ce certification lcd panel in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

What are the criteria and procedure for CE marking of LCDs and which institutions can I contact? A liquid crystal display is a kind of flat panel display. It is used for the screen display of televisions and computers. The advantages of this display are low power consumption, small size, and low radiation. The LCD uses a liquid crystal solution in two polarized materials, so the current flowing through the liquid causes the crystals to rearrange themselves to achieve the purpose of the image. If you need to apply for CE certification, you can contact our company BEST ONE Inspection for the procedure.

CE marking provides a single technical specification for products from all countries for trade in the European market and simplifies trade procedures. In order to enter the European Union and the European Free Trade Area, products from all countries must be CE certified and have the CE mark on the product. CE marking is therefore the passport for products to enter the EU and EFTA markets.

CE certification means that the product meets the safety requirements set out in the EU Directive; it is a company’s commitment to consumers and increases their confidence in the product; products bearing the CE mark reduce the risk of being sold on the European market.

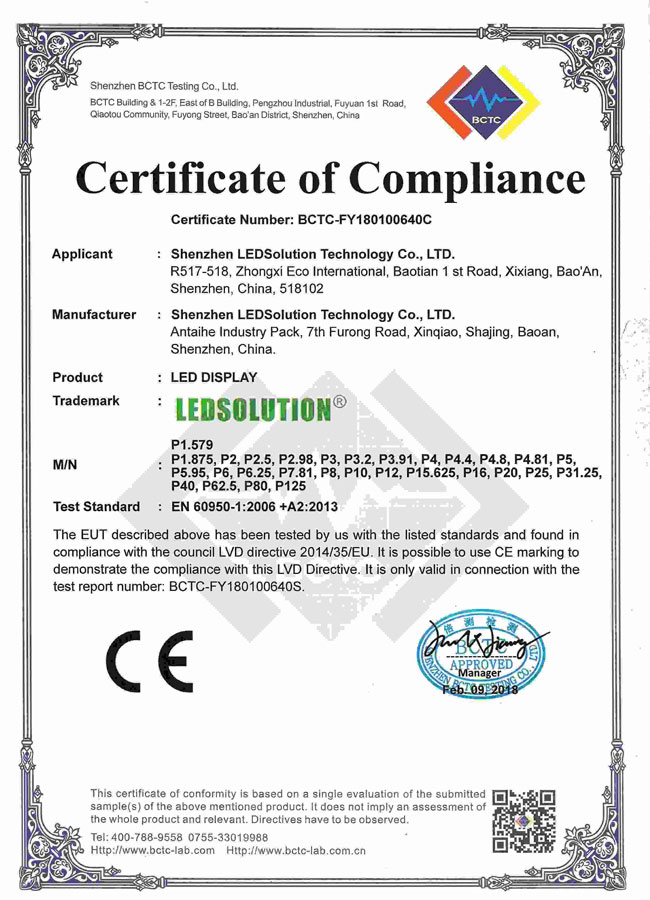

CE consists of EMC (Electromagnetic Compatibility) + LVD (Low Voltage Directive), EMC also includes EMI (interference) + EMC (anti-interference), LVD is also commonly known as SAFETY safety, general low voltage products AC less than 50V, DC less than 75V can not LVD project. Low voltage products only need to test EMC and issue CE-EMC certificate, high voltage products need to test EMC and LVD and issue two certificates and reports CE-EMCCE-LVD.

Safety design documents (including main design drawings, i.e. design drawings indicating creepage distance, clearance distance, number and thickness of insulation layers).

the certificate of registration of the product in the EU (for certain products, such as Class I medical devices, general IVD in vitro diagnostic devices).

EU laws, regulations, and harmonized standards are not only numerous but also very complex, so seeking the help of an EU notified body is a wise move to save time and effort and reduce risks.

A loved classic household item – the TV is an essential piece of technology for the modern family. Our wholesale smart lcd tv with ce certification offer great versatility. In addition to watching normal TV, viewers can connect to the internet and browse through programs online for instant streaming. For all of the family, these lcd tv with ce certification can play games, use apps, and are set up for social networking. With built-in voice control and touch screen features, these smart TV"s really are one not to miss. They come in a range of sizes. For those wanting the big screen experience, try the following sizes (inches): 60, 65, 70, 75 80, and 85. For customers who want something smaller, then our range of 24-32-inch lcd tv with ce certification are ideal.

TV definition improves vastly every day with constant new technology. With our wholesale 4k Ultra HD TVs, viewers can watch their favorite programs in ultra-high definition. These lcd tv with ce certification come in the highest resolution for optimal viewing. For customers who want the latest technology at affordable prices, then choose from our range of 4k TVs.

LED TVs are known for their great contrast and lighting, producing stunning clarity and colors. They are more durable than other TVs, so viewers do not have to worry about buying an expensive TV they then have to replace in a year"s time.

Whatever your customer"s preference, we will have the TV for them. Choose from wholesale flat-screen lcd tv with ce certification to curved lcd tv with ce certification. Outdoor TVs are also great for those wanting to install a TV on their terrace or in their back garden. For the full range, then visit our online wholesalers at Alibaba.com.

A Machinery shall be CE Marked before it is placed on the market or put into service or use. Normally a Machinery has an Electrical Equipment made of one or more control panels and components “in the field”.

The Control panel is often engineered and manufactured by a different producer then the machinery itself and it falls under the Low Voltage Directive 2014/35/EU (if powered above 50Vac).

That was interpreted in the following way: Manufacturer P of the control Panel sells to Manufacturer M of the Machinery and is not obliged to CE Mark its product.

In other terms: manufacturer “P1” of a part of the control panel sells it to the final manufacturer “P2”, who assembles the product and sells it to “M”. P2 has to CE mark the product before it is transferred to “M”.

As for “making available”, the concept of placing on the market refers to each individual product, not to a type of product, and whether it was manufactured as an individual unit or in series.

Not all experts think that way.There is a school of thought that strasses the fact that there is no specific product standard for Industrial Control panels in Europe: therefore the product cannot be CE Marked. The only way to support that reasoning is to demostrate the ICP is not a product falling under the Low Voltage Directive, in other termsit is not an Electrical Equipment. Here the definition taken from the Guide to the LVD:

Electrical Equipment: item used for such purposes as generation, conversion, transmission, distribution or utilisation of electrical energy, such as machines, transformers, switchgear and controlgear, measuring instruments, protective devices, wiring material, current-using equipment.

Nobody argues a swichgear must be CE Market - it actually has a product standard: EN 61439-1. Than, what is the difference between a Distribution Panel and an Industrial Control Panel? An ICP is not an Electrical Equipment, falling under the LVD, because it does not have a specific product standard? We consider that reasoning "weak".

For quick installation, these counters fit standard DIN panel cutouts. Wire them up to an electrical pulse-emitting switch, sensor, or encoder for use on machine tools, packaging machinery, or other equipment.

Press-on counters have a front panel that is rated NEMA 4 and IP66 for protection against dust and washdowns and outdoor use. The screw terminals are rated IP20.

For quick installation, this counter fits standard DIN panel cutouts. Wire it up to an electrical pulse-emitting switch, sensor, or encoder for use on machine tools, packaging machinery, or other equipment. An output relay sends a signal to another device when the counter reaches a set point. The signal can start/stop a process or trigger an alarm. A gasket provides protection from direct water sprays (meets IP65). UL Recognized Component, C-UL Recognized Component, and CE marked, this counter meets American, Canadian, and European safety standards.

You can set these counters up to count with or without voltage inputs based on the switch, sensor, or encoder you have. An output relay sends a signal to another device when the counter reaches a set point. The signal can start/stop a process or trigger an alarm. If power is lost, count backup maintains the count and programming backup maintains settings. A scaling function lets you adjust the unit of measure to suit your application.

85-250V AC5 A @ 250 V ACGasketCount Backup, Programming Backup, Scaling FunctionIP65, NEMA 4XUL Recognized Component, C-UL Recognized Component, CE Marked0000000

The digits displayed on these counters are visible up to 100 ft. away and the display can be adjusted to suit lighting conditions. You can set counters up to count with or without voltage inputs based on the switch, sensor, or encoder you have. They can be wired for remote reset. An output relay sends a signal to another device when a set point is reached. The signal can start/stop a process or trigger an alarm. Counters are protected from dust and washdowns and can be used outdoors (rated NEMA 4X). Programming backup maintains settings if power is lost.

For quick installation, these counters/ratemeters fit a standard 1/8 DIN panel cutout. Wire them up to an electrical pulse-emitting switch, sensor, or encoder to count input while tracking rates in units such as gallons per minute. The scaling function lets you adjust the unit of measure to suit your application. Counters are protected from dust and washdowns and can be used outdoors (rated NEMA 4X).

YesUp and Down62,000,000 (Voltage), 2,000,000 (Switch Contact)1/81.77"3.62"2"3.8"4.2"0-30V DC85-250V AC12V DC Power Source for External SensorIP65, NEMA 4XCE Marked, UL Listed, C-UL Listed0000000

YesUp and Down62,000,000 (Voltage), 2,000,000 (Switch Contact)1/81.77"3.62"2"3.8"4.2"0-30V DC11-36V DC12V DC Power Source for External SensorIP65, NEMA 4XCE Marked, UL Listed, C-UL Listed000000

This meter does not require voltage to register a count. It is protected from dust, water, and splashing oil and coolant (meets IP65, NEMA 4X, NEMA 12). Use it to display running time on a machine so you can schedule preventative maintenance.

With a display that can be placed up to 25 feet from the sensor, these flowmeter/totalizers are often used in hard-to-access areas. For a complete unit, order a display, a sensor, and a tee fitting.

Optional output module transmits output signals to an external device such as a data recorder, logger, or remote display (not included). It includes 10 feet of cable with wire leads.

Optional remote panel-mounting kit lets you mount the meter’s display up to 100 feet away. It includes a sensor module and 10 feet of cable with wire leads.

Also known as encoders, these sanitary transmitters convey motion to an electrical signal that conveys distance, direction, and speed. They’re often used in control systems to automate servomotors, robotics, and assembly machines in sanitary environments such as food and pharmaceutical plants. Made of corrosion-resistant stainless steel, they won’t rust from frequent washdowns with harsh cleaners. These transmitters are sealed and have a highly polished surface, leaving no room for bacteria to grow and making them easier to clean. They’re rated IP67 for protection from dust, high-pressure jets of water, and submersion in up to a meter of water for 30 minutes.

Check pH in harsh field conditions. These floating meters that have a housing that meets IP67 for complete resistance to dust and protection from temporary submersion. Automatic temperature compensation standardizes readings at 77° F to prevent inaccurate results in fluctuating temperatures. Use a calibration solution and the calibration button to maintain accuracy. They do not include Calibration Solution. Meters cannot be sold to Canada due to import regulations.

Check your indoor air quality (IAQ) by measuring the amount of particles present. These counters are often used to monitor dust levels in workshops, check for particles in classrooms, and measure filter efficiency in HVAC systems. The sensor probe detects and identifies particles of six different sizes, helping you confirm that your clean room complies with ISO Class requirements. First, use the zero count filter to establish a baseline before taking a sample. Then, either measure the amount of air particles detected within a set time range or the amount of air particles detected within a certain air volume. Counters store up to 10,000 readings in their internal memory, and you can transfer data to your computer via Ethernet or USB connection—no special software required. Compact, lightweight, and battery powered, these counters are portable and able to operate in tight spaces. They’re CE marked as compliant with European health, safety, and environmental standards.

Since these meters float and have a housing that meets IP67, they won’t be damaged by temporary submersion and have complete resistance to dust. They detect total dissolved solids (TDS) in water, hydroponic solutions, and other clean liquids to determine contaminant levels. Automatic temperature compensation standardizes readings at 77° F to prevent inaccurate results in fluctuating temperatures. Use a Calibration Solution (not included) and the calibration button to maintain accuracy.

Since this oxidation reduction potential (ORP) meter has a housing that meets IP67 for complete resistance to dust and protection from temporary submersion, it’s often used to determine a solution’s ability to break down contaminants in harsh field conditions. For use with dirty liquids containing heavy metals, sulfides, and harsh chemicals, this meter is often used for wastewater treatment. Automatic temperature compensation standardizes readings at 77° F to prevent inaccurate results in fluctuating temperatures. Use a Calibration Solution (not included) and the calibration button to maintain accuracy. Meters cannot be sold to Canada due to import regulations.

Check the oxygen levels of water and other clean liquids in harsh field conditions. This meter has a housing that meets IP57 for good resistance to dust and protection from temporary submersion. It has automatic temperature compensation that standardizes readings at 77° F to prevent inaccurate results in fluctuating temperatures. Use distilled water and the calibration button to maintain accuracy.

Don’t worry about dropping this meter in your tank when checking electrical conductivity—it floats and has a housing that meets IP67 for complete resistance to dust and protection from temporary submersion. For use with water, hydroponic solutions, and other clean liquids, this meter measures a liquid"s conductivity to indicate the concentration of salts, nutrients, chemicals, and other substances. It displays temperature in addition to conductivity. Automatic temperature compensation standardizes readings at 77° F to prevent inaccurate results in fluctuating temperatures. Use a Calibration Solution (not included) and the calibration button to maintain accuracy.

Don’t strain your eyes reading a scale—these bench-top meters indicate exact results on the digital display. For complete resistance to dust and protection from temporary submersion, these meters float and have a housing that meets NEMA 6 and IP67. They"re for use with water and other clean liquids. Automatic temperature compensation standardizes readings at 77° F to prevent inaccurate results in fluctuating temperatures. Use a Calibration Solution (not included) and the calibration button to maintain accuracy.

Take multiple water-chemistry and temperature measurements in hard-to-reach places from up to 3 feet away. Often used in tap water and wastewater, these meters work in both clean and dirty liquids. Automatic temperature compensation standardizes readings to 77° F to prevent inaccurate results in changing temperatures. The data hold function freezes the current reading on the display. For easy viewing, temperature and chemistry measurements appear on the same screen. These meters are IP57 rated, so they resist dust and withstand temporary submersion. They cannot be sold to Canada due to import regulations.

Conductivity, salinity, temperature, and total dissolved solids (TDS) meters take four measurements at once. Conductivity measures the concentration of salts, nutrients, chemicals, and other substances. Salinity measures the amount of dissolved salts. TDS determines the contaminant levels. The stainless steel sensor is durable and resists breaking.

Test temperature, chemical concentration, contamination, and salt levels in liquid from up to 6 ft. away, then send the results to your computer for analysis. These meters include a USB cable that transfers up to 1,000 readings. Often used to test water quality, they work on both clean and dirty liquids—from tap water to wastewater. Conductivity tests measure the concentration of salts, nutrients, chemicals, and other substances. Total dissolved solids (TDS) tests report contaminant levels. Salinity tests determine the salt levels in liquid. The sensor is made of stainless steel, so it’s durable and resists breaking. IP67 rated, these meters are dust tight and withstand temporary submersion.

Often used to save rinse water in beverage and pharmaceutical lines, these sensors test the amount of chemicals, cleaners, and other substances in liquids by measuring how well the liquid conducts electricity. They’re 3-A and European Hygienic Engineering and Design Group (EHEDG) certified, thanks to their design that’s easy to keep clean. Highly polished, they limit where bacteria could grow. They also withstand washdowns with hot water, chemicals, and cleaners common to sanitary lines because of their PEEK probe, stainless steel body, and IP ratings. Their IP ratings also mean they’re dust tight and won’t fail if briefly under water. All are FDA compliant to safely touch food.

Highly accurate, these sensors test almost any liquid. They also measure temperature—no need for a separate sensor. To compare readings as temperature changes, they automatically standardize readings at 77° F. All meet European safety standards, since they’re CE marked.

The CE mark indicates that a product is compliant with all applicable directives and regulations – which in turn requires the CE mark. Such ‘CE marking directives’ and regulations apply to a wide range of products, including electronics, toys, helmets, sunglasses, and medical devices.

In this guide, we list the directives and regulations for which the CE mark is required. Each directive and regulation also includes a product list andother requirements that EU importers and manufacturers must be aware of.

The European Commission requires that manufacturers place the CE mark on their products if such products are covered by one or more of the CE marking directives or regulations. Additional requirements also apply, as we explain in the next section.

Currently, there are more than 20 CE marking directives and regulations. Each one covers a certain product scope and describes the technical and regulatory requirements for manufacturers, importers, and distributors.

Many CE marking directives and regulations do not list the specific products under their scope. Instead, these list the general product scope (e.g. input and output voltage). Therefore, it is sometimes confusing for manufacturers or importers to determine which particular directive or regulation applies to their products.

CE marking directives and regulations specify technical, regulatory, environmental, or other requirements for manufacturers, importers, or distributors. Each directive and regulation have different requirements for the product it covers. Here we summarized some general requirements:

The Radio Equipment Directive (RED) establishes a regulatory framework, including electrical safety, electromagnetic compatibility, radio spectrum use efficiency, and other circulation requirements, for the radio equipment placed in the EU market.

Note that radio equipment is defined as any electrical or electronic device that intentionally emits and/or receives aiming at radio communication and/or determination.

Also, according to the directive, if the manufacturer or importer demonstrates compliance via relevant harmonized standards, then the conformity assessment procedure might be completed without Notified Body involvement.

However, if the manufacturer or importer has not applied harmonized standards – or such standards do not exist for the product – then a Notified Body shall be required, either via EU-type examination or conformity based on full quality assurance.

According to Article 2 of the Directive, ‘radio equipment’ is defined as any electrical or electronic product that intentionally emits and/or receives radio waves for the purpose of radio communication. This can include WiFi, LTE, 5G, Bluetooth or GPS-enabled devices.

a. EN 303 354 V1.1.1 Amplifiers and Active Antennas for TV Broadcast Reception in Domestic Premises; Harmonised Standard Covering the Essential Requirements

b. EN 300 422-1 V2.1.2 Wireless Microphones; Audio Pmse Up to 3 GHz; Part 1: Class a Receivers; Harmonised Standard Covering the Essential Requirements

The RoHS Directive restricts the use of hazardous substances in electrical and electronic equipment (EEE) and establishes waste disposal methods for such products in order to protect human health and avoid environmental pollution.

The RoHS Directive applies to almost all electronic products placed in the European Union market, although there are some exemptions listed on the annexes of the directive.

b. EN IEC 63000: Technical Documentation for the Assessment of Electrical and Electronic Products with Respect to the Restriction of Hazardous Substances

The Ecodesign Directive sets up the regulatory framework for improving the performance of the so-called “energy-related products”, that is electrical and electronic products that might have a big impact on energy consumption.

The directive mainly sets compulsory requirements on the energy efficiency of household appliances and other products, with the goal of protecting the environment.

The Toy Safety Directive establishes safety requirements for toys and certain types of children’s products intended to be used by children under 14 years of age.

It requires that products under the scope of the directive must follow the technical requirements regarding the chemicals and heavy metals concentration limit, mechanical/physical properties specification, flammability rate, and more.

Annex I of the directive lists exempted products such as puzzles with more than 500 pieces, and bicycles with a maximum saddle height higher than 435 mm.

The Personal Protective Equipment (PPE) Regulation establishes designing and manufacturing requirements for personal protective equipment (PPE) placed in the EU market for the purpose of protecting the health and safety of the user, either on worksites or other places that present potential physical danger.

The regulation classifies PPE into Category I, II, or III, depending on the level of risk of the environment associated with their use. The hazardous levels are arranged in ascending order.

Annex I of the Personal Protective Equipment Regulation established three risk classes for which PPE is intended to protect users. Below we explain the differences among these classes.

contact with cleaning materials of weak action or prolonged contact with water; contact with hot surfaces not exceeding 50 °C or other types of relatively minor risks take place in the working environment. Examples of Category I PPE include:

Protective equipment that is intended for military use, self-defense, and resistance to non-extreme climate conditions are often exempted from the PPE Regulation, although there are some exemptions, which you can find in the text of the regulation itself.

The Construction Products Regulation (CPR) established rules and standards for products used for construction purposes in the EU. The Regulation provides a regulatory framework to assess the performance of construction products from the perspective of mechanical resistance, stability, flammability, health, environmental impact, and more.

According to Annex III of the regulation, when the product is covered by harmonized standards then Notified Body involvement might not be necessary in order to complete a declaration of performance.

“‘construction product’ means any product or kit which is produced and placed on the market for incorporation in a permanent manner in construction works or parts thereof and the performance of which has an effect on the performance of the construction works with respect to the basic requirements for construction works;”

The Medical Devices Regulation applies to medical devices and their accessories and establishes a regulatory framework for the safety and health of the patients and users.

“This Regulation lays down rules concerning the placing on the market, making available on the market or putting into service of medical devices for human use and accessories for such devices in the Union. This Regulation also applies to clinical investigations concerning such medical devices and accessories conducted in the Union.”

‘Medical Device’ can mean any instrument, apparatus, appliance, material, or other articles intended to be used for diagnosing, preventing, monitoring, predicting or alleviating disease, disability, physiological or pathological problems.

The regulation classifies medical devices into four classes: Class I, IIa, IIb, and III, where the medical devices of Class III hold the highest risk. The higher the number is, the stricter the rules that apply to the products.

Class IIa: Medical devices that have some potential low to medium risk and can generally be used for less than 30 days. Products belonging to this category include surgical gloves, hearing aids, and diagnostic ultrasound machines.

Class IIb: Medical devices that might constitute medium to high-risk to the patients and are generally designed to be used for more than 30 days. Products belonging to this category include long-term corrective contact lenses and surgical lasers.

Class III: Medical devices that have the potential highest risk. Products such as cardiovascular catheters, aneurysm clips, hip-joint implants, and prosthetic heart valves are considered as Class III medical devices.

a. EN IEC 60601: Medical Electrical Equipment – Part 2-83: Particular Requirements for the Basic Safety and Essential Performance of Home Light Therapy Equipment

b. EN ISO 17664: Processing of Health Care Products – Information to Be Provided by the Medical Device Manufacturer for the Processing of Medical Devices – Part 1: Critical and Semi-critical Medical Devices

The In-Vitro Diagnostic Medical Devices Regulation lays down rules and regulatory requirements for in-vitro diagnostic medical devices intended to be used by humans in the EU.

c. EN ISO 25424: Sterilization of Health Care Products – Low Temperature Steam and Formaldehyde Requirements for Development, Validation and Routine Control of a Sterilization Process for Medical Devices

The Measuring Instruments Directive regulates measuring instruments placed in the market of the EU. In particular, according to the regulation, measuring instruments shall provide an accurate measurement.

This directive stipulates that, for all non-automatic weighing instruments, it is compulsory to conduct a product performance assessment and ensure the products meet all essential requirements of the EU legislation before being marketed among the member states of the EU. Notified Body involvement is generally required.

“This Directive, which comes under the SAVE programme concerning the promotion of energy efficiency in the Community, determines the efficiency requirements applicable to new hot-water boilers fired by liquid or gaseous fuels with a rated output of no less than 4 kW and no more than 400 kW, hereinafter called ‘boilers’.”

The Noise Emission in the Environment Directive regulates the noise emissions into the environment generated by machinery used in outdoor areas, including the conformity assessment procedure and technical documentation.

The directive provides two options for certification of the regulated outdoor machinery. When such equipment is subject to permissible sound power levels, the Notified Body involvement is required in the aspects of product design manufacturing procedures.

The Gas Appliances Regulation covers a wide range of household appliances function by means of burning gaseous fuels for the purpose of cooking, heating, refrigerating, lighting, and washing. The regulation establishes harmonized standards and procedures from the aspects of design, structure, and safety.

“ ‘appliances’ means appliances burning gaseous fuels used for cooking, refrigeration, air-conditioning, space heating, hot water production, lighting or washing, and also forced draught burners and heating bodies to be equipped with such burners.“

The Pressure Equipment Directive regulates pressure equipment and assemblies with a maximum allowable pressure greater than 0.5 bar gauge in terms of safety requirements, product design, and manufacturing procedures.

The directive classifies pressure equipment into four categories, ranging from I to IV. The hazardous levels are arranged in ascending order. Conformity with the directive requires Notified Body involvement. Note, however, for a product classified under the category I is generally optional.

“ ‘pressure equipment’ means vessels, piping, safety accessories, and pressure accessories, including, where applicable, elements attached to pressurised parts, such as flanges, nozzles, couplings, supports, lifting lugs.”

The Simple Pressure Vessels Directive establishes procedures for simple pressure vessels in terms of design, manufacturing, safety, conformity assessment procedures, free movement, and other essential requirements for these products.

The Lifts Directive regulates lifts in terms of design, manufacture, components, installation, safety rules, and maintenance methods. The directive provides standards for manufacturers, importers and owners of lifts to refer to.

(c) goods alone if the carrier is accessible, that is to say a person may enter it without difficulty, and fitted with controls situated inside the carrier or within reach of a person inside the carrier.”

The Cableway Installations Regulation sets up rules for cableways designed with the purpose of transporting people. This regulation involves requirements for the design, components, construction, subsystems, installations, infrastructure, operation, safety analysis, and the process of the cableway entry into service in the EU market.

a. EN 1709: Safety Requirements for Cableway Installations Designed to Carry Persons – Precommissioning Inspection, Maintenance, Operational Inspection and Checks

The Rail System Interoperability Directive sets standards for community rail systems concerning the design, construction, placement in service, upgrading, renewal, operation, and maintenance of the system, as well as the health condition of the staff who operate the system.

The ATEX Directive defines the essential health and safety requirements and conformity assessment procedures for equipment and protective systems used in an environment with potential explosive hazards in the EU market.

Most of the products regulated by this directive require Notified Body involvement. However, there are some exceptions, which can be found in Article 13 of the Directive

‘pyrotechnic article’ means any article containing explosive substances or an explosive mixture of substances designed to produce heat, light, sound, gas or smoke or a combination of such effects through self-sustained exothermic chemical reactions.”

Let iCertifi help you with your CE approvals. Since we are a consulting firm, we offer a different approach to homologations. Since we are not a test laboratory, we have partnerships with several test laboratories worldwide. We will negotiate the pricing from multiple test labs to ensure you obtain the best pricing possible. Since we are not tied to a single laboratory, we can also find laboratories with the best completion time. This allows you to obtain your certifications much faster which will allow your time to market to be expedited.

We have helped many companies become certified to sell their products in the European Union. Our experience in accordance with CE norms and our international partnerships with laboratories and regulators allows you to engage a single company for all your International Market Access (IMA) needs.

Product manufacturers needed to display the CE mark(stamp) on their product. The process of getting a CE mark(stamp) may seem vague. An outline of the process is as follows:

Distributors of products requiring CE marking should be inspected to ensure that this brand is present and properly positioned in the items. Distributors must also examine the accompanying documentation to ensure that the CE mark is obtained legally and correctly.

If you are a merchant for a product that is distributed in the European Economic Area, please contact us for professional certification services. We can help you to ensure that your products are on a legal level of safety, a level of health and environmental protection.

Postal stamps are established in accordance with the EC directives. This Directive is a legal act of the European Union (EU). The EU has established product codes for many industries in 1985. These standards are standards of health, safety and environmental protection.

Presently, set standards and legal standards are managed by two separate entities. While the European Union has established compliance with CE rules, you do not have to go through the EU. Instead, compliance can be applied in different ways.

1. Each distribution company has the opportunity to check the compliance efforts of their manufacturers. If the distributor checks their client’production, the manufacturer of the product must provide evidence of their CE mark.

iCertifi can assist you with your CE certification which often is the first step in International Market Access. If your ambitions are to sell your products globally, iCertifi can assist you with this process as well. We are proficient in certifications such as; CE, FCC, Industry Canada (IC), safety type approval (CB Scheme, IRAM S-Mark), Energy Efficiency such as CONUEE in Mexico and more. iCertifi can also provide you with local applicant services in any country you wish to penetrate. Let us help you eliminate the burdens to International Market Access. Contact us at (541) 275-5020 to get started on your CE certification.

CE Certificate of Compliance allows products to move freely and sell on the European market. This brand offers consumers proof that the product meets the environment, health and safety standard set by the EEA. Performance requirements are not a guarantee of quality. This simply means that the product fulfills the conditions for sale in the EU.

It is important to note that the CE marking does not mean that the product is made in the EEA. The European conformity marking indicates that it has reviewed, approved and pass the environment, safety and health that the EEA has established for a product to be sold in the EEA.

This Mark is our Enhanced Certification Mark, and it includes information to assist in verifying the product is certified and describing the scope of the certification. For more answers to common questions about the Enhanced Certification Mark click here

A CE Marking is a European marking of conformity that indicates that a product complies with the requirements of the applicable European laws or directives. The European Community established the CE marking system to ensure free movement of products between member countries and to remove internal barriers to trade. The CE marking is a legally required marking in the European Union (EU) and applies to a variety of product categories. It is usually a manufacturer’s self-declaration that the product complies with European laws and may not include assessment to safety requirements.

Because most products bearing the CE mark are not required to be third-party certified, are not subject to ongoing factory surveillance of production, and may not be compliant with applicable U.S. product safety standards, they are not considered to be Listed as defined in NFPA and ICC model codes and standards. For more information about the CE mark click here

No, UL Marks may only be applied at manufacturing facilities authorized by UL. Any violations should be immediately reported to UL. The only exception is if UL authorizes the UL Mark to be applied in the field as a result of a field inspection. During a field inspection UL representatives determine if the product complies with applicable safety standards and requirements, and if compliance is determined product labeling is performed in the presence of the UL representative. However, this takes place only after the local authority having jurisdiction has been consulted. Click here for additional details.

I am often contacted by Architects and other design professionals with specific questions, is there a place to direct them for answers to common questions?

A manufacturer’s literature indicates a product complies with a UL standard, but the certification cannot be located in UL ProductiQTM. What does this mean?

The UL certification may be very recent and is not yet available in UL ProductiQTM. In this case, the manufacturer should be able to provide documentation from UL confirming the certification.

An authorized use of the UL Mark is the manufacturer’s declaration that the product was manufactured in accordance with all applicable requirements, and was in compliance with those requirements when it was shipped from the factory. If that product is modified after it leaves the factory, only a UL Field Evaluation can determine if the modified product complies with UL’s requirements. It is the responsibility of the Authority Having Jurisdiction to assess the acceptability of the modifications or to determine if the modifications are significant enough to require a UL staff member to evaluate the modified product. UL can assist the AHJ in making this determination. For information on UL field evaluations click here.

Yes, UL is committed to protecting the integrity of the UL Mark and, by extension, protecting the individuals and communities that rely on UL. You can help correct potential problems with UL certified products by filing a product incident report, which will start a formal investigation into the problem. The product incident report program covers problems related to:

Product markings, packaging, literature and web site content that imply an inaccurate or inappropriate association between the product and a UL certification.

UL Standards for Safety are not needed to determine code compliance, even if the installation code indicates that a product or material must comply with a specific UL Standard. The Guide information in UL ProductiQTM, or in UL’s published product directories, usually identifies the standard(s) used to investigate and certify products in a particular product category. This information can assure code officials that a product was evaluated to the appropriate product standard, which is often referenced in a model code or regulation. If there is a need to access the UL Standards this can now be done using our complimentary web based service. To learn more about creating an account and accessing UL Standards for freevisit this page

UL Codes & Regulatory Services experts are available to provide code authorities with answers about the applications for which products are certified. Leave a message or send an email and we will respond promptly. Please call +1.800.595.9844 or email

RF2K7X3YT–The CE (Conformité Européenne) Logo to show the compliance to European standards of electric appliances on a heap on a table. Copy Space, web banner f

RF2KNH1DX–packaging symbols: CE mark symbol, fragile or handling with care symbol, keep dry symbol and side up symbol. Collection of symbols for cardboard packa

RM2D9GHAF–Mark Dion"s yurt-like circular metal Environmental Field Station installation. In the south fields during autumn, peak fall color at Storm King Art Ce

RM2G2FJB7–Metal plaque with a CE marking on a wooden telegraph pole, indicating it meets European Union legislation for safety, health and environmental protect

RM2G2FJC2–Metal plaque with a CE marking on a wooden telegraph pole, indicating it meets European Union legislation for safety, health and environmental protect

RFTDN749–COMO, ITALY - MAY 8, 2015: The baroque cupola with the scucco of Four Evangelist in Cathedral (Duomo di Como) by Gaspare Mola di Coldrerio from 17. ce

What is CE certification? And why should you care? Let us provide you with an overview of PPE regulation and CE certification and what it means for you.

Since April 2018, all motorcycle garments fall under the scope of the PPE regulation, which basically means that if it is sold as protective motorcycle apparel, it’s deemed to be personal protective equipment and should be tested at an official notified body under a strict set of standards to comply with the PPE regulation.

In this article, we’ll run you through the basics of CE certification and compliance and what that means for you as a consumer, so you know what to look for when you’re out shopping for motorcycle equipment, either online or in store.

You’ve likely seen the “CE” marking on items you’ve purchased from a store including: children’s toys, electronics, cookware, you name it. CE stands for “Conformité Européenne” (French for European Conformity).

A CE label or marking on a product is a declaration of compliance with the relevant or applicable health, safety, and environmental protection legislations for products sold within the European Economic Area (EEA). The CE marking is also found on products sold outside the EEA that are manufactured in - or created to be sold in - the EEA.

Let’s face it, safety isn’t a sexy topic! When people throw numbers and letters around in regard to certification requirements, there’s a tendency to let the mind wander to more exciting places. We get it.

Very much, actually. Motorcycle clothing (specifically jackets and pants/trousers, notwithstanding gloves, boots, and impact protectors) is grouped into what’s called Personal Protective Equipment – aka PPE. And like your kitchenware or electronics, PPE is governed by their own specific set of rules and regulations depending on how these products are used and how they are classified, and which group/subgroup they fall under. Here’s where it gets quite complicated. The set of standards that “govern” PPE - specifically motorcycle clothing - for leisure use is CE-standard EN 17092, which has now become a harmonized European standard.

Harmonized standard, meaning that it is a recognized throughout the EU as a tool that’s widely accepted for the certification of PPE motorcycle garments. We’ll talk more about this a little later on. That said, we’ll disclaimer here and say that this is intended to be a general overview of an incredibly complex subject that is both politically and economically charged. The purpose is to help riders understand that even with an arguably imperfect system in place, the CE-certification label/marking does mean something. It means that the garments have been tested to meet at least the minimum safety requirements, so you actually know what it’s intended use is. And that’s Personal Protective Equipment in the form of motorcycle clothing.

Anything deemed personal protective equipment (PPE) has always had to meet the PPE Directive 89/686/EEC, which was introduced 21 December, 1989, and fully implemented 30 June, 1994. This “old” PPE Directive specified an extensive set of requirements that PPE should comply with. The requirements were rather vague, and demonstrating compliance to them was, more or less, open to interpretation and subject to the “imagination” of manufacturers and accredited test institutes.

Here’s one of many sharp turns. The PPE directive is different from the PPE regulation. In order for CE certification to happen, PPE would need to be tested against a specific set of standards pertaining to its specific use. A set of standards within a set of rules and regulations, so to speak. Enter EN 13595. In order to harmonize criteria among European countries, EN 13595 was created which gave a tool for the testing of motorcycle apparel, however it was widely ignored by the motorcycle apparel industry as it only referred to professional use.

In EN 13595, it described, in four parts, how certification could be achieved: 1) general requirements, 2) the test methods for the determination of impact abrasion resistance, 3) the test method for determination of burst strength, and 4) the test method of determination of impact cut resistance when applied to motorcycle clothing for professional use.

Examples of professional riders can include: someone who delivers letters, parcels, or other small freight; the transport of passengers by motorcycle; emergency medical treatment; or vehicle breakdown support. If you have to ride a motorcycle to perform your job, then your “clothing” needs to comply with EN 13595 in order to be CE certified. But since the bulk of motorcycle apparel was meant for - as many argued – leisure use, the standard was essentially ignored by the industry.

Since the industry widely ignored/overlooked the professional EN 13595 standard, that meant that a blind eye was also turned on the PPE Directive. Furthermore, there was no guarantee, or no science that would back up a claim, that the garment you were purchasing at a motorcycle apparel distributor for your personal/leisure use lived up to minimum safety requirements. Because, let’s face it, if you don’t have a set of standards in place to test against, this simply isn’t easy. Very, very few garments in the leisure segment, leading up to the last few years, were CE-certified using the EN 13595 standard.

That lead to people buying garments that they perceived to be safe; by touch and sight. But in reality, when put to the test, could fail miserably. Furthermore, a set of standards which would allow the testing of motorcycle garments as PPE is not something that happens overnight. It’s an incredibly long process that has many moving parts. It also includes legislators, government officials, industry professionals, test-house representatives, and many more. To even reach some sort of compilation of standards, with different insights from lobbyists and various organizations, took many sleepless nights and the brainpower of those who are at the core of the industry.

After years and years of discussion and deliberation, WG9 (which means Working Group 9 – a collective of 30-40 European representatives including stakeholders, clothing manufacturers, or for example, test-house institutes that specialize in specific testing processes), came up with a provisional set of standards that reflect – as accurately as possible – a way of achieving CE certification for leisure use of motorcycle garments. Enter EN 17092.

Urban riders likely won’t be wearing full-leather one-piece suits to commute in, despite it being a “safer” choice. Nor will adventure riders. That said, it’s a fine balance between making sure safety is a top priority, but also that comfort, breathability, waterproofing, flexibility, and more is taken into consideration, all while offering the protection best suit to the riding style.

Within EN 17092, just as there are in EN 13595, there are specific requirements for CE certification. While the standard explains what tests need to be performed and how, it doesn’t necessarily explain why these specific elements are tested. We’re here to elaborate on a few of them.

The determination of impact abrasion resistance– One of the biggest differentiators between the professional and leisure standard - though both are requirements - is in the way in which determination of impact abrasion resistance is tested. It determines if a fabric can withstand/resist an impact abrasion slide. A hole bigger than 5 mm when tested using the AART Machine (Advanced Abrasion Resistance Tester) equates to a fail. This test is in place so the outer shell of the fabric can take the hit. Not your skin. The lowest outcome of a material is how it will be graded.

Tear strength – Here a pre-slit specimen is “pulled apart” and we measure the force that’s necessary to further tear it. If you rip open your garment via a sharp object, we want to make sure that it’s very difficult to rip the fabric open further.

Seam strength – Seam strength is tested on the structurally strong seams. For example, the sleeve that’s attached to the body of a jacket. It measures the force necessary to rip the seam open. We want to make sure that if you fall of your bike, then slide, that the seams from vital connection points remain connected.

Dimensional stability – Dimensional what?! Exactly. This test requires a garment to be washed five times, not in a regular washing machine but one that is specific for fabric testing, with water speed, volume, how fast it spins, temperature, etc. all regulated. The purpose it to make sure the garment doesn’t shrink over time/washings, to ensure the correct fit, and to make sure the protectors in the garment stay in the proper location. There can be no more than five percent shrinkage, or it fails.

Innocuousness – This is another example. The amount of chemicals used – such as dyes - on the garment must be safe, especially when it comes into contact with your body. We test pH to make sure it’s gentle on the skin and no irritation occurs. Additionally, we also test any substances that are known to endanger the health of the user or that of the environment.

We’ve been fervently working at making sure our garments are not only at the CE-certification class, but at a class beyond. A level that gives you additional peace of mind when on the road.

It was widely accepted that as of this date, in order to comply with the PPE regulation, companies were given one year to update their motorcycle clothing collections to make sure their garments lived up to the new standards. In short, that was a large demand for a standard that wasn’t even set in stone (at the time).

At REV’IT!, we never shy away from a tall order. Especially if it means your safety is at risk. We’ve been fervently working at making sure our garments are not only at the CE-certification class (EN 17092 parts 1 to 6), but at a class beyond. A level that gives you additional peace of mind when on the road.

Impact protectors aren’t clothing, so they require their own set of standards. So do boots and gloves, despite them generalized as clothing. That’s why it’s so important to certify something based on the appropriate set of standards depending on the foreseen use of the PPE product

For a standard to be harmonized, it must be published in the Official Journal of the European Commission. This will mean that it is a tool that’s widely accepted, and it allows for consistency on motorcycle clothing sold regardless of what region/country/city you live in within Europe (and beyond!). CE certification has a life of five years from the time the product is certified.

Class AAA garments offer the highest level of protection from impact and abrasion, using materials and constructions that meet higher requirements than for garments classified as Class AA and Class A. Class AAA garments may have limiting ergonomic, weight, and thermal penalties for some riding activities. Some common examples include one-piece or combi suits.

Class AA garments offer protection from impact and abrasion, using materials and constructions that meet higher requirements than for garments certified as Class A and lower requirements than Class AAA certified garments. Class AA garments generally offer protection against the risks of the greatest diversity of riding activities, and they may have lower ergonomic and weight penalties than Class AAA garments.

Class A garments offer the minimum necessary degree of protection from impact and abrasion; using materials and constructions that meet lower requirements than garments certified as Class AAA or Class AA. Class A garments are expected to have the least ergonomic and weight penalties. Some examples can be garments designed to be worn in warm climates or garments designed to be worn alone or over other clothing.

This class is specialized for garments designed to provide equivalent abrasion protection of Class A garments but without the inclusion of impact protectors. Class B garments do NOT offer impact protection and it is recommended that they be worn with, at least, EN 1621-1 shoulder and elbow impact protectors, in the case of a jacket, or EN 1621-1 knee impact protectors, in the case of trousers/pants, in order to offer complete minimum protection. Keep in mind, to achieve maximum protection from Class B garments (for example the Sierra jersey in the REV’IT! DIRT Series collection), they should always be coupled with Class CO or Class CU (Proteus protector jacket); that way the rider is getting both abrasion resistance and impact protection. We do not recommend wearing Class B garments without impact protection.

This class is for specialized non-shell, impact protector ensemble garments, designed only to hold one or more impact protectors in place, either as an Undergarment(U) or an Overgarment(O) – hence the CO and CU designation. Class C garments are designed to provide impact protection for areas covered by the impact protector(s) only and they do not offer complete minimum abrasion protection, and may not offer complete minimum impact protection. Class C garments are designed to offer supplemental impact protection only. It is intended for Class C garments to be worn in combination with AAA, AA, or B garments to enhance protection class.

Because of our in-house test lab, we have the ability to run potential fabrics and materials through rigorous tests (the same ones used in the CE certification process) that we could end up using in our garments; an advantage that other clothing manufacturers don’t necessarily have. That said, we don’t self-certify for PPE regulation. We investigate, we test, we see how certain fabrics perform, and based on this data, we compile a fabrics and constructions library. The ones that pass and exceed – based on CE criteria, as well as our own REV’IT! standard – as mentioned, can end up in your next favorite jacket or trousers.

To have a garment CE certified, the tests must be conducted through/at a notified body, a third party that’s involved. As the company, we provide detailed product information (called a “technical file” which includes what materials are used where, drawings, constructions, etc.) and the notified body will take those documents and compare them to the garment itself; making sure what we provide on paper is not falsified and truly reflects the garment. The notified body will then run the required tests on the garment(s) and confirm compliance or not. A garment either passes or fails for a certain classification.

Not everyone plays by the rules, and so it’s important to take notice of the following information when trying to figure out whether a garment, boot , protector, or pair of gloves is actually CE-compliant. Part of CE compliance is also correct labeling, and this is a relatively easy way to distinguish fake labeling from authentic labeling.

Every garment/protector/gloves/boots/shoes in the store (products launched to market after April 2018), which has been CE certified will always have a booklet explaining in which class it has been certified in. There will also be either markings or labels indicating which class of protection it provides and the standard against which it was tested. Care and maintenance instructions will also be provided, among others.

Furthermore, in the booklet, you will find a special website address, on which you can request a so-called DoC; the Declaration of Conformity of the product. This will then be provided to you by mail. If the item you’re looking at is not certified, there is no DoC. Easy, isn’t it?

There’s quite a bit of literature being disseminated that riders must wear CE-certified motorcycle clothing while riding. This is false. Depending on the country or region you live in, there are minimum requirements of what you are legally obligated to wear (likely only a helmet, a pair of boots or gloves, if even that), but the rest is up to you. This is, however, likely to change in the nearby future.

With the EN 17092 standard being harmonized, it means that clothing sold in stores with the purpose of being used while motorcycling do comply with specific requirements. Because, as mentioned, clothing that looks like it’s geared toward riding must actually reflect it in the worst-case scenario situation.

What you choose to wear while riding is (still) your choice. No one is forcing you to wear CE-certified garments. Please also note that clothing developed before 2018 did not have to be compliant, so you will still find plenty of garments at your favourite dealership that does not have the appropriate labels inside. That does not necessarily mean the garment isn’t safe. It just has never been submitted to certification. But, in our experience, and in your best interest, we absolutely recommend that you wear the maximum protection you can atop your bike. You owe that to yourself and your loved ones.

It’s important to remember that there’s a common misconception that your motorcycle clothing will walk away from an accident unscathed. That it will remain intact despite a fall at a certain speed on an abrasive/non-abrasive surface even if it lives up to strict standards by which it was tested against. That’s not always the case. Riding clothing – including jackets, pants, gloves and boots – are there as a second skin; a shield so to speak. They are there to mitigate/minimize damage to your body. Meaning, they’ll be there to take the hit so your skin and body can stay intact.

At REV’IT!, our goal is to not only provide you, the rider, with some of the most innovative and design-driven technical motorcycle clothing on the market, but to make sure you’re as protected as possible. That’s why we take the CE requirements very seriously. And not just that. We enthusiastically embrace the fact that the new rules apply to all apparel manufacturers as it will prevent the market from being overflooded with protective claims that simply don’t hold up to any scientific test. Certifying a garment based on EN 17092 is the art of balancing safety, engineering, affordability, weather protection, breathability, and more. It’s a well-thought-out standard created by industry professionals.

.background-image-63b24fc64342a {background-image: url(https://www.revitsport.com/media/images/footer/learning-center/ce-explained/C010-CE-Infographic_Gloves_UK.jpg);}.background-image-63b24fc643431 {background-image: url(https://www.revitsport.com/media/images/footer/learning-center/ce-explained/C010-CE-Infographic_Footwear_UK.jpg);}.background-image-63b24fc643439 {background-image: url(https://www.revitsport.com/media/images/footer/learning-center/ce-explained/C010-CE-Infographic_Limp-Protection_UK.jpg);}.background-image-63b24fc64343f {background-image: url(https://www.revitsport.com/media/images/footer/learning-center/ce-explained/C010-CE-Infographic_Back-Protection_UK.jpg);}.background-image-63b24fc643446 {background-image: url(https://www.revitsport.com/media/images/footer/learning-center/ce-explained/C010-CE-Infographic_Chest-Protection_UK.jpg);}

CE Certification is required for all recreational boats entering or being sold in the European Union. Manufacturers must test and document to ensure conformity to all applicable European directives and requirements. CE certification is obtained from Notified Bodies, organizations that are recognized by European states to conduct CE assessments and issue CE certification documents.

NMMA works closely with the International Marine Certification Institute (IMCI), a notified body in Europe that issues conformity certificates, to assist U.S. boat builders in the certification process. Certification by a notified body enables you to display the CE mark on your products and allows you free and open access to the European Union market.

The EN standards were established as universal EU standards in order to facilitate EU directives. These standards were merged with the international IEC standards and henceforth reflect the standards in all countries. Also, the CE marking show that products conform to EC directives, and guarantee the free flow of products within the EC.

The EMC directive was 1 January 1996, and the low voltage directive was enacted from 1 January 1997. The telecom directive was established by the separate CTR (Common Technology References.)

With some exceptions, the directive covers mainly machine tools and injection mold equipment, automated machinery, construction equipment, and other industrial machinery,

Effectively, such equipment must neither be a source of EMI (electromagnetic interference), nor malfunction owing to extraneous EMS (electromagnetic susceptibility).

So, not only must equipment not emit electromagnetic waves that have a powerful external effect, it is also required to be immune to influence from extraneous electromagnetic waves.

This directive applies to all terminal equipment that is directly or indirectly connected to public lines and all communications equipment that sends or receives radi

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey