mbed lcd display free sample

For a quick geolocation demo with mbed (without a user key), the web page from one of these sites can be read, and by parsing the web page’s HTML the data can be used for display in the LCD. In a web browser, use view source to examine the HTML to find the data fields of interest and search for the strings that can be used to locate and recover the data in a program. Of course the problem with this approach is that any changes to their IP location web page will require a program update, unlike something like the Google Latitude API or the iPInfoDB API. In most cases, it would likely require a change in the search strings. For the demo, the iPInfoDB API was used after getting a free key via email.

If you still get the net error message, make sure that DHCP service is enabled for your mbed. On some networks, you need to add the module"s MAC address to enable the DHCP server to give it an IP address. It times out with an error, if no IP address is returned in about fifteen seconds. If the location does not display on the LCD after seeing "net OK", you may have DNS problems or a very slow network.

Where N/C is not connected and the top left pin of the TextLCD’s header is GND and the right most pin is D7 in the LCD orientation shown in the images above. The resistor sets the contrast and some LCDs may need a different value or a contrast adjust potentiometer. See Text LCD for additional help, if needed.

(*) Note: some older LCDs may use 5V, but 3.3V is more common on current LCDs. If you cannot find a data sheet to confirm this, try 3.3V first and if the display is still blank (after double checking all other connections and code) it might need 5V. To save jumper wires, this setup uses the four bit interface to transfer ASCII characters to the LCD.

To run the demo code you need to obtain a free key by filling out a short web form at iPInfoDB. Then click on the link in the email. This code must be added as a suffix to the URL in the source code to run it on your mbed. Find http://api.ipinfodb.com/v3/ip-city/?key=PUT_YOUR_API_KEY_HERE in the source code after downloading it.

mbed determines its location using a web-based geolocation API that uses the IP address and displays it on the LCD. Timezone is also included. A free API key must be inserted in the URL. See http://mbed.org/users/4180_1/notebook/geolocation-lcd-display/

The uLCD-144-G2 from 4D Systems is a low-cost ($25 qty. 100) smart color LCD display board with a serial interface. They are also available from Sparkfun. It looks like a nice alternative to the now hard to find Nokia 6100 LCD breakout boards. It has a TTL level serial interface and a reset pin. An optional uSD card inserted in the display module"s socket can be used to load fonts, images, and play videos in response to serial commands.

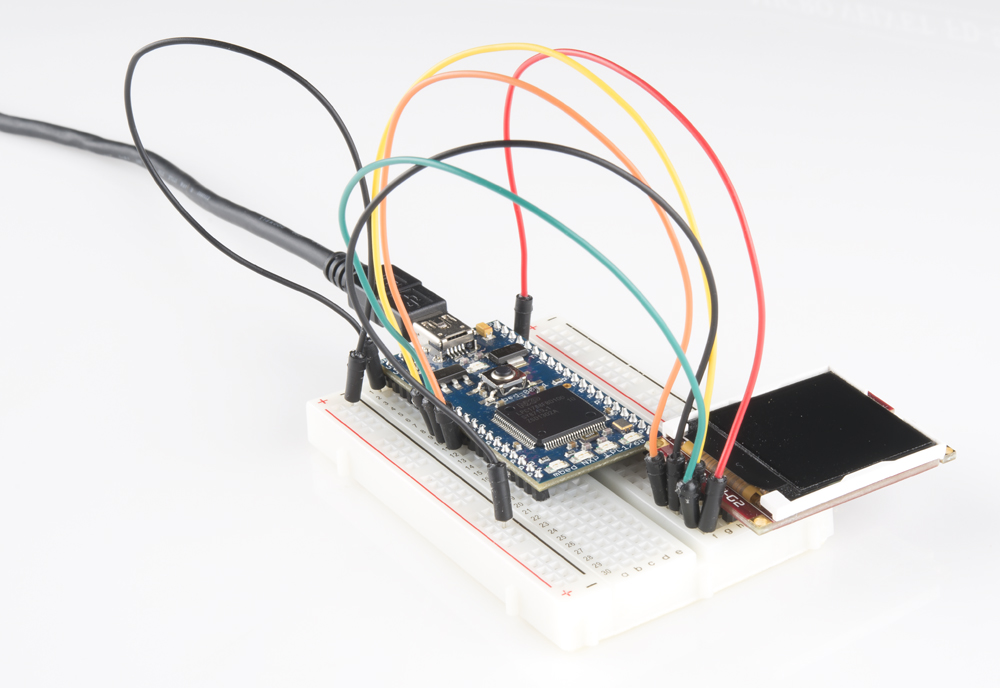

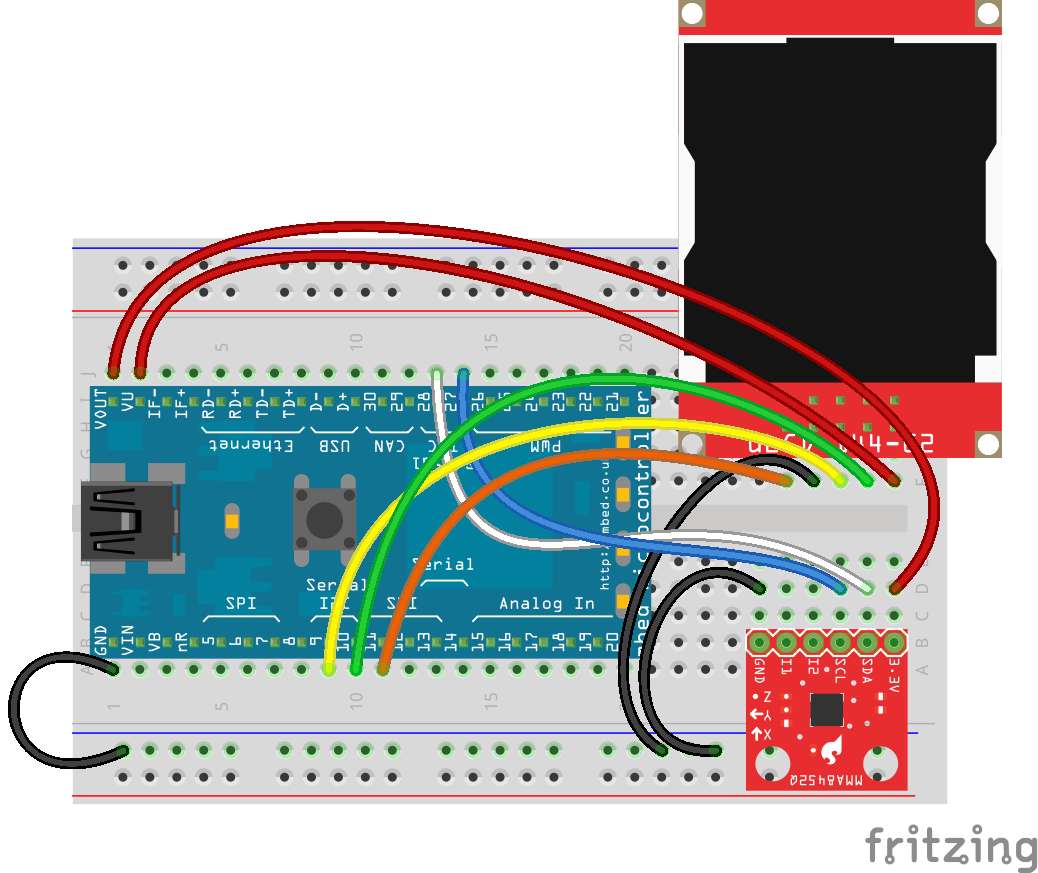

In the drawing above, the pins are labeled from the uLCDs perspective with TX and RX pins. Mbed RX goes to uLCD TX and mbed TX goes to uLCD RX. So mbed TX goes to the middle pin on the connector which is the uLCD"s RX pin. The included cable seen below is plugged into the bottom row of pins and plugged into a breadboard using the male header pins for hookup. Note that on the cable silkscreen seen in the image below RX and TX have been swapped to indicate the connections needed to the microprocessor pins.

As an alternative, a two row 10-pin M/F header socket with long PCB leads can be used to make a breadboard adapter by cutting off one row of pins. The header socket plugs into the breadboard and the module plugs into the header socket. The second row of pins could also be cutoff on the LCD module itself, but this would preclude later use of the board’s GPIO pins and 3.3V supply for other projects. For more stable mounting, there are 2mm screw holes at the corners that could be used, but the header socket alone holds it rather well given the small size and weight.

The real problem on a breadboard is shorting the 3.3V pin to the reset pin. The board needs a 5V input, but it outputs 3.3V in case it is needed for external devices when it is used in standalone mode. Shorting the other 4 pins does not impede normal serial slave mode operation. Without a reset, the board typically locks up whenever mbed is reset. If the 3.3V pin is carefully bent down 90 degrees towards the center of the board and away from the reset pin, it will plug directly into a breadboard and work as seen in the photo below. The 3.3V pin could be bent back later if it is ever needed, but don’t count on this working more than once or twice before it breaks off. It would be a good idea to just leave it bent over and use a F/M flexible jumper wire to connect to it, if 3.3V from the display module is ever needed later in other projects. This might be the best solution for most users that want to plug it directly into a breadboard, avoid cutting off pins and avoid hooking it up through another connector.

If you are using an mbed plugged into an application board or other baseboard, use the cable provided with the display and stick short jumper wires in one end of the display"s cable connector and the other end of the jumper wires into the mbed header pin sockets that are found on most of these boards.

Initially, it would seem that the existing mbed cookbook 4DGL library would work with this module. It turns out that it has a different processor, Goldelox, and a different but similar command set than the earlier 4D Systems displays supported by the 4DGL mbed library. So a fork of 4DGL was required with quite a few changes in #defines for command values and baud rate divisors. Some functions are not available and some now have 16-bit arguments instead of 8. The basic features used in the demo code below work correctly and some additional work on the new library code could add other features. Support was also added for the use of printf by using the Stream base class and providing _putc and _getc virtual functions. With some minor changes (#defines for number of x and y pixels) the library should also work with the other small LCD displays from 4D systems that use the Goldelox processor. The large LCD modules and modules with touch use a different processor.

Video of demo code. A micro SD card on the LCD module is required for images and videos. The display is actually a bit more colorful and clearer than it appears in the video. Demos include text using printfs, basic graphics commands, a simple bouncing ball animation, computing the Mandelbrot set pixel by pixel, a Plasma wave BLIT, a JPEG image, and a *.wmv video clip.

The more complex Mandelbrot and Plasma wave demo code is not listed here for brevity but can be found after the code seen above in main.cpp in the uLCD144G2_demo program with the download link below.

Fork of 4DGL lib for uLCD-144-G2. Different command values needed. See https://mbed.org/users/4180_1/notebook/ulcd-144-g2-128-by-128-color-lcd/ for instructions and demo code.

The Goldelox Serial Command Manual explains the command set used in serial slave mode. It works in serial slave mode out of the box. Mbed can send it data too fast at higher baud rates and some small time delays (<=1ms) between characters in the library code are needed to avoid dropping characters when sending out some of the longer commands such as text string (perhaps a display UART buffer overflow?). Each complete command sent gets back an acknowledge character and the library code waits for it for synchronization.

After some experimentation with delays, the driver library now works up to the LCD"s maximum supported baud rate of 600,000. For extreme overclockers, the undocumented baud rates of 750,000, 1,000,000, 1,500,000 and 3,000,000 are running this demo successfully on the mbed LPC1768 with the current delay setup. On other mbed platforms, it will depend on the processor"s baud rate clock and divisor hardware. The quickest way to find out is likely to be through experimentation. The mbed serial API computes the closest possible baud rate match. The demo starts out with 9600 baud which should work on any platform. After the first demo screen, the baud rate is changed on the display and mbed with uLCD.baudrate(value). If it hangs in the demo with the message, "Change baudrate", that baud rate is not working on the platform. For fast transfers and more bandwidth, most applications should use the highest baud rate that works.

The Free 4D Workshop IDE (click "download" icon on that page and again on the next page for download) contains tools to translate fonts, images, and videos on a PC into formats used on the module’s micro SD card in response to serial display commands. This data is then stored on an unformatted uSD card mounted on the PC. Most laptops have an SD reader slot and many uSD cards come with a larger SD adapter, if not there are low cost USB to SD adapters that can be used on a PC. After writing the files, the uSD card is then removed from the PC and inserted in the display module. Serial commands from mbed can then load the fonts, images, and play video clips. For speed, the unformatted uSD card uses disk sector addresses in the serial commands and not filenames in a directory to locate this data, and files are stored in a contiguous RAW format. The procedure to create these files with the IDE tools is described in more detail in two application notes:

The module now comes with the serial mode firmware preinstalled, so it is not necessary to reprogram the module"s firmware to use these features as shown in the manuals with the special programming cable. When starting a new project in the IDE tool, be sure to select the correct LCD module and "Serial". This means that the display"s special IDE tools only need to be used to convert font, image, and video files and write them to the uSD card. The optional programming cable is not needed to write to the uSD card from the PC.

Using the 4D Workshop IDE, a Windows True Type Font was converted to RAW format and written on the unformatted uSD card. The initial steps are not intuitive, so be sure to read the font application note. The new font from the uSD card was selected and a double size "hello world" message was printed out to the display as seen in the image above. The serial commands sent from mbed are shown in the code below . The disk sector address varies depending on what files are already on the uSD card. In this case, nothing else was on the uSD card (i.e., 0,0). In addition to the new IDE tools, there is also an older free True Type Font conversion tool that can be used to generate font files for the uSD card or even C include files with font data.

Paint.net was used to resize the original jpeg image to 128 by 128. The IDEs disk partition tool, RMPet, was used to create two partitions on the uSD card, one FAT and one unformatted (50/50 on a 2G uSD) . The graphics composer tool (tool in IDE) converted the image file and created the new image file on the unformatted partition on the SD card. Windows will not be able to read files on a RAW SD card.This tool can also resize images and *.wmv videos for the display by selecting the file and clicking the "edit" button. It reported which sector address to use for the image (listed in project"s *.GC file).

JPEG, BMP, and other encoded image files could also be stored on a filesystem on mbed such as the SD card, local filesystem, or a USB flash drive. It could be read, decoded, and sent to the display using the BLIT (BLock Image Transfer) command. A fairly complex program is required to decode image files and the RAM buffers needed for decoding use most of the available RAM on mbed, so not much is left for any other purpose such as networking or the RTOS. Information on a student project that ported simple open source JPEG and BMP file decoders to mbed for use on an earlier LCD display is available on the project’s notebook page.

It takes a bit less than 1MB/sec for full screen videos and a couple minutes on a PC to initially render the video into the RAW binary format to write it to the unformatted SD card. The original video clip used in the demo was 900 frames with a play time of 30 seconds. The module"s uSD card video player will be able to support higher video frame rates than sending video data over the serial connection from mbed using the BLIT command.

This is working in the beta version of the driver that I will update in a few days after some more testing - (i.e., flush_media and write_byte needed to read in a two byte return error code from the display).

If the LCD display functions are used in multiple threads, or in a main program and an interrupt routine or callback additional steps are needed to insure mutual exclusion when accessing the LCD"s IO hardware. In general, the use of LCD commands in interrupt routines and callbacks should be avoided and all LCD commands should be placed in main. Global variables can be set in interrupt routines that code in main could check to send out any needed LCD commands.

With the RTOS, a mutex synchronization lock from the RTOS should be used to control access to the display in the case of multiple threads. In such cases, I/O devices typically need mutual exclusion locks to avoid problems. For example, one thread could be in the middle of a long LCD display command just at the point when execution switches to another thread (or interrupt routine) using the display. The display could wind up in the wrong state when a new command is sent before the first one is completed. In general, printf also contains non re-entrant code. An mbed RTOS LCD mutex lock code example (demo4) is available using a different LCD with several threads that display data in different areas of the display. If the RTOS is not being used, it is also possible to implement a mutex lock by disabling and enabling interrupts on a processor with one core.

With the 4D IDE tool it is possible to create high quality images of various instrument gauges. Each frame in the video clip stored on the uSD card shows a different gauge setting, and the display frame command can be used to select the correct frame needed for the desired gauge setting. It is possible to achieve a high update rate (higher than using graphics to redraw the gauge). There is a components page and video demoing this feature with mbed.

The module"s firmware can also be changed to work as a standalone module and a development tool IDE that supports and programs it is also available. The IDE needs a special programming cable available separately to download to the module"s flash. It might be possible to setup a serial bridge program on mbed to use in place of the special programing cable.

Not every single possible serial command is included in the library and more commands could be added. The existing commands are likely the most useful ones, but the remaining ones could be added at the expense of a bit more code memory. To aid debugging of new features, messages can be sent out on the mbed USB serial port at 115200. To enable these debug messages, change DEBUGMODE in the *.h file.

It should be possible to add support for a file system driver on the display"s SD card using the serial commands. The FATFILESYSTEM library needs a couple virtual functions to read and write disk sectors and initialize the disk to provide support for new media. It is about the same as the SD card file system driver, but it is using serial and not SPI for transfers. Might even work for an SD card with two partitions, one formatted for files and another unformatted for fonts, images, and videos.

Student projects using the LCD are shown above. They include a Pac Man game using an accelerometer, an IoT Alarm Clock with networking, an iPod-like music & video player, a Nest-like thermostat using a temperature sensor, and a Missile Command game using pushbuttons.

The LCD on the mbed lab board has 128 x 32 pixels and is connected via spi. It use a ST7565R controller. The spi connection is fast, but it has one drawback - you can"t read the display buffer. This is a problem, because each bit reflect a pixel. If you want to set only one bit / pixel, you have to know the status of the other seven bits / pixel. Because of this we have to use a framebuffer (128 * 32 / 8 = 512 Byte). All drawing functions are working on this framebuffer. If you use the LPC1768 based mbed, the dma channel 0 is used to speed up the transfer to the lcd. This information is only relevant if you also want to use the dma controller. You have to switch to a other channel.

There are two update mode. After startup the automode is turned on. This means that the display is automaticly updated after the drawing. For example - if you call the function

a line from x0,y0 to x1,y1 is drawn inside the framebuffer and after that the framebuffer is copied to the lcd. If you draw more lines, it will be faster to draw all graphics inside the framebuffer and update the lcd only once.

set a single pixel at x,y. If color is 1 : black, 0 : white. This function is not updating the lcd ! Even if the autoupdate is on. You have to call lcd.copy_to_lcd() after using this function - or to use a other function with autoupdate afterwards.

To use the mbed rtos with the lib we have to make the lib thread save. What is the problem ? If different threads are writing to the lcd it can end in troubble. Thread1 is using the pintf("hello mbed") function to print this string to the actual position. After the chars "hel" are printed ,the scheduler is switching to thread2. This thread is writing at a different position on the screen. After that the scheduler is switch back to thread1 and the print function continue. Thread1 did not know that the internal cursor position has changed ....

Fourth test the test will work ok for a 20*2 lcd, for example if the text start as column 16 when it reach the end at 20 it will go fine to next line and continue the text

This Internet of Things example displays the current weather conditions on a text LCD. It uses a Google Weather API to retrieve a web page containing XML with weather data for Los Angeles. The Simple Plain XML parser library ported to mbed is used to parse the XML and retrieve the desired data fields for the LCD display. It is based on an earlier XML parser example and the Text-LCD library.

If you still get the net error message, make sure that DHCP service is enabled for your mbed. On some networks, you need to add the module"s MAC address to enable the DHCP server to give it an IP address. It times out with an error, if no IP address is returned in about fifteen seconds. If the weather does not display on the LCD after seeing "net OK", you may have DNS problems or a very slow network.

Where N/C is not connected and the top left pin of the TextLCD’s header is GND and the right most pin is D7 in the LCD orientation shown in the images above. The resistor sets the contrast and some LCDs may need a different value or a contrast adjust potentiometer. See Text LCD for additional help, if needed.

(*) Note: some older LCDs may use 5V, but 3.3V is more common on current LCDs. If you cannot find a data sheet to confirm this, try 3.3V first and if the display is still blank (after double checking all other connections and code) it might need 5V. To save jumper wires, this setup uses the four bit interface to transfer ASCII characters to the LCD.

The code sets up networking and reads a special Google web page containing XML data with weather using http.get(). Data extracted from this XML web page is then displayed in the LCD using the TextLCD library lcd.printf() function. Here is a typical web page of XML data in response to http://www.google.com/ig/api?weather=Los+Angeles

Note that the data needed is found above under -

When the USB cable is plugged in, mbed powers up and contacts the DHCP server to get an IP address. It gets an IP address and responds with "net OK". It then reads the web page containing the XML with the current weather, parses the XML to extract the data, and displays it on the LCD.

These examples for the application board were developed for the ARM University Program Faculty Workshop at ESWEEK 2013. They are based on selected code examples and I/O libraries posted earlier in the cookbook’s mbed application board page. Libraries used have also been updated to the most recent versions as of 9/22/13. While working through the demos, keep this web page open in one browser tab while the compiler is open in another browser tab so that it is possible to quickly switch back and forth between the two web pages. PowerPoint slides used prior to this material at the workshop to introduce mbed to faculty are also available.

This first demo just blinks an LED on the mbed module and the application board is not required. It is the default project code for a new project in the online cloud compiler. A new user account must be setup to use the cloud compiler and the mbed module must be plugged in first to setup a new account. The mbed module appears as a USB flash drive, open the flash drive, and click on the file“mbed.htm” and follow the instructions to signup for a new account. Logon, click on the compiler link (upper right) and select new when the compiler appears. Select a name for your new program and click "OK". The project files are all stored on a cloud server. You must always logon first to use the compiler. Click “compile” and save the compiled bin file to the mbed flash drive. Hit the reset button on the mbed module, to run the most recently downloaded code. Click on “main.cpp” to view the C++ code in the compiler window. In the code, note the use of the mbed DigitalOut() and wait() APIs.

For the second demo, the mbed must first be carefully plugged into the mbed application board. Note the correct orientation in the photo below. There are also small “GND” and “VOUT” silkscreen labels on the board and mbed module that should line up (near USB cable on left in image below). There should be an extra row of black socket pins on both sides of the mbed module.

The second demo uses the board’s three axis accelerometer and the LCD display working in graphics mode to build an electronic version of a bubble level. Clicking on the “import program” link below copies all of the project files into the cloud compiler and sets up a new project. The project can then be compiled and downloaded to the mbed module. As the board is tilted, the X and Y G forces are used move the small black bubble on the display. The LCD graphics library has a handy member function to draw circles and the library code for the accelerometer returns G force readings, so the code is relatively short.

This demo uses the application board’s three axis accelerometer and the LCD display working in graphics mode to build an electronic version of a bubble level.

The third demo uses the board’s I2C temperature sensor to measure the board’s temperature. After a few minutes of operation, the board is typically around 5C above room temperature. The temperature is displayed on the LCD using text mode with printfs.

Pot 1 (blue dial near LCD) is used to adjust a temperature alarm setting (also shown on LCD). When the board temperature is below the alarm setting, the RGB LED is green and when it is above the RGB LED changes to RED and the speaker outputs a tone. The RGB LED and speaker are attached using hardware PWM outputs and setup using the mbed PwmOut API . The pot voltage is read in and scaled between 0.0 and 1.0 by the mbed AnalogIn API.

This demo uses the application board’s I2C temperature sensor to measure the board’s temperature. Pot 1 (blue dial near LCD) is used to adjust a temperature alarm setting. Alarm uses speaker and RGB LED.

This demo also sends the temperature reading to the PC using a USB virtual comm port at 9600 baud. Windows users will first need to install the mbed virtual comm port driver (with the mbed module attached). A terminal application also needs to be downloaded and installed such as TeraTerm. After installing the driver and starting the mbed program, start TeraTerm, click the serial port and select the COMx port showing “mbed” in the name and click "OK"as seen below. The number of the mbed COM port will vary from PC to PC.

Macs and Linux users can use the built-in terminal and connect at 9600 baud to the mbed device. When the mbed is connected, on Macs the new mbed USB serial device name (need the number at end) can be found using the command "ls /dev/tty.usbmodem*". In Linux, use the command "ls /dev/ttyACM*". Note the mbed device name with the number included that should appear. Start a terminal application and use the command "screen yourmbeddevicename". When properly connected, you should see temperature outputs in the terminal application window from the “pc.printf()” statement in the code as shown in the image above.

In case of problems, more details can be found in the handbook"s serial communication web pages. During serial data transfers, the blue power/status LED in the center of the mbed module will flicker to indicate activity.

Data logging could be added to the thermostat with just a few additional lines of code. File system drivers are available for an external SD card, USB flash drives, and the mbed module’s 2M flash. More details can be found in the mbed handbook under File System. The Application Board Waveplayer Demo reads a *.wav audio file from a USB flash drive and plays it on a speaker.

This demo uses the mbed RTOS to run eight threads (including main). The threads are using different I/O devices. Several of the threads output to the LCD and an OS mutex lock is used to control access to the LCD and make the LCD thread safe. Additional details are available in the handbook"s mbed RTOS web pages.

This demo uses the mbed RTOS to run eight threads (including main). The threads are using different I/O devices on the application board. Several of the threads output to the LCD and an OS mutex lock is used to control access to the LCD and make the LCD thread safe.

This demo uses the TCP/IP networking stack and RTOS, to obtain the current time from an NTP server via the Internet and automatically set the mbed real-time clock. After setting the clock, the current time is displayed every second on the LCD. A network cable is required attached to a network with DHCP service enabled for the mbed module. Some networks may have security settings that require the mbed MAC address to be setup in the DHCP server. Another approach of setting up a "network bridge” can be used on any laptop that has an active Wi-Fi connection and an Ethernet jack to attach mbed to the Internet.

Clock display on app board LCD is set using an NTP network time server. DHCP service must be enabled for mbed to get an IP address. A network cable is needed.

This demo uses the ARM/Keil tools uVision (offline) compiler to show debugging with hardware breakpoints via the USB cable. It is first necessary to download and install the compiler locally on the PC. The free demo version download for Windows is limited to 32K code size, but the demo version becomes the full version with a license file or when connected to a Flex license server on the network. A firmware upgrade to the mbed module and a new USB serial driver are also required. Mixed C++ and ARM assembly language debugging is supported as well as full I/O pin level hardware emulation. An existing mbed cloud compiler project can be exported in a zip file to the offline compiler for initial setup, whenever hardware debugging using the offline compiler is required.

WikiSyntax - for developer.mbed.org (how to add links to posts, inline code in posts, add videos, general markup) very useful for creating good forum posts and code documentation on notebook pages

The mbed libraries allow for standardized, simplified usage of more peripherals. However there are also user libraries which allow for faster, more efficient and/or more flexible use of these peripherals. With the exception of the software emulators of peripherals, these libraries are generally limitted to a subset of the mbed supported boards, so you need to make sure yours is supported!

WQVGA RA8875 TFT 4.3" and larger - SPI - Driver library for an RA8875-based display. Supports up to 800x600, 16-bit color, Touch, Keypad, and Backlight control.

Library for interfacing with Nokia 5110 LCD display (https://www.sparkfun.com/products/10168) using the hardware SPI on the mbed. The display is powered from a GPIO pin meaning it can be controlled via software. The LED backlight is also software-controllable (via PWM pin). Can print characters and strings to the display using the included 5x7 font. The library also implements a screen buffer so that individual pixels on the display (84 x 48) can be set, cleared and read. The library can print primitive shapes (lines, circles, rectangles) Acknowledgements to Chris Yan"s Nokia_5110 Library.

This function fills the buffer with random data. Can be used to test the display. A call to refresh() must be made to update the display to reflect the change in pixels. The seed is not set and so the generated pattern will probably be the same each time. TODO: Randomise the seed - maybe using the noise on the AnalogIn pins.

This Internet of Things example uses mbed"s networking features to display live RSS news feeds on the LCD. It is based on earlier networking examples from the cookbook that read a web page and the Text LCD library to display characters on a text LCD. CNN Technology news is used for the live RSS feed.

If you still get the net error message, make sure that DHCP service is enabled for your mbed. On some networks, you need to add the module"s MAC address to enable the DHCP server to give it an IP address. It times out with an error, if no IP address is returned in about fifteen seconds. If the news does not display on the LCD after seeing "net OK", you may have DNS problems or a very slow network.

Where N/C is not connected and the top left pin of the TextLCD’s header is GND and the right most pin is D7 in the LCD orientation shown in the images above. The resistor sets the contrast and some LCDs may need a different value or a contrast adjust potentiometer. See Text LCD for additional help, if needed.

(*) Note: some older LCDs may use 5V, but 3.3V is more common on current LCDs. If you cannot find a data sheet to confirm this, try 3.3V first and if the display is still blank (after double checking all other connections and code) it might need 5V. To save jumper wires, this setup uses the four bit interface to transfer ASCII characters to the LCD.

A small portion of the RSS news feed web page containing XML is seen below. The data displayed on the LCD is the title. The format is "

In the video above, mbed is powered up and obtains an IP address from the DHCP server. Net OK appears on the LCD. It then opens and reads a portion of the web page, searches for news items displaying them as they are found on the LCD and reads through the rest of the web page. When it reaches the end of the web page, "Read Complete" is displayed.

7. Use a Google RSS news feed. Google also has several RSS news feeds and news can be searched to generate a new RSS feed. Here is an example https://news.google.com/news/feeds?q=mbed&output=rss.

It looks like you are using the wrong class, AnalogOut, and should instead be using the class AnalogIn. See https://os.mbed.com/docs/mbed-os/v5.15/apis/analogin.html

So your program should look something like the following. I don"t have your facilities so can"t test this but it is in accordance with the Mbed documentation. You will need to make sure you have things wired up to the proper analog pin and that you specify the correct analog pin to be reading from.

The C027 will now dial up to the internet. You will see the status “updated” in the LCD display. If the device cannot connect to the internet, it will display an error message. If there is an error message “Wrong APN setting” or “Unknown APN setting”, follow the instructions below in the section Troubleshooting.

, it will show its current status in the LCD display. The first line always displays the tenant name (until there is a message received from the platform, see the section To interact with control operations). The second line shows the signal quality in units of dBm. The third line displays information about which sensor data the u-blox is sending and their corresponding values. In the case of repeatedly sending similar data, the third line remains empty.

Switch to the Cockpit application using the application switcher and then navigate to Groups >

In the “Message sending” widget, enter a message in the text field, and then click Send. After several seconds, the first line of the LCD display should display the message you sent. This message will be displayed in the first line until you send another message or restart the device.

In the Configuration tab of the device, the supported configuration parameters are shown with their current values. Currently for the mbed u-blox, the only parameter is “interval” with the default value of 20 minutes, which determines the time period at which Cloud of Things

For temperature sensor: Place one finger atop the temperature sensor, which is located in the top middle of the u-blox device, above the text “Temperature LM7580”. You should immediately see its effect on the LCD display updating its status to send a temperature reading.

For acceleration sensor: Simply turn aside or rotate the device. You should immediately see the device sending an acceleration reading on its LCD display.

For analog sensor: Turn right or left the two blue knobs below the LCD display. You should immediately see the device sending analog readings on its LCD display.

Prior to 2.1, after the LCD display shows “Join Network” and the device is correctly joined to the network, you should see “Reset Success” shown on the LCD display, which indicates a successful factory reset. Starting from version 2.1, a factory reset is much faster, simply wait for “Factory resetting” to appear on the screen, and you can release your finger. After about 2 seconds, you should see “Reset Success” on the display.

The device failed to join a network and displays “Wrong APN setting” or “Unknown APN setting”: Review the source code file C027_Support/MDMAPN.h and add an entry with the Mobile Country Code (MCC), Mobile Network Code (MNC) and your APN setting. The current MMC and MNC code should be shown on the LCD display below the error message “Wrong APN setting” or “Unknown APN setting”.

The device does not appear as CONNECTED in the device registration process: Review the application output using a serial console. See https://os.mbed.com/handbook/SerialPC for details. Also make sure you flashed the device with the correct firmware version, that is, the one that performs the bootstrap against the correct server.

The device does not appear in the devices list in the UI: Review the application output using a serial console. See https://os.mbed.com/handbook/SerialPC for details.

Upon boot-up, the device displays “Connect to Cloud” right after “Agent Run”, instead of showing “Bootstrapping” and IMEI: The device is already registered with Cloud of Things

mbed industrial module with 24V I / O for inserting a processor module NXP LPC1768 or KBED K60 (not included). Without rail mount enclosure CamdenBoss CNMB/6/KIT.

DIN 43880 rail enclosure with 24V I / O for inserting a processor module NXP LPC1768 or KBED K60 (not included). Allows the use of mbed/kBed in a harsh cabinet environment.

DIN 43880 mbed DIN rail enclosure with 24V I / O for inserting a processor module NXP LPC1768 or KBED K60 (not included). SD-Card slot and RS232 integrated in front panel.

Why not have mbed perfectly suit your requirements? Whether in this enclosure or fitting into any other space - let us arrange drivers, relays, signal conditioning around mbed for your particular application. There is some setup cost for the layout but often we might save you a lot of external wiring. 25 units minimum order.

The m3pi was designed as a robot platform for an mbed development board, and using an mbed as the main controller of the m3pi robot is the easiest way to take advantage of all the features of the m3pi. The mbed also adds plenty of processing power and free I/O lines to the m3pi robot.

As long as the 3pi robot base is running its stock serial slave program or the most recent version of the 3pi demo program, a socketed mbed can control the 3pi base through a series of serial commands while simultaneously performing high-level tasks like wireless communication (e.g. via a Wixel, XBee, Bluetooth, or Wi-Fi), route planning, sensor processing, and data logging. The m3pi cookbook on mbed.org provides a high-level overview of using the mbed with an m3pi and a sample “hello world” program.

The 3pi robot included with the fully-assembled m3pi is pre-programed with a serial slave program that works well with the m3pi library; many of the serial-slave commands are supported by the m3pi library. To use the library in your mbed program, either base your program off of an existing m3pi program or click the “import this library into a program” link on the m3pi library webpage.

If you are using the m3pi expansion kit to upgrade your 3pi robot to an mbed-controlled m3pi robot, you should use your AVR programmer to load the serial slave program onto the 3pi. The source code for the serial slave program is included with the Pololu AVR library, as is a precompiled hex file.

To control the base, the mbed communicates serially with the 3pi’s serial slave program at 115,200 bps. If you ordered a fully-assembled m3pi robot, the included 3pi ships with a special demo program that waits for five seconds on startup for a serial command. If the 3pi does not receive a serial command during this initial five seconds, it goes into a demo mode that shows off the various features of the 3pi. To avoid going into demo mode, the mbed should at least send one command within the first 5 seconds of turning on (a good choice would be m3pi.cls(), which clears the LCD).

For more information on how the mbed connects to the 3pi base and other m3pi peripherals, see Section 4. The m3pi mbed library makes it possible to use the m3pi robot without knowing exactly which pins connect to which peripherals, but advanced users might find this information useful if they are modifying the library or writing their own.

NXP offers a variety of evaluation and prototyping platforms that are enabled through the popular, easy to use, web-based Arm mbed development platform. With an online software development kit, free software libraries, hardware designs and online tools, it is the fastest way to create products based on Arm microcontrollers.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey