ascii lcd display in stock

Displaying ASCII characters on MXN lcd is very easy. Where M represents number of coulombs and N number of rows. You just need to know about the internal structure of character lcds, registers of character lcds and the characters supported by lcd controller. Below tutorial will help you in knowing about the internal structure of lcd.

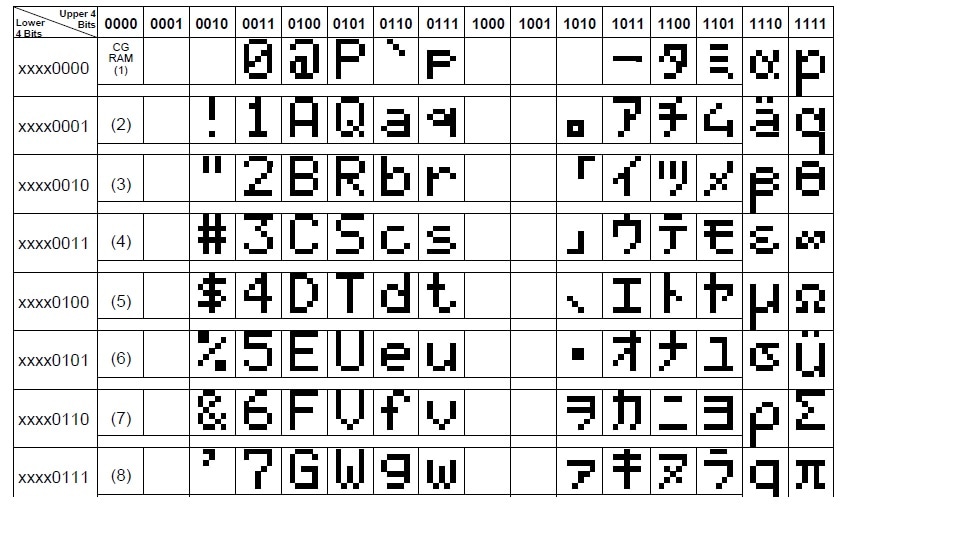

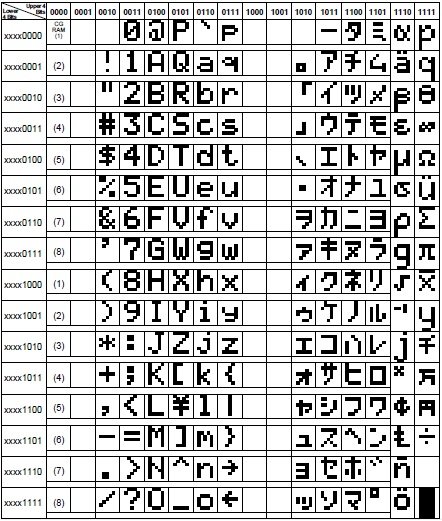

Normally lcd contains HD44780 controller in them. Hd44780 is responsible for all the communications with external controller and displaying text on lcd screen. HD44780 is designed by Hitachi and it supports 255 characters. Which means you can display 255 different characters on lcd directly through its controller. The supported characters are ASCII, Digits(0,9) and Japanese characters. Refer to data sheet of controller if you want to know about all characters and their address in ROM of hd44780 lcd controller.

Now to display ASCII character on 16×2 lcd simply pass the address of the ASCII characters present in 16×2 lcd controller ROM(read only memory). I did same in my code. Started from the first character and prints all of them one by one on lcd. Some characters are missing in ROM of hd44780 and special Japanese language characters are present on their locations. So some Japanese language characters will also be displaced on lcd. Few characters in ROM are greater than 5×10 font. These characters will not appear on lcd. Their decimal value will be displayed on lcd but they will not appear on the lcd.

NOTE: You will see some spaces and weird shape characters displayed on lcd. Those characters are present in controller of 16×2 lcd that’s why they are displayed on lcd. Some Japanese characters will also be displayed on lcd. All the characters present in lcd controller will be displayed on lcd. Characters present in HD44780 lcd controller are given below. Pic is taken from data sheet of hd44780 lcd controller.

Coming to the project code. On first row of 16×2 lcd decimal values of ASCII characters will be displayed and on second row ASCII characters will be displayed. ASCII characters start from 34 location of the hd44780 ROM location. So in code i started the ASCII characters from 34th location.

Each character will appear on 16×2 lcd for 1 second after 1 second it disappears and the next ASCII character will appear on 16×2 lcd with its corresponding decimal value.

Some more projects on displaying ASCII characters on 16×2 lcd using various microcontrollers. Each project code is open source. You an use and modify it according to your needs.

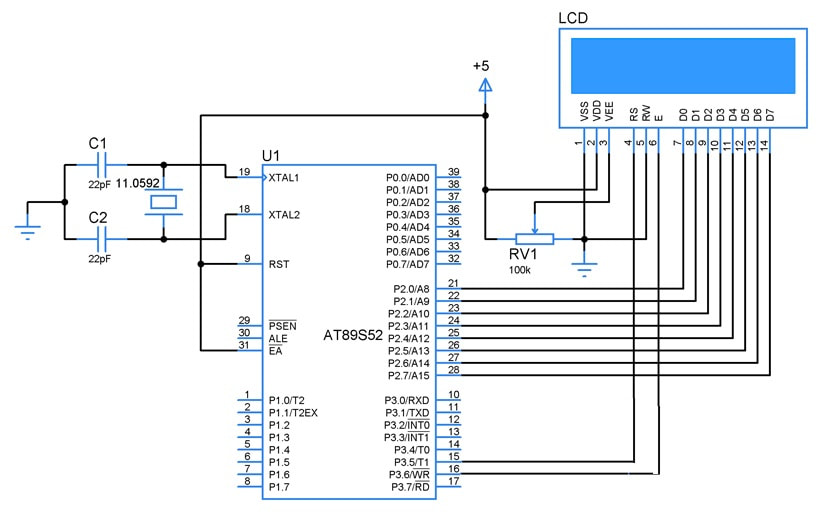

In this tutorial i am going to print/display ASCII characters on 16×2 lcd using pic16f877 microcontroller. Lcd is interfaced with pic microcontroller in 8-bit mode. Code is written in c language. High tech c compiler is used to compile code and code is written in Mp-lab ide. Interfacing 16×2 lcd with pic microcontroller and displaying characters on lcd is very easy. Only the portion which is little bit complex is how to generate/display ASCII characters on lcd. Well you don’t need to generate ASCII characters they are already present in the 16×2 lcd controller (HD44780) Ram, like other characters and numbers. You just need to know how to invoke the ASCII characters to be displayed on the lcd screen.

If you are new in the field of microcontrollers and lcd’s and don’t know about lcd pin out, working and internal structure of lcd then please go through the following tutorials. They will clear you about the working of 16×2 lcd. You will learn how to display characters on lcd? Difference between commands and data send to lcd? It will also explain you about how to use lcd in 4-bit and 8-bit mode.

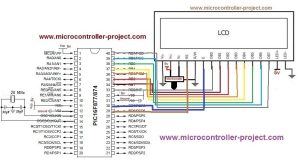

The circuit diagram of the project is given below. Port-B of Pic16f877 microcontroller is connected with data pins of 16×2 lcd. It means Port-B is used to send commands and data to 16×2 lcd. Lcd control signals(read/write, enable, register select) are provided using individual bits of Port-D. All the other connections are normal connections applying +5 volts to microcontroller and lcd. You can see the circuit diagram given below. Rs(Register select) is connected to Port-D Pin#6. En(Enable) is connected to Port-D Pin#7. Read/Write pin is grounded. Lcd will always remain in write state since we made the R/W pin ground.

Coming to the code portion, I first include the header file htc.h. If you are using high tech c compiler always include this library, this library is necessary to be included in every project that is going to be compiled with high tech c compiler. It contains the compilers directives etc. Then the frequency of the oscillator is defined which is 20 MHz. Then individual pins of Port-D are defined. These pins are used to provide control signals to lcd. delay() function is used to generate some arbitrary delay where necessary. lcdcmd() function is sending commands to lcd with control signals. display() function is sending data to lcd with control signals. lcdint() function is initializing our lcd(8-bit mode, display on ,cursor off etc).

In the main function two instructions are invoking ascii characters. The instructioni=j/10; wherej is integer(int) and i is character(char). Now when we divide two integers and save result in character(char) variable. The result is stored in ascii format. Sincej is 0 and dividing 0 by 10 gives 0. So icontains 0, ASCII value of zero.

The ascii character 0 is present at address 0x30. To go to address 0x00 negate 0x30 from 0x30. The instruction i=i-0x30; is doing the same job. First i contains 0x30 after executing i=i-0x30 i contains 0x00. Hence we are at starting address of ascii characters. Now increment the address one by one and display the ascii character associated with that address on the lcd screen.

Notethat the ascii characters of the HD44780 controller differs from the standard ascii characters. The HD44780 controller contains ascii characters in the format given on the right side. Some addresses are also void. So don’t get confused when you see the characters like below displayed on your lcd screen.

Total digits in ram of 16×2 lcd are 256. So i decided to display them all. It contains ASCII, numeric, alphabet and special characters(Chinese). Some address are void so nothing will display on the lcd screen across these addresses.

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

When current is applied to these crystals, they become opaque, blocking the backlight that resides behind the screen. As a result that particular area will be dark compared to the others. And this is how the characters are displayed on the screen.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. For example, if we want to see an uppercase ‘A’ character on the display, we set these pins to 0100 0001 (as per the ASCII table).

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

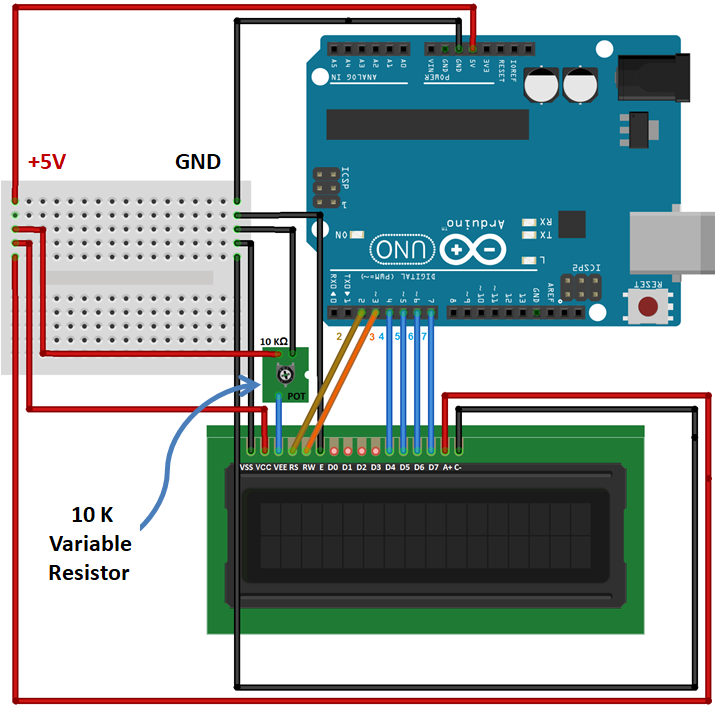

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

It depends on the exact model of LCD you are using. Or more exactly, on the Dot Matrix Liquid Crystal Display Controller/Driver, like the Hitachi HD44780U that is used in many 16x2 LCD.

In this table, the char "°" is at col 0b1101, row 1111, (0xDF, or 223). But, you have to cast that value to a char before displaying, otherwise you will get the value (223), not the symbol.

This 2×16 character LCD Module with BLUE Backlight uses an I2C interface to communicate with the host microcontroller. This budget-conscious LCD is used on projects requiring the display of text, data, or ASCII characters of all types. Connect to Vcc, Gnd, SDA (serial data line), and SCL (serial clock line). This is a 5VDC device and will be found on the I2C bus at address 0x27 / 0x3F.

In the previous chapter, we have discussed how a character LCD is interfaced with a PIC microcontroller in 8-bit mode, where we used predefined characters stored in the LCD to display our data. In this article, we will learn more about the LCD and how we can create and use custom characters.

DDRAM or “Data Display Random Access Memory” is the working data buffer of the display. Each character on the display has a corresponding DDRAM location and the byte loaded in DDRAM controls which character is displayed.

CGROM or “Character Generation Read Only Memory” holds all the standard patterns for the 5 x 7 dot matrix characters. For instance, if you want to display character “A”, you would send ASCII code 65 (decimal) to the DDRAM. The display controller looks up the pattern of dots to display for this code in the CGROM and lights up the ones appropriate for “A”. The CGROM contents depend on the particular character set and model of display, US, Chinese etc. and cannot be changed.

CGRAM or “Character Generation Random Access Memory” allows the user to define special supplementary non-standard character types that are not in the CGROM. You can load your own dot pattern shapes and call these up for display.

For making custom patterns we need to write values to the CGRAM area defining which pixel to glow. These values are to be written in the CGRAM address starting from 0x40. CGRAM has a total of 64 Bytes. For LCD using 8×5 dots for each character, you can define a total of 8 user defined patterns (1 Byte for each row and 8 rows for each pattern).

Custom characters are assigned fixed display codes from 0 to 7 for pattern stored in the location pointed by CGRAM address 0x40, 0x48, 0x56… and so on. So, if the user wants to display second pattern (pattern stored at CGRAM address 0x48), simply call the data function with value 1 as an argument at a desired location in the LCD.

To display the sequence in the LCD, we need to specify the position on LCD and which pattern to display at the position. Provide adequate delay in between frames to observe the sequence distinctly.

Send bytes with the bit patterns for your symbol(s). The LCD controller automatically increments CGRAM addresses, just as it does cursor positions on the display.

To leave CGRAM, switch to COMMAND MODE to set the address counter to a valid display address (e.g., 128, 1st character of 1st line); the clear-screen instruction (byte 1); or the home instruction (byte 2). Now bytes are once again being written to the visible portion of the display.

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

Next is the E pin which enables the writing to the registers, or the next 8 data pins from D0 to D7. So through this pins we are sending the 8 bits data when we are writing to the registers or for example if we want to see the latter uppercase A on the display we will send 0100 0001 to the registers according to the ASCII table. The last two pins A and K, or anode and cathode are for the LED back light.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

The character set on the printer is extremely limited because of the hardware used. I think the LCD display in the RepRap Smart Controller supports a basic ASCII character set and allows for 8 custom characters to be defined by the firmware that is driving it. These are used for the symbols like the thermometer, heat bed, folder, clock, navigation arrows etc. All the custom characters are defined in the ASCII control character range, but as far as I know there isn"t any way to send control characters to the printer using a Code M117 command. Unknown characters just get a "?" as you have already seen.

I had a play around in the OctoPrint terminal and found that the ASCII ">" character is supported (use M117 >) and that the "~" symbol is mapped to a "right arrow" (enter M117 ~) - your lucky day!

There may be other standard ASCII characters that have a non-standard mapping, so I suggest to have a play around with the M117 command if you have time.

it just passes an invalid address to it and thus gibberish are displayed. If instead you copy it first to RAM, as you did in your solution, it works fine:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey