ascii lcd display factory

Winstar offers a wide range of standard Character LCD modules for customers" application. Our LCD character displays are available from 8x2, 12x2, 16x1, 16x2, 16x4, 20x2, 20x4, 24x2 through to 40x4 formats with 5x8 dot matrix characters. The LCD panel technologies include TN, STN, FSTN, FFSTN types and also with polarizer positive mode and negative mode options. There are different LED backlights are available in various colors including yellow/green, white, red, blue, green, amber, and RGB LEDs as well as no backlight option.

To meet the demands of customer applications, these character LCD displays are available with viewing angles of 6:00, 12:00, 3:00, and 9:00 o"clock. Winstar offers various IC options of character fonts including English/Japanese, western European, eastern European, Scandinavian European, Cyrillic (Russian), and Hebrew/Arabic. These LCD character module and LCM Modules can be used on industrial and consumer"s applications including entrance guard"s equipment, telegram, medical device, car and home audio, white goods, game machine, toys and etc.

Text LCD displays are among the simplest. They are popular for their ease of operation and programming thanks to the HD44780 LCD controller and their analogs with the built-in set of characters including ASCII characters. Text displays consist of a matrix of dots combined into rows and columns. Formats of rows and columns are standardized by manufacturers and can be 8x1, 8x2, 10x1, 10x2, 16x1, 16x2, 16x4, 20x1, 20x2, 20x4, 24x1, 24x2. Each LCD controller is capable of operating up to 80 characters so the text LCD display with the 20x4 format is the largest. There are even larger text LCD displays such as 40x4 using several LCD controllers but they are too rare.

Initially, text LCD displays communicate with microcontrollers such as Arduino using parallel 4 or 8-bit interfaces. Some manufacturers add shift registers and port expanders to the display, making it possible to control via I2C or SPI bus. It is done for connecting convenience and reducing the number of mounting wires.

These nodes contain everything you need to start working with displays. You only have to connect your display to the microcontroller and set up proper connection parameters.

If the display communicates via an I2C bus the input parameter is the device address. Put the I2C address value of the byte type to the ADDR pin field.

If the display is controlled using a parallel interface fill in the pin values RS, EN, D4, D5, D6, D7 according to the microcontroller ports through which the display is connected.

The L input pins of the string type have indexes from 1 to 4 and correspond to the lines on your text display. The boolean value at the ACT pin is responsible for updating the display screen if the incoming string values change. Versions controlled by the I2C bus have an additional BL pin which turns on and off the display backlight.

Here is a simple example of using quick start nodes. For the example we use a 16x2 format display controlled by I2C. Connect the display to the microcontroller. Create an empty patch and put the text-lcd-i2c-16x2 quick start node onto it. The LCD screen from this example has the 38 I2C address so we put the 38h value to the ADDR pin.

Let’s print the “HELLO” word on the first line of the text display. Add a constant-string node onto the patch, fill it with the "HELLO" string value, and then link it with the L1 input pin of the quickstart node denoting the first line of the display.

A text can be entered directly into a value field of the input pin. To demonstrate it, let’s print the “WORLD” word on the second line of the display. Put the "WORLD" string value into the L2 pin of the text-lcd-i2c-16x2 quick start node.

Try a more dynamic example. Let’s display the system time, it is the time that has passed since the start of the program. To obtain the time value use the system-time node from the core library.

Remove the "WORLD" value from the L2 pin of the quickstart node and change the text inside of the constant string node to "Time: ". In XOD you can add different strings together or combine a string with a value of another data type using concat or join nodes. Put the concat node onto the patch to unite the static "Time: " text with a value received from the system-time node. To display the combined string on the first line of the display link the output pin of the concat node with the L1 pin of the quickstart node.

If the quickstart node doesn’t suit your task or the display is of a non-common format try to operate some developer nodes from the library xod-dev/text-lcd library.

Define the display you want to use to start working with it in XOD. Find out how your display communicates and place the appropriate device node from the xod-dev/text-lcd library. These nodes construct and output an lcd-device custom type value which is necessary for further work.

Use the text-lcd-parallel-device node if the display is controlled using a parallel interface. This node allows the display connection only through a 4-bit parallel interface. Here enter the pin values RS, EN, D4, D5, D6, D7. These values correspond to the microcontroller ports through which the display is connected.

Use the text-lcd-i2c-device node if the display communicates via an I2C bus. For this node, the input parameter is the device address. Enter the I2C address of your display to the ADDR pin value.

When the device is initialized, you can display text on it. To output text, use the print-at node. It fits any type of LCD device because it is generic.

The input values of the print-at nodes determine what text to display and where it should be on the display screen. Text to display is set at the VAL pin value. The ROW and POS field values set the cell coordinates on the display for the first character. That’s the place where your text begins. The LEN pin value sets the number of character cells for the text to reserve. The text can’t go beyond the boundaries you specify. It is useful, for example, when the length of your text changes during the program or you want to organize free space between several text parts. Printing is performed when the DO pin receives a pulse.

At first, let’s make a patch to print the "HELLO" text. Put the text-lcd-i2c-device node onto the patch and fill it with parameters. According to the format of the display, the number of columns is 20 and the number of rows is 4. The I2C address of the used display is 0x39 so put the 39h byte to the ADDR pin. Add the print-at node and link it with the device node. Put the HELLO to the VAL input pin.

Add one more print-at node and link with the LCD device bus. Put the "WORLD" word into the VAL field. The new text is on the same line as the previous one so set the ROW value to 1. The POS value now should be calculated. The “HELLO” word begins from the cell with index 4 and occupies 5 cells. By adding one empty cell for space and the “HELLO” word length to the previous text position you can get the POS for the new text: it is 10. Link the input DO pin of the new node with output DONE pin of the previous to execute printing sequentially.

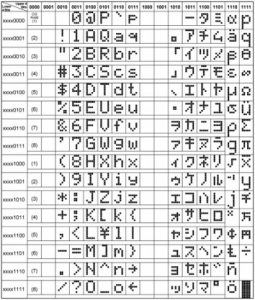

Text displays contain a table of images for each character in their memory. These tables are used to generate letters, numbers and other symbols. Almost always a full list of all available characters can be found in the manufacturer’s datasheet. To display a specific symbol, it is necessary to transfer its hexadecimal number from the sign generator table. Use the \x## sequence to embed the character code in the string.

For example, the display that is used for this example contains five symbols which can indicate a battery capacity level. Hexadecimal codes for these symbols are 9B,9C,9D,9E, and 9F. Let’s try to display these symbols on the 3rd line of the display. Let’s change the previous example patch. Leave one print-at node and set up new printing coordinates. Put the 2 value into the ROW pin and let the POS be 7. Then, put the "\x9B\x9C\x9D\x9E\x9F" sequence of the character codes into the VAL pin…

Make your project or device more attractive and informative with a text display. Get started with quickstart nodes from the xod-dev/text-lcd library. Combine strings using concat. For non-standard cases, dive deeper into the library. Use a device node together with various action nodes, such as set-backlight and clear.

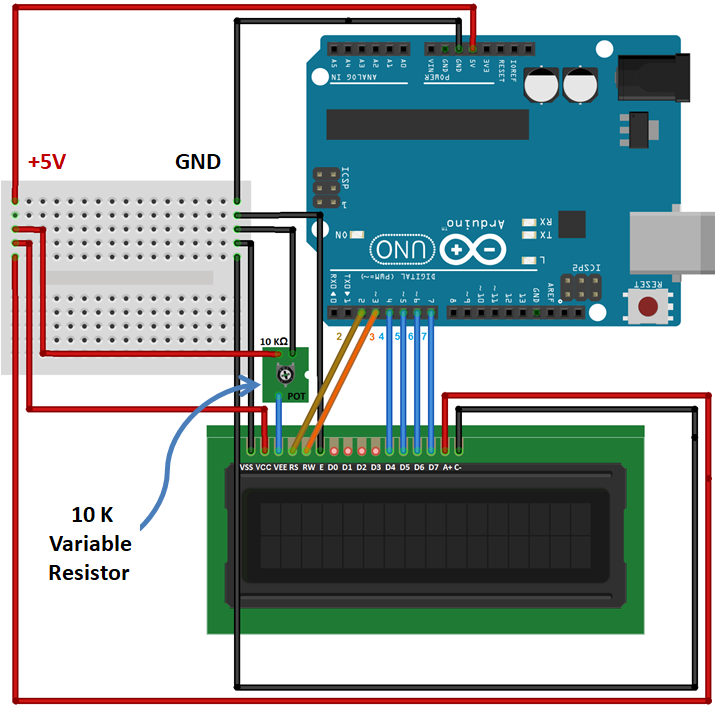

An LCD (Liquid Crystal Display) is a great way to display information in our Arduino Uno controller. We will be wiring and programming an alphanumeric, two rows with 16 characters on each row. The display has an LED (Light Emitting Diode) backlight with adjustable contrast.

This white and blue LCD will display “Hello World!” on the top line and temperature on the bottom line. The thermistor temperature circuit created last time will be displayed in both Celsius and Fahrenheit degrees. Let’s get started.

When you look at an LCD display, it is made up of a series of dots or pixels. Each of these pixels is a liquid crystal. If electricity flows through the liquid crystal it will change its structure and be more rigid. This rigidity will look darker than if no electricity is applied. If we use a light behind this LCD then the backlight will make the pixels more pronounced. So electricity on the pixel will block the light and no electricity will allow the light through. This contrast is what we see using an LCD display.

This first part will set up the library and declare the variables for the LCD display unit. Using the Steinhart-Hart Equation we declare our variables and set the coefficients for the equation.

The LCD is set up with 16 characters and 2 lines. The cursor for the LCD display is set for the first character on the first line by default. We then print the message “ Hello, World!”.

The program will calculate the temperature in Celsius (T) and in Fahrenheit (TF). The LCD cursor is then set to the second row and column 0. We can then print our temperatures and units of measure.

You will see the ‘Hello World!’ and the current temperature in two units of measure displayed on the LCD. Hold the thermistor between your fingers to see how rapidly the temperature can be read.

If you’re like most of my readers, you’re committed to learning about technology. Numbering systems used in PLCs are not difficult to learn and understand. We will walk through the numbering systems used in PLCs. This includes Bits, Decimal, Hexadecimal, ASCII, and Floating Point. To get this free article, subscribe to my free email newsletter.First Name:

This is not official manufacturer"s information. It is distilled from information on many different data sheets and from my own experience. I have never used some of these displays. I have extrapolated what I know about the displays that I have used to the ones that I have just read about. I welcome any suggestions and corrections. Contact information is at the bottom of the page.

The HD44780 type controller chip is used with a wide variety of Liquid Crystal Displays. These LCDs come in many configurations each with between 8 and 80 viewable characters arranged in 1, 2, or 4 rows.

The problem is that there is no way to inform the controller of the configuration of the display that it is driving. The controller operates exactly the same way for all displays and it is up to the programmer of the device that is controlling the LCD controller (usually a host microcontroller) to deal with this situation.

The controller contains 80 bytes of Display Data Random Access Memory which is usually referred to as DDRAM. When the controller is used with a 40 x 2 display (forty characters on each of two rows) the operation is quite straightforward and that operation will be explained first. Each of the other configurations introduces one or more quirks so it is best to understand the operation of the 40 x 2 before proceeding to the description of the operation of any of the others.

Each of these DDRAM memory addresses corresponds to a character position on an attached display, but the specific position varies depending on the configuration of that display. As part of the initialization sequence the display is cleared by storing the ASCII code for a space in each of the 80 memory locations. Subsequently if a different ASCII code is stored in any of those memory locations then the character corresponding to that ASCII code is automatically displayed at a specific location on the display.

You can tell the controller where you want the first ASCII character that you send it to be stored, this is usually address 00h. After receiving that character it will automatically update its address pointer and put the next ASCII character you send into an adjacent memory location with no more addressing work on your part. You can specify whether to increment or decrement the address counter but normally it is incremented, so the next character will be put into address 01h. The LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

Here is a simplified diagram of the display on a 40 x 2 LCD Module. Each of the boxes in the diagram represents a location where a character can be displayed.

Here is a copy of the memory map of the controller. Remember, each of the memory locations in the controller chip is directly associated with one of the character locations on the display.

By some miracle of modern technology there is actually a one for one relationship between these two diagrams. If an ASCII code is stored at address 00h in memory the corresponding character will appear at the left end of the top row of the display. If an ASCII code is stored at address 63h in memory the corresponding character will appear five locations in from the right end of the second row of the display.

Here is a diagram showing how the two rows of the display are mapped into the two lines of memory. It is basically a combination of the two diagrams just above.

When the host controller wants to display a string of characters on the display all it has to do is specify a starting DDRAM address and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another. The LCD controller takes the first code that it receives, stores it at the specified address, and simultaneously displays the corresponding character on the display. It then increments it"s internal address counter and stores the next ASCII code that it receives in the next DDRAM location which causes the corresponding character to appear in the next location on the display. As mentioned before the LCD controller automatically accounts for the gap in addresses and after storing an ASCII code in address 27h it puts the next code in address 40h. Similarly it increments from address 67h back to 00h.

This display also has 80 characters, but the relationship between the DDRAM addresses and the character locations on the LCD is not quite as straightforward as the LCD with two rows of 40 characters. Here is a diagram of the device.

The memory map is always the same regardless of the display configuration, but in this drawing I have shown a small space between addresses 13h and 14h on the first line and another between addresses 53h and 54h on the second line.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 20 x 4 LCD. Note how the right half of the previous diagram is now below the left half and note the resulting sequence of starting addresses for each display row (00h, 40h, 14h, 54h).

Remember that the LCD controller still considers this to be two lines of RAM. It is important to understand that this way of picturing the DDRAM addresses helps relate the memory addresses to the character locations but does not change the fact that as far as the controller is concerned there are only two lines of memory. In other words, although this diagram shows the DDRAM differently than before, the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display since there is no way of telling the LCD controller that there are now 4 rows of 20 characters instead of 2 rows of 40 characters.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for the 40 x 2 display. After the first row is full the characters will continue on to the third row. The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After that the following characters will appear back on the first row, and so on.

In order to get a coherent display on sequential rows it is necessary to compensate for the design of the LCD controller when programming the host microcontroller. Basically the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address.

For each of the above displays there are 80 addresses in memory and there are 80 character locations on the display so it should be obvious that any time you send an ASCII code to the controller the corresponding character will show up somewhere on the display. If you mess up the address the character may not show up where you expected it, but it will be visible somewhere. If you work back from where it actually appears you can usually figure out where you made your mistake. All of the displays that follow have fewer character locations on the display than memory addresses in the controller. This makes the operation somewhat more complicated and troubleshooting more difficult.

This can be thought of as a truncated 40 x 2 display, but there are some ramifications of this truncation that may not be readily apparent. Here is a drawing of the device.

It is important to understand that, although this diagram shows only the part of the DDRAM that is normally used to display information on the 20 x 2 LCD, the actual memory map and controller operation is exactly the same as described above for the previous displays. Again that is because there is no way of telling the LCD controller that there are only 40 characters on the attached display.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 4 display except that the addresses on the right side are greyed out.

Although this display has only 40 characters there are still 80 bytes of DDRAM and they are still configured the same as they were before. The greyed out addresses are the locations in DDRAM that do not have corrresponding locations on the display. Any ASCII codes that are written to those locations are not lost, and it is possible to display them by "shifting" the display window, but in normal use as described here they are simply not displayed.

When a long string of ASCII codes is sent to this LCD controller the action is not quite as simple as for either of the 80 character displays. Assume that the host controller is sending a string of characters as described above. Consider what happens after the LCD controller stores an ASCII code in address 13h and displays the corresponding character at the right end of the top row on the LCD. It then stores the next ASCII code in address 14h, which has no corresponding location on this 20x2 display. As more ASCII codes are sent to the LCD controller they are stored in the DDRAM but do not appear on the display until the LCD controller finally increments it"s address counter from 27h to 40h at which time subsequent characters start to appear on the second row of the display. As far as a viewer of the display is concerned there is a gap of 20 missing characters. The same thing will happen on the second row when ASCII codes are stored in addresses 54h - 67h.

In order to prevent any missing characters the program on the host microcontroller can keep track of the DDRAM addresses, and when appropriate it can set up a new starting DDRAM address. On the other hand the display can be shifted to display those missing characters, but the techniques to do that will not be covered here.

This is a commonly found configuration and its operation is almost identical to that of the 20 x 2. The relationship between the DDRAM addresses and the character locations on the LCD is a subset of the example shown above. Here is a drawing of the device.

Once again it is important to understand that although this diagram shows only the part of the DDRAM that is normally used to display information on the 16 x 2 LCD the actual DDRAM configuration and operation is exactly the same as described above for the 40 x 2 display. This is because there is no way of telling the LCD controller that there are only 32 characters on the attached display.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 display except that a different range of addresses on the right side are greyed out.

The operation of this display when a long string of characters is sent to it is that same as described for the 20 x 2 display except that there is a gap of 24 missing characters at the end of each line (instead of 20).

There are actually two different varieties of 16 x 1 LCD displays and the initialization and operation of each is different so it is important to determine which one you have.

When power is first applied to any of the multi-row LCD modules and before the controller is initialized you will see that the character locations corresponding to the first line of memory are dark and the others are light (assuming that the contrast adjustment is properly set). If you apply power to a 16 x 1 LCD module and only the left 8 character locations are dark you have what I will call a type 1 module. If only the right 8 character locations are dark this is also a type 1 module but it is upside down! If all 16 character locations are dark then it is what I will call a type 2 module. This is my own terminology used only for the purpose of keeping them differentiated while describing their operation. The type 1 modules will have only one IC on the back of the pcb while the type 2 will have 2 (I guess this tidbit gives away the source of my "type" designations). This distinction may apply to newer devices with epoxy blobs instead of ICs, but I believe that sometimes one blob may cover more than one equivalent IC function.

From this you can see that although the display has only a single row of characters, as far as the LCD controller is concerned it is using two lines of memory and it must be considered to be a 2 line device when initializing the controller.

Here is a drawing of the complete memory map. Note that this drawing is the same as the one for the 20 x 2 and 16 x 2 displays except that a different range of addresses on the right side are greyed out.

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after each 8 characters are displayed the next 32 will "disappear".

Also, to display a message of more than 8 characters on the 16 character display the host controller will have to readjust the DDRAM address after displaying the first 8 characters.

Here is a drawing of the complete memory map. Note that this memory map is different than all of the previous ones. This is the only device described here that is a true "one-line" display (see note 2) and as such it has a different memory map.

Here you can see that if the host controller sends a long string of characters after the first 16 characters are displayed the next 64 will "disappear".

At the expense of an extra IC you get some slightly easier programming since, in order to display a message of more than 8 characters on the 16 character display, the host microcontroller does not have to readjust the DDRAM address after displaying the first 8 characters.

Since only one line of memory is in use this LCD module should be configured as a 1-line device. As far as I can determine, this changes the multiplex frequency which changes the display brightness and/or contrast. Also, there are some single row LCDs that are capable of displaying a larger 5x10 font instead of the more common 5x7 font.

Here is the same memory map, rearranged this time to show how the memory addresses relate to the character positions on a 16 x 4 LCD. Note how the center of the previous diagram is now below the left part, the right part is missing, and the resulting sequence of starting addresses for each display row is different than for the 20 x 4 (00h, 40h, 10h, 50h).

Here you can see that if the host controller sends a long string of characters without periodically adjusting the DDRAM starting address then after the first row is full the characters will continue on to the third row. After the third row is full the next eight characters "disappear". The normal automatic incrementing from 27h to 40h will then cause the display to continue on the second row, and from there it will continue to the fourth row. After the fourth row is full the next eight characters will "disappear" and then it"s back to the first row.

The 40 x 4 LCD is treated essentially as two 40 x 2 devices stacked one on top of another in the same glass enclosure. Electrically it uses what amounts to two HD44780 controller chips and it therefore has two separate memory maps each with the same address range. One is used for the top two lines and the other is used for the bottom two lines. The memories are accessed individually by strobing the desired Enable pin of which there are now two. Here is a diagram of the device.

To display a really long string of characters on this display the host controller would start out just like it did for the 40 x 2 display. It would specify a starting DDRAM address (typically 00h) and then start sending the string of ASCII codes corresponding to the desired characters to the LCD controller, one after another, making sure to strobe the enable pin associated with the upper memory bank. After storing an ASCII code in address 67h the LCD controller will automatically increment to address 00h as before and at this time the host controller must stop strobing the enable pin for the upper bank and start strobing the one for the lower bank.

There are other LCD configurations available but I believe that any of them can be handled by a technique similar to one of the examples above. If you have a display that seems to be considerably different from any of these I would like to hear from you.

(1) The mysterious gap is due to considerations resulting from the multiplexing of the display. The DDRAM addressing uses seven bit addressing and the highest bit signifies which row of memory is involved. If you compare the addresses in the first row with those just below in the second row you will see that the only difference is in that one bit.

(2) As implied above the number of rows of characters that can be displayed on the LCD is not the same as the number of lines of memory used by its controller. Only some of the 16x1 displays use "one line" of memory, all of the other displays including most 16x1 displays, use "two lines" of memory.

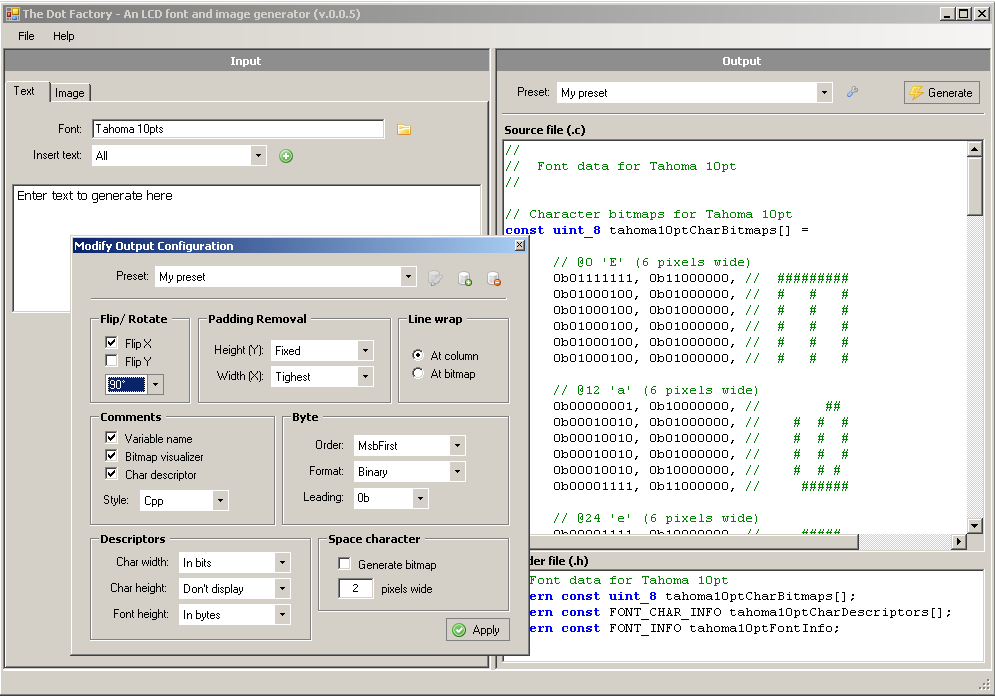

The Dot Factory is a small open source tool (MIT licensed) intended to generate the required C language information to store many fonts and images, as efficiently as possible, on a microcontroller. These fonts are then uploaded via the LCD driver (see the Drivers and Modules page for a few) to the actual dot matrix LCD. It is written in C# for Visual Studio 2008 and has been tested on Windows XP, 2003, Vista, 7 and Linux via Mono.

Working with dot matrix LCDs with microcontrollers, while not difficult, is tedious. The actual LCD controller allows us to upload simple visual data (dot on or dot off) into the LCD’s dot matrix, but not much else. It is up to our software to decide what to upload when we want to draw lines, circles and more importantly – text.

While there are software graphic libraries that allow us to generate a character “on the fly” using vector graphics (the character is described as a series of drawing commands that allow scaling and decoration) – these are much too complex and large to integrate in a microcontroller environment. Consequently, we must store the exact appearance of a character as a series of 1s and 0s, equivalent to a “dot on” “dot off” on the LCD, and upload this as a bitmap when we want to display text. While it is possible to generate this manually, it is desired to have a tool to do our grunt work by converting windows fonts (given a size and decoration) into a series of bitmaps.

TDF is comprised of two panes – the input pane on the left (what you want to generate) and the output pane on the right (the generated output, in C code). The input pane can accept either a font of your choice (for writing text to the LCD) or an image. When generating a font, you have the option of either generating all the available letters (by selecting “All” in the Insert Text box and clicking the plus button) or by typing in which letters, numbers or symbols you are actually using in your application (for example: 0123abcd). If you are writing a simple application that has only a few sentences, you can type them wholly in this box without fear of duplicating letters – TDF takes care of that by discarding any duplicates. This way only the letters you use will take up space.

Once you have completed setting up what it is you’d like to generate (be it an image or font), select the output method in the output pane. If you are using the LCD drivers on this website, you want it to generate an MSb first output, otherwise images will come out wrong. If you have a compiler that supports the “0b” binary specifier, you can select “binary” rather than “hex”. This will allow you to visually see the pixels you will set and allow for manual touch up by the user without having to calculate hex and experimentation. Click generate and your C code will be outputted to the text box below. Copy paste this into your application (it is recommended to put this in a separate module, not your LCD driver module, for organizational reasons).

The character bitmap array: This holds the actual characters as a bitmap (only the characters selected in the input pane). Each byte represents a single vertical page sent to the LCD. All vertical padding is removed from the characters

The character descriptor array: Allows O(1) mapping between a character’s ASCII value and required meta information about the character – namely its width in bits and its offset into the character bitmap array. When the LCD driver needs to find where character X is located in the bitmap array, it will jump to index [X - font.startCharacter] in the descriptor array. The startCharacter is the first character (that is, the character with the lowest ASCII value) used for this font. By defining a startCharacter we can reduce the number of elements in the descriptor array.

The font information: This element is essentially the font descriptor for this font. It holds information regarding this font like the name of the character bitmap and descriptor arrays, the font start character and how many pixels wide a space character is for this font. The LCD driver will replace the space character with empty pixels (this saves both processing time, space in the character bitmap array and space in the character descriptor array – since the space is the first ASCII character and is commonly used).

Version 0.1.1 (25may11): Added support for multiple descriptor arrays with a double lookup. Before this version TheDotFactory could generate Unicode characters but the lookup tables were usually too huge to be of any use. Using this feature, a double lookup is employed, allowing for fast lookups for characters residing at disparate ranges. See the video for an explanation (will be posted in the next few days). In addition to this, added support for specifying character ranges instead of inputing the actual characters. For example, <<100-120>> will generate characters for ASCII characters 100 to 120. Thanks a bunch to Archis Bhave for inputs and testing. Source is now distributed via github.

Version 0.0.7 (28may10): Added ability to select whether character descriptor array is to be created and which character will be used to visualize the font (thanks Christian Treczoks), syntax coloring automatically disabled when generating large amounts of text (will be fixed properly next version), properly handled bitmaps with no black pixels in them (displays error instead of a crash), some minor cosmetics

Use this method/macro to send a specific command to the LCD. Refer to the Matrix Multimedia EB006 datasheet for a list of supported instructions. For Non-Matrix LCD"s refer to the manufacturers datasheet.

In this digital age, we come across LCDs all around us from simple calculators to smartphones, computers and television sets, etc. The LCDs use liquid crystals to produce images or texts and are divided into different categories based on different criteria like type of manufacturing, monochrome or colour, and weather Graphical or character LCD. In this tutorial, we will be talking about the 16X2 character LCD Modules.

The 16x2 LCDs are very popular among the DIY community. Not only that, but you can also find them in many laboratory and industrial equipment. It can display up to 32 characters at a time. Each character segment is made up of 40 pixels that are arranged in a 5x8 matrix. We can create alphanumeric characters and custom characters by activating the corresponding pixels. Here is a vector representation of a 16x2 LCD, in which you can see those individual pixels.

As the name indicates, these character segments are arranged in 2 lines with 16 characters on each line. Even though there are LCDs with different controllers are available, The most widely used ones are based on the famous HD44780 parallel interface LCD controller from Hitachi.

Vo / VEE Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

The 16x2 LCD modules are popular among the DIY community since they are cheap, easy to use and most importantly enable us to provide information very efficiently. With just 6 pins, we can display a lot of data on the display.

The module has 16 pins. Out of these 16 pins, two pins are for power, two pins are for backlight, and the remaining twelve pins are for controlling the LCD.

If you look at the backside of the module you can simply see that there are not many components. The main components are the two controller chips that are under the encapsulation. There is an onboard current limiting resistor for the backlight. This may vary from different modules from different manufacturers. The only remaining components are a few complimentary resistors for the LCD controller.

In the module PCB, you may have noticed some unpopulated footprints. These footprints are meant for charge pump circuits based on switched capacitor voltage converters like ICL7660 or MAX660. You can modify your LCD to work with 3.3V by populating this IC and two 10uF capacitors to C1 and C2 footprint, removing Jumper J1 and adding jumper J3. This modification will generate a negative contrast voltage of around 2.5V. This will enable us to use the LCD even with a VCC voltage of 3.3V.

To test whether a 16x2 LCD works or not, connect the VDD, GND and backlight pins to 5v and GND. Connect the centre terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND. Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working

There are 16 pins on the display module. Two of them are for power (VCC, GND), one for adjusting the contrast (VEE), three are control lines (RS, EN, R/W), eight pins are data lines(D0-D7) and the last two pins are for the backlight (A, K).

The 16x2 LCD has 32 character areas, which are made up of a 5x8 matrix of pixels. By turning on or off these pixels we can create different characters. We can display up to 32 characters in two rows.

Yes, we can. We can store up to eight custom characters in the CGRAM (64 bytes in size) area. We can create load the matrix data for these characters and can recall when they need to be displayed.

Controlling the LCD module is pretty simple. Let’s walk through those steps. To adjust the contrast of the LCD, the Vo/ VEE pin is connected to a variable resistor. By adjusting the variable resistor, we can change the LCD contrast.

The RS or registry select pin helps the LCD controller to know whether the incoming signal is a control signal or a data signal. When this pin is high, the controller will treat the signal as a command instruction and if it’s low, it will be treated as data. The R/W or Read/Write pin is used either to write data to the LCD or to read data from the LCD. When it’s low, the LCD module will be in write mode and when it’s high, the module will be in reading mode.

The Enable pin is used to control the LCD data execution. By default, this pin is pulled low. To execute a command or data which is provided to the LCD data line, we will just pull the Enable pin to high for a few milliseconds.

To test the LCD module, connect the VDD, GND, and backlight pins to 5v and GND. Connect the center terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND as per the below connection diagram-

Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working.

Let’s see how to connect the LCD module to Arduino. For that first, connect the VSS to the GND and VDD to the 5V. To use the LCD backlight, connect the backlight Anode to the 5V and connect the backlight cathode to the GND through a 220Ωresistor. Since we are not using the read function connect the LCD R/W pin to the GND too. To adjust the contrast, connect the centre pin of a 10KΩ trimmer resistor to the VEE pin and connect the side pins to the VCC and GND. Now connect the registry select pin to D12 and Enable pin to D11.

Now let’s connect the data pins. The LCD module can work in two modes, 8-bit and 4-bit. 8-bit mode is faster but it will need 8 pins for data transfer. In 4-bit mode, we only need four pins for data. But it is slower since the data is sent one nibble at a time. 4-bit mode is often used to save I/O pins, while the 8-bit mode is used when speed is necessary. For this tutorial, we will be using the 4-bit mode. For that connect the D4, D5, D6 and D7 pins from the LCD to the D5, D4, D3 and D2 pins of the Arduino.

The following Arduino 16x2 LCD code will print Hello, World! on the first line of the display and the time the Arduino was running in seconds on the second line.

Now let’s discuss the code. As usual, the sketch starts by including the necessary libraries. For this tutorial, we will be including the LiquidCrystal library from Arduino. This library is compatible with LCDs based on the Hitachi HD44780, or any compatible chipset. You can find more details about this library on the Arduino website.

Let’s create an object to use with the LiquidCrystal library. The following line of code will create an object called lcd. We will be using this object in the entire code to access the library functions. The object is initialized with the pin numbers.

Now let’s look at the setup()function. The lcd.begin function is used to initialize the LCD module. This function will send all the initialization commands. The parameters used while calling this function are the number of columns and the number of rows. And the next function is lcd.print. with this function, we have printed the word Circuit Digest! to the LCD. Since the LCD cursor is set to home position within the lcd.begin, we don’t need to set any cursor position. This text will stay there for two seconds. After that, the text will scroll from left to right until the entire text is out of the display. To scroll the display to the right, we have used the function lcd.scrollDisplayRight. After that, to clear display, we used lcd.clear, this will clear any characters on the display.

Now let’s look at theloop function. The for loop will count from 0 to 9, and when it reaches 9, it will reset the count and repeat the process all over again. lcd.setCursor is used to set the cursor position. lcd.setCursor(8, 1) will set the LCD cursor to the eighth position in the second row. In the LCD, the first row is addressed as 0 and the second row is addressed as 1. And the lcd.print(i) will print the count value stored in the variable i to the display.

Wrong characters are displayed: This problem occurs usually when the LCD is not getting the correct data. Make sure you are sending the correct ASCII value. If you are sending the correct ASCII characters, but still showing the wrong one on the LCD, check your connections for loose contact or short circuits.

Display shows Black boxes or does not show anything: First thing to do in these situations is to adjust the contrast voltage by rotating the variable resistor. This will correct the contrast value and will give you a visible readout.

Contrast is Ok, but still no display: Make sure to provide a sufficient time delay in between sending each character. Because if you don’t give enough time to process the data the display will malfunction.

Contrast and delay are ok, but still no display: Make sure you are powering the LCD from a 5V source. By default, these displays won’t work with a supply voltage below 5V. So if you are using the display with a 3.3V microcontroller make sure to power the display from 5V and use level shifters in between the display and the microcontroller.

In this project we will provide the input voice using Google Voice Keyboard via a Android App (BlueTerm) and print the text on 16x2 LCD using Raspberry Pi.

In this tutorial we are interfacing a Liquid Crystal Display (LCD) module with the Raspberry Pi Pico using Micropython to display strings, and characters on the LCD.

We used some Python scripts to find the local IP address of your Raspberry Pi on the network and display it on the 16x2 LCD Screen. We also added the script in the Crontab so that it can be run on every 10 minutes and we will have the updated IP address every time.

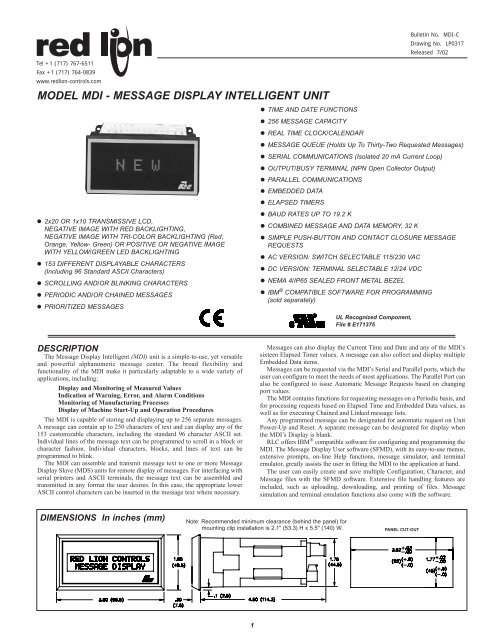

In this case, D500 is the MRR that the OIT has been configured to poll once every 200 milliseconds. When input coil X1 is activated, the controller puts the decimal number 30 into the MRR. The OIT then sees the number 30 in the MRR and Displays Screen #30

Maple Systems OITs can be programmed to send the number representing the screen currently Displayed on the OIT to a register in the controller called the Current Message Register (CMR). The CMR can be used by the controller to determine which screen is currently being Displayed on the OIT, whether Displayed due to MRR, Set Point Limit, Function Key, etc. This might be used to determine which screen an OIT operator sees in a chained sequence.

Clear Alarm is monitored by the OIT to allow the controller to clear the currently Displayed alarm. When the controller sets this coil, the OIT cancels the alarm in progress.

The controller"s discrete and register memory can be monitored, Displayed, and updated by the OIT. This can be done by configuring the OIT"s screens to Display the controller"s discrete and register memory as embedded data fields (register monitors). When the OIT Displays a screen containing a register monitor, the OIT reads the specified memory address in the controller and then Displays the data. If the register monitor has been configured as read/write, when the operator changes the data in the register monitor on the OIT"s Display, the OIT writes the change to the controller"s memory.

Lcd stands for liquid crystal display. Character and graphical lcd’s are most common among hobbyist and diy electronic circuit/project makers. Since their interface serial/parallel pins are defined so its easy to interface them with many microcontrollers. Many products we see in our daily life have lcd’s with them. They are used to show status of the product or provide interface for inputting or selecting some process. Washing machine, microwave,air conditioners and mat cleaners are few examples of products that have character or graphical lcd’s installed in them. In this tutorial i am going to discuss about the character lcd’s. How they work? their pin out and initialization commands etc.

Character lcd’s come in many sizes 8×1, 8×2, 10×2, 16×1, 16×2, 16×4, 20×2, 20×4, 24×2, 30×2, 32×2, 40×2 etc .Many multinational companies like Philips, Hitachi, Panasonic make their own custom type of character lcd’s to be used in their products. All character lcd’s performs the same functions(display characters numbers special characters, ascii characters etc).Their programming is also same and they all have same 14 pins (0-13) or 16 pins (0 to 15).

In an mxn lcd. M denotes number of columns and n represents number of rows. Like if the lcd is denoted by 16×2 it means it has 16 columns and 2 rows. Few examples are given below. 16×2, 8×1 and 8×2 lcd are shown in the picture below. Note the difference in the rows and columns.

On a character lcd a character is generated in a matrix of 5×8 or 5×7. Where 5 represents number of columns and 7/8 represent number of rows. Maximum size of the matrix is 5×8. You can not display character greater then 5×8 dimension matrix. Normally we display a character in 5×7 matrix and left the 8th row for the cursor. If we use the 8th row of the matrix for the character display, then their will be no room for cursor. The picture below shows the 5×8 dot matrix pixels arrangement.

To display character greater than this dimension you have to switch to graphical lcd’s. To learn about graphical lcds here is a good tutorialGraphical Lcd’s Working and Pin out.

The picture above shows the pin out of the character lcd. Almost all the character lcd’s are composed of the same pin out. Lcd’s with total pin count equal to 14 does not have back light control option. They might have back light always on or does not have a back light. 16 total pin count lcd’s have 2 extra A and K pins. A means anode and K cathode, use these pins to control the back light of lcd.

Character Lcd’s have a controller build in to them named HD44780. We actually talk with this controller in order to display character on the lcd screen. HD44780 must be properly handled and initialized before sending any data to it. HD44780 has some registers which are initialized and manipulated for character displaying on the lcd. These registers are selected by the pins of character lcd.

When we send commands to lcd these commands go to Command register and are processed their.Commands with their full description are given in the picture below.When Rs=0 command register is selected.

When we select the register Rs(Command and Data) and set Rw(read – write) and placed the raw value on 8-data lines, now its time to execute the instruction. By instruction i mean the 8-bit data or 8-bit command present on Data lines of lcd. For sending the final data/command present on the data lines we use this enable pin.Usually it remains en=0 and when we want to execute the instruction we make it high en=1 for some mills seconds. After this we again make it ground en=0.

To set lcd display sharpness use this pin. Best way is to use variable resistor such as potentiometer a variable current makes the character contrast sharp. Connect the output of the potentiometer to this pin. Rotate the potentiometer knob forward and backward to adjust the lcd contrast.

NOTE: we can not send an integer, float, long, double type data to lcd because lcd is designed to display a character only. Only the characters that are supported by the HD44780 controller. See the HD44780 data sheet to find out what characters can we display on lcd. The 8 data pins on lcd carries only Ascii 8-bit code of the character to lcd. How ever we can convert our data in character type array and send one by one our data to lcd. Data can be sent using lcd in 8-bit or 4-bit mode. If 4-bit mode is used, two nibbles of data (First high four bits and then low four bits) are sent to complete a full eight-bit transfer. 8-bit mode is best used when speed is required in an application and at least ten I/O pins are available. 4-bit mode requires a minimum of seven bits. In 4-bit mode, only the top 4 data pins (4-7) are used.

Command 0x30 means we are setting 8-bit mode lcd having 1 line and we are initializing it to be 5×7 character display.Now this 5×7 is some thing which every one should know what it stands for. usually the characters are displayed on lcd in 5×8 matrices form. where 5 is total number of columns and is number of rows.Thus the above 0x30 command initializes the lcd to display character in 5 columns and 7 rows the last row we usually leave for our cursor to move or blink etc.

NOTE:You can send commands in hexadecimal or decimal form which one do you like the result is same because the microcontroller translate the command in 8-bit binary value and sends it to the lcd.

Character Lcd’s can be used in 4-bit and 8-bit mode.Before you send commands and data to your lcd. Lcd must first be initialized. This initialization is very important for lcd that are made by Hitachibecause they use HD44780 driver chip sets. Hd44780 Chip set first has to be initialized before using it. If you don’t initialize it properly you will see nothing on your lcd.

In 4-bit mode the high nibble is sent first before the low nibble and the En pin is toggled eachtime four bits is sent to the LCD. To initialize in 4-bit mode:

To learn more about the difference between 4-bit and 8-bit character lcd mode and operation with demo example visit the tutorial link given below. Demo examples are very easy to understand and one can make changes easily in the code. Please also give us your feed back on the post.

![]()

Bought this from Robotshop retailer. Worked right away like a charm. I even changed splash screen to display my software version. However at some point it stopped displaying text, then backlight started spontaneously switching off several seconds after powering on. I connected LCD to different device and started experimenting just sending one command at a time.

ALL 0xFE commands work just fine. I am able to switch display on/off, change between underline and blinking cursor, directly position cursor on screen and scroll screen around. 0x7C commands work too, I can control backlight and turn splash screen on/off. Reset 0x12 also works.

The only thing that does not work is actual text display. I tried all acsii characters at different cursor locations. It seems that something is going on, at least cursor jumps to 2nd line after printing 16 characters (does not move otherwise), except characters are invisible. Note that splash screen still works, with exact text I put there!

My only complaint with this product is the difficulty in mounting. Finally had to drill out the holes to accept 4-40 standoffs. The Eagle files don"t include the complete board so making a screw hole template from the PCB is impossible. Otherwise works fine with my stand alone Atmega 328P using the SerLCD.h and SoftwareSerial.h libraries.

Does anybody know how to do a hard reset on this LCD? While I was uploading my code, I left it plugged into TX, and it doesn"t work anymore. I"m realizing that it probably got spammed with commands and the configuration got messed up. Does anybody know how to reset to factory defaults?

I have the same question. I now have the 3.3v serial enabled LCD (with backpack) and want to use this one for future usage. VDD of 5V can be supplied, but will the TTL work when its getting 3.3V signals from the TX from Netduino?

I"ve put together some python code for sending serial data to these LCD screens. In particular, the code pulls my twitter status and writes it to the LCD. To work with the extra characters, I wrote functions to page the text (vertical scroll) or scroll the text (horizontal scroll). Details are available here: http://dawes.wordpress.com/2009/12/23/twitter-to-lcd/

Is it possible to wire this up in parrellel rather than use the serial function? I ran into a snag and am unable to use the serial function of this lcd? I see the pinouts on the schematic but when wired it doesn"t seem to work.

I"ve created a new splash screen for the Serial LCD, now I want to save it to the Serial LCD memory. So, exactly how do I write a "control-j" to the Serial LCD. I"ve put in the required line to transmit special character 124, but I can figure out how to format the "control-j" line of code. I"ve Googled this for about an hour and can"t find an explanation or sample code anywhere. Here"s my code...void setup() {

I"m not sure if you"re referring to comments on the website, or on your LCD screen. You can contact techsupport@ and they"ll be able to assist you further.

I have used a Labview program for this LCD. When i send character "a", the display is "0". Does anyone having a same problem. How should I troubleshoot this problem.Tq

Has anyone managed to get the PWM backlighting working with an Arduino? I"m trying variations of this and nothing works except the standard On/Off commands using 0xFE as the escape. All my attempts turn the display off but the backlight LED is on full.

Why do I get power out of the VDD port with only RX and GND hooked up? I have a 5V rail that I use to power everything on my board - and when I added this SerLCD I now have a bridge between the arduino power and my 5v line ... which I dont want. Can I add a diode to the VDD to stop reverse voltage from powering my board?

It seems like the MCLR function has been disabled through the config bits. No pullup to Vdd is installed. This makes it really irritating to work with this display. Programming an arduino with this hooked the HW serial port will screw up the display, and without the reset line you have to pull power. A simple solution would just be to wire the PICs MCLR pin to the Arduinos reset line, but this isn"t possible without the MCLR function obviously.

Quick suggestion... It"d be very helpful for some people if you guys added a note in the description pointing people to the correct 3-pin JST jumper wire to be used with these serial LCDs. Two reasons... it"s not clear that the jumper is not included, and you have 3-pin jumpers in your catalog which don"t work with this serial LCD.

I have ported LiquidCrystal library for use with the serial LCD you can look at my code here. Still working on finishing all the documentation. But putting up for now hopefully someone will find it usefull.

I"m also having the same problem after accidentally sending the control character "|" followed by "\", "-", "/" to the LCD as I was trying to animate a rotating bar to indicate a busy status.

The baud rate problem can be solved by writing at 9600, at startup, a "change baud rate" command to the target rate. At worst, the display is already at the target rate and will misinterpret the command and display garbage, at best, it will be set to the right baud rate.

Does the serial version of the display still have the parallel pins available on it? I would like to use the serial access for the most part, but I might need regular old parallel for one project.

Yes you can, but you are limited to only 8 custom characters. First define 8 bytes that will hold your custom character, one byte per line (obviously only the lower 5 bits can be used since this is a 5x8 display). Then decide which character (from 0-7) you want to set. Call this "x". Then do this pseudocode:

I"m surprised that a mechanical drawing is not included in the data sheet. It"s not too hard to measure but seems like a documentation oversight for anyone who wants to integrate the display into a case.

Having ordered this exact LCD myself, I can say that aside from the issue mentioned in my other comment, it looks exactly like the picture. No bulky backpack module, everything is on a single board. Pretty sleek, really.

Hi...noob question. how do i send data on the fly via arduino? it only has 1 connection to tx. i tried using the serial monitor to send something, but it doesnt work...im looking for something which i guess is similar to liquidCrystal->SerialDisplay example.

Nevermind, my own fault. I calculated the wrong offset to the start of the second line when I repositioned the cursor. Although the second line was displayed correctly, the offset was wrong by -32.

The data stream I tapped into once inadvertently changed the backlight level to something less than 100%, and I noticed that the dimmed display had a noticeable flicker.

I have a couple of suggestions for a future version: On the PCB layout, please add a thermal to the ground pin for the user connectors to make it easier to hand solder. Please change the firmware to make it more difficult for a random serial stream to stumble upon a configuration sequence. Maybe pick a non-printable prefix character like ESC instead of the vertical bar. Please make the brightness values more user friendly, like 1, 2, 3, etc. Maybe have an option to make the display scroll when it gets full, instead of resetting the cursor to home and overwriting. All-in-all, a fun little platform. Thanks for using a PIC on this one! I think I may try my hand at writing some new firmware for it. Cheers!

Edit: Got mine fixed. If you checked the soldering on all the terminals, check them again. I also sometimes was getting strings of garbage if I wriggled the terminals on the LCD (I suspect because I was getting a partial connection on the bad terminal). Resoldered and it is working fine now.

Wait, so I get the 3 pins for power and control, but whats with all the other pins on the sides? Can it be used to control another LCD besides the one built in?

The other pins are used if you want to control the LCD without using the serial standard. There"s some tutorials on how to do that with the arduino below. You have more control over what you can do with it, but it takes up more pins on the arduino. If you want to wire it up this way, don"t spend the money on the serial interface, they have cheaper LCD"s that allow you to do it this way, without the serial.

Parallax 20 x 4 serial backlit mono LCD display. The Parallax Serial LCDs are very functional, low-cost liquid crystal displays that can be easily interfaced to and controlled by a microcontroller using a I/O pin. Code examples are included for the BASIC Stamp® and Propeller™ chip. The LCD displays provide basic text wrapping so that your text looks correct on the display. Full control over all of their advanced LCD features allows you to move the cursor anywhere on the display with a single instruction and turn the display on and off in any configuration. They support the same visible characters as the BASIC Stamp Editor"s Debug Terminal (ASCII Dec 32-127). In addition, you may define up to eight of your own custom characters to display anywhere on the LCD. Clear 4 line x 20 character display Turn backlighting on or off with a single command Directly supports ASCII DEC characters 32-127 Eight user-definable custom characters Move the cursor anywhere on the display with a single command Baud mode selector and adjustable contrast on the back of the display Power requirement: +5Vdc, 20mA (light off), 80mA (light on) Selectable UART serial baud rates: 2400, 9600, 19200 Dimensions: 60.2 x 98.1mm Operating temp range: -20 to +70°C

The Display Data RAM holds the letters that get shown on the LCD of a character LCD module. For instance the letter ‘A’ is stored in its ASCII equivalent 65DEC (0x41HEX) in the DDRAM.

So a 20×2 character LCD would have enough DDRAM to store 40 letters. The value in the DDRAM is used to find the correct bitmap in the CGROM (Character Generator ROM) or CGRAM (Character Generator RAM), it is this small bitmap that gets displayed on the LCD.

Therefore on the 1st Parameter: "0" (Column); (Considering you"re reading from Left to Right and Top to Bottom); You Set the Cursor on the very 1 Column on the LCD.

Make sure you’re using the correct library (I2C library: if your LCD has the module: use a compatible I2C Library; and specify the LCD parameters accordingly).

Not clearing the LCD whenever there is New data can simulate the effect of weird characters; but actually they are old data characters that remained there.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey