lcd panel market share 2016 factory

BOE was the leading LCD TV panel vendor during the first half of 2020, having shipped approximately 23.26 million units worldwide. In that period, global shipments of LCD TV panels totaled over 115 million units.

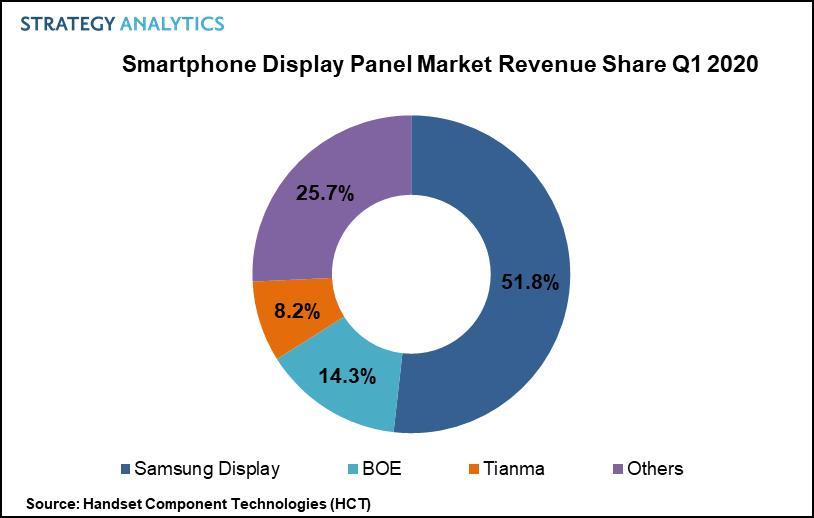

BOE Technology, founded in 1993, has become China’s largest TV panel maker and it continues to make a name for itself in the global consumer electronics market. It was the first company to introduce a gen 10.5 LCD plant in late 2017. Since then, BOE’s LCD panel production capacity has grown annually, surpassing former leading manufacturer LG Display. In recent years, BOE accounted for over 20 percent of large-area TFT LCD display unit shipments worldwide.

Chinese panel makers accelerate worldwide LCD TV panel shipmentsChina became the leading LCD panel producer worldwide in 2017, overtaking powerhouses South Korea and Taiwan. Chinese shipments of LCD TV panels 60-inch and larger have also increased significantly in recent years, with roughly 2.24 million units sold in the first quarter of 2019 worldwide, in comparison to just 117,000 units a year before. This figure is forecast to increase in the future, paving the way for Chinese panel makers’ worldwide success. At the same time, the concurrent specialization on large LCD panels by Chinese and South Korean suppliers will likely push down panel prices.Read moreGlobal LCD TV panel unit shipments from H1 2016 to H1 2020, by vendor(in millions)tablecolumn chartCharacteristicBOELGDInnoluxCSOTSDCAUOCEC GroupOthers1H 202023.2611.7920.3421.312.1310.14-16.17

TrendForce. (July 28, 2020). Global LCD TV panel unit shipments from H1 2016 to H1 2020, by vendor (in millions) [Graph]. In Statista. Retrieved January 29, 2023, from https://www.statista.com/statistics/760270/global-market-share-of-led-lcd-tv-vendors/

TrendForce. "Global LCD TV panel unit shipments from H1 2016 to H1 2020, by vendor (in millions)." Chart. July 28, 2020. Statista. Accessed January 29, 2023. https://www.statista.com/statistics/760270/global-market-share-of-led-lcd-tv-vendors/

TrendForce. (2020). Global LCD TV panel unit shipments from H1 2016 to H1 2020, by vendor (in millions). Statista. Statista Inc.. Accessed: January 29, 2023. https://www.statista.com/statistics/760270/global-market-share-of-led-lcd-tv-vendors/

TrendForce. "Global Lcd Tv Panel Unit Shipments from H1 2016 to H1 2020, by Vendor (in Millions)." Statista, Statista Inc., 28 Jul 2020, https://www.statista.com/statistics/760270/global-market-share-of-led-lcd-tv-vendors/

TrendForce, Global LCD TV panel unit shipments from H1 2016 to H1 2020, by vendor (in millions) Statista, https://www.statista.com/statistics/760270/global-market-share-of-led-lcd-tv-vendors/ (last visited January 29, 2023)

Global LCD TV panel unit shipments from H1 2016 to H1 2020, by vendor (in millions) [Graph], TrendForce, July 28, 2020. [Online]. Available: https://www.statista.com/statistics/760270/global-market-share-of-led-lcd-tv-vendors/

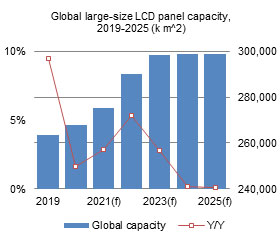

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved January 29, 2023, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed January 29, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: January 29, 2023. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited January 29, 2023)

LCD panel production capacity share from 2016 to 2025, by country [Graph], DSCC, June 8, 2020. [Online]. Available: https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

The upstream materials or components of the LCD panel industry mainly include liquid crystal materials, glass substrates, polarizing lenses, and backlight LEDs (or CCFL, which accounts for less than 5% of the market).

The middle reaches is the main panel factory processing and manufacturing, through the glass substrate TFT arrays and CF substrate, CF as upper and TFT self-built perfusion liquid crystal and the lower joint, and then put a polaroid, connection driver IC and control circuit board, and a backlight module assembling, eventually forming the whole piece of LCD module. The downstream is a variety of fields of application terminal-based brand, assembly manufacturers. At present, the United States, Japan, and Germany mainly focus on upstream raw materials, while South Korea, Taiwan, and the mainland mainly seek development in mid-stream panel manufacturing.

With the successive production of the high generation line in mainland China, the panel production capacity and technology level have been steadily improved, and the industrial competitiveness has been gradually enhanced. Nowadays, the panel industry is divided into three parts: South Korea, mainland China, and Taiwan, and mainland China is expected to become the no.1 in the world in 2019.

In the past decade, China’s panel display industryhas achieved leapfrog development, and the overall size of the industry has ranked among the top three in the world. Chinese mainland panel production capacity is expanding rapidly, although Japanese panel manufacturers master a large number of key technologies, gradually lose the price competitive advantage, compression panel production capacity. Panel production is concentrated in South Korea, Taiwan, and China, which is poised to become the world’s largest producer of LCD panels.

Up to 2016, BOE‘s global market share continued to increase: smartphone LCD, tablet PC display, and laptop display accounted for the world’s first market share, and display screen increased to the world’s second, while TV LCD remained the world’s third. In LCD TV panels, Chinese panel makers have accounted for 30 percent of global shipments to 77 million units, surpassing Taiwan’s 25.5 percent market share for the first time and ranking second only to South Korea.

In terms of the area of shipment, the area of board shipment of JD accounted for only 8.3% in 2015, which has been greatly increased to 13.6% in the first half of 2016, while the area of shipment of hu xing optoelectronics in the first half of 2015 was only 5.1%, which has reached 7.8% in the first half of 2016. The panel factories in mainland China are expanding their capacity at an average rate of double-digit growth and transforming it into actual shipments and areas of shipment. On the other hand, although the market share of South Korea, Japan, and Taiwan is gradually decreasing, some South Korean and Japanese manufacturers have been inclined to the large-size HD panel and AMOLED market, and the production capacity of the high-end LCD panel is further concentrated in mainland China.

Domestic LCD panel production line capacity gradually released, overlay the decline in global economic growth, lead to panel makers from 15 in the second half began, in a low profit or loss, especially small and medium-sized production line, the South Korean manufacturers take the lead in transformation strategy, closed in medium and small size panel production line, South Korea’s 19-panel production line has shut down nine, and part of the production line is to research and development purposes. Some production lines are converted to LTPS production lines through process conversion. Korean manufacturers are turning to OLED panels in a comprehensive way, while Japanese manufacturers are basically giving up the LCD panel manufacturing business and turning to the core equipment and materials side. In addition to the technical direction of the research and judgment, more is the LCD panel business orders and profits have been severely compressed, Korean and Japanese manufacturers have no desire to fight. Since many OLED technologies are still in their infancy in mainland China, it is a priority to move to high-end panels such as OLED as soon as possible. Taiwanese manufacturers have not shut down factories on a large scale, but their advantages in LCD technology and OLED technology have been slowly eroded by the mainland.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

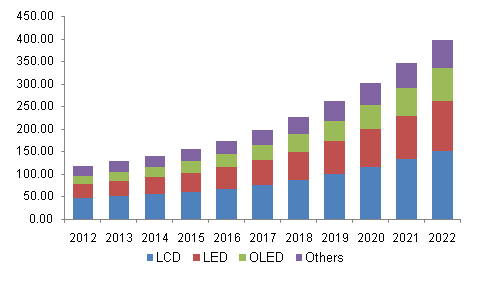

This market research report includes a detailed segmentation of the global large area LCD display market by application (TVs, notebooks, monitors, tablets, and others). It outlines the market shares for key regions such as the Americas, APAC, and EMEA. The key vendors analyzed in this report are AU Optronics, BOE Technology, Innolux, LG Display, and Samsung Display.

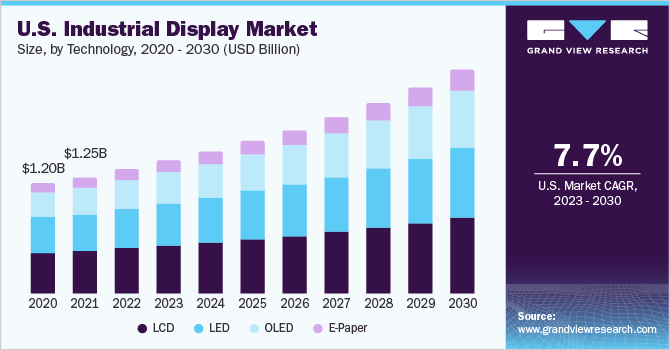

Technavio’s research analyst predicts the global large area LCD display market to grow at a CAGR of 3% during the forecast period. The formation of UHD alliances is the primary growth driver for this market. During 2015, supply chain members of the global UHD TV market announced the formation of the UHD Alliance to support innovative technologies including 4K and higher resolution, high dynamic range, immersive 3D audio, and wider color gamut.

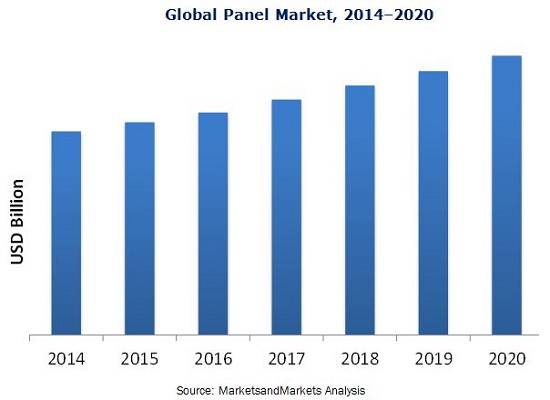

The decline in ASP of the LCD panel is expected to boost the market growth during the forecast period. During 2014, per meter square, ASP of LCD panel was $472, which declined to $416 during 2015. Vendors reduced the ASP to reduce excess inventory. The declining per square meter ASP of LCD panel drove the shipment of LCD display in terms of area.

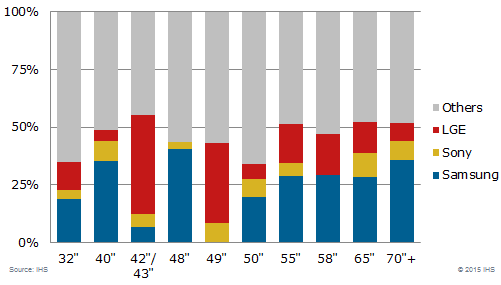

During 2015, the TV segment dominated the large area LCD display market with a market share of 38%. The primary reason for the growth of this product segment was the strong demand for 4K TVs of 40 inches and larger screen size. During 2015, several manufacturers introduced 4K TVs ranging from 50 inches and above.

During 2015, APAC accounted for 81% of the market share and is expected to grow at a CAGR of 1% during the forecast period. The high concentration of display device manufacturers and LCD panel manufacturers in this region are the primary growth drivers. Technavio expects that the well-established supply chain for display devices in APAC would continue to support the dominance of this region in the market during the forecast period. China is emerging fast as a leading hub for large area TFT LCD display manufacturers because of the rise in the number of display device manufacturers in the country.

Manufacturing LCD display panels require economies of scale because the equipment used to manufacture displays are expensive. This presents high entry barriers for LCD display panel manufacturers. Currently, the global large area LCD display market is dominated by China, Japan, South Korea, and Taiwan in terms of production and revenue contribution. Chinese manufacturers have the advantage of manufacturing LCD panels at a lower cost. This has resulted in price wars among LCD manufacturers and has accelerated the declining ASP of LCD panels. Vendors such as LG and Samsung are under a lot of pressure as profit margins have come down because of increased competition.

Other prominent vendors in the market include Chi Mei Optoelectronics, Chunghwa Picture Tube (CPT), HannsTouch Solution, HannStar Display, InfoVision Optoelectronics, Japan Display, Kaohsiung Opto-Electronics, NEC Display Solutions, Panasonic, and Sharp.

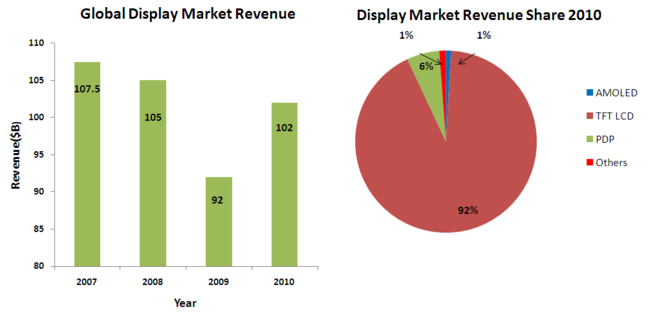

According to IMARC Group’s latest report, titled “TFT LCD Panel Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022-2027”, the global TFT LCD panel market size reached US$ 157 Billion in 2021. Looking forward, IMARC Group expects the market to reach US$ 207.6 Billion by 2027, exhibiting a growth rate (CAGR) of 4.7% during 2022-2027.

A thin-film-transistor liquid-crystal display (TFT LCD) panel is a liquid crystal display that is generally attached to a thin film transistor. It is an energy-efficient product variant that offers a superior quality viewing experience without straining the eye. Additionally, it is lightweight, less prone to reflection and provides a wider viewing angle and sharp images. Consequently, it is generally utilized in the manufacturing of numerous electronic and handheld devices. Some of the commonly available TFT LCD panels in the market include twisted nematic, in-plane switching, advanced fringe field switching, patterned vertical alignment and an advanced super view.

We are regularly tracking the direct effect of COVID-19 on the market, along with the indirect influence of associated industries. These observations will be integrated into the report.

The global market is primarily driven by continual technological advancements in the display technology. This is supported by the introduction of plasma enhanced chemical vapor deposition (PECVD) technology to manufacture TFT panels that offers uniform thickness and cracking resistance to the product. Along with this, the widespread adoption of the TFT LCD panels in the production of automobiles dashboards that provide high resolution and reliability to the driver is gaining prominence across the globe. Furthermore, the increasing demand for compact-sized display panels and 4K television variants are contributing to the market growth. Moreover, the rising penetration of electronic devices, such as smartphones, tablets and laptops among the masses, is creating a positive outlook for the market. Other factors, including inflating disposable incomes of the masses, changing lifestyle patterns, and increasing investments in research and development (R&D) activities, are further projected to drive the market growth.

The competitive landscape of the TFT LCD panel market has been studied in the report with the detailed profiles of the key players operating in the market.

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Dublin, Sept. 27, 2021 (GLOBE NEWSWIRE) -- The "Global TFT LCD Display Panel Market Report and Forecast 2021-2026" report has been added to ResearchAndMarkets.com"s offering.

The global TFT-LCD display market attained a value of approximately USD 164 billion in 2020. Aided by use of TFT-LCD displays in automotive, the market is projected to further grow at a CAGR of 5.2% between 2021-2026 to reach USD 223 billion by 2026.

TFT-LCD display is a kind of liquid crystal display where each pixel is attached to a film transistor to improve colour quality, as each pixel on a TFT-LCD is attached to a transistor. TFT is deployed in all computer screens television screens since the start of century, because the technology offers better response time and improved colour quality than older technologies and prevents distortion of image. With favourable properties like light weight, slim, and high-resolution features, and due to the small size of each transistor, they consume less power owing to which TFT-LCD displays find applications in nearly every electronic device with a display including smartphones, television screens, computers, and PCs.

The market demand for TFT-LCD display can be attributed to increasing deployment of TFT-LCD display in average and large sized flat panel TVs in the household sector. The growing demand for slim, high resolution smart phones among the younger generation, owing to the work from home trends is further invigorating market growth. Other electronic devices like PCs and desktops that deploy TFT-LCD display for better screen resolution, sharp, and vibrant colours are supporting the market growth.

Due to the rapidly expanding industrialisation and a subsequent rise in disposable incomes, especially in emerging economies of the Asia-Pacific region like India and China, the market demand for personal vehicles equipped with LCD displays for specific functions and entertainment purposes is positively impacting the market growth of TFT-LCD displays. Furthermore, transportation vehicles like aeroplanes, trains, and, buses are emerging as users of TFT-LCD displays, aided by government spending on public transport. Therefore, a rising demand for TFT-LCD displays from the automotive sector is providing lucrative industrial growth opportunities.

The report looks into the market shares, plant turnarounds, capacities, investments, and mergers and acquisitions, among other major developments of the key players in the industry.

ResearchAndMarkets.com is the world"s leading source for international market research reports and market data. We provide you with the latest data on international and regional markets, key industries, the top companies, new products and the latest trends.

The report covers extensive analysis of the key market players in the market, along with their business overview, expansion plans, and strategies. The key players studied in the report include:

The report focuses on the LCD Display Panel market size, segment size (mainly covering product type, application, and geography), competitor landscape, recent status, and development trends. Furthermore, the report provides detailed cost analysis, supply chain. Technological innovation and advancement will further optimize the performance of the product, making it more widely used in downstream applications. Moreover, Consumer behavior analysis and market dynamics (drivers, restraints, opportunities) provides crucial information for knowing the LCD Display Panel market.

The Research Report delivers knowledge about sales quality, sales value and different brands related to top market players with highest number of market tables and figures at a guaranteed best price. Additionally, it comes with exhaustive coverage of post pandemic forces that are likely to impact the LCD Display Panel Market growth. The overview of report contents includes market dynamics, market share information, analysis of smaller companies, investment plans, merger and acquisition, gross margin, demand supply, import-export, covering key market segmentation that includes by types, applications, end-user, and regions.

Chapter 1 provides an overview of LCD Display Panel market, containing global revenue and CAGR. The forecast and analysis of LCD Display Panel market by type, application, and region are also presented in this chapter.

Chapter 2 is about the market landscape and major players. It provides competitive situation and market concentration status along with the basic information of these players.

Chapter 3 introduces the industrial chain of LCD Display Panel. Industrial chain analysis, raw material (suppliers, price, supply and demand, market concentration rate) and downstream buyers are analyzed in this chapter.

Chapter 6 provides a full-scale analysis of major players in LCD Display Panel industry. The basic information, as well as the profiles, applications and specifications of products market performance along with Business Overview are offered.

Chapter 7 pays attention to the sales, revenue, price and gross margin of LCD Display Panel in markets of different regions. The analysis on sales, revenue, price and gross margin of the global market is covered in this part.

Chapter 10 prospects the whole LCD Display Panel market, including the global sales and revenue forecast, regional forecast. It also foresees the LCD Display Panel market by type and application.

Geographically, the report includes the research on production, consumption, revenue, market share and growth rate, and forecast (2016 -2026) of the following regions: ● United States

The report delivers a comprehensive study of all the segments and shares information regarding the leading regions in the market. This report also states import/export consumption, supply and demand Figures, cost, industry share, policy, price, revenue, and gross margins.

The report delivers a comprehensive study of all the segments and shares information regarding the leading regions in the market. This report also states import/export consumption, supply and demand Figures, cost, industry share, policy, price, revenue, and gross margins.

Is there a problem with this press release? Contact the source provider Comtex at editorial@comtex.com. You can also contact MarketWatch Customer Service via our Customer Center.

The report covers extensive analysis of the key market players in the market, along with their business overview, expansion plans, and strategies. The key players studied in the report include:

The report focuses on the LCD Panel market size, segment size (mainly covering product type, application, and geography), competitor landscape, recent status, and development trends. Furthermore, the report provides detailed cost analysis, supply chain. Technological innovation and advancement will further optimize the performance of the product, making it more widely used in downstream applications. Moreover, Consumer behavior analysis and market dynamics (drivers, restraints, opportunities) provides crucial information for knowing the LCD Panel market.

The Research Report delivers knowledge about sales quality, sales value and different brands related to top market players with highest number of market tables and figures at a guaranteed best price. Additionally, it comes with exhaustive coverage of post pandemic forces that are likely to impact the LCD Panel Market growth. The overview of report contents includes market dynamics, market share information, analysis of smaller companies, investment plans, merger and acquisition, gross margin, demand supply, import-export, covering key market segmentation that includes by types, applications, end-user, and regions.

Chapter 1 provides an overview of LCD Panel market, containing global revenue and CAGR. The forecast and analysis of LCD Panel market by type, application, and region are also presented in this chapter.

Chapter 2 is about the market landscape and major players. It provides competitive situation and market concentration status along with the basic information of these players.

Chapter 3 introduces the industrial chain of LCD Panel. Industrial chain analysis, raw material (suppliers, price, supply and demand, market concentration rate) and downstream buyers are analyzed in this chapter.

Chapter 6 provides a full-scale analysis of major players in LCD Panel industry. The basic information, as well as the profiles, applications and specifications of products market performance along with Business Overview are offered.

Chapter 7 pays attention to the sales, revenue, price and gross margin of LCD Panel in markets of different regions. The analysis on sales, revenue, price and gross margin of the global market is covered in this part.

Chapter 10 prospects the whole LCD Panel market, including the global sales and revenue forecast, regional forecast. It also foresees the LCD Panel market by type and application.

Geographically, the report includes the research on production, consumption, revenue, market share and growth rate, and forecast (2016 -2026) of the following regions: ● United States

The report delivers a comprehensive study of all the segments and shares information regarding the leading regions in the market. This report also states import/export consumption, supply and demand Figures, cost, industry share, policy, price, revenue, and gross margins.

The report delivers a comprehensive study of all the segments and shares information regarding the leading regions in the market. This report also states import/export consumption, supply and demand Figures, cost, industry share, policy, price, revenue, and gross margins.

Is there a problem with this press release? Contact the source provider Comtex at editorial@comtex.com. You can also contact MarketWatch Customer Service via our Customer Center.

TFT or thin-film transistor is combined with LCD to improve colour quality leading to a sharper image, as each pixel on a TFT-LCD is attached to a transistor. Due to the small sizes of each transistor, TFT-LCD display panels consume less power. They are widely used in computers, TVs, laptops, and mobile phones as it gives a more enhanced image than older technologies and prevents the distortion of image.

With the growing applications of TFT-LCD, there has been an increased competition among the manufacturers for the best cutting technology, i.e. ‘generations’, to produce TFT-LCD panels. In 2017, BOE, one of the major TFT-LCD manufacturers globally, put the world’s highest generation line, Generation 10.5 TFT-LCD production line, into production ahead of schedule in Hefei, China. With more Gen 10.5 facilities starting mass production, the market is primed for the production of 65 inches and larger TFT-LCD panels. More than 85.5% of the TFT-LCD display panels consumed in 2018 were large-sized panels sized over 10 inches.

Driven by the demand for TFT-LCD display panels in TV and monitor panels, the global shipment of large TFT-LCD panels grew again in 2018, despite over-supply concerns. The market is also driven by a rising demand for automotive displays. While automotive display systems were earlier reserved for luxury vehicles, cars for the mass-market are increasingly including high resolution display systems in their design due to a decline in prices along with the rising production and demand for automobiles. This growth in automotive displays has been supported by the rising investments in automotive display panels by big display panel manufacturers in Asia. The Asia Pacific countries like China and India are the fastest growing markets in the region due to rapid economic growth and a growing demand for consumer-based electronics. Currently, the global market for TFT-LCD display panel is dominated by North America.

Region-wise, the global market for TFT-LCD display panel can be divided into North America, Europe, the Asia Pacific, Latin America, and the Middle East and Africa.

The report also offers historical (2018-2022) and forecast (2023-2028) market information for the sizes, applications, and major regions of TFT-LCD display panel.

The report analyses the market dynamics, covering the key demand and price indicators in the market, along with providing an assessment of the SWOT and Porter’s Five Forces models.

The major players in the global TFT-LCD display panel market are Samsung Electronics Co., Ltd., LG Display Co., Ltd., Japan Disney Inc., Sharp Corporation, BOE Technology Group Co., Ltd., AUO Corporation, Raystar Optronics Inc., WINSTAR Display Co., Ltd., Kingtech Group Co., Ltd., and Tricomtek Co., Ltd., among others. The comprehensive report by EMR looks into the market share, capacity, and latest developments like mergers and acquisitions, plant turnarounds, and capacity expansions of the major players.

*At Expert Market Research, we strive to always give you current and accurate information. The numbers depicted in the description are indicative and may differ from the actual numbers in the final EMR report.

A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large (over 32 inches diagonal) flat panel displays to be released to the public.

Until about 2007, plasma displays were commonly used in large televisions (30 inches (76 cm) and larger). By 2013, they had lost nearly all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Manufacturing of plasma displays for the United States retail market ended in 2014,

Plasma displays are bright (1,000 lux or higher for the display module), have a wide color gamut, and can be produced in fairly large sizes—up to 3.8 metres (150 in) diagonally. They had a very low luminance "dark-room" black level compared with the lighter grey of the unilluminated parts of an LCD screen. (As plasma panels are locally lit and do not require a back light, blacks are blacker on plasma and grayer on LCD"s.)LED-backlit LCD televisions have been developed to reduce this distinction. The display panel itself is about 6 cm (2.4 in) thick, generally allowing the device"s total thickness (including electronics) to be less than 10 cm (3.9 in). Power consumption varies greatly with picture content, with bright scenes drawing significantly more power than darker ones – this is also true for CRTs as well as modern LCDs where LED backlight brightness is adjusted dynamically. The plasma that illuminates the screen can reach a temperature of at least 1,200 °C (2,190 °F). Typical power consumption is 400 watts for a 127 cm (50 in) screen. Most screens are set to "vivid" mode by default in the factory (which maximizes the brightness and raises the contrast so the image on the screen looks good under the extremely bright lights that are common in big box stores), which draws at least twice the power (around 500–700 watts) of a "home" setting of less extreme brightness.

Plasma screens are made out of glass, which may result in glare on the screen from nearby light sources. Plasma display panels cannot be economically manufactured in screen sizes smaller than 82 centimetres (32 in).enhanced-definition televisions (EDTV) this small, even fewer have made 32 inch plasma HDTVs. With the trend toward large-screen television technology, the 32 inch screen size is rapidly disappearing. Though considered bulky and thick compared with their LCD counterparts, some sets such as Panasonic"s Z1 and Samsung"s B860 series are as slim as 2.5 cm (1 in) thick making them comparable to LCDs in this respect.

Wider viewing angles than those of LCD; images do not suffer from degradation at less than straight ahead angles like LCDs. LCDs using IPS technology have the widest angles, but they do not equal the range of plasma primarily due to "IPS glow", a generally whitish haze that appears due to the nature of the IPS pixel design.

Superior uniformity. LCD panel backlights nearly always produce uneven brightness levels, although this is not always noticeable. High-end computer monitors have technologies to try to compensate for the uniformity problem.

Uses more electrical power, on average, than an LCD TV using a LED backlight. Older CCFL backlights for LCD panels used quite a bit more power, and older plasma TVs used quite a bit more power than recent models.

Fixed-pixel displays such as plasma TVs scale the video image of each incoming signal to the native resolution of the display panel. The most common native resolutions for plasma display panels are 852×480 (EDTV), 1,366×768 and 1920×1080 (HDTV). As a result, picture quality varies depending on the performance of the video scaling processor and the upscaling and downscaling algorithms used by each display manufacturer.

Early high-definition (HD) plasma displays had a resolution of 1024x1024 and were alternate lighting of surfaces (ALiS) panels made by Fujitsu and Hitachi.

A panel of a plasma display typically comprises millions of tiny compartments in between two panels of glass. These compartments, or "bulbs" or "cells", hold a mixture of noble gases and a minuscule amount of another gas (e.g., mercury vapor). Just as in the fluorescent lamps over an office desk, when a high voltage is applied across the cell, the gas in the cells forms a plasma. With flow of electricity (electrons), some of the electrons strike mercury particles as the electrons move through the plasma, momentarily increasing the energy level of the atom until the excess energy is shed. Mercury sheds the energy as ultraviolet (UV) photons. The UV photons then strike phosphor that is painted on the inside of the cell. When the UV photon strikes a phosphor molecule, it momentarily raises the energy level of an outer orbit electron in the phosphor molecule, moving the electron from a stable to an unstable state; the electron then sheds the excess energy as a photon at a lower energy level than UV light; the lower energy photons are mostly in the infrared range but about 40% are in the visible light range. Thus the input energy is converted to mostly infrared but also as visible light. The screen heats up to between 30 and 41 °C (86 and 106 °F) during operation. Depending on the phosphors used, different colors of visible light can be achieved. Each pixel in a plasma display is made up of three cells comprising the primary colors of visible light. Varying the voltage of the signals to the cells thus allows different perceived colors.

In a monochrome plasma panel, the gas is mostly neon, and the color is the characteristic orange of a neon-filled lamp (or sign). Once a glow discharge has been initiated in a cell, it can be maintained by applying a low-level voltage between all the horizontal and vertical electrodes–even after the ionizing voltage is removed. To erase a cell all voltage is removed from a pair of electrodes. This type of panel has inherent memory. A small amount of nitrogen is added to the neon to increase hysteresis.phosphor. The ultraviolet photons emitted by the plasma excite these phosphors, which give off visible light with colors determined by the phosphor materials. This aspect is comparable to fluorescent lamps and to the neon signs that use colored phosphors.

Every pixel is made up of three separate subpixel cells, each with different colored phosphors. One subpixel has a red light phosphor, one subpixel has a green light phosphor and one subpixel has a blue light phosphor. These colors blend together to create the overall color of the pixel, the same as a triad of a shadow mask CRT or color LCD. Plasma panels use pulse-width modulation (PWM) to control brightness: by varying the pulses of current flowing through the different cells thousands of times per second, the control system can increase or decrease the intensity of each subpixel color to create billions of different combinations of red, green and blue. In this way, the control system can produce most of the visible colors. Plasma displays use the same phosphors as CRTs, which accounts for the extremely accurate color reproduction when viewing television or computer video images (which use an RGB color system designed for CRT displays).

Plasma displays are different from liquid crystal displays (LCDs), another lightweight flat-screen display using very different technology. LCDs may use one or two large fluorescent lamps as a backlight source, but the different colors are controlled by LCD units, which in effect behave as gates that allow or block light through red, green, or blue filters on the front of the LCD panel.

Each cell on a plasma display must be precharged before it is lit, otherwise the cell would not respond quickly enough. Precharging normally increases power consumption, so energy recovery mechanisms may be in place to avoid an increase in power consumption.LED illumination can automatically reduce the backlighting on darker scenes, though this method cannot be used in high-contrast scenes, leaving some light showing from black parts of an image with bright parts, such as (at the extreme) a solid black screen with one fine intense bright line. This is called a "halo" effect which has been minimized on newer LED-backlit LCDs with local dimming. Edgelit models cannot compete with this as the light is reflected via a light guide to distribute the light behind the panel.

Image burn-in occurs on CRTs and plasma panels when the same picture is displayed for long periods. This causes the phosphors to overheat, losing some of their luminosity and producing a "shadow" image that is visible with the power off. Burn-in is especially a problem on plasma panels because they run hotter than CRTs. Early plasma televisions were plagued by burn-in, making it impossible to use video games or anything else that displayed static images.

In 1983, IBM introduced a 19-inch (48 cm) orange-on-black monochrome display (Model 3290 Information Panel) which was able to show up to four simultaneous IBM 3270 terminal sessions. By the end of the decade, orange monochrome plasma displays were used in a number of high-end AC-powered portable computers, such as the Compaq Portable 386 (1987) and the IBM P75 (1990). Plasma displays had a better contrast ratio, viewability angle, and less motion blur than the LCDs that were available at the time, and were used until the introduction of active-matrix color LCD displays in 1992.

Due to heavy competition from monochrome LCDs used in laptops and the high costs of plasma display technology, in 1987 IBM planned to shut down its factory in Kingston, New York, the largest plasma plant in the world, in favor of manufacturing mainframe computers, which would have left development to Japanese companies.Larry F. Weber, a University of Illinois ECE PhD (in plasma display research) and staff scientist working at CERL (home of the PLATO System), co-founded Plasmaco with Stephen Globus and IBM plant manager James Kehoe, and bought the plant from IBM for US$50,000. Weber stayed in Urbana as CTO until 1990, then moved to upstate New York to work at Plasmaco.

In 1995, Fujitsu introduced the first 42-inch (107 cm) plasma display panel;Philips introduced the first large commercially available flat-panel TV, using the Fujitsu panels. It was available at four Sears locations in the US for $14,999, including in-home installation. Pioneer also began selling plasma televisions that year, and other manufacturers followed. By the year 2000 prices had dropped to $10,000.

In late 2006, analysts noted that LCDs had overtaken plasmas, particularly in the 40-inch (100 cm) and above segment where plasma had previously gained market share.

Until the early 2000s, plasma displays were the most popular choice for HDTV flat panel display as they had many benefits over LCDs. Beyond plasma"s deeper blacks, increased contrast, faster response time, greater color spectrum, and wider viewing angle; they were also much bigger than LCDs, and it was believed that LCDs were suited only to smaller sized televisions. However, improvements in VLSI fabrication narrowed the technological gap. The increased size, lower weight, falling prices, and often lower electrical power consumption of LCDs made them competitive with plasma television sets.

At the 2010 Consumer Electronics Show in Las Vegas, Panasonic introduced their 152" 2160p 3D plasma. In 2010, Panasonic shipped 19.1 million plasma TV panels.

Panasonic was the biggest plasma display manufacturer until 2013, when it decided to discontinue plasma production. In the following months, Samsung and LG also ceased production of plasma sets. Panasonic, Samsung and LG were the last plasma manufacturers for the U.S. retail market.

This report includes all of DSCC"s content on OLED and LCD fab schedules, OLED and LCD capacity and LCD and OLED equipment market sizes, market share and forecasts for 79 different segments. All design wins and units by fab by equipment type are shown and quarterly revenues are provided for >130 different display equipment suppliers. Also included are typical process flows for each major process.

This report provides all of the market intelligence that a display equipment manufacturer, supplier to display equipment manufacturer or analysts covering display equipment suppliers would want. It is also ideal for panel suppliers tracking the market shares for all major display equipment segments. In total, 79 different equipment segments have been covered compared to 22 from other research firms.. Market share and design wins are provided for every segment as well on a quarterly, annual, billings and bookings basis, while other research firms don"t offer any market share data.

Quarterly and annual equipment market share provided from 2016 to as far as 2025 for all backplane, frontplane, color filter, cell and most module segments, >70 different segments.

AU Optronics Corp (AUO, 友達光電), the nation’s second-largest LCD panel maker, is poised to become the world’s No. 2 supplier of low-temperature polysilicon (LTPS) displays in 2016 due to increased capacity resulting from the launch of the company’s new plant in China, TrendForce Corp (集邦科技) said yesterday.

The capacity boost is likely to triple AUO’s share of the high-definition display market to 16 percent in the next four years, compared with the 5.6 percent stake it held last year, and surpassing LG Display Co’s 13.3 percent share and the 10.8 percent commanded by Sharp Corp, the Taipei-based researcher said.

Japan Display Inc is forecast to remain the world’s No. 1 LTPS display supplier in 2016, with a market share of 21.6 percent compared with 41 percent last year, TrendForce said in a report.

Rising demand for high-resolution displays for smartphones is another key factor driving panel makers to boost capacity for LTPS displays, the report said.

Global LTPS display production capacity is expected to surge to 14.89 million square meters in 2016, from 6.74 million square meters last year, the researcher said.

“In 2016, Taiwan, Japan and South Korea will become the world’s major LTPS display suppliers, ending the dominance Japan has exerted over the sector in the past few years,” TrendForce analyst Boyce Fan (范博毓) forecast.

“Since most [new] products will enter the market almost simultaneously, there will likely be oversupply concerns for the next two or three years,” Fan said.

In January, AUO said it planned to invest NT$50 billion (US$1.6 billion) in the construction of a 6G plant in China to produce high-resolution displays for smartphones and tablets. The company had originally proposed setting up an 8.5G plant on the site to produce large-size TV panels.

In its report, TrendForce also said that since AUO rival Innolux Corp (群創光電), the nation’s biggest LCD panel maker, bucked the LTPS manufacturing investment trend, it could see its share of the market drop to 3 percent in 2016 from last year’s 6.6 percent.

The researcher added that Hon Hai Precision Industry Co (鴻海精密), Innolux’s major shareholder, plans to increase its LTPS display capacity in China via a panel manufacturing subsidiary in Chengdu in Sichuan Province, adding that Innolux does not operate any factories across the Taiwan Strait.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey