using a tft lcd to move a servo in stock

This project’s aim is to design a display interface for controlling a Servo motor. The Servo angle or position is changed either by dragging or pressing the button on the LCD display interface. The interface is built on a 4.3-inch touch display and programmed using an STM32 development board.

The serial screen is a type of screen that is controlled by the serial port. This screen saves a lot of time as it requires no programming and is perfect for those who use microcontrollers in designing the UI. By using this screen, you can get some common spaces through simple settings and there is no need to write the code for the UI implementation.

First of all, the interface of the serial port screen is designed. You can design a picture of the same using paint or any other similar tool. For each key effect, a particular image should be designed. For example, here I have designed separate display pictures for the separate key effect:

The original image is displayed when the screen is turned ON. In other words, it is the foreground display picture. Whereas the second picture with the corresponding position is displayed when the +ve or -ve position buttons are pressed.

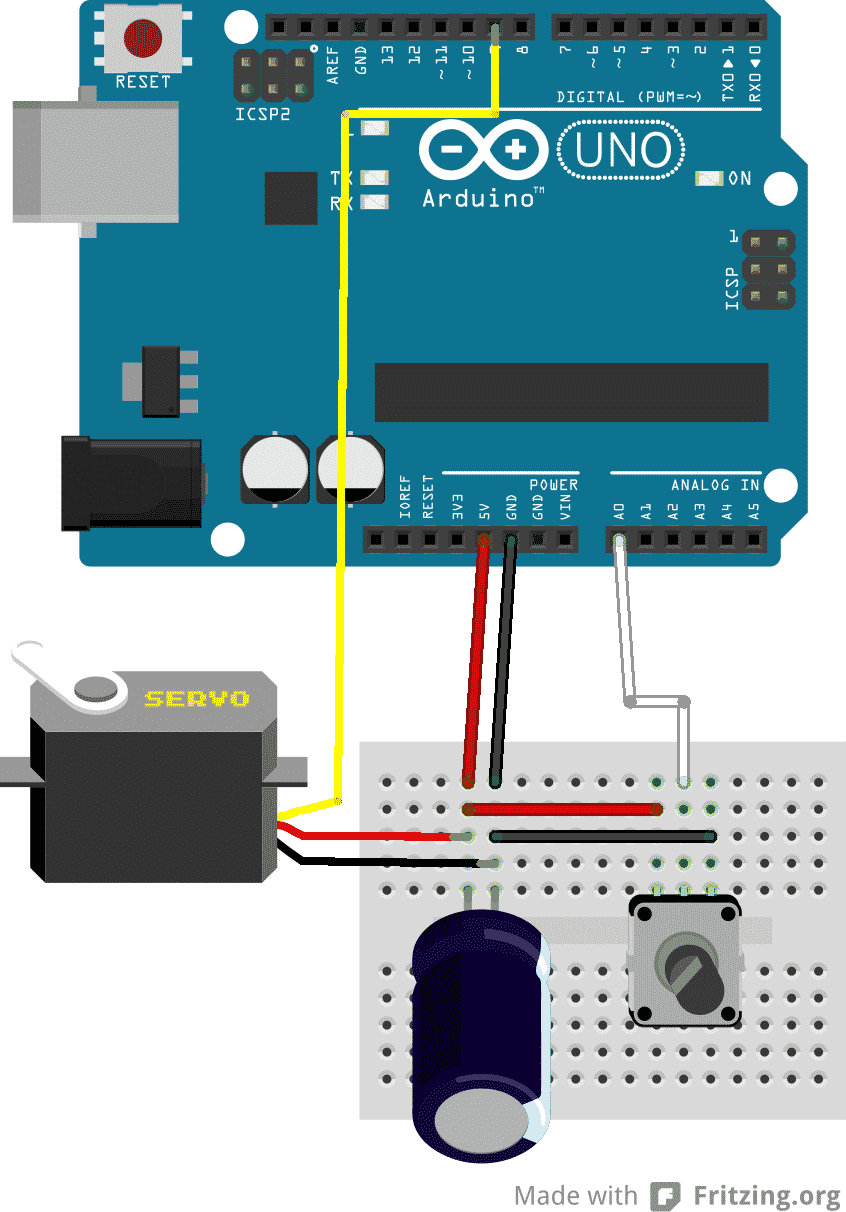

This project is made by using hand to hand connections. The display, microcontroller board, and stepper motor are connected together by using jumper wires. To make this project more reliable, sturdy, and permanent, I suggest you use a custom made PCB board from PCBWay. They provide high-quality PCBs at a very low price.

After installing the software, open it, and create a new project. Since the resolution of the display screen is 480×272 px, select this resolution in the project details. I want to use the screen horizontally, so all other options are set to default.

Add the designed picture you want to use in the GUI. The picture name must start with a number, although there are no special requirements for the specified number. The size of the picture should be consistent with your screen resolution, otherwise, it will prompt an error.

Here I have added the two pictures, the default or foreground display picture is named as number 2. For this, I changed the screen settings inside the startup picture display. In this setting, the startup display picture corresponds to picture number 2.

On the right side of the interface, there is a hotkey area where you need to modify the storage address and the adjustment method. For the same operation or function of the -ve side, the storage address is made the same as the + address.

Under the variable configuration column, select the slider scale. In the right column, modify the slider file and slider icon properties that you want to display over the image.

Adjust the size of the slider scale control so that it fits your scale value. But keep in mind that the icon may exceed the lower scale. So, you can control the slider scale control by adjusting the size of the slider scale control. Or adjust the offset of X coordinate to align it, try to generate a project to debug it to see if the position is suitable.

There are other properties of the sliding scale control that need to be modified: the stored address corresponds to the +ve and -ve address and the minimum and maximum scale corresponding to the scale bar at the bottom.

In the touch configuration toolbar drop-down menu, select the drag adjustment to place over the picture. Now adjusts it to the appropriate size and modify its properties. The storage address is still consistent with the above but the maximum and minimum value range needs to be adjusted.

Add a data variable and the data should be stored at the same address as above. This is mainly to display the data and to better observe the changes in the data.

After completing this step, you can download or run the simulation test. If there are no problems with the design of the serial screen, move on to write the microcontroller program.

I used STM32cube IDE software to write the program for the board. But before that, the configuration setting should be selected for STM32, and I’ll give a brief description of the configuration here.

Open tim2 ch1 channel output PWM wave. The minimum adjustment is 1us for accuracy. The servo adjustment is 0° – 270° corresponding to the pulse of 0.5ms-2.5ms. After the configuration is complete, select the output frequency of 100K PWM wave.

Open the serial port 1. Here I used the DMA, mainly a matter of habit, there is this more advanced configuration on the use of it. Get used to the future of the project also helps ah! The images given below are the screenshot of the configuration information. And after the completion of the configuration, you can generate code.

After the configuration is completed, you have to add the code. All you have to do is add the array and the serial port receives the completion flag data.

c) In a regular project, the serial port processing function should be handled separately. But we don’t do it here because our function is relatively simple.

After the completion of the entire project, compile and download the code to the board. It should be noted that the screen communication connections are of 232 and TTL types. My board is not connected to 232, so it is directly connected to the IO port. Here on the screen, there are J17 solder joints that need to be welded open.

And the project is complete. The entire UI design is based on the picture. The MCU development was relatively simple as the serial port is used which greatly reduces the burden on the developers.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

All you need to do is drag and drop components and Connect them together. Visuino will create the working code for you so you don’t have to waste time on creating the code. It will do all the hard work for you fast and easy! Visuino is perfect for all kind of projects, you can easily build complex projects in no time!

Please be aware that there are some critical bugs in Arduino IDE 1.6.6. Make sure that you install 1.6.7 or higher, otherwise this Instructable will not work! If you have not done follow the steps in this Instructable to setup the Arduino IDE to program Arduino UNO! The Visuino: https://www.visuino.eu also needs to be installed. Start Visuino as shown in the first picture Click on the "Tools" button on the Arduino component (Picture 1) in Visuino When the dialog appears, select "Arduino UNO" as shown on Picture 2

NOTE: Some Displays have diferent properties so experiment by selecting diferent types to find the one that works best, in my case I choose "dtST7735R_BlackTab"

Congratulations! You have completed your project with Visuino. Also attached is the Visuino project, that I created for this Instructable. You can download and open it in Visuino: https://www.visuino.eu

DSS-M15S servos have been well received by customers in these years. It has extremely wide angle control range, huge load capacity and excellent quality. This DSS-M15S with analog feedback has broken its internal potentiometer signal. This is an analog signal with 0~3.3V feedback. You can connect it to MCU to realize close-loop feedback control.

DSS-M15S 270° Metal servo with feedback is compatible with Arduino Servo library. You can drive it with Arduino Board and read the angle value from analog side.

There will be some error between each servos. If you want to use the servos with scenes that require precise control, you can calibrate them separately. A quick three-point calibration method is provided here:

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

In this simple sketch we show you the most useful and important functions from the LiquidCrystal_I2C library. So, let’s take a quick look at how the code works.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

After reading the previous section, you should be familiar on how this sketch works, so we’ll just take a look at the newly created function: scrollText()

delayTime: delay between each character shifting. Higher delay times will result in slower text shifting, and lower delay times will result in faster text shifting.

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

Then, in the setup(), create a custom character using the createChar() function. This function accepts as arguments a location to allocate the char and the char variable as follows:

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

The four sample codes: DisplayString, DrawGraphic, ShowBMP, and TouchPanel are used to display strings, graphics, pictures in BMP format, and touch pen functions.

Before performing the ShowImage display picture experiment, first, copy the pictures in the PIC folder in the data to the root directory of the SD card

Before experimenting with the TouchPanel, the touchscreen must be calibrated according to the displayed prompts. Open the corresponding project, burn the program, and you will be prompted when running:

This demo has been tested on XNUCLEO-F103RB, just insert XNUCLEO-F103RB directly as shown below. The model of XNUCLEO-F103RB is STM32F103RBT6. If you need to transplant the program, please connect it according to the actual pin and the schematic diagram

The demos are developed based on the HAL library. Download the program, find the STM32 program file directory, and open the STM32 with four project folders: DisplayString, DrawGraphic, ShowImage, and Touchscreen.

The four sample codes: DisplayString, DrawGraphic, ShowBMP, and TouchPanel are used to display strings, graphics, pictures in BMP format, and touch pen functions.

Before performing the ShowImage display picture experiment, first, copy the pictures in the PIC folder in the data to the root directory of the SD card

Before experimenting with the TouchPanel, the touchscreen must be calibrated according to the displayed prompts. Open the corresponding project, burn the program, and you will be prompted when running:

For some development boards without ICSP interface (such as NUCLEO), you need to use 0 ohm resistor or solder to short the pads in the following three positions

Today, we shall talk about how [Adam Bäckström] took a DS3225 servo and rebuilt it to improve its accuracy, then built a high-precision robot arm with those modified servos to show just how much of an improvement he’s got – up to 36 times better positional accuracy. If this brings a déjà vu feeling, that’s because we’ve covered his servo modifications before, but now, there’s more. In a year’s time since the last video came out, [Adam] has taken it to the next level, showing us how the modification is made, and how we ourselves can do it, in a newly released video embedded below.

After ordering replacement controller PCBs designed by [Adam] (assembled by your PCBA service of choice), you disassemble the servo, carefully setting the gearbox aside for now. Gutting the stock control board is the obvious next step, but from there, you don’t just drop the new PCB in – there’s more to getting a perfect servo than this, you have to add extra sensing, too. First, you have to print a spacer and a cover for the control board, as well as a new base for the motor. You also have to print (or perhaps, laser-cut) two flat encoder disks, one black and one white, the white one being eccentric. It only escalates from here!

Both of these disks go inside the motor. That is, you have to pry the servo’s DC motor apart, take its base with brushes out, then insert the encoder disks. Then, you snip and file away at the base’s plastic parts to free up as much space inside the motor’s base as possible, and add the optical encoders in the space you freed. Once that’s done, you solder the motor, the optocoupler and the potentiometer connections to the new controller PCB, and assemble the motor back together.

After you’re finished with the surgery, you have to calibrate your servo, for which [Adam] shows how to properly set it up mechanically, provides the code you need to run, and even nice GUI tools with controls to tweak servo parameters – his firmware gives us way more power than we could ever expect from a servo like this. All the knobs and sliders available to control coefficients, limits and curves, show us that [Adam] really does understand what makes for proper servo movement. Enough care is put into the documentation, the explanations and the tools for this modification process, that we don’t have to be anxious about being left behind if we are to follow these steps ourselves!

In a robot arm, small accuracy errors at the base scale into large errors at the arm’s end. If what you crave is high accuracy on a budget, and you have a bit of time to devote to modifying stock servos, this approach might be just what you need, and [Adam] has basically laid all the groundwork for you. Last time we talked about these servo modifications, one of our commenters suggested that this could be a viable successor to the goals of the OpenServo project, and we definitely see where they’re coming from. What if you wanted to go even less expensive than this? You could build a servo out of junk DC motors with a “3 cent” microcontroller, then.

Thanks for setting up a nice project. I was able to follow and my project works. The only issues i found that the scanning is not very fast. I tired to reduce the angle and at the end looked into increasing the serial baud rate which didn’t resulted in fast scanning. Serial monitor always showed very same reading speed. So, the radar lines on frame move very slowly and distance get updated slow when compared to you video.

hi, i want to construct it for my school project. but i just have a week for that. can it be made that easily? in addition to that i have zero knowledge of arduino devices. should i just follow the steps? or is there any more explanation on your site? being honest i m really confused

Hi there, well if you follow all the steps from the video and the article the project should work. There isn’t anything hidden, though you would need a bit of knowledge in case you connect something wrong, because you will wonder that is going on. Check my other beginner tutorials if you are complete beginner.

I realize I’m just another voice in the choir, here, but I feel I have to say it anyway: This was a delightfully whimsical project. I did “just because”, and it was very fun. Thanks! I learned a handful of things that may turn out ot be useful, later on.

Thanks! Of course, everything is possible with Arduino, but that would requite appropriate code changes. You would have to code the GUI to suit the TFT screen.

Really cool project! And, it was easy enough for me to pull off with only minimal mess ups. I only first bought an Arduino (Uno R3+) 3 days ago. I went through all of the tutorials in the starter kit I bought, and then purchased some other stuff to add on to it (shields, sensors, etc.).

I really appreciate the tutorial on setting up and working with Processing, as well. I didn’t know about that before, but now can add that into my learning. Thanks!

Yes sorry I found that. But also in the latest ‘complete source code’ bit, there is no #include and I am getting confused and I have already written half of the the code titled in red letters. Help!

I just wanted to ask that, is it possible to adapt the code for measuring the speed of an approaching object. I reduced the angle of scanning to 60 degrees and I want to see the speed on the screen if an object is getting closer to the sensor. Any tips to get me started?

Thanks. That sounds like a good project idea and you might be able to make it with this or similar sensor and setup. You comparing the distanced the object has approached in a particular period of time.

Dejan, The project is excellent. The code all works and the instructions and tutorials are excellent. My only trouble was finding out how to clear the font error in Processing but a quick google search taught me how to create the font. It’s a great project!

Well the servo motor can only rotate 180 degrees. You would need different motor, so different code for both Arduino and processing. But sure, it’s possible to make it.

hi i just want to ask how can i match the distance of the detected object in the sonar since i already change the distance that the sensor to 1m, the distance that the sonar give doesnt match with the distance that the sensor detect

It’s possible but you would have to make a suitable application for your mobile. I already have a tutorial on how to make your own custom Android application using the MIT App Inventor, so you can check it out and find some more details there.

I get the program to work some of the time, but not every time. The sensor will often hesitate on the swing back (165 to 15 degrees) at about 80 to 90 degrees and then will often hesitate on the swing forward (15 to 165 degrees) at about 70-80 degrees. Any idea why it hesitates on the swing back and forward? What is weird, is that sometimes it doesn’t hesitate at all, but most of the time it does. Any help would be appreciated.

Thanks a ton man!. The project definitely works. The coding is free of error. There is just one slight modification though. The font which you use in the processing IDE needs to be moved into the sketch folder first and you seem to have skipped mentioning that part.

It seems like your Arduino doesn’t have enough power to run the servo motor smooth (although this shouldn’t happen) or your servo motor might be faulty.

The ultrasonic sensor u used for this project is HC- SR04. I read data sheet of it. range of sensor is upto 400 cm. then why only upto 40 cm can be got by this code. if we consider its measuring efficiency is lesser than ideal one then also it could measure atleast upto 100cm. What changes in code required if i want output of 400cm or 100cm.

I need the most high possible precision for my project but this code (processing code) is not very precise. Arduino and the sonar are working good, sending the right distance to the serial port. Processing IDE is recieving the right distance but the results showed by the radar are not! The value showed near “Distance” is correct but the red line is wrong by 3, sometimes 4 cm. Also, the segment from point 0 and 10 cm is much bigger then segments between 10-20, 20-30 and 30-40. I also modified the processing code to show red lines only at a certain distance (eg. 10cm) to see exactly how much is the red line long when processing read 10cm from the serial port and the red line is at about 7/8cm (so it starts before the 10cm segment). Same as for 20cm or any other distance.

That’s true, this project is not that accurate, considering both the cheap electronics components used in this project, as well as the coding in the Processing IDE. The point was to make it as simple as possible so that everyone can easily understand it and make it on their own, and sure there is always room for any project to be improved.

Can i make the radar screen with LCD touch screen 2.8 or 3.2 inch? And if the answer is yes, can you give the code with LCD screen (processing code). thanks very much bro!

That’s a different approach to this project. You would need to program the Arduino to display the radar on the LCD, you won’t need Processing code. I don’t have such a code though.

hey, i really like this project you have, but I am having, is that for starters the screen for some reason does not fit, but my main problem is that the red lines are not showing up for me when i run the program. everything else is working fine, the green lines are moving and all, but when i place somthing in front of the sensor, no red lines appear. do you know how to fix this? thanks for the help

Are you using the right Processing IDE code, the updated to work on each screen resolution, the one on the bottom of the post. If you are using that one you just have to set your screen resolution and all other drawings will be adjusted according to the set resolution.

I’m having a small problem. The green and red lines are not moving at all and the angle is only showing 0° all the time. Please give me some instructions of solving this problem!

Check your connections twice, you probably have connected something wrong. Test the sensor whether is working with the simple tutorial code for the ultrasonic sensor.

The lines plotted are only red, its always In Range, and the distance is not calculating on the plot, it’s at zero. I made another project to test the pinger, and it works. What should i try next?

Hi sir, thank you for your great tutorial ! but I have a problem. It says in the Processing IDE that “Could not load font OCRAExtended-30.vlw. Make sure that the font has been copied to the data folder of your sketch.”. Can you help me out sir , please ?

Great project. Even I have followed and done it. Everything is working fine but the problem I am facing is that my servo motor is getting hot and after 1 or 2 rotation it stops rotating and then it doesn’t rotate till it doesn’t cool down. May be next day it start to work and again after 2 roation it heats up and stops.

I want to just ask you that whatever distance which is measured, I want it to be uploaded to my Cloud, So can I do that? Can you help me out? Please.!

Sure you could store your measurements, but I don’t have any tutorial about storing them on Cloud. If storing them to a MicroSD card could do the job for you, you can check my particular tutorial for that.

I am experiencing really noisy HC-SR04 data. I was wondering if you have experienced that and if so how did you solve it. Or do you have any advice on what might be the problem.

But I wanted to know how can we make it rotate 360 degrees because the servo can rotate up to 190 degrees. Can we have a wireless radar configuration for making it rotate 360 degrees or a sensor equivalent to 360 radiation pattern?

Hi Dejan I would like to know how did you set up the screen and how to connect it in order to have the green radar lines going on if you could explain me this thank you I already scrolled the other comments…

The resolution issue is solved. I think I had used a previous version of your code, I see that all graphics are sized for width and height of the size() function.

Thanks for making this project available, it’s very impressive. We brought it to a group of about 60 students and they made it. All were very impressed with the results.

I’ve done it on my computer and it works very well. On the student laptops, coming with many different setups, screen resolutions and operating systems, we had issues on some. The main one was with resolution. Even using your last code for all screen resolution, and changing the “size (1920, 1080); ” line with their respective screen resolution did not change the size of the radar graph. We can only see the top left corner of the radar, with the base and angles-distances out of the screen. This mainly happened with the lower screen resolutions, around 1360, 768. I think other feedbacks mentioned this as well, I’m trying to troubleshoot on my computer but if you can help it would be great.

Others were getting error messages when compiling the Arduino code, I’m thinking it could be linked to their antivirus softwares as they were getting prompts from it. Anyway we’ll work through this one.

I have a problem with Processing. Last time I used this app everything functioned. Now the radar’s drawing is broke. I can’t attach a picture to show you what is happening. Radar appear regular when I open Processing but it doesn’t scan the near environment. It just draw a bold red line from the center to the begining degree of scanning.

I tried to change pins in the testing program for the sensor with the pins 10 and 11 and the sensor is working. do you know another software like processing?

I have a question regarding the display. after clicking the run button in processing, my display only shows partial screen of the scanning radar. Changing the display resolution does not fix the problem. I also change to different font. Please help.

and since i’m not familier with IDE Processing i still trying to change the resolution wich comes for (1920, 1080) screen i guess ,in way to make it compatible with my own 1280*1024.

I tried to use this code but it seems that the bottom half is in Javascript instead of c++ or any other compatible code, so it won’t work with my Arduino. How could I fix this?

we have used your code word to word and even worked out the font and screen resolution errors. But in the end we are facing a problem. when we disconnect the sensor, the green line shows but as soon as we connect the sensor the green lines disappear and only the red lines are visible. The sensor doesn’t detect anything as the distance is always 0 but the red lines move from 15-165 degrees. we thought there was something wrong with the sensor so we changed it but that didn’t help. so please help.

Can the given processing code work on Processing 3.0.2…….for some unknown reason i am not getting any output after i run the code because or is there any additional steps i need to take before/after uploading the arduino code and then immediately running the processing code

I have copied the 2 programs for arduino and processing as given…..but after connecting the arduino uno to my laptop and running the code in processing the console window is not appearing…….the program is uploaded in the arduino and the connections are fine….i am getting the output on the serial monitor…….i am a beginner so i am not sure where i am going wrong..

sir my processing shows a message could not load font OCRAExtended-30.vlw. make sure that the font has been copied to the data folder of your sketch. what does that mean? im new in this field pls help me

Read the other comments of this tutorial and you will see that the most of the people have managed to get it working. So the program is working, the problem has to be with you, you are probably doing something wrong.

hi sir good day thank for the amazing project I like it . but im not experience , I want to ask u about 1 thing i upload the arduino code its good done uploading but at the prociccing i get the error :

sir my processing shows a message could not load font OCRAExtended-30.vlw. make sure that the font has been copied to the data folder of your sketch. what does that mean?

Hi Dejan, first I have to say that I saw your other projects and I am glad to see that we also have succesful arduino developers in our neighborhood.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey