lcd module 1602 python code made in china

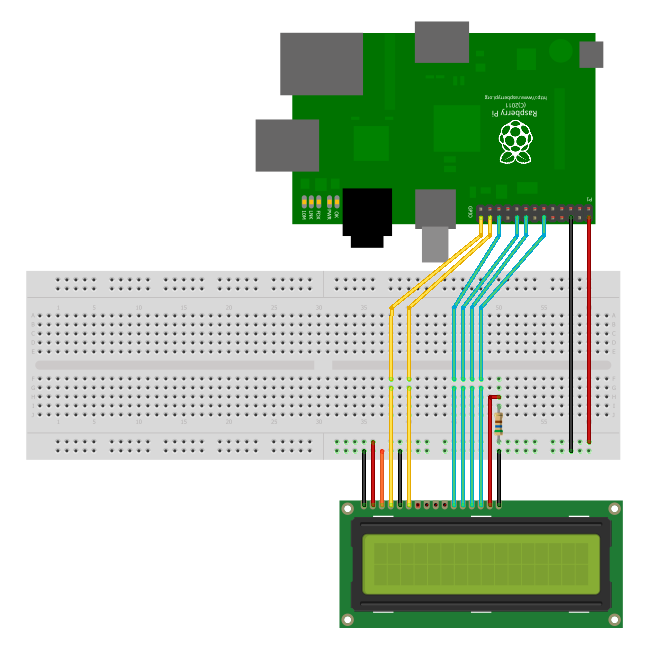

Once you’ve played with LEDs, switches and stepper motors the next natural step is 16×2 alphanumeric LCD modules. These modules are cheap (less than $10) and easy to interface to the Raspberry Pi. They have 16 connections but you only need to use 6 GPIO pins on your Pi.

Most of the 16×2 modules available are compatible with the Hitachi HD44780 LCD controller. This allows you to buy almost any device and be sure it is going to work in much the same way as any other. There are loads to choose from on eBay with different coloured backlights. The one I purchased had a blue backlight.

You can control a HD44780 style display using any programming environment you like but my weapon of choice is Python. I use the RPi.GPIO library to provide access to the GPIO.

This script can be downloaded using this link or directly to your Pi using the following command :wget https://bitbucket.org/MattHawkinsUK/rpispy-misc/raw/master/python/lcd_16x2.py

If you use this code the only thing you will need to change is the GPIO pin mapping depending on what pins you use on your Pi GPIO header. Here are some photos :

Additional Notes : RS is low when sending a command to the LCD and high when sending a character. RW is always low to ensure we only ever input data into the module. 8 bit bytes are sent 4 bits at a time. Top 4 bits first and the last 4 bits second. Delays are added between certain steps to ensure the module can react to the signal before it changes.

The code above was inspired by code submitted by ‘texy’ on the RaspberryPi.org forum. I changed the way the bytes are broken down to bits as this significantly increased the response time of the display.

You can directly attach it to the 40PIN GPIO of Raspberry Pi. Or you can wire it to Raspberry Pi with PH2.0 4PIN interface of the Module, please refer to the Pin definition below:

Take the LCD1602 RGB Module as an example, just connect it to the Raspberry Pi. The color of actual cable may be different with the figure here, please connect them according to the pins instead of color.

Find the LCD1602-RGB-Module-demo.uf2 file under the build file under the demo directory, press and hold the BOOTSEL button of Pico, connect the USB of Pico to the PC with a MicroUSB cable, and drag the uf2 file into Pico, and then the Pico will run the demo directly.

1. Copy LCD1602-RGB-Module-demo folder to your pico-examples file directory, and then modify the CMakelists.txt configuration file in the pico-example directory as shown in the figure below.

2. Open Visual Studio Code, open your pico-examples folder, select LCD1602_RGB_Module_demo, click Generate, you can find the LCD1602_RGB_Module_demo.uf2 file in the build folder.

HW: HP dc7900 USD running ESXi, RaspberryPi (few of it), AEON S2 USB stick, Fibaro modules (Dimmers, switches), 1-wire (DS18B20, DS2423), DSC Alarm with Envisalink ethernet module, MySensors, RFLink

Check the number in the table, this is your address. If there are more devices on your I2c bus, there will be several addresses visible. To be sure, unplug all other devices and the address left will be the LCD (or try them all)

HW: HP dc7900 USD running ESXi, RaspberryPi (few of it), AEON S2 USB stick, Fibaro modules (Dimmers, switches), 1-wire (DS18B20, DS2423), DSC Alarm with Envisalink ethernet module, MySensors, RFLink

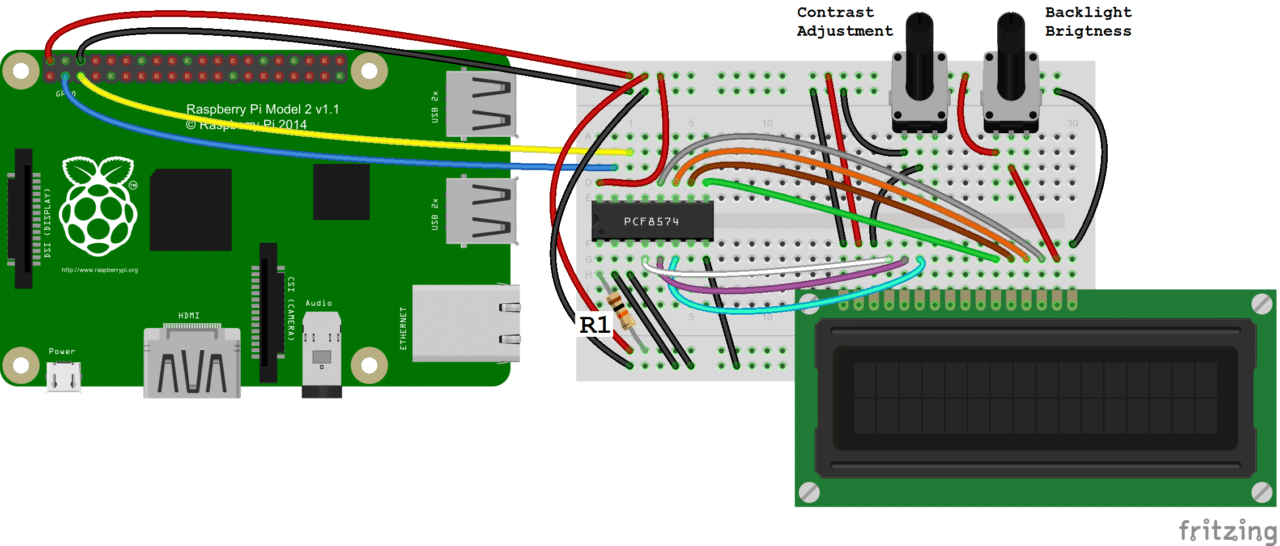

Connecting an LCD to your Raspberry Pi will spice up almost any project, but what if your pins are tied up with connections to other modules? No problem, just connect your LCD with I2C, it only uses two pins (well, four if you count the ground and power).

In this tutorial, I’ll show you everything you need to set up an LCD using I2C, but if you want to learn more about I2C and the details of how it works, check out our article Basics of the I2C Communication Protocol.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

There are a couple ways to use I2C to connect an LCD to the Raspberry Pi. The simplest is to get an LCD with an I2C backpack. But the hardcore DIY way is to use a standard HD44780 LCD and connect it to the Pi via a chip called the PCF8574.

The PCF8574 converts the I2C signal sent from the Pi into a parallel signal that can be used by the LCD. Most I2C LCDs use the PCF8574 anyway. I’ll explain how to connect it both ways in a minute.

I’ll also show you how to program the LCD using Python, and provide examples for how to print and position the text, clear the screen, scroll text, print data from a sensor, print the date and time, and print the IP address of your Pi.

Connecting an LCD with an I2C backpack is pretty self-explanatory. Connect the SDA pin on the Pi to the SDA pin on the LCD, and the SCL pin on the Pi to the SCL pin on the LCD. The ground and Vcc pins will also need to be connected. Most LCDs can operate with 3.3V, but they’re meant to be run on 5V, so connect it to the 5V pin of the Pi if possible.

If you have an LCD without I2C and have a PCF8574 chip lying around, you can use it to connect your LCD with a little extra wiring. The PCF8574 is an 8 bit I/O expander which converts a parallel signal into I2C and vice-versa. The Raspberry Pi sends data to the PCF8574 via I2C. The PCF8574 then converts the I2C signal into a 4 bit parallel signal, which is relayed to the LCD.

Before we get into the programming, we need to make sure the I2C module is enabled on the Pi and install a couple tools that will make it easier to use I2C.

Now we need to install a program called I2C-tools, which will tell us the I2C address of the LCD when it’s connected to the Pi. So at the command prompt, enter sudo apt-get install i2c-tools.

Next we need to install SMBUS, which gives the Python library we’re going to use access to the I2C bus on the Pi. At the command prompt, enter sudo apt-get install python-smbus.

Now reboot the Pi and log in again. With your LCD connected, enter i2cdetect -y 1 at the command prompt. This will show you a table of addresses for each I2C device connected to your Pi:

We’ll be using Python to program the LCD, so if this is your first time writing/running a Python program, you may want to check out How to Write and Run a Python Program on the Raspberry Pi before proceeding.

I found a Python I2C library that has a good set of functions and works pretty well. This library was originally posted here, then expanded and improved by GitHub user DenisFromHR.

There are a couple things you may need to change in the code above, depending on your set up. On line 19 there is a function that defines the port for the I2C bus (I2CBUS = 0). Older Raspberry Pi’s used port 0, but newer models use port 1. So depending on which RPi model you have, you might need to change this from 0 to 1.

The function mylcd.lcd_display_string() prints text to the screen and also lets you chose where to position it. The function is used as mylcd.lcd_display_string("TEXT TO PRINT", ROW, COLUMN). For example, the following code prints “Hello World!” to row 2, column 3:

On a 16×2 LCD, the rows are numbered 1 – 2, while the columns are numbered 0 – 15. So to print “Hello World!” at the first column of the top row, you would use mylcd.lcd_display_string("Hello World!", 1, 0).

You can create any pattern you want and print it to the display as a custom character. Each character is an array of 5 x 8 pixels. Up to 8 custom characters can be defined and stored in the LCD’s memory. This custom character generator will help you create the bit array needed to define the characters in the LCD memory.

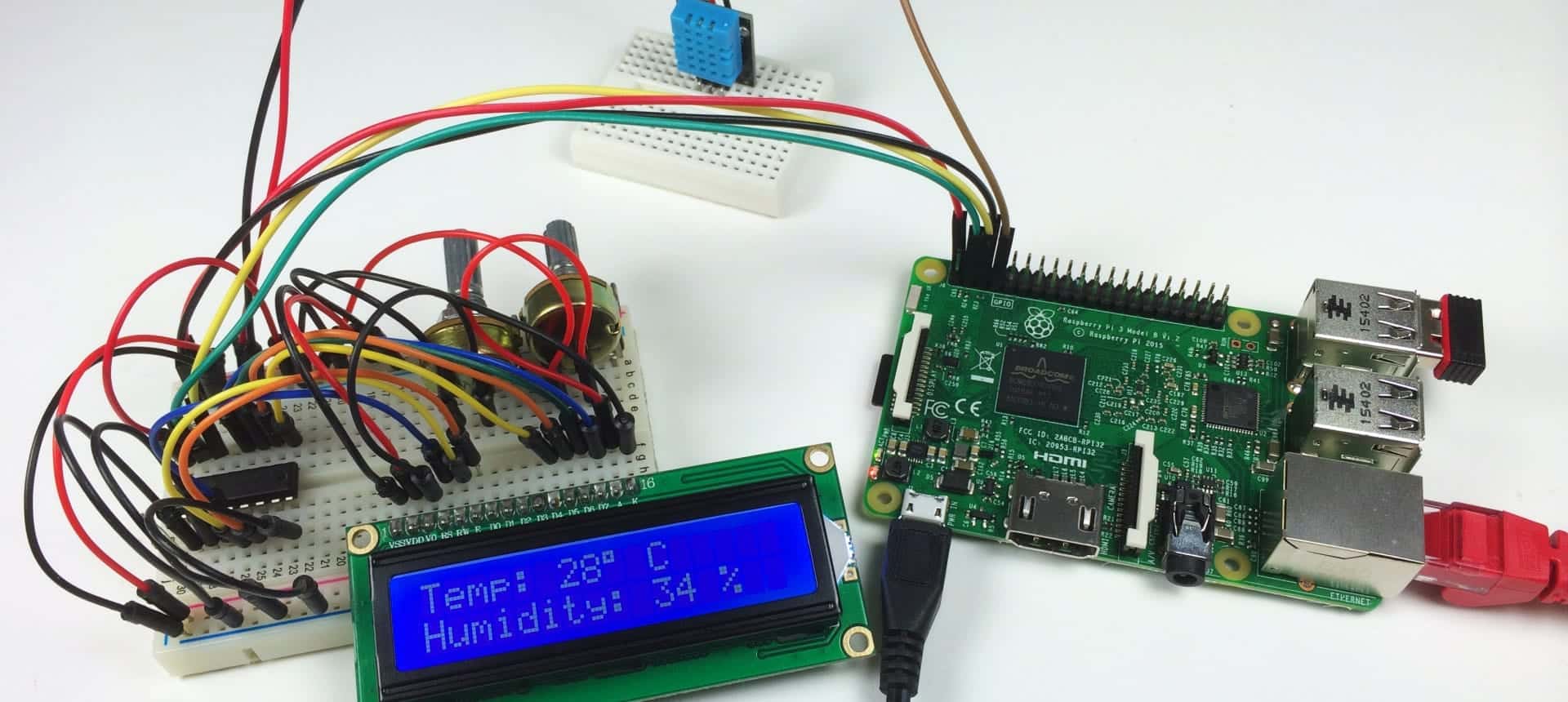

The code below will display data from a DHT11 temperature and humidity sensor. Follow this tutorial for instructions on how to set up the DHT11 on the Raspberry Pi. The DHT11 signal pin is connected to BCM pin 4 (physical pin 7 of the RPi).

By inserting the variable from your sensor into the mylcd.lcd_display_string() function (line 22 in the code above) you can print the sensor data just like any other text string.

These programs are just basic examples of ways you can control text on your LCD. Try changing things around and combining the code to get some interesting effects. For example, you can make some fun animations by scrolling with custom characters. Don’t have enough screen space to output all of your sensor data? Just print and clear each reading for a couple seconds in a loop.

HTS221, LPS22, LIS2DW12, LIS2MDL, LSM6DSO, STTS751, si7051, bme280, bmp280, APDS9930, TM1650, TM1637, LCD1602, GNSS, all kinds of micropython drives, examples, libs

This repository contains all of the code for interfacing with a 16x2 Character I2C LCD Display. This accompanies my YouTube tutorial here: https://www.youtube.com/watch?v=fR5XhHYzUK0

Qnap lcd python module, features both writing to the display as wel as reading keypresses from the panel keys. It was developed on a Qnap TS-459 and a TS-453A, it works on some other models as well.

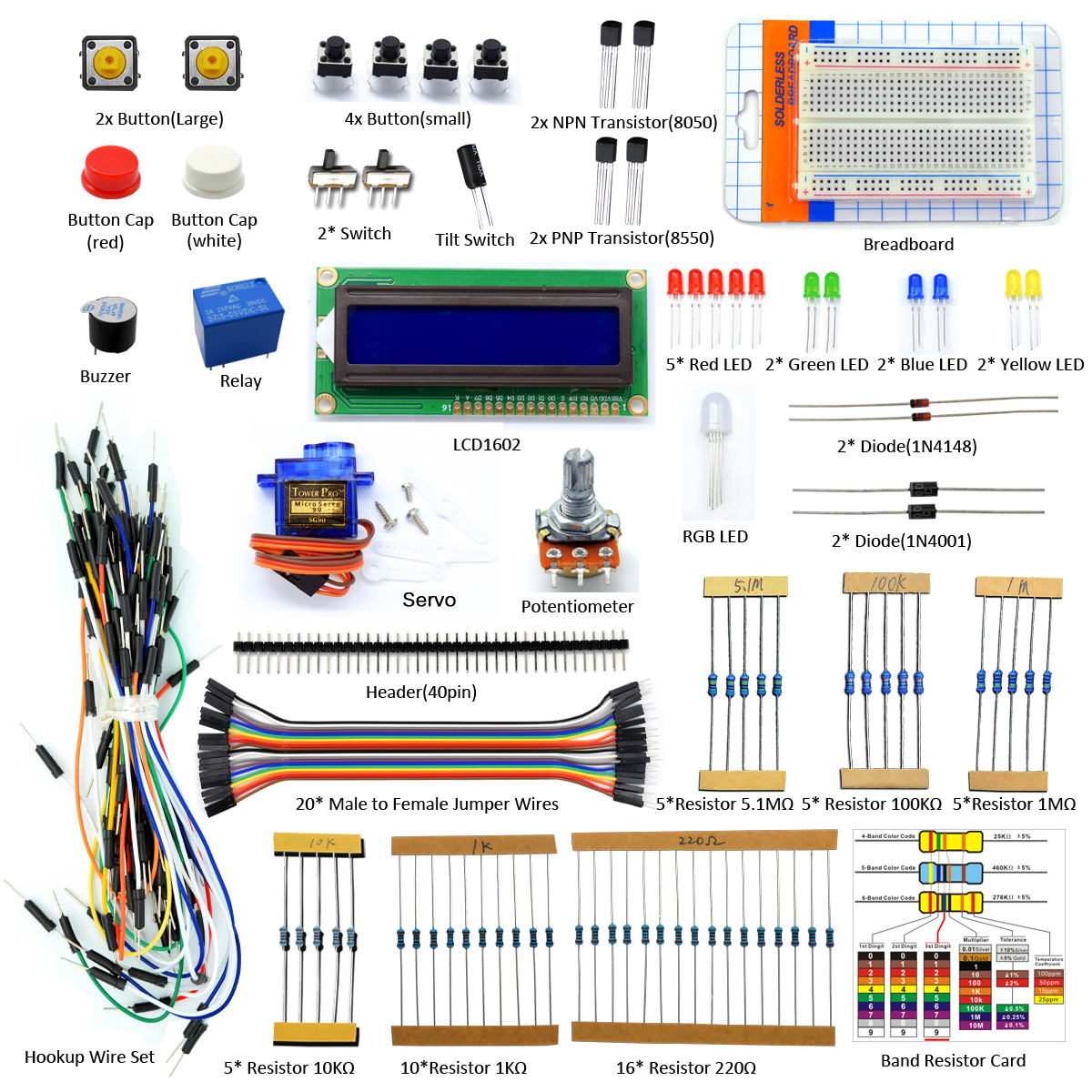

A detailed user manual and guidebook in PDF with 13 lessons and two versions of code (Python and C) are provided; it is easy for you to learn Raspberry Pi and C and Python Programming.

Fast, free shipping with a tracking number. A detailed user manual/guidebook(PDF) with 13 lessons and two versions of code (Python and C) are provided; it is easy for you to learn Raspberry Pi and C and Python Programming.

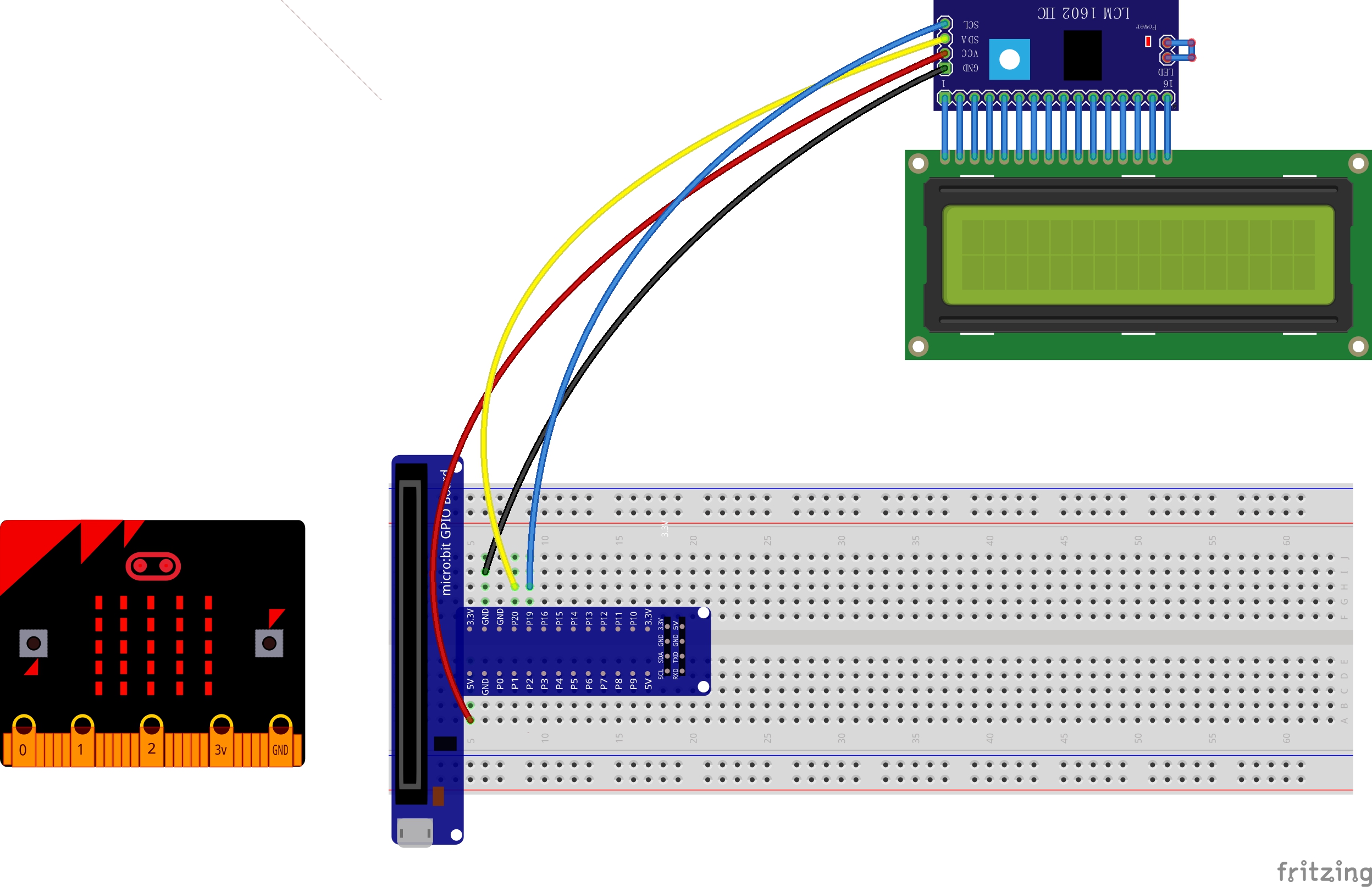

Overhere we will show you what is the I2C LCD 1602 Display and how it works, you can follow the next lesson to get how to use the I2C LCD 1602 Display with the micro bit.

The integration of an LCD display greatly facilitates the interactivity of the project you are developing, allowing the user to directly read some output parameters. These values can be either a simple text or numerical values read by the sensors, such as temperature or pressure, or even the number of cycles that the Arduino is performing.

The LCD1602 display has an integrated microchip that manages this type of communication, and then all of the input and output information are limited to only two PINs (excluding power supply). I2C is a type of serial bus developed by Philips, which uses two bidirectional lines, called SDA (Serial Data Line) and SCL (Serial Clock Line). Both must be connected via pulled-up resistors. The usage voltages are standard as 5V and 3.3V.

The blue potentiometer on the I2C LCD1602 (see the figure below) is used to adjust the backlight for better display.And there is a jumper on the board, if you take away this jumper , the backlight will aways be off.

Because the output power of the micro bit is limited, please connect the USB cable to the USB port on the micro bit when downloading the program. After the program is successfully downloaded to the board, connect the USB cable to the USB port on the expansion board, ensure the LCD display can work perfectly.

If you are not familiar to make code, don’t worry. At first, you can enter this link: https://makecode.microbit.org/reference to get the reference of microbit block.

Either copy and paste, or re-create the following code into your own MakeCode editor by clicking the open icon in the upper right-hand corner of the editor window. You can also just download this example by clicking the download button in the lower right-hand corner of the code window.

After downloaded this code to your micro bit, pull out the USB line and insert the USB line to the expansion board, you will see “OSOYOO”,”Hello” on the LCD screen, then the entire screen will be full of random numbers.

The code is not very clever, and also not very fast - I,m sure that some of you python experts can improve upon it, but it is clear (to me, at least!), and working !

Thanks for the confirmation. I have used these LCD for some years now, mainly with picaxe. I usually only toggle E for 1ms without problems. The biggest hurdle is usually getting the initialisation correct.

The code is not very clever, and also not very fast - I,m sure that some of you python experts can improve upon it, but it is clear (to me, at least!), and working !

A little lost here, meds don`t help. Can a 5v HD44870 compatible 4x20 LCD (Sparkfun Electronics-00256 model) be wired directly to the RasPi and utilize Python? Wondering if avoiding the read status would still make it safe in Python too. I`d like to learn Python and feel more than a little lost with C.

Just not sure how to get started and safely too. At the moment I do have the LCD wired and working with the Arduino but would much prefer a direct option with Python and the RasPi to get started with. Purchased LCD and header from Proto-Pic in the UK. If it`s wired the same as remoraebers` then I can do that, if it`s compatible with my LCD module and Python. Maybe I can convert someones Python program to suit then get it working.

Yes, the LCD I used above is a 5v device. As long as you do not input a 5v signal into the pi, you should be OK. As you are only writing to the LCD from the Pi, a high at only 3.3volts should still register as a high at the LCD. As for the Read/Write line, tie it to 0volts at the LCD end. If you do need to Read from the LCD, then you"ll need a resistor pair to alter the voltage accordingly, but most circuits do not require the LCD to be Read from. The code above should work "as is", even though you have a 20 x 4 LCD, but I,ve never used one, so can"t be sure.

I,ve just noticed the comments for the initialisation codes are all "8-bit mode", which of course is incorrect. Also the code, although working, is now very inefficent and slow - see my Nokia LCD thread for improvements using the wiringpi class, which is considerably quicker.

Thanks Texy, have you any clear pictures of your wiring diagram/schematic? Since I was looking at remoraebers` textual instructions re his setup, with a view to converting to Python usage. Yours has a Python script but no diagram so I need to play it safe with this difference between the 3.3v and 5v. My first experiment either used a dud 16x2 LCD (not given up on it yet, top shows squares, bottom doesn`t, backlight works, may desolder and put a header in like I did with the present one) or I blew part of it, so I don`t want to lose the 20x4 or the RasPi. I notice also that rem didn`t use a resistor to ground so not sure on that or the size to use if I do.

I would keep with the 16 x 2 LCD for now - they are pretty probust, and usually its a connection or initialisation code problem if you are getting those blocks.

To drive it I forked texys code and made it into a class that is a fair amount faster, however it is still using RPi.GPIO which is painfully slow overall (1sec+ to update screen). Will probably port to WiringPi this weekend and make it into a proper python library.

No I didn"t, or at least I haven"t yet. However, the RPi.GPIO module has been upgraded and is considerably faster, if you use the existing LCD code, and update the RPi.GPIO function, you"ll find it will be much improved.

So now I`m back to using this fine example and I said all along I really wanted to use Pi. Now I just need to know how to change it to 4 line display as I will definitely be using that from now on. Information is either low on the ground, hard to find or I`m using the wrong search terms but I`ll get there eventually. If anyone else wires up a 20x4 LCD and uses Python please post what you did and how you programmed it. I know once I get started I`ll be able to introduce a few tricks to it that I picked up in USB LCD Modules. If you see any posts/tutorials on 20x4 LCD and Python please post those too.

The address + 128, don`t ask and I won`t tell. So we use the codes in brackets as the final number. This means Line 1 = 128, Line 2 = 192, Line 3 = 148, Line 4 = 212. Lines 2 and 3 are not switched or a misprint. I showed the figures before 128 were added simply to explain how they are arrived at for our use.

So here we go and apologies to Texy for reusing his code as an example. At least giving both 16x2 and 20x4 users a shot at it (not tested or amended for 20 characters yet but at least we have a start). Rome wasn`t built in a day.

4 line test for 20x4. I posted ABCDEFGHIJKLMNOPQRST to all four lines and got all four lines back. Not being fully au fait with Python I was concerned there may be a code in there locking it to 16x2 as it was originally devised for that. I may have over written the 4 lines from 2 but not managed to get 20 characters. It seems from this that 20x4 is fully unlocked and all 20 cells in each line are accessible and possible to write to.

My secondary concern was the way lines 1 and 3, 2 and 4 are interconnected. I had visions of entries moving from line 1 to line 3 for example, instead of line 2. This test again has removed those fears and gives us a chassis to start using all 4 lines, firmly in the knowledge that what we use a code for to place a character in a given line and position is going to work.

So if we want centre for our chosen text on line 2 we see the code starts at 192 - 211, so it restarts at line 212 in line 4 (1&3, 2&4). There are 11 characters inc spaces in our line 2 text so 20 - 11 = 9 then divide by 2 (to get an equal gap both ends of the text) and we see approx 4 characters at the start and 5 at the end. So add 4 to 192 inc 192, 195 would centralize the chosen text. In line 4 it would be 215. Change the text to something else and count the characters inc spaces between words, subtract from 20 and divide by two. Then add that figure to the start code, that`s where you want to be roughly, assuming you want centred text.

I know with my LCD it expects 16 characters exactly. So if it is less I have to pad it to 16 with spaces and if it is more I have to trim it to 16 or it will not display correctly. Maybe it"s a similar thing?

The code supplied here works good pretty fast too the only issue I have is that if I write to both lines there is a flicker on the second line because it has to write the first line first I think. It would be better to write the lines separately like I do in my USB lcd driver.

The 1602 LCD display with 2 rows, 16 characters each. Connected with a I2C backboard. Currently showing the (Python read) temp and humidity output from a DTH11 sensor.

The I2C connector that has 4 pins for the RPi connection. The potentiometer is for LCD contrast and it has a power on LED on the right, above the jumper.

One of the cheapest solutions is to get a 16×2 or a 20×4 (ie 1602 or 2004) LCD display. You can get versions that have a I2C backplate or just the actual display with 16 connectors.

By default Raspian, which I’ll use in my examples, has the I2C disabled – so make sure the first thing you do is enable it either by running the raspi-config or editing the config files. Don’t forget to install python-smbus and i2c-tools either.

micro: bit is a powerful hand-held, fully programmable, computer designed by the BBC. It is only half size of a credit card, available for children’s programming education. Onboard comes with Bluetooth, accelerometer, compass, three buttons, 5x5 LED matrix, USB interface, connection pins. In order to learn micro bit more easier, we particularly make this kit, in which includes a keyestudio sensor shield fully compatible with micro bit and other commonly used sensor modules. In addition, this sensor kit also provides various learning projects for you, including wiring diagram, source code and more. It can help you make learning easy and fun to enjoy the programming.

When doing experiment with latest micro:bit, you need to transfer code into Makecode online editor first, save code again then download it to micro:bit.

After mastering the basic information of BBC micro:bit, in the following part let’s move on to programming projects. Use this small board with keyestudio micro bit sensor shield and other sensor modules to make some interactive experiments. Play it and learn it. Enjoy your wonderful time!

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

The LED blink is one of the more basic experiments. In the above example use of micro:bit, we have mentioned the 25 LED display of micro:bit. In this project, you will learn how to control an LED blink using a keyestudio digital white LED module and micro:bit sensor shield. Before testing, you should first turn off the 5*5 LED function of micro:bit.

This shield is very easy for microbit wiring. It breaks out the PI0 ports in the form of 3Pin (GND, VCC, PI0), easy to connect other sensor modules. Also with communication interfaces, like serial port、I2C and SPI pin headers.

You can power the shield via USB connection or external DC power jack (DC7-9V). If power the sensor module, you can control it via two cap V1 and V2 on the shield, with DC3.3V and 5V.

when connect external sensor module to the shield for working,the operating current of AMS1117-3.3V and NCP1117ST50T3G chip is too large, so it is easy to get hot. Pay special attention to avoid touching the two chips and causing burns.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect LED module to microbit sensor shield, connect the S pin to S pin header, + pin to V1 header, - pin to ground header.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

The light breath experiment is a little bit similar to the previous project. This time we connect the keyestudio LED module to the sensor shield. Connect the Signal pin of LED module to P0 of micro:bit. From the Pinout diagram of microbit, you can get the P0 can be used as Analog IN. This lesson you will learn how to control the brightness of LED on the module, gradually becoming brighter and dimming, just like the LED is breathing.

This keyestudio red LED module has 3 Pins; - pin is connected to ground, + pin is connected to VCC(3.3-5V), S pin is for signal control; you can set the High or Low level to control the LED on and off.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

Done wiring and powered up, send the code to MICROBIT, you should finally see an LED on the module gradually become brighter, then gradually dim, circularly just like the LED is breathing.

In this project, we combine the project 2 and project 3. You will learn how to control the LED on the module blink for two times, then breath for two times, circularly. This time we use keyestudio 3W LED module, which has high brightness and can be used as illumination.

This LED module is of high brightness because the lamp beads it carries is 3w. You can apply this module to Arduino or other projects, ideal for Robot or search and rescue application. For example, intelligent robots can use this module for illumination purpose.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect 3W LED module to micro:bit sensor shield, connect the S pin to S pin header, + pin to V1 header, - pin to ground header.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

Done wiring and powered up, send the code to MICROBIT, you should see the LED on the module firstly blink two times, then breath two times, circularly.

In this project, you will learn how to generate a sound with keyestudio digital active buzzer module. Here you can refer to LED blink, in this lesson control the buzzer on and off circularly.

Buzzers can be categorized as active and passive ones. The difference between the two is that an active buzzer has a built-in oscillating source, so it will generate a sound when electrified. The buzzer on this module is an active buzzer.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect buzzer module to micro:bit sensor shield, connect the S pin to S7 pin header (P7 of micro:bit), + pin to V1 header, - pin to ground header.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

Done wiring and powered up, send the code to MICROBIT, you should hear the buzzer module sound and then stop, circularly. It seems like the sound is interrupted.

One is to directly control the High and Low level input of micro:bit P0 end, set two square waves to control the buzzer sound. The other is to use the software"s own function, input the square waves of different frequencies and different lengths on the P0 end. Finally make the buzzer module play the song "Ode to Joy".

Buzzers can be categorized as active and passive ones. The difference between the two is that an active buzzer has a built-in oscillating source, so it will generate a sound when electrified. The buzzer used on this module is a passive buzzer. A passive buzzer does not have such a source, so DC signal cannot drive it beep. Instead, you need to use square waves whose frequency is between 2K and 5K to drive it. Different frequencies produce different sounds. You can use micro:bit to code the melody of a song, quite fun and simple.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect passive buzzer module to micro:bit sensor shield, connect the S pin to S0 pin header, + pin to V1 header, - pin to ground header.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

Done wiring and powered up, send the code 1 to MICROBIT, you should hear two sounds produced from passive buzzer circularly. If send the code 2 to MICROBIT, the buzzer will play the song Ode To Joy! Really amazing. Right? You can try to change the tone to play other music.

In this project, we will use a keyestudio RGB LED module. This Common Anode RGB LED module is a fun and easy way to add some color to your projects. In our program, we will connect the RGB module to micro:bit, then control the P0, P1, P2 Analog Input of micro:bit main board. You will learn how to control the RGB LED on the module firstly show three colors (Red, Green and Blue), then quickly change the color state.

This keyestudio RGB LED module is Common Anode. It can be seen as separate LEDs. LEDs have three different color-emitting diodes that can combined to create all sorts of colors. This RGB LED module is very easy for wiring, with a fixed hole that you can mount it on your any devices..

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect RGB LED module to micro:bit sensor shield, separately connect the B, R,G pin to P0, P1, P2 Analog Input header, ground pin to ground.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

Done wiring and powered up, send the code to MICROBIT, you should see the RGB module firstly show three colors, separately red, green and blue light. Then change the color quickly and circularly.

When design the circuit, button switch is a commonly used component. The micro:bit main board has two built-in buttons, however, sometimes still need to use external button when design the circuit. So in this project, you will learn how to use our push button module to control 5*5 LED of micro:bit display different images.

This is a basic button module. Buttons are a type of commonly used components to control electronic devices. Usually they are used as switches to connect or disconnect circuits to control the operation of electronic devices or other devices. This module integrates a push button on it and with three connection pins. It is very convenient for you connect it to other IO shields.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect button module to micro:bit sensor shield, connect S pin to S0 pin header, + pin to V1 header, - pin to ground. Shown below.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect tilt module to micro:bit sensor shield, connect S pin to S0 pin header, + pin to V1 header, - pin to ground. Shown below.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

In daily life, we often need to implement the function of counting and speed measurement. How to achieve these functions? You can easily match photo-interrupter module with microcontroller via code debugging. In this lesson, we connect a keyestudio photo-interrupter module to micro:bit sensor shield, then control 5*5 LED of micro:bit show different images.

During the test, if let an object continue to block the notch of photo-interrupter sensor, the module’s signal end will continuously appear High and Low level changes, then we can get the motion state of object through calculating the signal data, thus implement the counting and Speed measurement function.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect light interrupter module to micro:bit sensor shield, connect S pin to S0 pin header, + pin to V1 header, - pin to ground. Shown below.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference.

The module is based on a touch detection IC. This module allows you to remove the troubles of conventional push-type buttons. It has low power consumption and wide working voltage.

Powered on, the module requires the stable time about 0.5sec, at the moment all functions are banned to conduct self-calibration, do not touch the key, the calibration cycle is about 4.0sec.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference. You can change the icon as you like.

When walking at the crossroad, you can see the traffic light command the orderly movement of pedestrians and vehicles. So how is the traffic light controlled to operate? In this project, we will connect a traffic light module to our sensor shield, controlling traffic light blink with micro:bit. You will learn how to simulate the running of traffic light.

When learning the microcontroller, you may usually use three separate LEDs (red, green and yellow) to simulate the traffic light blinking. In this way you may need more wire connection. We specially design this traffic light module, which is very convenient for wiring. It has integrated three LEDs (red, green and yellow) together on the module. Also breaks out four pin interfaces. There are two positioning holes for easy installation.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect traffic light module to micro:bit sensor shield, separately connect R, Y,G pin to S2, S1,S0 pin header, GND pin to ground. Shown below.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference. You can change the icon as you like.

Done wiring and powered up, send the code to MICROBIT, eventually you should see the green LED lights 5 seconds then off, and yellow LED starts to blink 3 times with an interval of 0.5 second, then off, followed by red LED lights up for 5 seconds then off. Up to this moment, green LED lights again, forming a loop cycle.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference. In the code, you can change the icon as you like.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you as reference. You can change the icon as you like.

Done wiring and powered up, send the code to MICROBIT. When sensor detects no object or detects a black line, the infrared rays are not emitted or the intensity of emitted ray back are not sufficiently strong, so that the sensor’s signal terminal will output a High level, LED on the micro:bit will show the number 1. Or else show the number 0.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks. Then you can directly enter the https://makecode.microbit.org/ to edit your project program. Below is an example code we have done for you.

Done wiring and powered up, send the code to MICROBIT. When sensor detects an object ahead, its signal terminal will output a Low level, and LED matrix on the micro:bit will show the number 0. Or else show the number 1.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Done wiring and powered up, send the code to MICROBIT. When flame sensor detects the fire nearby, the buzzer module will sound immediately. If no fire detected, the buzzer not beeps.

Keyestudio crash sensor is a limit switch, available for 3D printer. It is in essence the same as button module. When printer reaches the top to crash the spring plate of module, module outputs Low level. If loosen the spring plate, module outputs High.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Done wiring and powered up, send the code to MICROBIT. When the spring plate of crash sensor is pressed, the buzzer module will beep, otherwise buzzer will not sound.

In this project, you will learn how to use a keyestudio reed switch module and micro:bit to detect the magnetic field. Finally show the result on the 25 LED matrix of micro:bit. Actually in the project 13, we have used a hall magnetic sensor to detect whether there is magnetic field nearby. So what is the differences between hall magnetic sensor and reed switch module? You can check it in component introduction below.

The keyestudio reed switch module is mainly composed of a reed switch. The reed switch is a mechanical magnetic switch, a passive device. Its working principle is that the magnetic field magnetizes its reed, so that it can be turned on and off to achieve the switch effect. However, since it is a contact type switch, its working life is limited, and it is easy to be damaged during transportation and installation.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

In this project, you will learn how to use our relay module and micro:bit to control an LED module on and off. (note that for easy wiring, the circuit does not add 220V voltage, still use 5V.)

This module uses a high-quality SONGLE 5V relay. The relay output is by a light-emitting diode, can be controlled through digital IO. It can be used to control lighting, electrical and other devices of high current or voltage.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then separately connect both single relay module and white LED module to keyestudio micro:bit sensor shield. Shown as below diagram.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

This Ultrasonic detector module HC-SR04 can provide 2cm-450cm non-contact measurement distance, and its ranging accuracy is up to 3mm. It includes an ultrasonic transmitter, receiver and control circuit.

Ultrasonic module will emit the ultrasonic waves after trigger signal. When the ultrasonic waves encounter an object and are reflected back, the module outputs an echo signal, so it can determine the distance of object from the time difference between trigger signal and echo signal.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect the ultrasonic module to keyestudio micro:bit sensor shield. Shown as below diagram.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Done wiring and powered up, send the above two codes to MICROBIT. You can get the same distance data. And you should see the distance data on the LED matrix of micro:bit. Or you can open the serial monitor of Arduino IDE to get the data. Shown as below.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield.Then connect the photocell module to keyestudio micro:bit sensor shield. Shown as below diagram.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Done wiring and powered up, send the above code to MICROBIT. You should see the brightness data on the LED matrix of micro:bit. Or you can open the serial monitor of Arduino IDE to get the data. Shown as below.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the analog temperature module to keyestudio micro:bit sensor shield. Shown as below diagram.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

This analog sound sensor module is typically used in detecting the ambient sound. You can use it to make some interactive works, such as a voice switch.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the analog sound module to keyestudio micro:bit sensor shield. Shown as below diagram.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the analog rotation module to keyestudio micro:bit sensor shield. Connect signal pin to P0, + pin to V1 header, - pin to ground.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the analog alcohol module to keyestudio micro:bit sensor shield. Connect VCC to V1 header, ground to ground, A0 pin to P0 header.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Firstly, we connect a soil sensor to the microcontroller for the purpose of detecting the humidity of soil. Then connect a relay module to the MCU as well. On the normally open (NO) terminals of relay, separately connect a pump and a power supply.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

So in this experiment, we are about to use a water sensor and a buzzer module to detect the water level in the glass, if beyond level, buzzer should make an alarm.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Read the value of signal end. The higher the water level, the greater the value. When the analog value is greater than 400, buzzer on the module will alarm. You should see the value is showed on the LED matrix of micro:bit. Or you can open the serial monitor of Arduino IDE to get the value. Like below figure shown.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the vibration sensor and LED module to the shield. Connect the signal pin of vibration sensor to Analog P0.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

If you slap the table where the sensor locates, when the vibration sensor detects the vibration signal, an LED on the Piranha LED module will lights up, otherwise, LED off.

On the joystick module, it has 3 signal interfaces, which can simulate the three-dimensional space. The signal pins X and Y will simulate the X-and Y-axis of space. Connect them to Analog Input of microcontroller. By controlling 2 analog input values to control the coordinate of an object in X- or Y-axis.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the joystick module to the shield. Separately connect the signal pins X,Y to P1, P0 of micro:bit, connect the pin B to P2. Shown below.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

For those DIY smart cars, they often have a function of automatic obstacle avoidance. In the DIY process, we need a servo to control the ultrasonic module to rotate left and right, and then to detect the distance between car and obstacles, so as to control the car to avoid obstacles.

If you are not familiar to make code, don"t worry. Firstly, you can enter this link:https://makecode.microbit.org/reference to know more about microbit blocks.

In life, we can use the display and other sensors to do a variety of experiments. You can DIY a variety of small items. For example, use a temperature module and display to make a temperature tester, or use an ultrasound module and display to make a distance tester.

In the following, we will use keyestudio 1602 I2C module as the display, connect it to I2C pin headers of micro:bit shield. You will learn how to control the 1602 LCD show the character“keyestudio”and number.

Insert the micro:bit into keyestudio micro:bit sensor V2 shield. Then connect the 1602 LCD to IIC pin headers on the shield. Connect the SCL pin to P19, SDA pin to P20, VCC pin to V2, GND to ground. Shown below.

You should see the character “Keyestudio” is showed on the first line of LCD screen, on the second line show the number. And the number will plus 1 per second.

This tutorial is designed for everyone to play the MICRO:BIT. You will learn all the basic information about how to control the micro:bit, controller board, sensor modules and more to make interactive projects. Easy play and enjoy your time!

Located in Shenzhen, the Silicon Valley of China, KEYES DIY ROBOT CO.,LTD is a thriving technology company dedicated to open-source hardware research & development, production and marketing. Keyestudio is a best-selling brand owned by KEYES Corporation, our product lines rang from Arduino boards, shields, sensor modules, Raspberry Pi, micro:bit extension boards and smart car to complete starter kits designed for customers of any level to learn Arduino knowledge.

I am looking for a simple library to pilot an LCD 1602 from WeMos D1 Mini (or other esp8266). Looking for simple API to send text on line 1 or 2, maybe adjust dim. Things like that.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey