using a tft lcd to move a servo factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

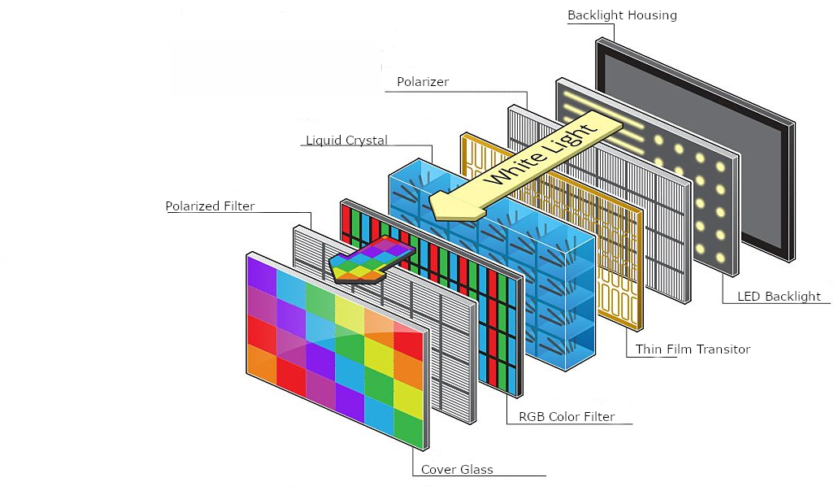

This is a 2.8” TFT Resistive Touchscreen Display. The module, with a resolution of 320x240, adopts ILI9341 as driver IC and SPI (4-line) communication mode. The board integrates touch chip XPT2046, which converts the touch data collected by the AD to SPI data. The module also integrates an SD card slot allowing you to easily read the full-color bitmap. There are two modes of wiring supplied, normal pin header wiring and GDI. The latter one requires to work with a main controller board with a GDI interface (e.g. FireBeetle-M0). You can use it with only one FPC line plugging in, which reduces the complexity of the wiring. Furthermore, it features high resolution, wide viewing angle, and simple wiring, which can be used in all sorts of display applications, such as, IoT controlling device, game console, desktop event notifier, touch interface, etc.

Backlight. The backlight is set to the default value, and the user can light up without connecting the backlight pin; in addition, when the backlight pin is connected, input high level (1) to adjust the backlight brightness to the maximum, input low level (0) to turn off the backlight

This product is Breakout module with SPI communication mode and GDI interface, which reduces the wiring complexity and makes it easy to display what was read from the SD card.

This is UI control demo -- digital keyboard. At the start, click the textbox, and click the number after the cursor shows in the textbox. The corresponding number will be shown in the textbox. The "x" at the bottom right corner is used to delete the context in the textbox.

* @brief Constructor When the screen uses hardware SPI communication, the driver IC is ILI9341, and the screen resolution is 240x320, this constructor can be called

This is UI control demo -- gesture. At the start, click the textbox. After the cursor appears in the text box, slide gestures on the screen (up, down, left, right, double click, single click). The instruction of the corresponding gestures will show in the textbox.

* @brief Constructor When the screen uses hardware SPI communication, the driver IC is ILI9341, and the screen resolution is 240x320, this constructor can be called

Veyron Servo Driver (24-Channel) is a multiple servo controller, especially designed for humanoid robots, spider robots, robotic arms, and many other likewise applications. The controller integrates wireless data transmission interface, which is fully compatible with DFRobot Bluetooth module, APC220 wireless data transmission module and Xbee module. The controlling modes include real-time, timer, constant speed. Veyron Servo Driver (24-Channel) is the most powerful Mirco USB servo driver with high reliability on the market. It uses a high-performance, low-power STM32F103 microcontroller as its core control unit, which has a powerful, fast execution speed, high accuracy, strong I / O drive power. It supports Futaba, Hitec, Fraser and most common servos. The servo control range could be 0 ~ 180 ° (for 360 ° continuous rotation, retrofitting is needed); It has two servo control modes: single servo control, group servo control. In group control mode, the same group can be coordinated automatically with start and stop at the same time. It will be very useful in multi-DOF biomimetic robots, which requires smooth actions.

NOTE: If you met any problem of installing the driver, you may need disable the Windows feature of Digital signature requirment, you need to disable that to install the driver. Actually, there is another way to install the driver for STM32, read at the end of the wiki > More > Share. |

Press the "reset" button again, and then press to hold "BOOTO" button during blue lights flashing rapidly, until the light starts blinking slowly. The blue light will keep flashing. Now you can install the driver.

Windows will prompt you for a driver, manually locate the directory, select mapleDrv -->dfu_x64/dfu_x32(Please select your OS bit: 64-bits or 32-bits) in the folder. Next install a virtual serial port driver:

Reset Veyron Servo Driver 24-Channel with RET button, wait for the blue light stops flashing. At this point Windows will prompt to install the driver, too. Please manually locate the directory, select mapleDrv -->serial in the folder. Until now, the driver has been installed.

In this section, we will use Arduino IDE as a Serial port communication tool to control the servo. And, you also could use other Serial port software, like putty, CoolTerm etc.

Connect Micro USB cable to the Veyron Servo Driver 24-Channel, then the power indicator LED will be on. Connect an external 5V power to the VS and GND. Then switch the DIP 3 at SERIAL, USB has been defaulted to 57600 baudrate (cannot be changed), should be consistent with software.

The Servo on Channel 5 will move to 1600us position and servo on channel 10 will move to the 750us position. They will arrive simultaneously after 2500ms. This command can coordinate multiple servo speed, even if the initial position of two servos are very far, you can make they start to rotate and stop at one specified position. This command is very suitable for humanoid bipedal robot

This command allows the 8-bit binary write-once and simultaneously update all channels in the bank, the update will be completed within 20ms after receive carriage return symbols

This command enables bank output 123 in decimalism, 123(decimal) = 01111011 (binary), bank 1 for channels 8-15, then channel 8 and 13 in bank 1 will be 0, the other channel will be 1.

If servo is rotating, it will return "+", if servo has moved to a specific location, it will return "." The return value of this command will delay 50us to 5ms.

The return value is one byte (binary), which means the servo current pulse width, resolution: 10us, for example, the pulse width is 1500us, then it will return to 150 (binary). This command can query multiple servo pulse width, each servo has a byte, the return value will delay 50us to 5ms, typical value is 100us.

Why I cannot control servo by external serial port, I mean when I use BT module or by arduino Uno serial port? I can do it through pc"s serial monitor.

Hello, it"s for the baud rate setting. Have you noticed the baudrate setting switch on the corner of the board. Is it in the right place, e.g. if your code is 115200, then the 3 switchs should be in the position as:A1, B1, SERIAL. Besides, the switch are not good to use, you might need a little strenth to poke it from one side to the other side to make sure it is connected firmly. We will update the switch in the next version.

Arduino STM32, this method can help you install all the drivers you need, besides, it could allow you to program it using Arduino IDE if you"d like to. Read the warning

Multiplex Machine is used to make Uniaxial, CBR and Marshall Tests. 50 kN capacity Multiplex Machine is equipped with a servo motor and BC100 TFT graphics data acquisition and control system. Suitable for CBR, Marshall, Triaxial and Uniaxial Tests and similar tests with appropriate accessories. The machine is also capable of doing load controlled tests. UTM-0108 Multiplex Machine is composed by a robust and compact two column frame with adjustable upper cross beam.

* Supplied complete with UTGM-1210 50 kN Load Cell, UTGM-0064 50 mm linear potentiometric transducer with holder (UTM-0114 and UTAS-1060) and lower compression platen.

.*** Choose the suitable cell for the specimen size (UTS-2400: 38-50 mm dia. samples / UTS-2401: 70-100 mm dia. samples). For cell and cell accessories see “Triaxial Cells, Cell Accesories and Sample Preparation” page.

BC100 TFT Graphic Display Data Acquisition and Control Unit is designed to control the machine and processing of data from load-cells, pressure transducers or displacement transducers which are fitted to the machine.

All the operations of BC100 are controlled from the front panel consisting of a 800x480 pixel 65535 color resistive touch screen display and function keys. 4 analogue channels (it would be simultaneous or not depending on the application at the factory) are provided for load-cells, pressure transducers or displacement transducers.

BC100 has easy to use menu options. It displays all menu option listings simultaneously, allowing the operator to access the required option in a seemless manner to activate the option or enter a numeric value to set the test parameters. The BC100 digital graphic display is able to draw real-time "Load vs. Time", "Load vs. Displacement" or "Stress vs. Time" graphics.

BC100 unit offers many addition unique features. You can save more than 10000 test results in its internal memory. BC100 unit has support for various off-the-shelf USB printers, supporting both inkjet and laser printers. Thanks to its built-in internet protocol suite, every aspect of BC100 device can be controlled remotely from anywhere around the world.

Calculates corrected CBR value at 2.5 and 5 mm the digital unit saves the load value at user defined displacement values such 0.625, 1.25, 1.875, 2.5, 3.75, 5, 7.5, 10, 12.5 mm

4 analog channels (it would be simultaneous or not depending on the application at the factory) for one analog channel for high capacity load cell, one analog channel for displacement transducer, one analog channel for low capacity load cell and one analog channel for pressure transducer for oil-water constant pressure unit

Programmable digital gain adjustment for load-cell, pressure transducers, strain-gauge based sensors, potentiometric sensors, voltage and current transmitters

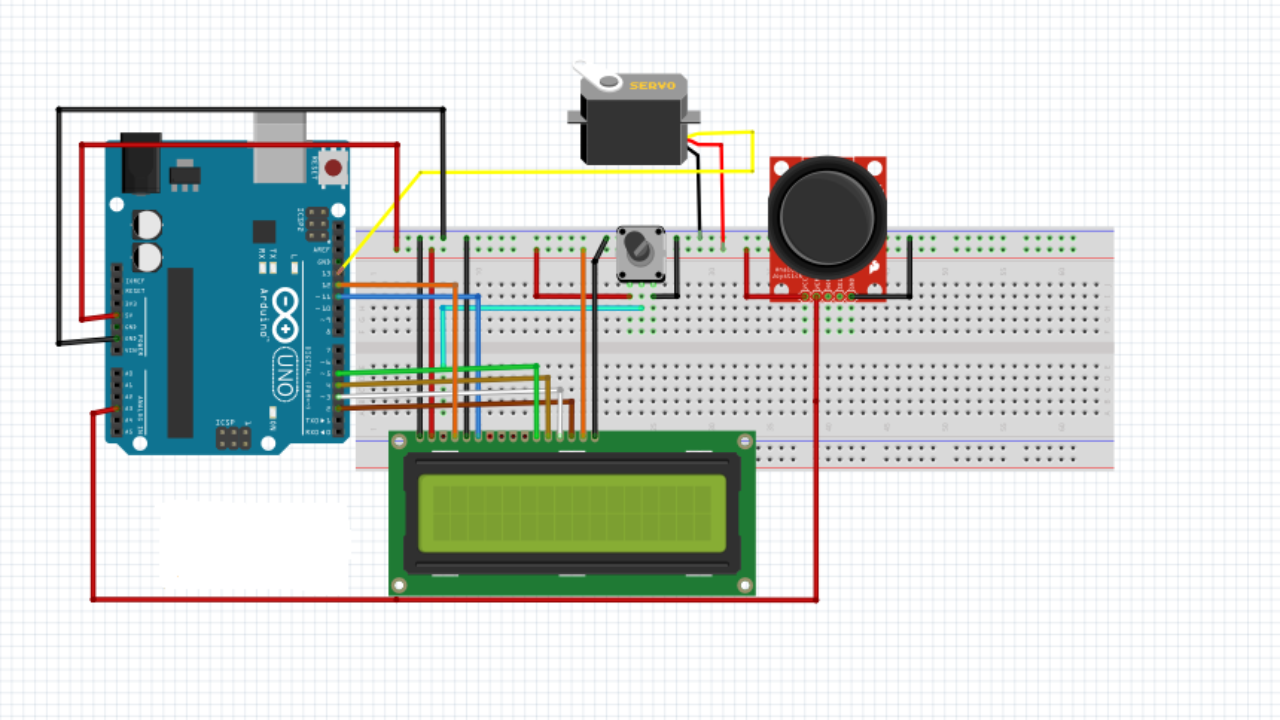

Welcome to my collection of Arduino projects. As a maker, techie and mechatronics engineer I’ve been using Arduino for more then 8 years. Arduino is an incredibly versatile microcontroller with limitless possibilities for developing electronics applications and prototypes.

We can use Arduino for simple tasks such as controlling LEDs and DC motors, to controlling real CNC machines and robots. That’s right, in the following list I will share my Arduino experience with you. You will find Arduino projects for beginners and more advanced projects for Arduino enthusiast.

Even if you are just getting started with Arduino, you don’t have to worry about that. Each of the following DIY Arduino projects is covered with detailed step by step tutorial on how to do it yourself and includes circuit schematics, source codes and videos.

Using the comments section below, you can also suggest your ideas, as well as discuss anything related to these Arduino projects. I will continuously update this article with all new stuff that I make. Last update: February 2022.

As an Arduino enthusiast, I found making robots with Arduino to be most fun for me. There is so much to learn from them as a maker and an engineer. So, here are my Arduino projects related to robotics so you can learn too.

When it comes to automated manufacturing, robot arms play big role with so many applications. They are often used for welding, assembling, packing, painting, pick and place tasks and much more. This Arduino project is actually a robotic arm made out of 3D printed parts, servo motors joints and controlled using an Arduino Nano. What’s even cooler we can control the robot arm wirelessly via a smartphone and a custom build Android application.

The robot arm has 5 degrees of freedom, so we need 5 servo motors, plus an additional servo for the gripper mechanism. For the communication with the smartphone we use the HC-05 Bluetooth module.

The following project is one of the coolest Arduino project in this list. It’s an Arduino robot car which instead of normal wheels, it employs omnidirectional wheels or mecanum wheels which enable to robot to move in any direction.

The wheels are attached on four stepper motors which are individually control. By rotating the wheels in certain pattern, they exert diagonal forces due the diagonally positioned rollers on the circumference of the wheels, and so they can move in any direction. The robot car can be remotely controlled either vie Bluetooth communication and an custom build Android application. Also, we can control it using an DIY RC transmitter with the help of the NRF24L01 transceiver module.

Here’s an upgraded version of the previous mecanum wheels robot project. On top of the platform I added the DIY Arduino Robot Arm project mentioned above and now they can work together.

As the robot uses stepper motors for the wheels and servo motors for the robot arm, we can precisely control them using the custom build Android application. What’s even cooler, we can record the movements of the robot and then the robot can automatically repeat them.

Of course, as for any of my Arduino projects, the Arduino code, the custom build Android application, as well as the 3D model files can be found and downloaded from the particular project article.

SCARA robot or Selective Compliance Articulated Robot Arm is the most common and suitable option, when it comes to pick and place and small assembly applications, which require moving a part from point A to point B.

This Arduino based SCARA robot is a step-up big compared to the previous projects in every aspect. It has a better and more robust design with precisely controlled stepper motors and custom build GUI for controlling it.

As a controller it has an Arduino UNO board, combined with a CNC shield and four A4988 stepper drivers. It has 4 DOF, driven by four NEMA 17 stepper motors.

This and extension of the previous project or I converted my 3D Printed SCARA robot to work as a laser engraver robot. Instead of the gripper mechanism, here we are using a Laser module for engraving.

For controlling the robot we are using an Arduino Mega board in combination with a RAMPs board. This a popular combination used for 3D printing and it can be used for laser engraving machines as well. As for a firmware, we are using the Marlin 3D Printer firmware and the Repetier control software.

Inspired by the NASA Mars 2020 mission and the successful landing of the Mars Perseverance Rover on the plant Mars, I build a 3D printed functional replica of it. I designed this DIY 3D Printed Mars Rover in a way that it can be easily recreated by following the instructions in the tutorial.

The rover features a rocker-bogie suspension which allows the rover to run smoothly on uneven terrain, just like the real rover. It has six independently controlled DC motors for driving and four servos for steering, and it’s controlled using an Arduino MEGA board. There’s also an FPV camera located in the cameras unit of the rover which can by used for controlling the rover remotely. The remote control is done with the help of a cheap commercial RC transmitter and receiver.

Making biologically inspired robots is very popular among engineering students. This Arduino project is all about it, we will build a hexapod robot which features six legs, a tail or abdomen, a head, antennas, mandibles and even functional eyes. All of this makes the robot look like an ant.

Each leg have three joints, and for each joint we need a servo motor. That means that we need total of 18 servos for this project, and additionally 3 servos for the head movements and 1 servo for the tail. The brain of the robot is an Arduino Mega. We need MEGA because it’s the only board that can control more than 12 servos using the Servo library.

I also designed a custom PCB which acts as an Arduino Mega Shield so we can easily attach all servo connects. We can control the ant robot via Bluetooth and a smartphone, or radio communication. The ant also has built-in ultrasonic sensor in the head. With that it can detect objects in front, and it can even strike if the object is present if front of it.

The following projects show how capable Arduino is. A CNC or Computer Numerical Control is an automated control of machines, like mills, lathes, plasma cutters, 3D printers and etc. So, using the Arduino as a controller we are actually able to build any of these CNC machines.

For the project my goal was to build the simplest CNC machine with minimum parts possible and by using just a single power tool. On top of that, I wanted to use common materials or avoid 3D printers so I used MDF board for building the base frame.

The CNC machine is composed of just two linear rails which are secured to a base frame made of 8mm MDF board. For controlling it we are using an Arduino UNO board in combination with a CNC shield and two DRV8825 stepper drivers. As a tool it has an laser module attached so this machine is actually a CNC laser engraver.

The idea for this Arduino project was similar to the previous one, to build a CNC machine using minimum parts possible. Here I used 3D several printed parts, and just two MGN15H linear rails for the main construction of the machine.

Building your own CNC machine might seem like a big challenge for many of you, but the following Arduino CNC Machine project shows that building a CNC machine is actually not that hard.

This CNC machine is actually a foam cutting machine. Instead of bits or lasers, the main tool of this CNC machine is a hot wire. It’s a special type of resistance wire, which gets really hot when current passes through it.

Controlling stepper motors using Arduino is without a doubt one of most satisfying thing for an Arduino enthusiast. There so many machines based on this motors, like CNC machines, 3D printers, various automation machines etc. This Arduino project is all about that. It describes how you can build such a machine. It’s a machine for bending wire, where with the help of stepper motors we can precisely bend wire and make various shapes and forms out of it.

The machine features three stepper motors. With the first stepper we feed the wire to the bending mechanism. Here we have another stepper motor used for the bending the wire at the right angle. There’s also another stepper, for controlling the Z-axis. This stepper enables the machine to create three dimensional shapes. With this project we can also see how useful 3D printers are for Arduino projects of this type or for prototyping.

Many Arduino projects that I make require wireless control and that’s why I build this Arduino based wireless radio controller. With this RC transmitter I can wirelessly control pretty much with a range up to 700m in open space. It features 14 channels, 6 of which are analog and 8 digital inputs.

The brain of this Arduino project is an Arduino Pro Mini board which is the smallest Arduino board. The radio communication is based on the NRF24L01 module, it has 2 joysticks, 2 potentiometers and 4 momentary push buttons. Also an accelerometer and gyro module which can be used for controlling things with just moving around or tilting the controller. I mounted all electronic components on a custom design PCB and made a cover out of transparent acrylic.

This is a follow up project of the above one. Just like DIY RC Transmitter, this DIY Arduino RC Receiver can be used for many application. We can easily pair the two projects together and control anything wirelessly. Among others, I made an example of controlling a commercial RC car model using these DIY transmitter and receiver.

The custom PCB that I made uses the same NRF24L01 module for the radio communication. The controller is an Arduino Pro Mini and it features input/ output 9 channels.

The following Arduino project is a great example of utilizing the DIY RC transmitter from above. It’s a 3D printed hovercraft which I entirely designed on my own, and of course, the 3D printing files are available for downloading. The hovercraft uses two brushless motors, one for creating an air cushion for the lift, and the other for generating thrust or moving forward.

For the wireless control we are using the NRF24L01 module, which accepts the data coming from the RC transmitter. Then using the Arduino and two ESCs (Electronic Speed Controler) we control the BLDC motors speed. On the back side of the hovercraft there is also a servo for controlling the rudders, or for controlling the steering. I must say that driving this DIY hovercraft is so fun.

Anyone who had a chance of playing around with some RC airplanes knows how cool and fun it is. It’s even cooler and more satisfying if you build the RC airplane on your own. The following project steps the satisfaction up even further, because here I will show you how to build your own RC airplane which is 100% DIY build. Also, we have a 100% DIY radio control system based on the Arduino.

The airplane is entirely made out of Styrofoam and what’s cooler, the shapes are made with the help of my DIY Arduino CNC Foam Cutting Machine, a project already mention above. The radio communication is based on the NRF24L01 transceiver modules. For that purpose, I used my DIY Arduino RC Transmitter and DIY Arduino RC Receiver.

You can choose one of the three different methods of wireless control explained in this project, or that’s the HC-05 Blueooth module, the NRF24L01 transceiver module and theHC-12 long range wireless module. Additionally you can learn how to make your own Android app for controlling the Arduino robot car.

This Arduino project idea is rather practical because it features indoor and outdoor temperature and humidity measurement. It is based on the DHT11/ DHT22 sensor, the NRF24L01 transceiver module for the wireless communication and theDS3231 RTC. For the display we can either use 16×2 character LCD or a 3.2 inches TFT touch screen.

The outdoor unit can be powered with batteries and the indoor unit with an AC adapter. The outdoor unit measures the temperature and the humidity and sends the values to the main indoor unit. Here these values are printed on the LCD along with the data and time values from the DS3231 RTC module.

Camera slider are great for capturing cinematic shots, and having pan and tilt system on top of it even further increase the possibility to capture better shots. In this project I will show you how you can build your own one, which costs way less then one found in the stores and still you can get great and super-smooth shots.

The slider has three NEMA 17 stepper motors controlled via the A4988 stepper drivers and the Arduino Nano board. Using a joystick we can control the pan and tilt movements and using a potentiometer we can control the sliding movement. With this DIY camera slider we can use the Set button to set two different IN and OUT points. Then the camera can automatically move from one to the other point.

If you are interested in building something more complex with Arduino then this project is the one for you. Although complex, you could easily recreate it as there is a detailed step by step explanation on how everything works, including circuit schematics and source codes.

The structure of the machine is made out of MDF. For discharging the items I used continuous rotation servo motors, while for the carrier system I used two NEMA17 stepper motors. For detecting the coins the machine uses an infrared proximity sensor.

The following Arduino project is a simple gimbal or a self-stabilizing platform. It can be used for keeping objects or the top platform level. The project is rather simple with just several electronic components.

The combination of DC motors and Arduino is always fun, and so is this project. Here we will build our own robot car from scratch. The car will be powered with Li-ion batteries and two 12V DC motors, and controlled using the L298N driver and an analog Joystick.

This is one of my most popular project and it’s really fun to build. The radar can detect objects in front of it and map them on PC screen using the Processing IDE.

For this project you just need two components along with an Arduino board, and that’s an ultrasonic sensor and small servo motor. The range of the radar can be adjusted to up to 4 meters with 180 degrees rotation.

Here’s another project utilizing the HC-SR04 ultrasonic sensor. This time we will use it to make an distance meter which can measure distances up to 4 meters, as well as, measure square area.

The project also includes and accelerometer which is used for the digital spirit level function or for measuring angle. The results are displayed on 16×2 LCD and all components are attached on a custom design PCB.

Sorting out objects or products by their color has an important real world application. These types of machines are often used for sorting fruits, seeds, plastics etc. The working concept of these machines is rather simple. All you need is a color detecting sensor and of course a system that feeds the object to the sensor and then sort it out.

In this project we will learn how to use a color detecting sensor along with the Arduino. We are going to be sorting out colored skittles but you can use the same sensor and method for sorting out anything else.

RFID technology has wide range of applications and access control is one of them. We often encounter this in hotels for accessing our room or at work for checking in or accessing restricted areas.

In this project we will learn how to use the Arduino to make an RFID controlled door lock. The system consists of an MFRC522 RFID reader and RFID tags/ cards that are based on the MIFARE protocol.

If you ever thought of making your own security system then this project is a great starting point. Here we will utilize an ultrasonic sensor for detecting movement.

If a human or object passes in front of the sensor, the alarm will be activated. For deactivating the alarm you will have to enter a password using a keypad.

In this project we will control LED Matrices using the MAX7219 driver. This driver can control up to 64 individual LEDs while using only three wires. Also we can connect up to 8 drivers in series and still using the same wires.

To make this project more interesting I also added an example where you can update the text on the LED matrixes through your smartphone using a custom-made Android app.

This game project is based on the popular Flappy Bird game for smartphones. Using the touch screen we control the bird while trying to avoid the pillars.

For this project we need a 3.2 inches TFT Touch screen, an TFT Mega shield adapter and an Arduino Mega board. The code is a bit longer but everything is explained in details.

The code behind this project is a bit more complex with around 550 lines but everything is explained in details with comments for each lines. There is also a detailed video explanation for it.

At first glance this table looks like a normal coffee table but once you turn on the power on it gets to a whole new level. The table has 45 sections which can glow in any color we want, plus it reacts on objects placed on top of it.

The heart of the table is an Arduino which controls the 45 WS2812B Addressable LEDs. The objects on top of the table are detected using infrared proximity sensors. What’s even cooler it has built-in Bluetooth module which enables interaction with a smartphone for selecting the LEDs colors.

Monitoring the indoor air quality is very important as it can affect us in many way. If we have a poor air quality in the room we are staying, it can lead to tiredness, headaches, loss of concentration, increased heart rate and so on.

In this Arduino project we are building an Air Quality Monitor which can measure several important air quality parameters such as PM2.5, CO2, VOC, Ozone, as well as temperature and humidity. I designed a custom PCB on which we can easily attach the sensors we need and show the results on a 2.8 inches touch display. The device can also keep track of the sensors values from the last 24 hours.

The following section of this article contains Arduino projects ideas based on my detailed tutorials on various sensors and modules, as well as your suggestions from the comments section below.

We can use NEMA 17 or 23 stepper motors in combination with these drivers which provide high speed reduction ratios. As for controller we could use an Arduino Uno or Arduino MEGA board.

Controlling your home power outlets via a smartphone is the first step in home automation. You can easily make your own Arduino controlled power outlets utilizing the knowledge you can get from my Arduino tutorials.

For this project you just need two components along with the Arduino board. An HC-05 Bluetooth module and a5V Relay module for which I already have detailed tutorials. For powering the Arduino and the relay you can use 220/ 110V AC to 5V DC converter.

Using your smartphone you can connect and control your power outlet via Bluetooth. You can either use some already made apps for controlling Arduino from the Play Store or create your own custom made app. In this way we can also control the power outlets through voice control commands.

Home automation is one of the most popular Arduino projects nowadays. The goal of this project is to remotely control anything in your house like lights, appliances, temperature, security devices and so on, with a single device or your smartphone.

In order to make such a project we need decent amount of knowledge in Arduino. The following home automation concept that I suggest is based on my detailed Arduino tutorials for various sensors and modules.

So the idea here is to have a master unit which includes a touch display, and several slave units which will execute commands coming from the master. As for the wireless communication we can use the NRF24L01 radio frequency modules. Each slave unit can have various functions like, temperature monitoring, power outlet control, lights control,security alarm and so on.

Of course, there are endless possibilities and combinations for building a home automation system using the Arduino board. You can always change and add more devices. You can also make a Bluetooth communication so you can control all of this using your smartphone etc.

The idea for this project is to remotely control an Arduino project using hand gestures. Let’s say we want to control the Arduino Robot Car that we mentioned above. So instead of the joystick we will use an MEMS module for the control.

We can use the GY-80 module which features an accelerometer, a gyroscope and a magnetometer. Then the data we are getting from these sensors to control the steering of the robot car. As for the wireless communication we can use the NRF24L01 transceiver modules.

The Second Edition of this well-respected publication provides updated coverage of basic nondestructive testing (NDT) principles for currently recognized NDT methods. The book provides information to help students and NDT personnel qualify for Levels I, II, and III certification in the NDT methods of their choice. It is organized in accordance with the American Society for Nondestructive Testing (ASNT) Recommended Practice No. SNT-TC-1A (2001 Edition).

Following the author"s logical organization and clear presentation, readers learn both the basic principles and applications for the latest techniques as they apply to a wide range of disciplines that employ NDT, including space shuttle engineering, digital technology, and process control systems. All chapters have been updated and expanded to reflect the development of more advanced NDT instruments and systems with improved monitors, sensors, and software analysis for instant viewing and real-time imaging.

Each chapter covers recommended practice topics such as basic principles or theory of operation, method advantages and disadvantages, instrument description and use, brief operating and calibrating procedures, and typical examples of flaw detection and interpretation, where applicable.

In addition to a serial/usb/host interface, Marlin also includes a menu-based user interface for inexpensive character and graphical LCD controllers. Rotate a knob or use buttons to navigate menu items, edit values, and make other adjustments. Click the knob or press a button to choose menu items, exit adjustment screens, and perform other actions.

Note: In low-level contexts we refer to the first extruder as E0, the second as E1, etc. However, at “user level” in the LCD menus, we refer to the first extruder as E1, the second as E2, etc. (Marlin 2.0 includes an option to show the first extruder as E0.)

The Tune menu is only available during active printing. Most items in this menu are editable values. Item Description Requirements Speed: -–- Feed Rate Multiplier

The move axis sub-menu was reorganized for Marlin 1.1. To use the move commands, first select the axis to move, then select the move distance. Use the controller wheel (or arrow buttons) to adjust the axis position. For larger move sizes, Marlin waits until you stop moving the controller for 1/2 second before it starts the move, giving you an opportunity to catch overshoot. Item Description Requirements Free XY Move Z down to safe-zone DELTA (above safe zone)

The Bed Leveling menu groups together commands for calibrating the nozzle-to-bed distance. Different options will appear depending on your setup and the type of leveling you’ve enabled. Level Bed runs the default G29 procedure. For auto bed leveling this will deploy the probe, measure all points, and stop. For manual leveling (PROBE_MANUALLY or MESH_BED_LEVELING) you’ll be taken through a step-by-step process. Item Description Requirements Free XY Move Z down to safe-zone DELTA (above safe zone)

The Unified Bed Leveling menu groups together commands for leveling and mesh editing. Since this menu is very large and complex, it will be described in a separate document - coming soon.

Set the fan speed plus bed and/or nozzle temperature to the preset “PLA” settings. Use M145 S0 ... to change the temperatures and fan speed used for this menu. Item Description Requirements Preheat PLA Active Extruder, fan, bed HOTENDS == 1

Set the fan speed plus bed and/or nozzle temperature to the preset “ABS” settings. Use M145 S1 ... to change the temperatures and fan speed used for this menu. Item Description Requirements Preheat ABS Active Extruder, fan, bed HOTENDS == 1

The Control sub-menu includes the Temperature, Motion, and Filament sub-menus and Settings/EEPROM commands, plus a few other miscellanous hardware control commands. Item Description Requirements LCD Contrast » HAS_LCD_CONTRAST

Use this sub-menu to set the target temperature for nozzles and the bed, fan speed, AUTOTEMP, PID factors, and material preheat settings. Item Description Requirements Nozzle: -–- Current E Target Temperature HOTENDS == 1

The motion settings provide control over tunable movement parameters which can be stored to EEPROM. Item Description Requirements Z Offset M851 Z HAS_BED_PROBE (with BABYSTEP_ZPROBE_OFFSET it babysteps)

When the ANTCLABS BLTouch probe acts up you can use the items in this sub-menu to reset and test the probe. Item Description Requirements Reset BLTouch Revive after an error

5) After the programming is completed, open the config.txt file in the root directory of the TF card, add the following code at the end of config.txt, save and eject the TF card safely.

6) Power on the Raspberry Pi and wait for a few seconds until the LCD displays normally. And the touch function can also work after the system starts.

Note: If you use the 2021-10-30-raspios-bullseye-armhf image or the laster version, please add the line dtoverlay=rpi-backlight to the config.txt file and reboot.

At the end of the config.txt file, add the following commands corresponding to disabling touch (the config file is located in the root directory of the TF card, and can also be accessed through the command: sudo nano /boot/config.txt):

Fine Cause"s Silk screen printing machine imported to industrial I.O.T., combine smart factory App, assist you to implement production management goals through synchronous monitoring

It"s different with pneumatic cylinder type screen printer, will not generate ink leaking problem which affected by the air pressure and the left and right anti-collision buffers.

This suction screen printer adpots 7.0 inches multicolor color touch screen with 65536 colors TFT;The man-machine interface can be easily switched to select the language:English, Indonesian, Vietnamese ,Thai andTraditional Chinese.

suction screen printing machine adopts a magnetic squeegee clip (Patent No. M390871) makes the squeegee position can be slided easily and is simple to adjust and disassemble.

Built in smart bar chart, production data displayed by graphs in the past 30 days. Connect with FineCause smart factory APP, no matter where you are, you can overview the production data of your silk screen printer.

Flat surface screen printng machine is able to install with disc divider, suction system, pressing positioning, pushing positioning, automatic load & unload mechanism, industrial cameras, actuators and other peripheral institutions.

FineCause is professional silk screen printing machine, servo screen printing machine,flat surface screen Printing equipment, semi automatic screen Printing equipment, semi automatic screen printer and automatic silk screen printing machine manufacturer.

FineCause have imported Servo motor ink scarping system in 2016, component production adopted extrude integrally molded. Currently have the best price among whole Taiwan servo motor screen printer manufacturers.

FineCause silk screen printer already have a foothold and good reputation in Taiwan. We have a professional team to provide service at any time, please feel free to contact us if you’re interest to our machine or be our distributor.

The purpose of this utility model just be to provide a kind of have China"s independent intellectual property right, the structure configuration is fit to China"s advanced level concrete practical situation, that reach international like product, domestic top standard"s TFT-LCD glass substrate automatic production line.

Realize that goal of the invention technical scheme of the present utility model is: the utility model TFT-LCD glass substrate automatic production line, set gradually according to operation and to be divided into three work areas, be followed successively by the annealing furnace end region, the post-treatment district, the test package district, three work areas are connected formation whole piece TFT-LCD glass substrate production line successively, be made as to be interrupted and be connected by manually transporting equipment between annealing furnace end region and the post-treatment district, be made as directly by automatic conveying equipment between post-treatment district and the test package district and be connected; Wherein the annealing furnace end region comprise be disposed with transverse cutting unit, load units, supply unit, weighting unit, rip cutting unit, verification unit, go up the paper unit, packaging unit constitutes, the terminal workspace of annealing furnace constitutes a whole set of sealing working cycle system, each working cell is connected successively, its supply unit connects each working cell thereafter and is loop structure, and each equipment of annealing furnace end region is realized the united and coordinating running by the electrical apparatus control system of supporting setting; The post-treatment district comprises the load units that sets gradually, gets paper unit, supply unit, transposable element, scribing unit, breaks disconnected unit off with the fingers and thumb, grinding unit, cleaning unit constitute, each working cell is connected successively, its supply unit connects each working cell thereafter, and each equipment of post-treatment district is realized the united and coordinating running by the electrical apparatus control system of supporting setting; The test package district comprises that supply unit, temporary storage location, verification unit, the unloading unit that sets gradually, the finished product packing unit of finishing the finished product packing constitute, each working cell is connected successively, its supply unit connects each working cell thereafter, and each equipment of test package district is realized the united and coordinating running by the electrical apparatus control system of supporting setting.

The transverse cutting unit is mainly the standard equipment transverse cutting unit in the terminal workspace of annealing furnace described in the utility model; Load units is mainly standard equipment and loads the robot device; Supply unit is to be conventional equipment for the automated cycle transmission system; Weighting unit is mainly special-purpose vertical Weighing device automatically; The rip cutting unit mainly comprises the standard equipment slitter; Verification unit is mainly the work in-process automatic checking system; Last paper unit is mainly the special-purpose paper robot of going up; Packaging unit comprises the standard equipment unloading robot and the simple and easy base plate glass packed and transported case of supporting setting.The vertical weighing device concrete structure of above-mentioned special use is: comprise the bed frame of weighing, be provided in the vertical fastening bracket of the glass mechanism on the bed frame and the electronic balance of weighing from top to bottom successively, and the electric control system of the power system of supporting setting and each parts coordinate operation of control.Described vertical fastening bracket mechanism comprises that then the bracket base, Mobile Slide, clamping crossbeam, mobile scale, the clamp arm of weighing, the chuck of weighing, the lifting location that are assembled together lift mechanism.Described bracket base is fixedly installed on the carriage of the electronic balance of weighing, on bracket base, be equipped with the clamping crossbeam of pair of parallel by Mobile Slide, the slide block of Mobile Slide seesaws with clamping crossbeam, and the guide rail of Mobile Slide is fixed on the bracket base; Be provided with the clamp arm of weighing in a pair of clamping crossbeam two ends pairings, supportingly on the paired clamp arm of weighing in carriage mechanism two ends be provided with the paired chuck of weighing, the lifting location is lifted mechanism and fixedly is provided on the bracket base, is equipped with mobile scale at the clamping crossbeam; The electronic balance of weighing is fixed on the bed frame.The described chuck of weighing adopts the silicon rubber chuck that can realize flexible contact, and the lifting location lifts the mechanism top and the glass contact position is provided with the silicon rubber pad.Preferably set Moving caster and adjust lower margin in the bed frame bottom of weighing.In the above-mentioned special use at interval the robot of paper comprise robot body"s frame, robot VTOL (vertical take off and landing) transfer assembly, the horizontal transfer assembly of robot and robot arm and constitute that wherein robot VTOL (vertical take off and landing) transfer assembly is assemblied in and comprises the fixed support mechanism that is contained on the main frame on the main frame, is assemblied in vertical shifting transfer mechanism and the supporting vertical servomotor mechanism that is arranged on regulation and control vertical shifting transfer mechanism in the fixed support mechanism in the fixed support mechanism; The horizontal transfer assembly of robot is assemblied in robot VTOL (vertical take off and landing) transfer assembly upper end, comprises the fixed support mechanism that is assemblied on the vertical shifting transfer mechanism, is assemblied in the horizontal servo motor mechanism that moves horizontally transfer portion mechanism and supporting setting in the fixed support mechanism; Robot arm is assemblied in to move horizontally and comprises arm main body frame and the supporting paper adsorption unit on the arm main body frame and the drive unit of adsorption unit of being assemblied on the transfer portion mechanism.

In this zone, glass substrate will be finished transverse cutting, loads, weighs, rip cutting, cooling, check, the processing of going up operations such as paper, packing.The realization of each operation process, realize the linking of inter process by automatic conveying system, it is the glass substrate after the crosscut, the process load units is behind transfermatic, deliver to above-mentioned each operation by the control of transfermatic follow procedure, realize the processing of glass substrate work in-process, the production of process segment property before finishing changes the processing of storehouse or postorder over to.Its every equipment (system) all establishes one"s own system, and is an independent body, under native instructions, finishes the work.And the terminal automatic production line of whole annealing furnace is again a unified integral body, and it is under the PLC time variable control, and co-ordination realizes the whole process of this zone to product processing.

Load units is mainly standard equipment and loads the robot device in the post-treatment described in the utility model district; Get the paper unit and be mainly the automatic paper extraction unit of special glass substrate; It is conventional equipment that supply unit is mainly automatic transmission system; Transposable element is mainly the standard equipment transposition control device that is arranged on the transmission system; Scribing unit is that disconnected processing machine is broken in the standard equipment line off with the fingers and thumb with breaking disconnected unit off with the fingers and thumb, sets in addition after disconnected processing machine is broken in line off with the fingers and thumb and is equipped with the sampling observation travelling belt; Grinding unit is mainly the standard equipment edge polisher; The standard equipment prewetting machine and the cleaning machine that set gradually before and after cleaning unit comprises, and the input locating device of supporting setting and output locating device, supporting corresponding pipe arrangement and the blowdown system of being provided with of cleaning machine; Break off with the fingers and thumb to set in addition on the disconnected processing machine position in line and be equipped with the sampling observation travelling belt, and connect the manual checking platform, on the position of prewetting machine, set and include two sampling observation travelling belts, and connect the manual checking platform.The automatic paper extraction unit of above-mentioned special glass substrate comprises general frame, be assemblied in slide assemblies on the general frame, be located at the electric control system that the equipment of paper at interval accepted that ground is positioned at slide assemblies integral body below is deposited the power system of paper frame and supporting setting and controlled each parts coordinate operation; Described slide assemblies comprises the straight reciprocating motion unit that is assemblied on the framework, be assemblied in and cooperate the unitary servo drive unit of straight reciprocating motion on the framework, with the paper extraction unit unit that is arranged on the servo drive unit, between servo drive unit and paper extraction unit unit, be equipped with the pendulum device of stretching that the control paper extraction unit is realized upper and lower, transposition action.Wherein the straight reciprocating motion unit comprises reducing motor, driving pulley, driven pulley to described slide assemblies, band, belt wheel pressing plate, slide plate, cable protect chain synchronously, reducing motor as power output is arranged on framework one side, the output shaft of reducing motor is connected with driving pulley, driven pulley is assemblied in the framework opposite side, band is enclosed within on driving pulley and the driven pulley synchronously, band is made as with slide plate and fixedlys connected synchronously, and the slide plate two ends are connected with crossbeam by slide rail; Servo drive unit comprises rail brackets, servo line slideway, horizontal sliding seat, servomotor, ball-screw, a pair of servo line slideway is assemblied on the slide plate bottom by rail brackets, laterally on the sliding seat assembling pair of guide rails, ball-screw is made as with horizontal sliding seat and is threaded, the servomotor mount is in the slide plate bottom, and servomotor is connected with an end of ball-screw by shaft coupling; The paper extraction unit unit is made as vacuum absorption device and is arranged under the horizontal sliding seat, comprises suction pipe, spring plate, mounting blocks, and suction pipe is connected and fixed piece by spring plate, and fixed block is fastened on to be stretched under the pendulum device; Stretch pendulum device and be made as and stretch the pendulum pneumatics, comprise and stretch the pendulum cylinder, connect bent plate, stretch the pendulum cylinder and be connected under the horizontal sliding seat by connecting bent plate.

At post-treatment district production line is the work in-process glass that the annealing furnace end region is produced, and through loading, get paper, transposition, ruling, break off with the fingers and thumb operations such as disconnected, produces the product that meets the requirement of postorder edging.Judge through sampling observation and the line quality of glass to drop into edge polisher then, finish the edge grinding chamfering of glass substrate, and mill cuts out location chamfering and non-location chamfering, eliminate by what line broke that the limit causes off with the fingers and thumb and smallly fall sheet and fine crack, avoid the diffusion of crackle.Glass behind the edging enters prewetting machine, cleaning machine, finish the preceding processing cleaning course of inspection after construction, this is an operation important in the glass processing, and it is coordinated different processing unit unified commands together by the electrical control program, by signal transmission and exchange, realize processing purpose.

Post-treatment district automatic production line is realized by following process: at first, the packaging unit at the work in-process glass place of annealing furnace end region is realized the location in " loaded " position, getting the paper unit takes the glass holding paper away, the glass load units utilizes grabbing device, glass overturn in the packaging unit keep flat on the entrance conveyor, according to the placement direction of glass, can realize the transposition of 90 degree, realize adaptation to various glass loading conditions; Glass substrate enters line and breaks disconnected processing units off with the fingers and thumb under the conveying of travelling belt, and this is the critical process that guarantees glass physical dimension, breaks the glass cullet bar of having no progeny off with the fingers and thumb and enters the cullet catcher collection; The line breaking machine what be provided with later is the sampling observation travelling belt, it can realize to glass at X-ray inspection X, to the line of glass, break disconnected quality off with the fingers and thumb and detect the most timely; Break the glass that breaks after finishing off with the fingers and thumb and enter edge polisher, realize processing, enter prewetting machine, prepare matting through the edge polisher exit conveyor to the glass corner by clamp mechanism, edging wheel, conveying, circular grinding water by entrance conveyor; Include two sampling observation travelling belts on the position of prewetting machine, it can adapt to product and pass in and out production line because of the needs of check or cleaning again.The processing tasks of post-treatment section occupies an important position in whole section, and it accepts the processing tasks of the work in-process of annealing furnace end region to finished product on the one hand, and an other important task is to guarantee the effect of check and be cleaning packing preparatory condition.

To be mainly automatic transmission system be conventional equipment to supply unit in the test package described in the utility model district; Temporary storage location is mainly the temporary check-out console of standard equipment; Verification unit comprises the finished product automatic checking system that is located on the production line, is equipped with the sampling observation travelling belt at this station, and it is connected with the manual checking platform; Unloading unit is mainly standard equipment unloading robot; Thereafter final finished packaging unit comprises paper robot and special glass base plate seals packed and transported case in the special use of supporting setting.The glass substrate of above-mentioned special use packs carrying case, it comprises base member, is located at the glass substrate bearing platform on the base member, it is characterized in that: be provided with the glass substrate gripping unit in the plummer bottom, it is made of the supporting rigidity clamp frame on the plummer, the adjustable locking device of adjusting clamp frame and the banded locking strip that has certain tensile to regulate clamp frame of being arranged on; Also be provided with the position-limit mechanism of restriction glass both sides displacement in the both sides of glass plummer; On the glass plummer, also be equipped with the whole guard shield that blocks glass substrate; The scarp of glass substrate bearing platform d2 and vertical surface are provided with the backing plate of damping anti-electrostatic; This glass substrate bearing platform d2 has adopted closed structure; On described glass substrate gripping unit, be provided with cushion plate.

Test package district production line is positioned at the last of total production line, and its glass substrate after with cleaning-drying is transferred to stations such as self-verifying, manual checking, temporary, unloading successively by travelling belt, adopt A type frame to carry out the final finished packing to qualified product then.Though this operation belongs to the non-course of processing,, also play important effect to the control of glass outgoing.Test package district production line is realized by following process: the dried glass substrate of its self-stip is in the future delivered to temporary roll-over table successively by travelling belt, automatic checking system, realize glass at X-ray inspection X, afterwards through being sent to the manual checking platform, realizing off-line check, after the inner quality of glass and surface quality confirmed fully, enter multiple package position, can be to the packing of product according to the different packaging means of requirement employing of using the user.

Its beneficial effect was after the utility model adopted technique scheme: the course of processing that The present invention be directed to glass substrate, a kind of successive automatic production line is provided, it is the strict requirement according to the user, special process process in conjunction with processing, the modern production line that utilizes various processing unitss to form, it absorbs the technical experience of external similar technology and has designed a glass substrate successive automatic production line that has from family"s intellecture property in conjunction with the practical situation of China domestic enterprise, it has filled up the blank that China does not have liquid-crystalline glasses substrate production line, broken the situation of China to the complete dependence on import of needs of glass substrate, enlarged the scope of domestic flat-panel monitor industry upstream industry chain, blockade for the liquid crystal industry breaks through foreign technology of China, realize the supporting of domestic industry chain, make initiative work.The present invention has passed through actual pilot scale check, and its every index has reached the advanced level of international like product, domestic top standard.

The DOP-W Series is a large Human Machine Interface (HMI) that comes with a high resolution and high brightness touch screen in 10.4”, 12” and 15” sizes. With the latest Cortex-A8 processor for up to 1GHz pulse wave, the DOP-W Series delivers high performance with rapid response. Its rugged and CE-certified aluminum enclosure protects from vibration and changing ambient temperatures, and features an IP65 waterproof front panel for harsh environments. Built-in stereo speakers increase utility and flexibility. The DOP-W Series complies with CE and UL safety approvals and provides an efficient and competitive solution to meet customer needs for a wide range of high-end industrial automation applications.

HMIs are used in bottling processes to control all aspects of the manufacturing line, such as speed, efficiency, error detection, and error correction.

User interface which receives a "batch" of data and commands from the user in advance, and then outputs the calculations when all the processing is done

Graphical User Interface; precursor to the HMI; interface allowing a user to communicate on-demand with a system via graphical icons, audio indicators, and more

Human Machine Interface; an interactive interface allowing a user to communicate commands to and receive feedback data from a system; capable of on-demand graphical and text-based communication, among others

Macro instructions are an advanced touch screen control method. Macro strengthens the functions of the touch screen, so it has the same logic and arithmetic operations as the PLC. The use of macros will enable the touch screen to implement many powerful functions that cannot be supported by regular components, perfecting the human-machine interface

A recipe activates data transmission of consecutive registers, and supports downloading data from the memory of the recipe card to the PLC, and vice versa

This project shows how to use the STONE display, STM32 microcontroller, ultrasonic sensors, and a servo. The purpose of the project is to be able to display the distance measured by ultrasound in real-time through the STONE display.

STONE provides TOOLBOX software for engineers to easily and visually set up various functions on the GUI, such as text, numbers, curves, image switching, keyboard, progress bar, slider, dial, clock, and touch buttons, data storage, USB download, video & audio.

Engineers can easily adopt the TFT-LCD color user interface and touch functions on various industrial devices and also reduce a lot of development time and cost.

Application areas: medical and beauty equipment, engineering machinery and vehicle equipment, electronic instruments, industrial control systems, electric power industry, civil electronic equipment, automation equipment, transportation equipment, etc.

Through the existing command set provided by the product, this TFT-LCD module can generate command transmission and recognition with the main controller. The main controller receives the commands from the TFT-LCD module to operate the industrial equipment.

The human ear can hear the frequency of sound waves for 20HZ ~ 20KHz. when the vibration frequency of sound waves is greater than 20KHz or less than 20Hz, we can not hear the sound waves. Therefore, we put the frequency higher than 20KHz sound waves called “ultrasonic”. Because of its good directionality, strong penetrating ability, ease to get more concentrated sound energy, in the water to spread far, can be used for measuring distance, measuring speed, cleaning, welding, stone crushing, sterilization, etc. There are many applications in medicine, the military, industry, and agriculture. Such as ultrasonic cleaning machine, ultrasonic humidifier, medical examination B ultrasound, color ultrasound, ultrasonic flaw detector, etc. Sound is generated by vibration, the device that can produce ultrasonic waves is the ultrasonic transducer, customarily called ultrasonic transducer, or ultrasonic probe. The ultrasonic probe is mainly composed of a piezoelectric chip, which can both emit and receive ultrasonic waves. There can be many different materials that make up the chip. The size of the chip, such as the diameter and thickness also varies, so the performance of each probe is different, and its performance must be understood in advance before using it.

Commonly used is the piezoelectric ultrasonic generator, which works by using the resonance of a piezoelectric crystal. Inside the ultrasonic sensor, probes are two piezoelectric chips and a resonant plate. When its two poles applied a pulse signal, its frequency is equal to the inherent oscillation frequency of the piezoelectric chip, the piezoelectric chip will resonate, and drive the resonance plate vibration, it will produce ultrasonic waves. Conversely, if the voltage is not applied between the two electrodes when the resonance plate receives ultrasonic waves, the piezoelectric chip will vibrate, converting mechanical energy into electrical signals, and then it becomes an ultrasonic receiver. Ultrasonic sensor uses the principle of the piezoelectric effect to convert electrical energy and ultrasound into each other, that is, in the emission of ultrasound, the electrical energy will be converted into ultrasound emission; and in the reception, the ultrasonic vibration will be converted into an electrical signal.

The most commonly used method of ultrasonic distance measurement is the echo detection method, as follows, the ultrasonic transmitter launches ultrasound to a certain direction, at the moment of launch while the counter began timing, ultrasound propagation in the air, the way to encounter the obstacle surface blocking immediately reflected back, the ultrasonic receiver received back the reflected ultrasound immediately stop timing. Ultrasonic waves in the air propag

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey