using a tft lcd to move a servo supplier

This project’s aim is to design a display interface for controlling a Servo motor. The Servo angle or position is changed either by dragging or pressing the button on the LCD display interface. The interface is built on a 4.3-inch touch display and programmed using an STM32 development board.

The serial screen is a type of screen that is controlled by the serial port. This screen saves a lot of time as it requires no programming and is perfect for those who use microcontrollers in designing the UI. By using this screen, you can get some common spaces through simple settings and there is no need to write the code for the UI implementation.

First of all, the interface of the serial port screen is designed. You can design a picture of the same using paint or any other similar tool. For each key effect, a particular image should be designed. For example, here I have designed separate display pictures for the separate key effect:

The original image is displayed when the screen is turned ON. In other words, it is the foreground display picture. Whereas the second picture with the corresponding position is displayed when the +ve or -ve position buttons are pressed.

This project is made by using hand to hand connections. The display, microcontroller board, and stepper motor are connected together by using jumper wires. To make this project more reliable, sturdy, and permanent, I suggest you use a custom made PCB board from PCBWay. They provide high-quality PCBs at a very low price.

After installing the software, open it, and create a new project. Since the resolution of the display screen is 480×272 px, select this resolution in the project details. I want to use the screen horizontally, so all other options are set to default.

Add the designed picture you want to use in the GUI. The picture name must start with a number, although there are no special requirements for the specified number. The size of the picture should be consistent with your screen resolution, otherwise, it will prompt an error.

Here I have added the two pictures, the default or foreground display picture is named as number 2. For this, I changed the screen settings inside the startup picture display. In this setting, the startup display picture corresponds to picture number 2.

On the right side of the interface, there is a hotkey area where you need to modify the storage address and the adjustment method. For the same operation or function of the -ve side, the storage address is made the same as the + address.

Under the variable configuration column, select the slider scale. In the right column, modify the slider file and slider icon properties that you want to display over the image.

Adjust the size of the slider scale control so that it fits your scale value. But keep in mind that the icon may exceed the lower scale. So, you can control the slider scale control by adjusting the size of the slider scale control. Or adjust the offset of X coordinate to align it, try to generate a project to debug it to see if the position is suitable.

There are other properties of the sliding scale control that need to be modified: the stored address corresponds to the +ve and -ve address and the minimum and maximum scale corresponding to the scale bar at the bottom.

In the touch configuration toolbar drop-down menu, select the drag adjustment to place over the picture. Now adjusts it to the appropriate size and modify its properties. The storage address is still consistent with the above but the maximum and minimum value range needs to be adjusted.

Add a data variable and the data should be stored at the same address as above. This is mainly to display the data and to better observe the changes in the data.

After completing this step, you can download or run the simulation test. If there are no problems with the design of the serial screen, move on to write the microcontroller program.

I used STM32cube IDE software to write the program for the board. But before that, the configuration setting should be selected for STM32, and I’ll give a brief description of the configuration here.

Open tim2 ch1 channel output PWM wave. The minimum adjustment is 1us for accuracy. The servo adjustment is 0° – 270° corresponding to the pulse of 0.5ms-2.5ms. After the configuration is complete, select the output frequency of 100K PWM wave.

Open the serial port 1. Here I used the DMA, mainly a matter of habit, there is this more advanced configuration on the use of it. Get used to the future of the project also helps ah! The images given below are the screenshot of the configuration information. And after the completion of the configuration, you can generate code.

After the configuration is completed, you have to add the code. All you have to do is add the array and the serial port receives the completion flag data.

c) In a regular project, the serial port processing function should be handled separately. But we don’t do it here because our function is relatively simple.

After the completion of the entire project, compile and download the code to the board. It should be noted that the screen communication connections are of 232 and TTL types. My board is not connected to 232, so it is directly connected to the IO port. Here on the screen, there are J17 solder joints that need to be welded open.

And the project is complete. The entire UI design is based on the picture. The MCU development was relatively simple as the serial port is used which greatly reduces the burden on the developers.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

I can do the soldering if I have to. I also agree that the TFT should be mounted on the Mega. I can hardwire this shield and mount it remotely if I need to.

I have connected the motor shield to the Mega and confirmed correct operation of a piece of example code and then manually connected all the digital pins except 13. I also connected +5V and 0V for power and it sort of works but not correctly. just vibrates the stepper motor and moves a little bit where it should do a full revolution as part of the test code.

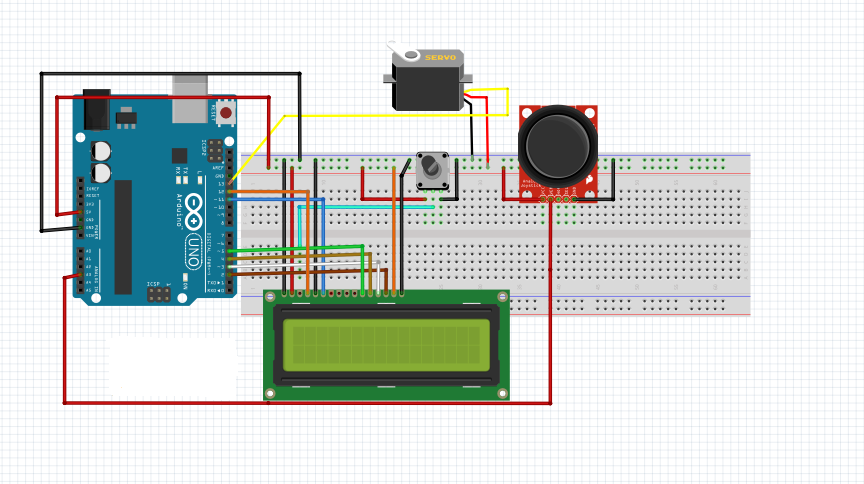

All you need to do is drag and drop components and Connect them together. Visuino will create the working code for you so you don’t have to waste time on creating the code. It will do all the hard work for you fast and easy! Visuino is perfect for all kind of projects, you can easily build complex projects in no time!

Please be aware that there are some critical bugs in Arduino IDE 1.6.6. Make sure that you install 1.6.7 or higher, otherwise this Instructable will not work! If you have not done follow the steps in this Instructable to setup the Arduino IDE to program Arduino UNO! The Visuino: https://www.visuino.eu also needs to be installed. Start Visuino as shown in the first picture Click on the "Tools" button on the Arduino component (Picture 1) in Visuino When the dialog appears, select "Arduino UNO" as shown on Picture 2

NOTE: Some Displays have diferent properties so experiment by selecting diferent types to find the one that works best, in my case I choose "dtST7735R_BlackTab"

Congratulations! You have completed your project with Visuino. Also attached is the Visuino project, that I created for this Instructable. You can download and open it in Visuino: https://www.visuino.eu

Lavishly illustrated by clear line diagrams and photographs,Ward"s Anaesthetic Equipmentis a highly accessible single source to aid understanding of the key principles behind equipment function and design. This sixth edition of the classic reference text on anaesthetic equipment is again extensively revised to reflect the very latest advances.

Ward"s is an invaluable resource for qualified anaesthetists, as well as essential reading for those in training or approaching examinations such as those of the Primary and Final Fellowship in the UK and Ireland. Trainees in Intensive Care Medicine, anaesthetic assistants, operating department practitioners, electronic and biomedical engineers in hospitals and manufacturers" representatives will also benefit from this most trusted guide.Provides a simple and comprehensive explanation of the function of anaesthetic equipment, ensuring its safe use in clinical practice

The physics and technology of ultrasound gains a devoted chapter, as does patient warming. There are enhancements on depth of anaesthesia monitoring, error management and ultrasound imaging in regional anaesthesia. Particular coverage of supraglottic airway devices substantially augments an extended chapter on airway equipment. Updates throughout, including on the anaesthetic workstation, infusion devices and equipment for anaesthesia in difficult locations, ensure Ward"s remains the most comprehensive and current text on anaesthetic equipment.

In this tutorial, we will be Interfacing a 7-inch DWIN HMI TFT LCD Display with Arduino Nano Board. Using this DWIN Display we can control various modules like Relay, Servo Motor, and RGB LED. We will also learn how to create the UI using the DGUS Software.

Before moving ahead, go through the DWIN Getting Started Guide to learn more about the DWIN Display and the method to upload the firmware. Since the DWIN Display has UART Interface, we can communicate with Arduino through Serial Communication. Let’s see how we can build this System.

DGUS(DWIN Graphic Utilized Software) is a cost-effective GUI software platform developed by DWIN Technology. Based on the K600+ Kernel hardware platform, GUI design, combined with a simple command interface, can be achieved quickly, eliminating the need for complicated programming and expensive development environments.

Download the DGUS Software from the above link and then extract the folder. Open the extracted folder and run the executable file called ‘DGUS_V7.642.exe‘. A DGUS Window will open. Initially, you need to change to the English language as the Chinese language is set by default.

The link for all the files including the DWIN_Set folder, images, ICL files, etc are inside the folder below. You can extract them and use them in your project.

Each and every module/units have a different Memory Address (assigned as VP). For example in the above UI, the memory address for Servo=5100, Red LED=5200, Green LED=5300, Blue LED=5400 & Relay=5500.

After creating the UI using the DGUS Software, download the firmware to DWIN LCD Display either using the T5L Download tool or using the SD Card. Follow the previous guide.

Before interfacing please check on the back of the DWIN Module whether the TTL Module is enabled or not. In case its not enabled, solder the terminals to enable the TTL Communication.

Connect the Servo Motor and Relay VCC & GND Pin to Arduino 5V & GND Pin. Also connect the Servo Motor to D3 of Arduino as Servo requires PWM Signal for operation. Connect the Relay output pin to D2 of Arduino. The RGB LED Module is connected to Pin D4, D5, and D6 of Arduino.

Coming to the DWIN LCD Display and Arduino part, UART Serial Communication is required. Therefore connect the TX2, and RX2 of DWIN Display to Arduino RX & TX Pin respectively. Supply the 5V to both Arduino and Display using their respective USB Cable. The GND connection should be common for both Arduino & Display.

If you don’t want to assemble the circuit on a breadboard and you want PCB for the project, then here is the PCB for you. I used EasyEDA to design the Schematic & PCB. The Schematic & PCB Board for DWIN LCD Arduino Interfacing looks something like the below.

You can now upload the Gerber File to the Website and place an order. The PCB quality is superb & high standard. That is why most of people trust NextPCB for PCB & PCBA Services.

This is the frame that display sends whenever any button is touched in the display UI. You can check this using by connecting USB-to-TTL Module to DWIN Display pins.

After the code is uploaded, you can start testing the entire system. The created UI looks like this and has the option to go into next page by clicking on Servo, LED and Relay.

Go back to the homepage and click on RGB LED to enter into the next page. You can slide the Red, Green, Blue Slider to control the brightness and intensity of RGB Light. You can also mix colors to generate different color lights.

Go back to the homepage again. Click on Servo Control option from the display. In this mode you can select ON/OFF option to turn on or off the Relay Module.

Herkulex DRS-0101 is state of the art modular smart servos incorporating motor, gear reducer, control circutry and communications capability in one single package.

Equipped with a lot of adapting pieces including Horn, Horn Bolt(BHT 2.6X8), Wheel Horn Bushing, Wheel Horn Washer, Wheel Horn Bolt(PHM 3X8), Cable Guard, I-type Joint, L-type Joint, L-type Joint(Single Nut), Bracket Bolt(PHT 2X5), Joint Bolt(PHM 2X5), Wire Harness(200mm) and with it"s amazing structure, DRS-0101 is extremely easy to assemble. Two connectors attached to each servo allows serial connection as well as parallel connection if required.

It carries different Control Algorithms like PID, Feedforward, Trapezoidal Velocity Profile so on and so forth, which makes the movement smoothly and precisely. By Using UART Serial communications ,we can lightly change the speed, position, LED, operational compliance, stop and operational status of up to 254 servos simultaneoulsy at once. Meanwhile we can get the feedback such as internal temperature, position, and overload sensors.

Servos are capable of diagnosing seven different types of errors which are then indicated by the LED. And we can directly control the RGB of the LED for diagnostics and decorative purposes. It"s especially suitable to mechanical arms, robots, joints and etc.

Various Control Algorithm: PID, Feedforward, Trapezoidal Velocity Profile, Velocity Override, Torque Saturator & Offset, Overload Protection, Neutral Calibration, Dead Zone

Tips: There is only one Hardware Serial port on UNO, so that Software Serial has to be used. However, the default baud rate of HerkuleX is up to 115200, which may be unstable when using the Software Serial. Thus it"s recommended to change the baud rate of HerkuleX to 57600 first.

DSS-M15S servos have been well received by customers in these years. It has extremely wide angle control range, huge load capacity and excellent quality. This DSS-M15S with analog feedback has broken its internal potentiometer signal. This is an analog signal with 0~3.3V feedback. You can connect it to MCU to realize close-loop feedback control.

DSS-M15S 270° Metal servo with feedback is compatible with Arduino Servo library. You can drive it with Arduino Board and read the angle value from analog side.

There will be some error between each servos. If you want to use the servos with scenes that require precise control, you can calibrate them separately. A quick three-point calibration method is provided here:

A multi-axis controller integrated with touchscreen interface, believed to be the most simplest one currently in the market. It comes with QuickSet intuitive software too. All you need to do is plug it, ...

... industrial PC and the 15″ touch screen. Design and ergonomics satisfy the highest demands. The hardware and software are state-of-the-art technology. The new CNC-S control and the new, revolutionary CNC-S ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Welcome to my collection of Arduino projects. As a maker, techie and mechatronics engineer I’ve been using Arduino for more then 8 years. Arduino is an incredibly versatile microcontroller with limitless possibilities for developing electronics applications and prototypes.

We can use Arduino for simple tasks such as controlling LEDs and DC motors, to controlling real CNC machines and robots. That’s right, in the following list I will share my Arduino experience with you. You will find Arduino projects for beginners and more advanced projects for Arduino enthusiast.

Even if you are just getting started with Arduino, you don’t have to worry about that. Each of the following DIY Arduino projects is covered with detailed step by step tutorial on how to do it yourself and includes circuit schematics, source codes and videos.

Using the comments section below, you can also suggest your ideas, as well as discuss anything related to these Arduino projects. I will continuously update this article with all new stuff that I make. Last update: February 2022.

As an Arduino enthusiast, I found making robots with Arduino to be most fun for me. There is so much to learn from them as a maker and an engineer. So, here are my Arduino projects related to robotics so you can learn too.

When it comes to automated manufacturing, robot arms play big role with so many applications. They are often used for welding, assembling, packing, painting, pick and place tasks and much more. This Arduino project is actually a robotic arm made out of 3D printed parts, servo motors joints and controlled using an Arduino Nano. What’s even cooler we can control the robot arm wirelessly via a smartphone and a custom build Android application.

The robot arm has 5 degrees of freedom, so we need 5 servo motors, plus an additional servo for the gripper mechanism. For the communication with the smartphone we use the HC-05 Bluetooth module.

The following project is one of the coolest Arduino project in this list. It’s an Arduino robot car which instead of normal wheels, it employs omnidirectional wheels or mecanum wheels which enable to robot to move in any direction.

The wheels are attached on four stepper motors which are individually control. By rotating the wheels in certain pattern, they exert diagonal forces due the diagonally positioned rollers on the circumference of the wheels, and so they can move in any direction. The robot car can be remotely controlled either vie Bluetooth communication and an custom build Android application. Also, we can control it using an DIY RC transmitter with the help of the NRF24L01 transceiver module.

Here’s an upgraded version of the previous mecanum wheels robot project. On top of the platform I added the DIY Arduino Robot Arm project mentioned above and now they can work together.

As the robot uses stepper motors for the wheels and servo motors for the robot arm, we can precisely control them using the custom build Android application. What’s even cooler, we can record the movements of the robot and then the robot can automatically repeat them.

Of course, as for any of my Arduino projects, the Arduino code, the custom build Android application, as well as the 3D model files can be found and downloaded from the particular project article.

SCARA robot or Selective Compliance Articulated Robot Arm is the most common and suitable option, when it comes to pick and place and small assembly applications, which require moving a part from point A to point B.

This Arduino based SCARA robot is a step-up big compared to the previous projects in every aspect. It has a better and more robust design with precisely controlled stepper motors and custom build GUI for controlling it.

As a controller it has an Arduino UNO board, combined with a CNC shield and four A4988 stepper drivers. It has 4 DOF, driven by four NEMA 17 stepper motors.

This and extension of the previous project or I converted my 3D Printed SCARA robot to work as a laser engraver robot. Instead of the gripper mechanism, here we are using a Laser module for engraving.

For controlling the robot we are using an Arduino Mega board in combination with a RAMPs board. This a popular combination used for 3D printing and it can be used for laser engraving machines as well. As for a firmware, we are using the Marlin 3D Printer firmware and the Repetier control software.

Inspired by the NASA Mars 2020 mission and the successful landing of the Mars Perseverance Rover on the plant Mars, I build a 3D printed functional replica of it. I designed this DIY 3D Printed Mars Rover in a way that it can be easily recreated by following the instructions in the tutorial.

The rover features a rocker-bogie suspension which allows the rover to run smoothly on uneven terrain, just like the real rover. It has six independently controlled DC motors for driving and four servos for steering, and it’s controlled using an Arduino MEGA board. There’s also an FPV camera located in the cameras unit of the rover which can by used for controlling the rover remotely. The remote control is done with the help of a cheap commercial RC transmitter and receiver.

Making biologically inspired robots is very popular among engineering students. This Arduino project is all about it, we will build a hexapod robot which features six legs, a tail or abdomen, a head, antennas, mandibles and even functional eyes. All of this makes the robot look like an ant.

Each leg have three joints, and for each joint we need a servo motor. That means that we need total of 18 servos for this project, and additionally 3 servos for the head movements and 1 servo for the tail. The brain of the robot is an Arduino Mega. We need MEGA because it’s the only board that can control more than 12 servos using the Servo library.

I also designed a custom PCB which acts as an Arduino Mega Shield so we can easily attach all servo connects. We can control the ant robot via Bluetooth and a smartphone, or radio communication. The ant also has built-in ultrasonic sensor in the head. With that it can detect objects in front, and it can even strike if the object is present if front of it.

The following projects show how capable Arduino is. A CNC or Computer Numerical Control is an automated control of machines, like mills, lathes, plasma cutters, 3D printers and etc. So, using the Arduino as a controller we are actually able to build any of these CNC machines.

For the project my goal was to build the simplest CNC machine with minimum parts possible and by using just a single power tool. On top of that, I wanted to use common materials or avoid 3D printers so I used MDF board for building the base frame.

The CNC machine is composed of just two linear rails which are secured to a base frame made of 8mm MDF board. For controlling it we are using an Arduino UNO board in combination with a CNC shield and two DRV8825 stepper drivers. As a tool it has an laser module attached so this machine is actually a CNC laser engraver.

The idea for this Arduino project was similar to the previous one, to build a CNC machine using minimum parts possible. Here I used 3D several printed parts, and just two MGN15H linear rails for the main construction of the machine.

Building your own CNC machine might seem like a big challenge for many of you, but the following Arduino CNC Machine project shows that building a CNC machine is actually not that hard.

This CNC machine is actually a foam cutting machine. Instead of bits or lasers, the main tool of this CNC machine is a hot wire. It’s a special type of resistance wire, which gets really hot when current passes through it.

Controlling stepper motors using Arduino is without a doubt one of most satisfying thing for an Arduino enthusiast. There so many machines based on this motors, like CNC machines, 3D printers, various automation machines etc. This Arduino project is all about that. It describes how you can build such a machine. It’s a machine for bending wire, where with the help of stepper motors we can precisely bend wire and make various shapes and forms out of it.

The machine features three stepper motors. With the first stepper we feed the wire to the bending mechanism. Here we have another stepper motor used for the bending the wire at the right angle. There’s also another stepper, for controlling the Z-axis. This stepper enables the machine to create three dimensional shapes. With this project we can also see how useful 3D printers are for Arduino projects of this type or for prototyping.

Many Arduino projects that I make require wireless control and that’s why I build this Arduino based wireless radio controller. With this RC transmitter I can wirelessly control pretty much with a range up to 700m in open space. It features 14 channels, 6 of which are analog and 8 digital inputs.

The brain of this Arduino project is an Arduino Pro Mini board which is the smallest Arduino board. The radio communication is based on the NRF24L01 module, it has 2 joysticks, 2 potentiometers and 4 momentary push buttons. Also an accelerometer and gyro module which can be used for controlling things with just moving around or tilting the controller. I mounted all electronic components on a custom design PCB and made a cover out of transparent acrylic.

This is a follow up project of the above one. Just like DIY RC Transmitter, this DIY Arduino RC Receiver can be used for many application. We can easily pair the two projects together and control anything wirelessly. Among others, I made an example of controlling a commercial RC car model using these DIY transmitter and receiver.

The custom PCB that I made uses the same NRF24L01 module for the radio communication. The controller is an Arduino Pro Mini and it features input/ output 9 channels.

The following Arduino project is a great example of utilizing the DIY RC transmitter from above. It’s a 3D printed hovercraft which I entirely designed on my own, and of course, the 3D printing files are available for downloading. The hovercraft uses two brushless motors, one for creating an air cushion for the lift, and the other for generating thrust or moving forward.

For the wireless control we are using the NRF24L01 module, which accepts the data coming from the RC transmitter. Then using the Arduino and two ESCs (Electronic Speed Controler) we control the BLDC motors speed. On the back side of the hovercraft there is also a servo for controlling the rudders, or for controlling the steering. I must say that driving this DIY hovercraft is so fun.

Anyone who had a chance of playing around with some RC airplanes knows how cool and fun it is. It’s even cooler and more satisfying if you build the RC airplane on your own. The following project steps the satisfaction up even further, because here I will show you how to build your own RC airplane which is 100% DIY build. Also, we have a 100% DIY radio control system based on the Arduino.

The airplane is entirely made out of Styrofoam and what’s cooler, the shapes are made with the help of my DIY Arduino CNC Foam Cutting Machine, a project already mention above. The radio communication is based on the NRF24L01 transceiver modules. For that purpose, I used my DIY Arduino RC Transmitter and DIY Arduino RC Receiver.

You can choose one of the three different methods of wireless control explained in this project, or that’s the HC-05 Blueooth module, the NRF24L01 transceiver module and theHC-12 long range wireless module. Additionally you can learn how to make your own Android app for controlling the Arduino robot car.

This Arduino project idea is rather practical because it features indoor and outdoor temperature and humidity measurement. It is based on the DHT11/ DHT22 sensor, the NRF24L01 transceiver module for the wireless communication and theDS3231 RTC. For the display we can either use 16×2 character LCD or a 3.2 inches TFT touch screen.

The outdoor unit can be powered with batteries and the indoor unit with an AC adapter. The outdoor unit measures the temperature and the humidity and sends the values to the main indoor unit. Here these values are printed on the LCD along with the data and time values from the DS3231 RTC module.

Camera slider are great for capturing cinematic shots, and having pan and tilt system on top of it even further increase the possibility to capture better shots. In this project I will show you how you can build your own one, which costs way less then one found in the stores and still you can get great and super-smooth shots.

The slider has three NEMA 17 stepper motors controlled via the A4988 stepper drivers and the Arduino Nano board. Using a joystick we can control the pan and tilt movements and using a potentiometer we can control the sliding movement. With this DIY camera slider we can use the Set button to set two different IN and OUT points. Then the camera can automatically move from one to the other point.

If you are interested in building something more complex with Arduino then this project is the one for you. Although complex, you could easily recreate it as there is a detailed step by step explanation on how everything works, including circuit schematics and source codes.

The structure of the machine is made out of MDF. For discharging the items I used continuous rotation servo motors, while for the carrier system I used two NEMA17 stepper motors. For detecting the coins the machine uses an infrared proximity sensor.

The following Arduino project is a simple gimbal or a self-stabilizing platform. It can be used for keeping objects or the top platform level. The project is rather simple with just several electronic components.

The combination of DC motors and Arduino is always fun, and so is this project. Here we will build our own robot car from scratch. The car will be powered with Li-ion batteries and two 12V DC motors, and controlled using the L298N driver and an analog Joystick.

This is one of my most popular project and it’s really fun to build. The radar can detect objects in front of it and map them on PC screen using the Processing IDE.

For this project you just need two components along with an Arduino board, and that’s an ultrasonic sensor and small servo motor. The range of the radar can be adjusted to up to 4 meters with 180 degrees rotation.

Here’s another project utilizing the HC-SR04 ultrasonic sensor. This time we will use it to make an distance meter which can measure distances up to 4 meters, as well as, measure square area.

The project also includes and accelerometer which is used for the digital spirit level function or for measuring angle. The results are displayed on 16×2 LCD and all components are attached on a custom design PCB.

Sorting out objects or products by their color has an important real world application. These types of machines are often used for sorting fruits, seeds, plastics etc. The working concept of these machines is rather simple. All you need is a color detecting sensor and of course a system that feeds the object to the sensor and then sort it out.

In this project we will learn how to use a color detecting sensor along with the Arduino. We are going to be sorting out colored skittles but you can use the same sensor and method for sorting out anything else.

RFID technology has wide range of applications and access control is one of them. We often encounter this in hotels for accessing our room or at work for checking in or accessing restricted areas.

In this project we will learn how to use the Arduino to make an RFID controlled door lock. The system consists of an MFRC522 RFID reader and RFID tags/ cards that are based on the MIFARE protocol.

If you ever thought of making your own security system then this project is a great starting point. Here we will utilize an ultrasonic sensor for detecting movement.

If a human or object passes in front of the sensor, the alarm will be activated. For deactivating the alarm you will have to enter a password using a keypad.

In this project we will control LED Matrices using the MAX7219 driver. This driver can control up to 64 individual LEDs while using only three wires. Also we can connect up to 8 drivers in series and still using the same wires.

To make this project more interesting I also added an example where you can update the text on the LED matrixes through your smartphone using a custom-made Android app.

This game project is based on the popular Flappy Bird game for smartphones. Using the touch screen we control the bird while trying to avoid the pillars.

For this project we need a 3.2 inches TFT Touch screen, an TFT Mega shield adapter and an Arduino Mega board. The code is a bit longer but everything is explained in details.

The code behind this project is a bit more complex with around 550 lines but everything is explained in details with comments for each lines. There is also a detailed video explanation for it.

At first glance this table looks like a normal coffee table but once you turn on the power on it gets to a whole new level. The table has 45 sections which can glow in any color we want, plus it reacts on objects placed on top of it.

The heart of the table is an Arduino which controls the 45 WS2812B Addressable LEDs. The objects on top of the table are detected using infrared proximity sensors. What’s even cooler it has built-in Bluetooth module which enables interaction with a smartphone for selecting the LEDs colors.

Monitoring the indoor air quality is very important as it can affect us in many way. If we have a poor air quality in the room we are staying, it can lead to tiredness, headaches, loss of concentration, increased heart rate and so on.

In this Arduino project we are building an Air Quality Monitor which can measure several important air quality parameters such as PM2.5, CO2, VOC, Ozone, as well as temperature and humidity. I designed a custom PCB on which we can easily attach the sensors we need and show the results on a 2.8 inches touch display. The device can also keep track of the sensors values from the last 24 hours.

The following section of this article contains Arduino projects ideas based on my detailed tutorials on various sensors and modules, as well as your suggestions from the comments section below.

We can use NEMA 17 or 23 stepper motors in combination with these drivers which provide high speed reduction ratios. As for controller we could use an Arduino Uno or Arduino MEGA board.

Controlling your home power outlets via a smartphone is the first step in home automation. You can easily make your own Arduino controlled power outlets utilizing the knowledge you can get from my Arduino tutorials.

For this project you just need two components along with the Arduino board. An HC-05 Bluetooth module and a5V Relay module for which I already have detailed tutorials. For powering the Arduino and the relay you can use 220/ 110V AC to 5V DC converter.

Using your smartphone you can connect and control your power outlet via Bluetooth. You can either use some already made apps for controlling Arduino from the Play Store or create your own custom made app. In this way we can also control the power outlets through voice control commands.

Home automation is one of the most popular Arduino projects nowadays. The goal of this project is to remotely control anything in your house like lights, appliances, temperature, security devices and so on, with a single device or your smartphone.

In order to make such a project we need decent amount of knowledge in Arduino. The following home automation concept that I suggest is based on my detailed Arduino tutorials for various sensors and modules.

So the idea here is to have a master unit which includes a touch display, and several slave units which will execute commands coming from the master. As for the wireless communication we can use the NRF24L01 radio frequency modules. Each slave unit can have various functions like, temperature monitoring, power outlet control, lights control,security alarm and so on.

Of course, there are endless possibilities and combinations for building a home automation system using the Arduino board. You can always change and add more devices. You can also make a Bluetooth communication so you can control all of this using your smartphone etc.

The idea for this project is to remotely control an Arduino project using hand gestures. Let’s say we want to control the Arduino Robot Car that we mentioned above. So instead of the joystick we will use an MEMS module for the control.

We can use the GY-80 module which features an accelerometer, a gyroscope and a magnetometer. Then the data we are getting from these sensors to control the steering of the robot car. As for the wireless communication we can use the NRF24L01 transceiver modules.

[Since this was originally posted I’ve come up with a low-noise, low-profile side mounting method. The mounting method does not change the programming required to control one, or more, servos.]

The first thing I do is prepare the servo by setting the position of the shaft to 90 degrees, the midpoint of its 180 degree total travel. I do this by attaching the servo to an Arduino Unoand uploading this little sketch once to set the servo (for those who don’t know, “//” signifies the start of a comment ):

Here is the basic circuit for controlling a servo with an Arduino Uno, where the servo draws power from the Arduino. Servos can be independently powered, in which case only the signal wire and ground are connected to the Arduino.

The Arduino can Source a maximum of 200 mA current, and can Sink a maximum of 400 mA current. As you connect and try to run more devices, you’ll get to those limits quickly. In Model Railroad applications, given that we’re already routing track power, routing a few amps of +5 volt power to supply actuators like servos is a no-brainer for performance and system integrity. Whenever you use a separate power supply, the servo ground has to connect to both the power supply ground and the Arduino ground.

I fabricate a simple mounting bracket with a small plywood plate and a couple of blocks. Now I mount the servo in the bracket, place the horn onto the shaft in the position shown and then screw it down to the shaft.

Using a 1/16″ bit, I drill out a hole in the horn (usually the second hole from the end of the horn) and a hole in the turnout actuator bar. Don’t over ream the holes; the soft, slightly flexible plastic will provide a snug fit so you don’t have to use adhesives. Then, I slide a piece of 1/16″ brass rod through the horn to establish the location for a hole in the mounting plate.

I mark and drill the hole in the base plate. I rock the bit along the axis the rod will move (left to right in the view below) to slightly elongate it, and give it a more hour-glass profile. This hole functions as a fulcrum for the rod.

I mount the servo below the turnout. For this demonstration, I used hot glue to mount the bracket to the underside of the demonstration layout segment; screws are a better idea for most situations, allowing you to build in some adjustability. With the turnout set in the straight-through position, I carefully thread the rod through the turnout actuator bar, down through a prepared hole in the layout to the hole in the mounting plate and then the servo horn. The brass rod is perpendicular to the horn at the 90 degree setting. Moving the servo horn tilts the rod, moving the turnout above to its divergent position.

At this point I test the servo and make any adjustments necessary for smooth operation. When I’m satisfied everything is right, I trim the rod to its final size.

I’m planning to try music wire instead brass rod in the near future. The problem with brass rod is that it is stiff, and the servo can get fussy at the end of movement ranges because there is no give. Music wire is like spring wire and should allow me to apply pressure at the ends of movement ranges without overtaxing the servo. I’ll update this page with the results of those tests.

The button takes power from the +5v board supply and, when the button is pushed, routes the power to a designated pin, putting the pin in a HIGH state. On the output side of the button a pull-down resistor routes stray power to ground to guarantee that the pin is in a LOW state whenever the button is not pushed.

Here is a simple sketch to control a servo and have it move over about 2 seconds every time a button is pressed. The straight position is always 90 degrees because of the way I install the servo. The divergent angle depends on how the servo was installed in relation to the turnout– it will either be a larger angle in the 110 – 120 degree range, or a smaller angle in the 60-70 degree range. With practice and consistent placement of servos, they can all be the same; but if not, storing unique settings for each servo is not difficult.

Finally, we can add one more refinement and have the Arduino feedback position status via two pins that we can use to power leds at the control panel. The circuit looks like this:

To control multiple servos with one Arduino, your sketch would need variables for each servo to hold its pin id and unique divergent angle. More advanced programmers will want to create something like an array of data structures to organize pertinent data about the servos.

NOTE: The delay() function is used a lot in small demonstration sketches to control timing. The problem with delay is that it throws the board into a do-nothing state that prevents anything else from happening. In more complex sketches it is often advisable to avoid delay() and use other methods to meter actions across multiple controller cycles. In this case, be aware that the board is tied up while the servo is in motion.

To meet the demanding requirements of motion control applications in industrial automation and satisfy the needs of high-precision positioning control requested by machine designers and system integrators, Delta launched the high-performance motion control ASDA-A2 series servo motors and servo drives in 2009.

The current trend of motion control is to have the control command source close to the drive. To catch this trend, Delta developed the new ASDA-A2 series, offering excellent motion control function so that the external controller could be almost eliminated. ASDA-A2 series features a built-in electronic cam (E-CAM) function which is the best solution for flying shear, rotary cutoff and synchronized motion applications. The whole new position control Pr mode is a unique and most significant function that provides a variety of control modes and definitely enhances system performance. The advanced CANopen interface for high-speed communication enables the drive to integrate with other parts of the automation more efficiently and effectively. The full closed-loop control, auto notch filter, vibration suppression and gantry control functions help to perform complex motions that require high precision and smooth operation. The 20-bit superior resolution encoder which is essential for accurate positioning applications is equipped as standard. In addition, the outstanding Capture and Compare functions for high-speed pulses offer the best support for stepless positioning. Other additional functionality, such as up to 1kHz frequency response, innovative editing software and the high-speed PC monitoring function (like oscilloscope), etc. all drastically maximize the performance of ASDA-A2 series.

Precise carving machine, precise lathe/milling machine, double column type machining center, TFT LCD cutting machine, robot arm, IC packaging machine, high-speed packaging machine, CNC processing equipment, injection processing equipment, label inserting machine, food packaging machine, printing

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey