskyLens" "+" symbol at different angles of the face. During this process, a yellow frame with words "Face: ID1" will be displayed on the screen, which indicates HuskyLens is learning the face. Please point the yellow frame at different angles of the same person"s face, such as front face and side face (or multiple photos of the same person), to enter all angles of this person"s face.

Then you can release the "learning button" to finish the learning. When Huskylens detected the learned face, a blue frame with words "Face: ID1" will be displayed, now HuskyLens can recognize the face from different angles.

When HuskyLens is in the face recognition mode, short press the "learning button", the screen will display "click again to forget". Before the countdown ends, short press the "learning button" again to delete the learned face information, then the yellow "+" symbol is displayed. Now you can let HuskyLens learn a new face.

Dial the function button until "Learn Multiple" is displayed, then short press the function button, and dial to the right to turn on the "Learn Multiple" switch, that is, progress bar turns blue and the square icon on the progress bar moves to the right. Then short press the function button to confirm this parameter.

Point the “+” symbol at the face, long press the "learning button" to learn the face of the first person. Then release the "learning button", a blue frame with words "Face: ID1" will be displayed if HuskyLens detects the same face,meanwhile, a message "Click again to continue! Click other button to finish" will be displayed. Please short press the "learning button" before the countdown ends if you want to learn the face of other person. If not, short press the "function button" before the countdown ends, or do not press any button to let the countdown ends.

In this chapter, we will learn the next face continuously. So we need to short press the "learning button" before the countdown ends. Then we can let HuskyLens learn the face of the second person. The same as the steps to recognize the first face, point the “+” symbol at the second face, long press the "learning button" to learn the face of the second person. Then release the "learning button", a blue frame with words "Face: ID2" will be displayed if HuskyLens detects the same face.

Point Huskylens to the target object, adjusting the distance and until the object is included in the yellow frame of the center of the screen. Then long press "learning button" to learn the object from various angles and distances. During the learning process, the yellow frame with words "Learning: ID1" will be displayed on the screen.

When tracking the object, the yellow words “Learning: ID1” will be displayed, indicating that HuskyLens is tracking the object while learning. This setting improves the object tracking ability.

Dial the function button until "Learn Multiple" is displayed, then short press the function button, and dial to the right to turn on the "Learn Multiple" switch, that is, progress bar turns blue and the square icon on the progress bar moves to the right. Then short press the function button to confirm this parameter.

Point the “+” symbol at the object, then short press the “learning button”, the color of the frame changes from white to blue, and the name of the object and it"s ID1 will appear on the screen, meanwhile, a message "Click again to continue! Click other button to finish" will be displayed. Please short press the "learning button" before the countdown ends if you want to mark the next object. If not, short press the "function button" before the countdown ends, or do not press any button to let the countdown ends.

When encountering the learned objects, they will be selected by the color frame, and the name and ID number will be displayed. When encountering new ones, the selection frame is white.

The ID number is related to the order of marking objects. For example, if a dog is marked for the first time and a cat is marked for the second time, when the dog is recognized, the words "dog: ID1" will be displayed on the screen; and when the cat is recognized, the words "cat: ID2" will be displayed on the screen.

Dial the function button until "Learn Multiple" is displayed, then short press the function button, and dial to the right to turn on the "Learn Multiple" switch, that is, progress bar turns blue and the square icon on the progress bar moves to the right. Then short press the function button to confirm this parameter.

Point the “+” symbol at the first color block, and long press the “learning button”. A yellow frame will be displayed on the screen, indicating that HuskyLens is learning the color. At this time, adjust the distance and angle between HuskyLens and the color block, to let HuskyLens learn the color block in various distances and angles. Then, release the "learning button" to complete learning the first color block, meanwhile, a message "Click again to continue! Click other button to finish" will be displayed. Please short press the "learning button" before the countdown ends if you want to learn other color blocks. If not, short press the "function button" before the countdown ends, or do not press any button to let the countdown ends.

When encountering the same or similar color blocks, some color frames with IDs will be automatically displayed on the screen, and the size of the frames are same as the size of the color blocks.

The ID number is related to the order of learned color. For example, if a yellow block is marked for the first time and a green block is marked for the second time, when the yellow block is recognized, the words "Color: ID1" will be displayed on the screen, and when the green block is recognized, the words "Color: ID2" will be displayed on the screen.

Dial the function button until "Learn Multiple" is displayed, then short press the function button, and dial to the right to turn on the "Learn Multiple" switch, that is, progress bar turns blue and the square icon on the progress bar moves to the right. Then short press the function button to confirm this parameter.

Point the “+” symbol at the first tag, and press the “learning button”. A yellow frame with words "Tag:ID1" will be displayed on the screen, indicating that HuskyLens is learning the tag now. Then, release the "learning button" to complete learning the first tag, meanwhile, a message "Click again to continue! Click other button to finish" will be displayed. Please short press the "learning button" before the countdown ends if you want to learn other tags. If not, short press the "function button" before the countdown ends, or do not press any button to let the countdown ends.

When encountering the learned tag, some color frames with IDs will be automatically displayed on the screen. The size of the frames changes with the size of the tags, and the frames automatically track these tags.

This function can learn multiple photos of different objects, and then use the built-in machine learning algorithm for training. After the training is completed, when the learned objects appear again in the HuskyLens" camera, HuskyLens can recognize them and display their ID numbers. The more HuskyLens learns the photos of the same object, the more accurate the recognition can be.

Dial the function button until "Learn Multiple" is displayed, then short press the function button, and dial to the right to turn on the "Learn Multiple" switch, that is, progress bar turns blue and the square icon on the progress bar moves to the right. Then short press the function button to confirm this parameter.

Point the large frame at the first target object(the worker with a helmet on the left in the picture above), and long press the “learning button”, a yellow frame with words "Learning XX/30 ID:1" will be displayed on the screen, indicating that HuskyLens is learning the object now. Adjust the distance and angle, let HuskyLens learn the object in various distances and angles. Then, release the "learning button" to complete learning the first object, meanwhile, a message "Click again to continue! Click other button to finish" will be displayed. Please short press the "learning button" before the countdown ends if you want to learn other objects. If not, short press the "function button" before the countdown ends, or do not press any button to let the countdown ends.

When HuskyLens encounters the learned object again, its ID number will be displayed on the screen. As shown in the figure below, when HuskyLens recognizes that the worker is wearing a helmet, the screen displays ID1, and if there is no helmet, it displays ID2.

The onboard screen can be used to display texts anywhere on itself. It supports English characters, numbers and symbols. The recognition results and data from sensors can be directly displayed on the screen. All 7 algorithms support the customized text.

Like a digital camera, HUSKYLENS can take photos or screenshots, and save them on an SD card. With an onboard SD card slot on HUSKYLENS, you can just plug in the SD card and use it. The screenshots contain the texts, frames displayed on the screen, while the photos contain only the image.

In object classification mode, aim HUSKYLENS at the following three images in turn. Press button A of micro:bit or pull down the Arduino Pin A0, then HUSKYLENS will learn these three images as objects:ID1 in turn. When HUSKYLENS recognizes any of these three images again, it displays object:ID1 on the screen, indicating that the three workers are wearing safety hats.

This chapter demonstrates how to connect HuskyLens to the micro: bit board, then the micro: bit board reads the face recognition results from HuskyLens. If HuskyLens recognizes you (the learned face), the dot-matrix screen of the micro: bit displays a smiling face, otherwise it displays a crying face.

When HuskyLens recognizes your face, the dot-matrix screen on the micro: bit board will show a smiling face. If it were not your face, or no face appeared, it would display a crying face.

This chapter demonstrates how to connect HuskyLens to the micro: bit board, then the micro: bit board reads the face recognition results from HuskyLens. If HuskyLens recognizes you (the learned face), the dot-matrix screen of the micro: bit displays a smiling face, otherwise it displays a crying face.

When HuskyLens recognizes your face, the dot-matrix screen on the micro: bit board will show a smiling face. If it were not your face, or no face appeared, it would display a crying face.

has a long experience in the market of displays for over more than three decades. The displays include products based on passive, TFT- and LTPS-technology, as well as colour filters and backlights. New display lines are utilizing AM-OLED technology.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey