mbed lcd display brands

The contrast VO pin seems to have different behaviour on different displays, so you may need to experiment for your display to see anything. I think I"ve seen some work tied to 0V, some to 3.3V, or with a different resistor.

Some displays need a negative voltage at VO. One side of the trimpot is connected to the negative voltage instead of GND in that case. F.i. a Maxim MAX1044 can be used to generate the negative voltage.

The underlying HD44780 chip is a driver used in many LCD character displays. It might sometimes be referred to as Hitachi HD44780U. There are also several compatible clones of this chip in use (eg Samsung KS0066).

E Ink is the originator, pioneer and commercial leader in ePaper technology. The company delivers its advanced display products to the world"s most influential brands and manufacturers, enabling them to install extremely durable, low power displays in previously impossible or unimaginable applications and environments.

E Ink encompasses the combined E Ink Corporation, which was spun out of the MIT Media Lab in 1997 to commercialize electronic ink and EPD technology, and Prime View International, which was established in 1992 as the first TFT LCD company in Taiwan, focusing on high quality small-to-medium-sized TFT LCDs. In 2009, Prime View acquired E Ink Corporation to further integrate and expand the EPD supply chain and the new combined companies were branded as E Ink.

This page describes an enhanced forked version of the basic driver code library for Text LCD panels using the 4-bit interface of the HD44780 LCD display controller.

Note that there are many HD44780 compatible LCD controllers around (e.g. KS0066, ST7066, SPLC780, SED1278, LC7985A, NT7603, AIP31066). There are also controllers available that are compatible and provide additional features like an increased number of segment drivers for more characters or internal LCD contrast voltage generators (e.g. KS0073, KS0078, ST7036, SSD1803, SSD1803A, HD66712, SPLC792A). Several other types of displays use controllers that are compatible with the HD44780 to allow an easy transition, for example OLED drivers such as the WS0010 and US2066 or SSD1311. The library controls the HD44780 through a 4-bit bus either directly or by using SPI or I2C portexpanders. Several compatible controllers also have native support for SPI and/or I2C serial interfaces in addition to, or instead of, the parallel bus (eg ST7032i, ST7036i, ST7070, SSD1803, AIP31068, PCF211X, AC780). The enhanced TextLCD library supports some of these devices.

TextLCD has been refactored to fix an issue with recent mbed libs and pins that are defined as NC by default. The change requires that the declaration of the SPI and I2C versions in user code needs a small modification: declare these as TextLCD_SPI() or TextLCD_I2C respectively. See example code below.

TextLCD has been extended with support for controllers that have native I2C or SPI interfaces (eg ST7032i). Declare these as TextLCD_SPI_N() or TextLCD_I2C_N respectively. See example code in header file.

TextLCD has been extended with additional LCDTypes for 3 or 4 line displays that are supported by some controllers (PCF211X, KS0078, ST7036 and SSD1803A). These LCDTypes use different addressing schemes and are identified by a letter added to the LCDtype enumerator. See example code in header file.

TextLCD has been extended with additional controllers (US2066/SSD1311 (OLED), PT6314 VFD). Added support for blinking UDCs and Powerdown on controllers with these capabilities.

Improved speed for PCF8574 and MCP23008 I2C expander interfaces, Fixed problem in Adafruit I2C/SPI LCD portexpander. Fixed occasional init problem. Added PCF2119R and HD66712. Added some I2C portexpander types.

The LCD driver HD44780 is designed for 2 rows of max 40 chars. Note that it needs some support segment drivers to control that maximum number of chars, without those external drivers the device can only display 2x8 chars using its own 16 common drivers and 40 segment drivers.

Four line displays are generally created by splitting the two line display and arranging the two parts above each other. For example 2x40 is split in 2 parts of 2x20 and arranged as 4x20. The addresses for the 3rd and 4th line just continue where the split was made:

The original TextLCD lib uses the address(column,row) method to return the memory address. However, the method adds 0x80 to the returned addressvalue to include the "set display datamemory address" command. This is rather confusing when you try to make sense of the actual address. See discussion here.

TextLCD has been extended with additional LCDTypes for 3 or 4 line displays that are supported by some controllers (eg PCF211X, KS0078, SSD1803). These LCDTypes use a different addressing scheme and are identified by letter "D" added to the LCDtype enumerator. The addressing scheme for such a 12x4 display is:

These 3 line displays are configured as 4 line displays where last or first line is not shown. This mode is selected by choosing LCDType 12x3D or 12x3D1 respectively.

The addressing scheme for the 24x4 display is similar in the sense that the address of the last character on first line is 0x17, for the second line it is 0x37 etc.

There is yet another format for 3 line displays in which the first half of the third line is actually a continuation of the first line and second half of the third line is a continuation of the second line. TextLCD has been extended to support this type. These LCDTypes use a different addressing scheme and are identified by letter "F" (eg LCDType 16x3F, which is actually a 24x2).

TextLCD has also been extended with additional LCDTypes for 3 line displays supported by the ST7036 controller. This LCDType use a different addressing scheme which is identified by letter "G" added to the LCDtype enumerator. The addressing scheme for such a 16x3 display is:

Note1: The HD44780 is pretty flexible and variations of driverhardware and LCD glass layout may result in differences. The 40x4 line displays actually use two controllers (in 2x40 mode) with separate enable pins.

Note2: The HD44780 supports left/right shifting of memory locations (address) wrt displayposition. That changes the address of the char that is shown on a displaylocation. This is pretty confusing and leads to inconsistencies between displaytypes of different numbers of lines or characters/line. The enhanced TextLCD lib therefore does not use this feature.

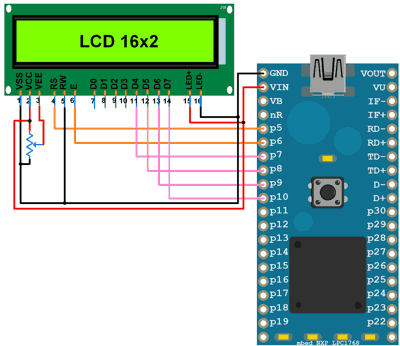

The most commonly found connector on LCDs has 14 pins in a single row or as 2x7 pins. Note there may also be 2 additional pins for the backlight. The pinout for the LCD connector is fairly standard. However, exceptions are known. Always check the datasheet and verify by visual or conductivity testing of the GND pin. GND is normally connected to the metal frame around the LCD glass.

The "standard" pinout has been used in the wiring table examples below. The tables refer to the pinnames of the LPC1768 mbed board and should be adapted to match your target platform.

The contrast voltage depends on the type of Liquid Crystal material that is being used for the display, it does not depend on the controller type. Obviously the controller has a certain voltage range it can withstand, but as long as you stay within its specs there will not be a problem. You will see that LCDs suitable for an extended temperature range often use larger and/or negative contrast voltages. The same is true for displays that have higher refresh frequencies, such as graphics displays. The contrast voltage is normally given or referenced against the positive powersupply (so NOT with reference to GND).

LCD Driving Supply voltage Vdd - Vee (so referenced against powersupply Vdd, which is 5V): -0.3...13V. That translates to 5V-0.3V = 4.7V down to 5V-13V= -8V (now referenced against GND).

Adjustable contrast can be achieved with a 10k trim-pot in a voltage divider configuration: one side to Vcc, other side to GND, wiper to VO. Adjust until you see a top line of solid rectangles, then back off until they just disappear. Most LCDs should be set at around 0.5 V for best results. The display goes dark or light for the largest part of the potmeter range and does not show much change in contrast anymore.

Displays powered at 3V3 instead of 5V may also need a (small) negative voltage at VO. One side of the trimpot is connected to the negative voltage instead of GND in that case.

Enhanced controllers which have LCD voltage generators onboard will usually support programmable contrast. This means you will not see anything on screen until the settings are correct! Some OLED displays will default to an average contrast.

The specsheet of the standard HD44780 says that powersupply should be between 4.5V and 5.5V. These displays should connect pin 2 VCC to 5V as shown in the tables below. The datapins will typically work with the 3V3 logiclevels provided by the processor since the minimum threshold for logic high is 2V2. Powersupply range is often less tolerant. More recent HD44780 compatible controllers may also run on 3V3 powersupply. Check the datasheet for details.

Use decoupling capacitors (100uF parallel to 100nF) on your 5V or 3V3 powersupply for the display, especially when the power is provided my mbed. This will help avoid brief powerline dips which could lead to distorted characters on the display.

The advantage of using the I2C bus and a PCF8574/PCF8574A or MCP23008 portexpander is that you save on mbed pins. This is even more true when you use the bus anyhow for other purposes.

The mbed I2C bus must be supplied in the TextLCD constructor and may be changed (p9,p10) or (p28,p27). Note that you must provide pullup Rs of about 4K7.

PCF8574 addresspins (p1,p2,p3) must be strapped to GND or Vcc to set the deviceAddress. That address must also be supplied in the LCDText constructor. The PCF8574 supports 8 different addresses (0x40..0x4E). The PCF8574A is similar but has a different baseaddress (0x70..0x7E). So in total you can connect upto 16 LCDs to one I2C bus!

Note1: Several other vendors supply full clones of the PCF8574 (eg Texas Instruments). The lib now also supports the MCP23008 portexpander. This device has some different features and it must be selected by activating the #define MCP23008 in TextLCD_Config.h.

Note3: You can change the wiring connections between the PCF8574 pins and the LCD. Just update the appropriate pin mapping definitions in TextLCD_Config.h.

Note4: You can roll-your-own PCF8574 interface or try to find one of the ready made modules on ebay. Search for TWI or I2C and LCD. The boards are all based on the same concept, but there are differences: pinmapping between serial port expander pins and LCD controller, slaveaddress hardwired of selectable by jumpers, solderbridges or a switch, support for backlight control, pull-up resistors for SDA/SCL onboard or not present.

Note5: Predefined mappings are provided for a DEFAULT version (used in wiring table below) and for several others such as the LCD2004 module from DFROBOT and for a very nice combination of SPI/I2C portexpander by Adafruit. This hardware supports both an I2C expander (MCP23008) and an SPI expander (74595) selectable by a jumper. Some other types with PCF8574 are branded as LCM1602, YFRobot, GY-LCD-V1 etc. The expanders produced by WideHK or Jeelabs use an MCP23008.

Here is a picture with a bunch of serial port expanders for LCDs. The top two (Adafruit and WideHK) have MCP23008 I2C expanders. The others use PCF8574 or PCF8574A I2C expanders.

The mbed SPI bus must be supplied in the TextLCD constructor and may be changed (p5,NC,p7) or (p11,NC,p13). You must also provide a CS pin. A simple schematic is here.

The SPI port on controllers with native "4 wire" SPI support needs MOSI, SCK, CS and RS pins on the mbed side. Optionally you may connect a Backlight control pin (BL). The default controller type is ST7032i running on 3V3 and using the internal voltage booster.

Some devices also use a native "3 wire" SPI interface which needs MOSI, SCK and CS on the mbed side. The RS bit (to select between Data and Command) is transmitted as bit 9 of the SPI communication. This mode is used by AIP31068 and other controllers. The enhanced TextLCD lib provides code for this device, but note that the current mbed libs only support 9 bit SPI messages for the NXP platforms. To make things even more complicated, some controllers (eg WS0010) use a 10 bit 3 wire SPI mode. Again, the code is included in the lib, but will only work on the NXP mbed. Finally there are some controllers (eg SSD1803) that use a 3 wire SPI interface to send a 24 bit message. The RS and RW bit are encoded in the message. This message is broken down into 3 messages of 8 bit each, which means all mbeds can support it.

The ST7070 and some other devices also use a "3 wire, 8 bit" SPI interface which needs MOSI, SCK and CS on the mbed side. There is no RS bit and Data exchange is started by first sending a special Command followed by a number of databytes. This mode is supported but is not very efficient wrt communication time.

The I2C port on controllers with native I2C support needs SCL and SDA pins on the mbed side. Optionally you may connect a Backlight control pin (BL). The default controller type is ST7032i running on 3V3 and using the internal voltage booster.

Note that some I2C controllers dont support the I2C Ack. This applies sometimes for Chip-on-Glass (COG) devices due to the electrical characteristics of that technology. The #define LCD_ACK may be used to modify TextLCD lib so that these devices can be used with the mbed I2C lib.

The 40x4 LCDs are different from the regular types because they have two controllers. In fact this is a combination of two 40x2 displays. They have a different pinout with two enable lines (e1 and e2). The example below shows how to connect it using the SPI 74595 shiftregister. Note that currently LCD40x4 is NOT supported by any of the native SPI or I2C controllers.

//TextLCD_I2C_N lcd(&i2c_lcd, PCF2116_SA0, TextLCD::LCD12x4D, NC, TextLCD::PCF2116_3V3); // I2C bus, Slaveaddress, LCD Type, BL=NC, LCDTCtrl=PCF2116_3V3

//TextLCD_I2C_N lcd(&i2c_lcd, PCF2116_SA0, TextLCD::LCD24x2, NC, TextLCD::PCF2116_3V3); // I2C bus, Slaveaddress, LCD Type, BL=NC, LCDTCtrl=PCF2116_3V3

//TextLCD_I2C_N lcd(&i2c_lcd, SSD1803_SA1, TextLCD::LCD20x4D, NC, TextLCD::SSD1803_3V3); // I2C bus, slaveaddress, LCDType=LCD16x2, BL=NC, LCDTCtrl=SSD1803A

//TextLCD_SPI_N lcd(&spi_lcd, p8, p9, TextLCD::LCD16x3G, NC, TextLCD::ST7036_3V3); // SPI bus, CS pin, RS pin, LCDType=LCD16x2, BL=NC, LCDTCtrl=ST7036

The HD44780 supports 8 different custom characters. They are shown by printing a charactervalue between 0 and 7. So rather than lcd.putc(‘a’) to display an ‘a’ you would call lcd.putc(0) to show the first user defined character. The UDC will display at the current cursorlocation. Any displaylocation where you have written a 0 will show that same UDC.

Obviously you first need to store a bitpattern before using this new UDC. All characters on the LCD consist of a 5 (horizontal) x 7 (vertical) pixel font. You can easily recognise that outline shape on the display by inspecting any character. There is in fact an 8th row at the bottom, but that is reserved for the cursor.

You define the 5x7 pattern by writing 8 bytes to 8 sequential UDC memory locations inside the LCD controller. The initial address for the UDC memory depends on which of the 8 available UDCs you want to define.

The method lcd.setUDC(unsigned char c, char *udc_data) makes UDC storage more easy. The first parameter selects the UDC you want to define (should be between 0 and 7 for default HD44780). The second param is a pointer to an array of 8 bytes that holds the pattern. Some sample patterns are defined in TextLCD_UDC.inc. Note that most of them are commented out to save memory space. Enable them as needed or add your own.

You can redefine the UDCs at any time, but note that whenever you change the UDC pattern for an index all occurrences of that index showing on the display will instantly change to the new pattern. Redefining the UDC at short regular intervals allows some simple animation on the display.

Note that b7-b5 are don’t care for the UDC pattern since the font is only 5 pixels horizontal. However, some enhanced LCD controllers (eg SDD1803A) use b7-b6 to enable blinking UDCs. This feature is supported by the lib. See setUDCBlink() method.

The TextLCD lib now supports methods setIcon() and clrIcon() to access Icon functions for several controllers. The mapping between the individual bits in the memory and the Icon on the screen depends on the hardware and glass patterns. These functions therefore need to be developed for each specific display.

Some controllers are available with different ROM fontsets. Examples are Asian, Cyrillic, special graphics symbols etc. The fontset is usually encoded in the controller type designation (eg PCF2119x). The default setting of the library assumes the regular ASCII compatible character set when using prinft() calls. Some conversion functions are available for different fontsets to make sure that at least ASCII text shows up readable in case of the PCF2119C and PCF2119R font. This conversion is provided by ASCII_2_LCD() method and it also works for several other alternative fonts, but does not cover all types. The conversion is not used in default setting to save some processing time. Activate the conversion when needed through the option in TextLCD_config.h

Some controllers support multiple tables that can only be selected by logic levels on a few pins. Some controllers (eg SSD1803A, US2066, ST7070) also support runtime fontable switching through a specific instruction. The setFont() method can be used on these controllers. The selected font must be provided as parameter. See enum LCDFont for options.

The lib now supports extended characters encoded as UTF-8 2-byte characters. This feature allows for example the use of Cyrillic charactersets for the Russian language. The method UTF8_2_LCD() converts the 2-byte codes into a 1-byte reference to the LCD controllers charactermap. The mapping depends on the specific fontset of the controller (some controllers support multiple fontsets, you have to switch fonts before it works).

Some of the additional features of this library over the original TextLCD lib may be switched off when not needed to reduce memory footprint. Select the desired options in the TextLCD_config.h file (multiple options allowed). Default all options are activated except for setFont().

There are many HD44780 compatible LCD controllers around (e.g. KS0066, SPLC780, SED1278, LC7985A), which will work fine with this library. There are also controllers available that are compatible while providing additional features like an increased number of segment drivers for more characters or internal LCD contrast voltage generators (e.g. KS0073, KS0078, ST7036, SSD1803A and WS0010, US2066/SSD1311 (OLED drivers)). Some of these controllers will work fine with the library without further software changes since they just remove the need for some supporting hardware that an HD44780 based display would have used. However, some new features require additional code and some displays won"t even work without these specific new set-up instructions.

Support for some controllers with native SPI or I2C interfaces is now available and will be further improved and extended. Support for setting LCD Contrast on controllers which provide that option has also been added.

Some controllers (eg US2066/SSD1311, SSD1803A) also support changing display orientation. This may be used to flip between top and bottom view when the display is turned upside down. This feature is controlled through the setOrient() method.

Double height lines are available on some controllers and may be selected by the setBigFont() method. However, this doesn"t look great on most displays due to the small gap between lines...

This Internet of Things example uses mbed"s networking features to display live RSS news feeds on the LCD. It is based on earlier networking examples from the cookbook that read a web page and the Text LCD library to display characters on a text LCD. CNN Technology news is used for the live RSS feed.

If you still get the net error message, make sure that DHCP service is enabled for your mbed. On some networks, you need to add the module"s MAC address to enable the DHCP server to give it an IP address. It times out with an error, if no IP address is returned in about fifteen seconds. If the news does not display on the LCD after seeing "net OK", you may have DNS problems or a very slow network.

Where N/C is not connected and the top left pin of the TextLCD’s header is GND and the right most pin is D7 in the LCD orientation shown in the images above. The resistor sets the contrast and some LCDs may need a different value or a contrast adjust potentiometer. See Text LCD for additional help, if needed.

(*) Note: some older LCDs may use 5V, but 3.3V is more common on current LCDs. If you cannot find a data sheet to confirm this, try 3.3V first and if the display is still blank (after double checking all other connections and code) it might need 5V. To save jumper wires, this setup uses the four bit interface to transfer ASCII characters to the LCD.

A small portion of the RSS news feed web page containing XML is seen below. The data displayed on the LCD is the title. The format is "

In the video above, mbed is powered up and obtains an IP address from the DHCP server. Net OK appears on the LCD. It then opens and reads a portion of the web page, searches for news items displaying them as they are found on the LCD and reads through the rest of the web page. When it reaches the end of the web page, "Read Complete" is displayed.

7. Use a Google RSS news feed. Google also has several RSS news feeds and news can be searched to generate a new RSS feed. Here is an example https://news.google.com/news/feeds?q=mbed&output=rss.

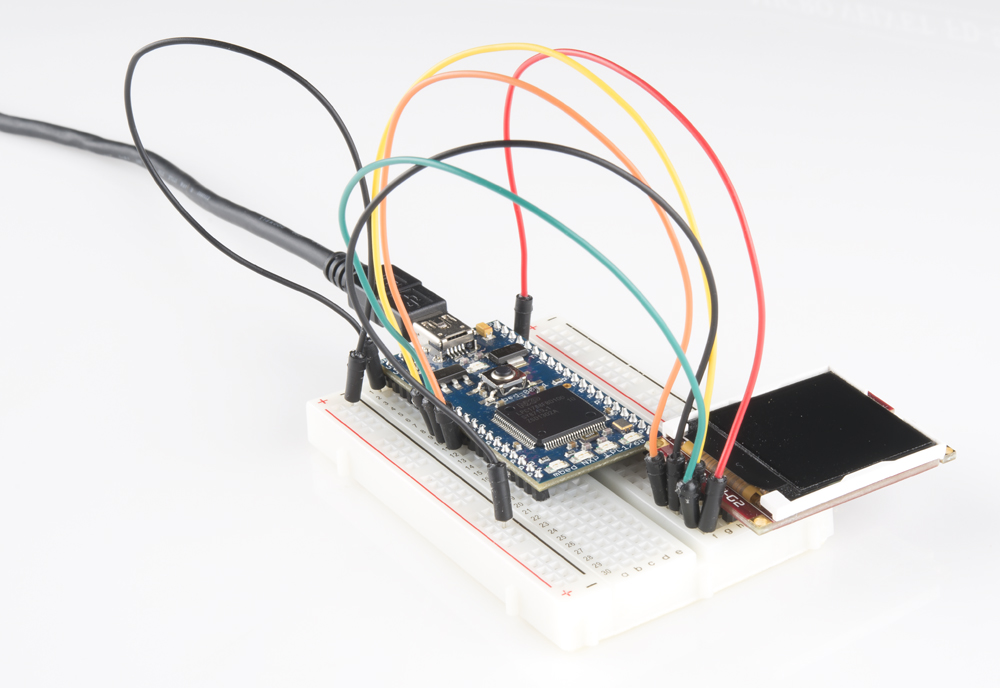

Let"s make some graphics! In this tutorial, we walk you through connecting your Serial Miniature Graphic LCD to the mbed LPC1768 and making some shapes and text. This tutorial is important as we will use the LCD in the next few tutorials, so pay close attention!

This circuit can be made with parts in the SparkFun mbed Starter Kit. Also, keep in mind that the LPC1768 box contains a USB mini-B cable for programming and power.

To follow this experiment, you would will need the following materials if you did not order the SparkFun mbed starter kit. You may not need everything though depending on what you have. Add it to your cart, read through the guide, and adjust the cart as necessary.

Before connecting the LCD to your breadboard, we recommend you carefully bend the 3.3V pin on the LCD back so that it does not short to the RESET pin. This can be accomplished with a set of needle nose pliers. You will likely never need 3.3V from the LCD, as you can get 3.3V from the VOUT pin on the LPC1768. The other pins in the second row can be shorted to pins in the first row and not affect the LCD"s operation.

For this tutorial, we will be using an mbed library. Libraries can be found under the Handbook for official, mbed-supported libraries or the Cookbook for user-created mbed libraries.

mbed.org user Jim Hamblen modified a 4D LCD library to work with our uLCD-144-G2. We copied (also known as "forked") his library for use in this tutorial.

Click "Import this library" on the right side of the page. You will be brought to the mbed Compiler and asked to import the library. Fill in a program name (e.g. "ulcd_demo") for "New Program" and click "Import."

That will bring you to the Import Wizard page. In the "Search criteria..." on the right type in "mbed" and click the "Search" button (Note: the mbed library is likely already listed, but it is good practice to know how to search for libraries).

With our libraries loaded, we can create our LCD program. Create a new file in our project by right-clicking on the "ulcd_demo" project in the left pane and selecting "New File..."

To communicate between the mbed and the LCD, we are relying on a protocol known as UART. While you can create a program that emulates UART, it is far easier to rely on the mbed"s built-in UART hardware peripherals. We are using pin 9 and pin 10, which are the TX and RX lines, respectively, of one of the LPC1768"s UART peripherals. To read more about UART and serial communications, see this tutorial.

Many software programs rely on "libraries." A library is a separate program or programs that may be called upon to perform one or several functions. We interface with libraries by linking to them in our project (the "Import" step in the mbed Compiler) and using the "#include" command in our main program. This tells the compiler to include the header file (".h"), which makes functions in the library available to us (e.g. the uLCD_4DGL class and methods, such as background_color()). Many mbed libraries can be found in the Handbook and the Cookbook.

Many simple embedded systems use the concept of "setup" and "loop" (more powerful embedded systems often use a Real-Time Operating System). For these tutorials, we rely on setting up some parameters and then looping forever within a while loop. This type of structure is known as a super loop architecture.

Now that you have learned about libraries and graphical displays, you are well on your way to becoming an mbed expert. We will be using the LCD in the coming tutorials, so don"t disconnect it yet!

hello, trying to get the onboard button on an mbed application board to allow me to clear the screen and put new info, the button currently does nothing, i am getting the first 4 parts of info on the screen however this does not change when the button is pressed, i need help to try to make this work

The m3pi robot is a fully-assembled, upgraded version of our popular 3pi robot. It consists of a 3pi robot base connected to an assembled m3pi expansion board that simplifies augmenting your robot’s capabilities with an mbed development board (or other microcontroller boards), wireless modules, and sensors.

While the m3pi’s abilities can be enhanced through the addition of a number of hardware modules, the robot is fully operational as it ships and can be used just as a 3pi robot with an expansion board (in which case you will need an AVR programmer). Alternatively, you can leave the default serial slave program on the 3pi base and use an mbed (or your favorite microcontroller board) as the high-level m3pi controller by using it to send serial commands to the 3pi base. Wireless functionality can be added via the XBee or Wixel sockets, and you can use the expansion board’s prototyping space for sensors or custom circuits. The m3pi is powered by four AAA batteries (not included). We recommend rechargeable batteries. For more information on additional components that you might want for your m3pi, please see the Other Things You Might Need section of the m3pi user’s guide.

The key feature of the m3pi expansion board is that it enables the use of one of ARM’s powerful 32-bit mbed development boards as the robot’s high-level controller, offering significantly more processing power and free I/O lines than the 3pi’s built-in 8-bit AVR microcontroller. The base 3pi robot ships preprogrammed to serve as a serial slave, so all you need to get started is an mbed controller (sold separately or as part of a combination deal that includes an mbed NXP LPC1768 with the m3pi robot). The mbed plugs directly into a socket on the expansion board (no soldering is required) and connects to all of the hardware on the m3pi expansion board as well as the serial lines of the 3pi base. Library support and sample programs for the m3pi are available from mbed.org, making it easy to get your mbed-controlled m3pi robot up and running.

This project originated as a prototype created by ARM’s mbed team to help showcase the mbed at various events and exhibitions. The picture below shows ARM’s original m3pi (left) next to our m3pi:

The expansion board also makes it easy to add wireless capabilities to your m3pi robot by providing sockets for XBee or Wixel modules. The expansion board connects these modules to one of the mbed’s serial ports, and jumpers can be used to connect them directly to the serial lines of the 3pi base, so your robot can communicate wirelessly even without an mbed as the high-level controller. Because the Wixel is programmable, the Wixel can also be used as the m3pi’s high-level controller when the serial jumpers are in place.

Note: If you want an mbed-controlled m3pi robot, you can save money with our m3pi robot + mbed NXP LPC1768 combination deal. If you already own a 3pi robot, you can upgrade it to an m3pi robot using our m3pi expansion kit.

The Pololu m3pi robot consists of a3pi robotbase with a fully assembled m3pi expansion board as its second level. This expansion board enables the use of a powerful 32-bitmbed development boardas the robot’s high-level controller, which offers significantly more processing power and free I/O lines than the 3pi’s built-in 8-bit AVR microcontroller. There are also sockets forWixeland XBee wireless serial modules as well as prototyping space for additionalsensorsand electronics.

The m3pi robot is a fully-assembled, upgraded version of our popular 3pi robot. It consists of a 3pi robot base connected to an assembled m3pi expansion board that simplifies augmenting your robot’s capabilities with an mbed development board (or other microcontroller boards), wireless modules, and sensors.

While the m3pi’s abilities can be enhanced through the addition of a number of hardware modules, the robot is fully operational as it ships and can be used just as a 3pi robot with an expansion board (in which case you will need an AVR programmer). Alternatively, you can leave the default serial slave program on the 3pi base and use an mbed (or your favorite microcontroller board) as the high-level m3pi controller by using it to send serial commands to the 3pi base. Wireless functionality can be added via the XBee or Wixel sockets, and you can use the expansion board’s prototyping space for sensors or custom circuits. The m3pi is powered by four AAA batteries (not included). We recommend rechargeable batteries. For more information on additional components that you might want for your m3pi, please see the Other Things You Might Need section of the m3pi user’s guide.

The key feature of the m3pi expansion board is that it enables the use of one of ARM’s powerful 32-bit mbed development boards as the robot’s high-level controller, offering significantly more processing power and free I/O lines than the 3pi’s built-in 8-bit AVR microcontroller. The base 3pi robot ships preprogrammed to serve as a serial slave, so all you need to get started is an mbed controller (sold separately or as part of a combination deal that includes an mbed NXP LPC1768 with the m3pi robot). The mbed plugs directly into a socket on the expansion board (no soldering is required) and connects to all of the hardware on the m3pi expansion board as well as the serial lines of the 3pi base. Library support and sample programs for the m3pi are available from mbed.org, making it easy to get your mbed-controlled m3pi robot up and running.

This project originated as a prototype created by ARM’s mbed team to help showcase the mbed at various events and exhibitions. The picture below shows ARM’s original m3pi (left) next to our m3pi:

In this project, micro:bit is programmed with mbed online IDE to demonstrate some of it"s features like accelerometer, magnetometer, switches and LCD display for showing the sensor data.

5V 16x2 LCD is interfaced with 3V system of micro:bit. Although, 3V logic will work for the display, 3V supply won"t. LCD requires 6 I/O pins to control it.

Since, the LCD will not work with 3V supply (but 3V logic is fine), I made this voltage doubler board with diode-capacitor network, which can boost 3V supply to 5.5 V for the LCD display. It can supply few mA current.

MBED Online IDE is enables in browser C editor and online compiler for ARM microcontrollers. Since, micro:bit"s main processor is nRF51822, which is basically a 32-bit ARM Cortex-M0 CPU with 256 flash and 32 KB RAM and 2.4 GHz radio BLE, thus micro:bit is programmable through MBED IDE.

Once the program is flashed successfully and powered up, it will ask user to press button A for initiating Magnetometer Calibration and display necessary instruction to swing the device like a infinity symbol. This is done to get the min/max of magnetic field which is necessary for accurate heading.

This is a peripherals shield - principally designed for mbed development boards with an Arduino form factor, it can actually be used with *any* development board with an Arduino form factor!

The m3pi robot is a fully-assembled, upgraded version of our popular 3pi robot. It consists of a 3pi robot base connected to an assembled m3pi expansion board that simplifies augmenting your robot’s capabilities with an mbed development board (or other microcontroller boards), wireless modules, and sensors.

While the m3pi’s abilities can be enhanced through the addition of a number of hardware modules, the robot is fully operational as it ships and can be used just as a 3pi robot with an expansion board (in which case you will need an AVR programmer). Alternatively, you can leave the default serial slave program on the 3pi base and use an mbed (or your favorite microcontroller board) as the high-level m3pi controller by using it to send serial commands to the 3pi base. Wireless functionality can be added via the XBee or Wixel sockets, and you can use the expansion board’s prototyping space for sensors or custom circuits. The m3pi is powered by four AAA batteries (not included). We recommend rechargeable batteries

Embedded and Internet of Things (IoT) development teams are under pressure to finish and ship their design as quickly as possible. To move fast, they need to use proven components and software frameworks that have a strong ecosystem around them. They also need to look at how their systems will be maintained and scaled in the future, which means that solutions also need to be portable and able to work across multiple hardware platforms if need be.

Considering these requirements, this article will introduce the Arm Mbed platform and operating system. It will show how developers can leverage the Mbed ecosystem to accelerate their embedded product development and use it to scale beyond the microcontroller vendor’s ecosystem.

Mbed is an online collaboration headed by Arm for developers interested in building IoT devices1. Mbed provides developers with a wide selection of resources designed to accelerate development, ranging from the Mbed OS and Mbed TLS all the way through development boards and individual hardware components that are supported by the Mbed libraries.

The premise behind Mbed is to enable developers to leverage a large ecosystem supported by 200,000 developers in online communities along with major microcontroller vendors such as Cypress Semiconductor, NXP Semiconductors, and STMicroelectronics to accelerate their development by using existing components, development tools, and libraries. There are many advantages to using the Mbed ecosystem:

Access to the Mbed online and offline compiler along with the Mbed command line interface (CLI), which makes developing software tests easy (and is even included in many examples and libraries).

The general architectural model for Mbed makes it extremely flexible and scalable for embedded developers. For example, the architectural model is generally broken up into three separate layers (Figure 1):

While Mbed provides a great software foundation, it offers more than just the software and the tools needed to develop that software. The quickest way that a team can develop a product is to also leverage the Mbed hardware ecosystem, which comprises three distinct areas:

Mbed boards are essentially development boards for different microcontroller families that are all supported by Mbed. Each development board has unique features and capabilities that are provided by the microcontroller vendor. For example, a developer interested in working with a board that supports Bluetooth Low Energy (BLE) might be interested in Cypress Semiconductor’s CY8CKIT-062-BLE (Figure 3).

The CY8CKIT is unique in that it features a multi-core PSoC 62 secure microcontroller. One core is an Arm® Cortex®-M4 processor while the second core is a low-power Arm Cortex-M0+. This allows developers to either partition their application code, such as having one processor handle the BLE communication, or lock down the application by using the Cortex-M0+ core as a security processor. All the I/O expansion available on the boards makes it a lot easier for developers to prototype their system by connecting Mbed components to them.

An Mbed component is a hardware component that has Mbed supported libraries and middleware associated with it that act as building blocks for creating a product. For example, a developer working on an IoT project may decide that they want to include a temperature sensor. A developer can search Mbed components for supported temperature sensors and they would come across, for example, Maxim Integrated’s MAX31723PMB1, which comes in a peripheral module that can be used for rapid prototyping (Figure 4).

What’s great about such Mbed components is that they nearly always come as a development board with schematics available. This allows a developer to not only see the hardware configuration required to make the sensor work, but have the software library available to get the sensor up and running.

Simple sensors like those measuring temperature and humidity aren’t the only types of sensors that are available through Mbed. For example, developers working on a medical device will find that the Maxim Integrated MAXREFDES220# module provides them with a reference design for a finger-based heart rate and SpO2 blood oxygen sensor (Figure 5).

Once a developer has selected their development board and components, they can start developing with Mbed by creating a “Hello World” LEDBlinky application to test that they can program their board successfully and blink an LED.

There are several different ways to develop an Mbed application: through the online compiler; the offline compiler; or by using the command line interface (CLI) tool. Personal experience suggests using the CLI because it provides more control over the development process and makes it easier to integrate into development processes, such as test harnesses and continuous integration servers.

The CLI provides command line interface capabilities so a developer working on Windows can use the command prompt to compile their code. The first step in creating the LEDBlinky application is to use the pre-made example provided with Mbed. This can be done by entering the following command into the command prompt:

It will take a few minutes to download the example as this also brings in supporting Mbed OS and other components that may be used in the application. Once the download is complete, a developer can navigate to the mbed-os-example-blinky folder where they will find a main.cpp file. This module can be opened in a developer’s favorite editor and will look something like the following:

Compiling the project for the first time can take several minutes since the toolchain will have to build all the associated files that automatically come into an Mbed application. Once the compilation cycle is completed, the result should look something like Figure 7 below.

Getting started with Mbed is straight forward, but there can be challenges for developers. Below are a few “tips and tricks” for starting to develop a product using Mbed:

Avoid using the online compiler. This is fine for hobbyists, but for professionals, having source code on someone else’s servers can be a problem. Also, the back and forth to the cloud can slow down debugging. A local compiler such as the Mbed IDE or the Mbed CLI are better options.

Embedded and IoT developers need a well-supported ecosystem that provides them with modern tools, processes, and software to help them accelerate their development efforts and minimize development costs. As shown, the Mbed platform and OS is one potential option that developers can leverage.

Mbed provides a scalable and flexible software architecture with many components that have already been integrated and tested together. The large support for various hardware modules, boards, and components makes it easy for developers to create a product prototype that can then be scaled into a production solution.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey