using a tft lcd to move a servo free sample

This project’s aim is to design a display interface for controlling a Servo motor. The Servo angle or position is changed either by dragging or pressing the button on the LCD display interface. The interface is built on a 4.3-inch touch display and programmed using an STM32 development board.

The serial screen is a type of screen that is controlled by the serial port. This screen saves a lot of time as it requires no programming and is perfect for those who use microcontrollers in designing the UI. By using this screen, you can get some common spaces through simple settings and there is no need to write the code for the UI implementation.

First of all, the interface of the serial port screen is designed. You can design a picture of the same using paint or any other similar tool. For each key effect, a particular image should be designed. For example, here I have designed separate display pictures for the separate key effect:

The original image is displayed when the screen is turned ON. In other words, it is the foreground display picture. Whereas the second picture with the corresponding position is displayed when the +ve or -ve position buttons are pressed.

This project is made by using hand to hand connections. The display, microcontroller board, and stepper motor are connected together by using jumper wires. To make this project more reliable, sturdy, and permanent, I suggest you use a custom made PCB board from PCBWay. They provide high-quality PCBs at a very low price.

After installing the software, open it, and create a new project. Since the resolution of the display screen is 480×272 px, select this resolution in the project details. I want to use the screen horizontally, so all other options are set to default.

Add the designed picture you want to use in the GUI. The picture name must start with a number, although there are no special requirements for the specified number. The size of the picture should be consistent with your screen resolution, otherwise, it will prompt an error.

Here I have added the two pictures, the default or foreground display picture is named as number 2. For this, I changed the screen settings inside the startup picture display. In this setting, the startup display picture corresponds to picture number 2.

On the right side of the interface, there is a hotkey area where you need to modify the storage address and the adjustment method. For the same operation or function of the -ve side, the storage address is made the same as the + address.

Under the variable configuration column, select the slider scale. In the right column, modify the slider file and slider icon properties that you want to display over the image.

Adjust the size of the slider scale control so that it fits your scale value. But keep in mind that the icon may exceed the lower scale. So, you can control the slider scale control by adjusting the size of the slider scale control. Or adjust the offset of X coordinate to align it, try to generate a project to debug it to see if the position is suitable.

There are other properties of the sliding scale control that need to be modified: the stored address corresponds to the +ve and -ve address and the minimum and maximum scale corresponding to the scale bar at the bottom.

In the touch configuration toolbar drop-down menu, select the drag adjustment to place over the picture. Now adjusts it to the appropriate size and modify its properties. The storage address is still consistent with the above but the maximum and minimum value range needs to be adjusted.

Add a data variable and the data should be stored at the same address as above. This is mainly to display the data and to better observe the changes in the data.

After completing this step, you can download or run the simulation test. If there are no problems with the design of the serial screen, move on to write the microcontroller program.

I used STM32cube IDE software to write the program for the board. But before that, the configuration setting should be selected for STM32, and I’ll give a brief description of the configuration here.

Open tim2 ch1 channel output PWM wave. The minimum adjustment is 1us for accuracy. The servo adjustment is 0° – 270° corresponding to the pulse of 0.5ms-2.5ms. After the configuration is complete, select the output frequency of 100K PWM wave.

Open the serial port 1. Here I used the DMA, mainly a matter of habit, there is this more advanced configuration on the use of it. Get used to the future of the project also helps ah! The images given below are the screenshot of the configuration information. And after the completion of the configuration, you can generate code.

After the configuration is completed, you have to add the code. All you have to do is add the array and the serial port receives the completion flag data.

c) In a regular project, the serial port processing function should be handled separately. But we don’t do it here because our function is relatively simple.

After the completion of the entire project, compile and download the code to the board. It should be noted that the screen communication connections are of 232 and TTL types. My board is not connected to 232, so it is directly connected to the IO port. Here on the screen, there are J17 solder joints that need to be welded open.

And the project is complete. The entire UI design is based on the picture. The MCU development was relatively simple as the serial port is used which greatly reduces the burden on the developers.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

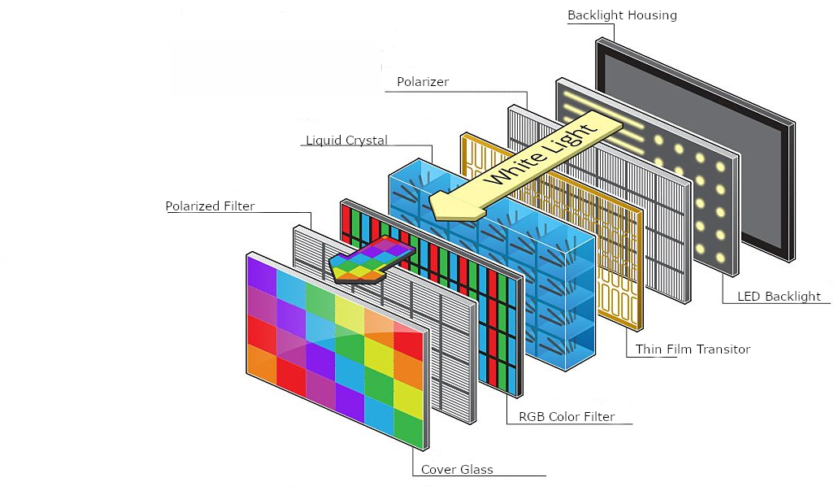

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We just used a string and 8 filled circles that change their colors in order. To draw circles around a static point ,You can use sin(); and cos(); functions. you should define the PI number . To change colors, you can use color565(); function and replace your RGB code.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

The speed of playing all the GIF files are edited and we made them faster or slower for better understanding. The speed of motions depends on the speed of your processor or type of code or size and thickness of elements in the code.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The 5 Servo motors in this project are connected to one Arduino UNO board. Each Servo motor has a unique function. This article will shed light on the example in detail, along with the code, Arduino Simulation, and connection diagram.

This is a very good example to understand how multitasking is achieved in an easier way. This will help you to gain knowledge on both multitasking as well as tips and tricks to manage future tasks. Let us begin.

The analog value read from the potentiometer decides the rate at which we increment the angle. The higher the analog value, the faster will be the rate at which we reach the maximum angle and reset. hence, the potentiometer position decides the rate of movement of the Servo motor.

In the Arduino simulation link, you can experiment as well by playing with the potentiometer. Wokwi Arduino simulator supports several other peripherals as well which you can use in your next simulation projects.

The Third Servo motor is driven in a simple way. There is anotherpotentiometerconnected to Arduino PINA1. the angle of the servo motor is directly proportional to the position of the potentiometer.

For every interval (10 ms or 20 ms) the position of the servo motor is changed by one step. Depending on the button pressed, the servo 4 will either move to one edge or the other. Since this is an example, some cases are not taken care.

The article gave you an example project where 5 servo motors were controlled in parallel. This was possible due to following reasonsNodelay()functions are used. Adding a delay() function causes the control to block the processor by doing other tasks

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this tutorial we will learn how servo motors work and how to control servo motors with Arduino. Servo motors are very popular and widely used in many Arduino projects because they are easy to use and provide great position control.

Servos are great choice for robotics projects, automation, RC models and so on. I have already used them in many of my Arduino projects and you can check out some of them here:

You can watch the following video or read the written tutorial below. It includes several examples how to use a servo motor with Arduino, wiring diagram and codes. In additional, it has a guide how to control multiple servo motors with Arduino using the PCA9685 PWM driver.

A servo motor is a closed-loop system that uses position feedback to control its motion and final position. There are many types of servo motors and their main feature is the ability to precisely control the position of their shaft.

In industrial type servo motors the position feedback sensor is usually a high precision encoder, while in the smaller RC or hobby servos the position sensor is usually a simple potentiometer. The actual position captured by these devices is fed back to the error detector where it is compared to the target position. Then according to the error the controller corrects the actual position of the motor to match with the target position.

Hobby servos are small in size actuators used for controlling RC toys cars, boats, airplanes etc. They are also used by engineering students for prototyping in robotics, creating robotic arms, biologically inspired robots, humanoid robots and so on.

There are four main components inside of a hobby servo, a DC motor, a gearbox, a potentiometer and a control circuit. The DC motor is high speed and low torque but the gearbox reduces the speed to around 60 RPM and at the same time increases the torque.

The potentiometer is attached on the final gear or the output shaft, so as the motor rotates the potentiometer rotates as well, thus producing a voltage that is related to the absolute angle of the output shaft. In the control circuit, this potentiometer voltage is compared to the voltage coming from the signal line. If needed, the controller activates an integrated H-Bridge which enables the motor to rotate in either direction until the two signals reach a difference of zero.

A servo motor is controlled by sending a series of pulses through the signal line. The frequency of the control signal should be 50Hz or a pulse should occur every 20ms. The width of pulse determines angular position of the servo and these type of servos can usually rotate 180 degrees (they have a physical limits of travel).

Generally pulses with 1ms duration correspond to 0 degrees position, 1.5ms duration to 90 degrees and 2ms to 180 degrees. Though the minimum and maximum duration of the pulses can sometimes vary with different brands and they can be 0.5ms for 0 degrees and 2.5ms for 180 degrees position.

There are many different models and manufacturers of RC or hobby. The main consideration when choosing a servo motor is its torque, operating voltage, current draw and size.

Let’s put the above said to test and make a practical example of controlling a hobby servo using Arduino. I will use the MG996R which is a high-torque servo featuring metal gearing with stall torque of 10 kg-cm. The high torque comes at a price and that’s the stall current of the servo which is 2.5A. The running current is from 500mA to 900mA and the operating voltage is from 4.8 to 7.2V.

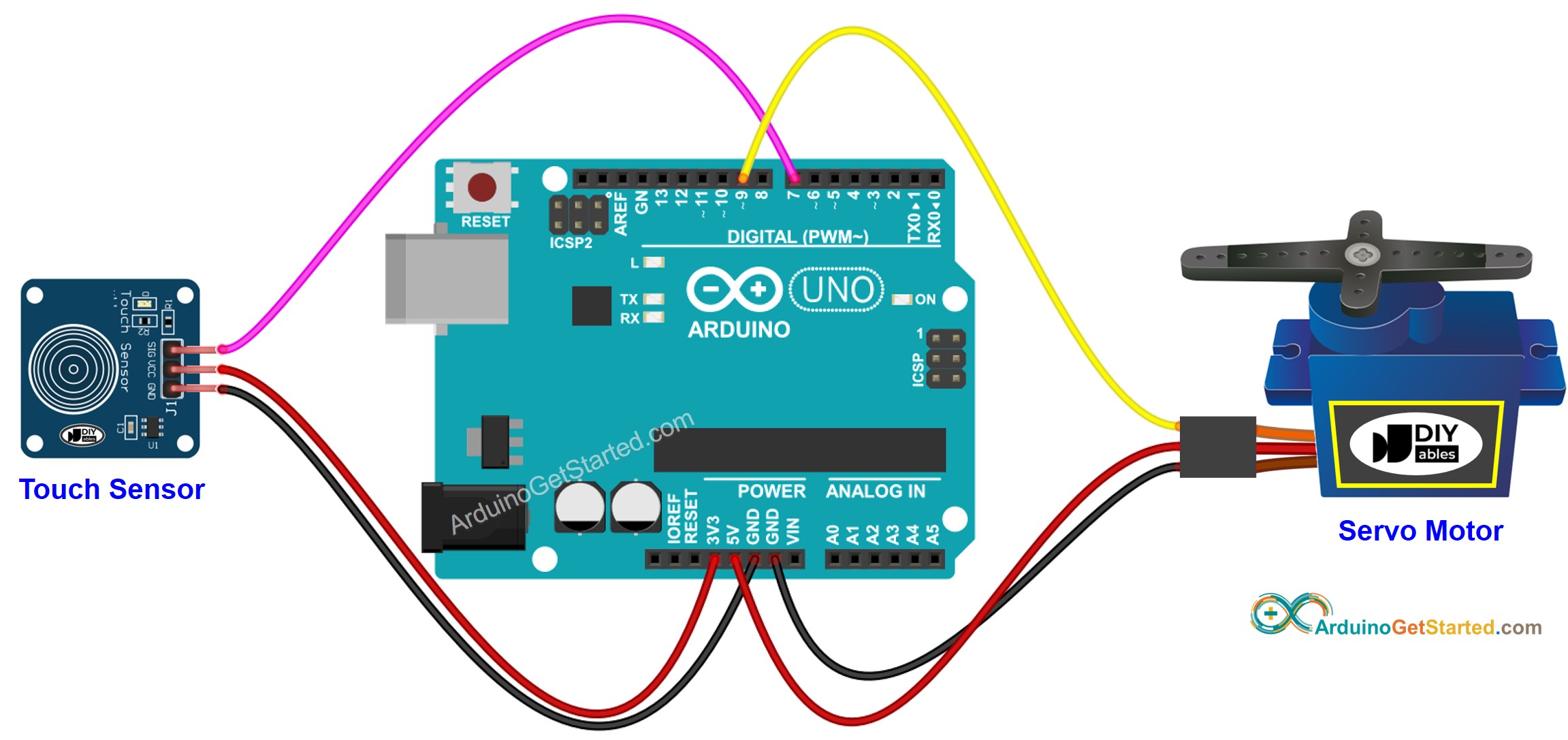

We simply need to connect the control pin of the servo to any digital pin of the Arduino board, connect the Ground and the positive wires to the external 5V power supply, and also connect the Arduino ground to the servo ground.

The S90 Micro Servo has lower current consumption, around 100-200mA no-load running current, but around 500-700mA stall current. On the other hand, the Arduino 5V pin can output only around 500mA if powered via USB, or up to 1A in powered via the barrel connector.

Even though it’s possible to run these 9g servo motors directly to Arduino, for more stable work I would suggest to always use an external power supply for them.

Now let’s take a look at the Arduino code for controlling the servo motor. The code is very simple. We just need to define the pin to which the servo is connect, define that pin as an output, and in the loop section generate pulses with the specific duration and frequency as we explained earlier.

After some testing I came up with the following values for the duration of the pulses that work with my servo. Pulses with 0.6ms duration corresponded to 0 degrees position, 1.45ms to 90 degrees and 2.3ms to 180 degrees.

I connected a multimeter in series with the servo to check the current draw. The maximum current draw that I noticed was up to 0.63A at stall. Well that’s because this isn’t the original TowerPro MG996R servo, but a cheaper replica, which obviously has worse performance.

Here we just need to include the library, define the servo object, and using the attach() function define the pin to which the servo is connected as well as define the minimum and maximum values of the pulses durations. Then using the write() function we simply set the position of the servo from 0 to 180 degrees.

The Arduino servo library supports controlling of up to 12 servos at the same time with most the Arduino boards, and 48 servos using the Arduino Mega board. On top of that, controlling multiple servo motors with Arduino is as easy as controlling just a single one.

So, we just have to create objects from the Servo class for each servo motor, and define to which Arduino pin is connected. Of course, we can set any servo to move to any position, at any time.

There’s also another way of controlling servos with Arduino, and that’s using the PCA9685 servo driver. This is a 16-Channel 12-bit PWM and servo driver which communicates with Arduino using the I2C bus. It has a built in clock so it can drive 16 servos free running, or independently of Arduino.

What’s even cooler we can daisy-chain up to 62 of these drivers on a single I2C bus. So theoretically we can control up to 992 servos using only the two I2C pins from the Arduino board. The 6 address select pins are used for setting different I2C addressed for each additional driver. We just need to connect the solder pads according to this table.

So first we need to include the libraries and define the PCA9685 object. Then using the Servo_Evaluator instance define the pulses duration or the PWM output of the driver. Note that the outputs are 12-bit, or that’s a resolution of 4096 steps. So the minimum pulse duration of 0.5ms or 0 degrees position would correspond to 102 steps, and the maximum pulse duration of 2.5ms or 180 degrees position to 512 steps. But as explained earlier these values should be adjusted according your servo motor. I had value from 102 to 470 which corresponded to 0 to 180 degrees position.

I connected a second servo to the driver, and as I expected, it wasn’t positioning the same as the first one, and that’s because the servos that I’m using are cheap copies and they are not so reliable. However, this isn’t a big problem because using the Servo_Evaluator instance we can set different output settings for each servo. We can also adjust the 90 degrees position in case it’s not precisely in the middle. In that way all servos will work the same and position at the exact angle.

So we should create separate PCA9685 object for each driver, define the addresses for each driver as well as set the frequency to 50Hz. Now simply using the setChannelPWM() and pwmForAngle() functions we can set any servo at any driver to position any angle we want.

This is a common problem with these hobby servo motors, the SG90 Micro Servo and the MG996R. The reason for this is that, as mentioned earlier, they can draw quite significant amount of current when they are at load. This can cause the Arduino board to reset, especially if you are powering the servo directly from the Arduino 5V pin.

In order to solve this issue you can use a capacitor across the GND and the 5V pin. It will act as a decouple capacitor which will provide additional current to the system at start up when the DC motor starts.

This is another common problem with these hobby servos. As we explained earlier, a pulse width of 1ms (0.5ms) corresponds to 0 degrees position, and 2ms (2.5ms) to 180 degrees. However, these values can vary from servo to servo and between different manufacturers.

In order to solve this problem, we need to adjust the pulse width we are sending to the servo motor with the Arduino. Luckily, using the Arduino Servo library we can easily adjust the pulse widths values in the attach() function.

The attach() function can take two additional parameters, and that’s the minimum and maximum pulse width in microseconds. The default values are 544 microseconds (0.544milliseconds) for minimum (0 degrees) angle, and 2400 microseconds (2.4ms). So by adjusting these values we can fine tune the moment range of the servo.

I made 3D models of the two most popular servo motors, the SG90 Micro Servo and the MG996R servo motor. You can download load them from the links below.

So, we have covered almost everything we need to know about using servo motors with Arduino. Of course, there are some many manufacturers and models of these type of hobby or RC servo motors, and each of them has its own unique features that might differ from what we explained above.

The possibilities for creating awesome robotics, automation and RC projects using motors are endless, however choosing the right model for your application is very important.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below, as well as make sure you can my Arduino Projects Collection.

Using a servo motor with Arduino is quite easy. The servo motor has just 3 wires, two of which are GND and 5V for powering, and the third wire is the control line which goes to the Arduino board.

We can run servo motors directly from Arduino, but we might have power problems. If the servo motor draws more than 500mA of current, the Arduino board might lose it’s power and reset. It’s better to always use a separate power source for the servo motors.

Using the Arduino Servo library we can control up to 12 servo motors with most Arduino boards, and up to 48 servo motors with the Arduino Mega board. Of course, we need to use a dedicated power source for the servo motors.

Adafruit invests time and resources providing this open source code, please support Adafruit and open-source hardware by purchasing products from Adafruit!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

In this simple sketch we show you the most useful and important functions from the LiquidCrystal_I2C library. So, let’s take a quick look at how the code works.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

After reading the previous section, you should be familiar on how this sketch works, so we’ll just take a look at the newly created function: scrollText()

delayTime: delay between each character shifting. Higher delay times will result in slower text shifting, and lower delay times will result in faster text shifting.

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

Then, in the setup(), create a custom character using the createChar() function. This function accepts as arguments a location to allocate the char and the char variable as follows:

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

Multiplex Machine is used to make Uniaxial, CBR and Marshall Tests. 50 kN capacity Multiplex Machine is equipped with a servo motor and BC100 TFT graphics data acquisition and control system. Suitable for CBR, Marshall, Triaxial and Uniaxial Tests and similar tests with appropriate accessories. The machine is also capable of doing load controlled tests. UTM-0108 Multiplex Machine is composed by a robust and compact two column frame with adjustable upper cross beam.

* Supplied complete with UTGM-1210 50 kN Load Cell, UTGM-0064 50 mm linear potentiometric transducer with holder (UTM-0114 and UTAS-1060) and lower compression platen.

.*** Choose the suitable cell for the specimen size (UTS-2400: 38-50 mm dia. samples / UTS-2401: 70-100 mm dia. samples). For cell and cell accessories see “Triaxial Cells, Cell Accesories and Sample Preparation” page.

BC100 TFT Graphic Display Data Acquisition and Control Unit is designed to control the machine and processing of data from load-cells, pressure transducers or displacement transducers which are fitted to the machine.

All the operations of BC100 are controlled from the front panel consisting of a 800x480 pixel 65535 color resistive touch screen display and function keys. 4 analogue channels (it would be simultaneous or not depending on the application at the factory) are provided for load-cells, pressure transducers or displacement transducers.

BC100 has easy to use menu options. It displays all menu option listings simultaneously, allowing the operator to access the required option in a seemless manner to activate the option or enter a numeric value to set the test parameters. The BC100 digital graphic display is able to draw real-time "Load vs. Time", "Load vs. Displacement" or "Stress vs. Time" graphics.

BC100 unit offers many addition unique features. You can save more than 10000 test results in its internal memory. BC100 unit has support for various off-the-shelf USB printers, supporting both inkjet and laser printers. Thanks to its built-in internet protocol suite, every aspect of BC100 device can be controlled remotely from anywhere around the world.

Calculates corrected CBR value at 2.5 and 5 mm the digital unit saves the load value at user defined displacement values such 0.625, 1.25, 1.875, 2.5, 3.75, 5, 7.5, 10, 12.5 mm

4 analog channels (it would be simultaneous or not depending on the application at the factory) for one analog channel for high capacity load cell, one analog channel for displacement transducer, one analog channel for low capacity load cell and one analog channel for pressure transducer for oil-water constant pressure unit

Programmable digital gain adjustment for load-cell, pressure transducers, strain-gauge based sensors, potentiometric sensors, voltage and current transmitters

The function below is used to draw the buttons and slider outlines to the display.void drawButton(int x, int y, int w, int h, char *text, int backgroundColor, int foregroundColor);

Using the values that are found in the above structure for the "PAN"button, we can easily draw a button using drawButton();drawButton(button[0].coords[X],button[0].coords[Y],button[0].coords[W],button[0].coords[H],"PAN",GREY,BLUE);

We can also use drawButton() to draw the outline of the sliders. Just need to specify no text and have a black background. Below is what we can use to draw a slider outline around the "PAN" button;drawButton(button[0].coords[X]-1, button[0].coords[Y]-1,

Below is used to detected touch within the "PAN" button area.//Does the current X input fall between the current X position and the width of the button?

To get the corresponding values from the button location as a percentage, we just need to device the button delta by the button slide length and height or width.float panValue = (float)button[0].delta/ (button[0].coords[L]+button[0].coords[W]);

pi@raspberrypi ~ $ gcc -o panTilt panTilt.c -I/opt/vc/include/ -I/opt/vc/include/interface/vmcs_host/linux -L/opt/vc/lib -lbcm_host -I/opt/vc/include/interface/vcos/pthreads

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey