difference between lcd touch screen digitizer supplier

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

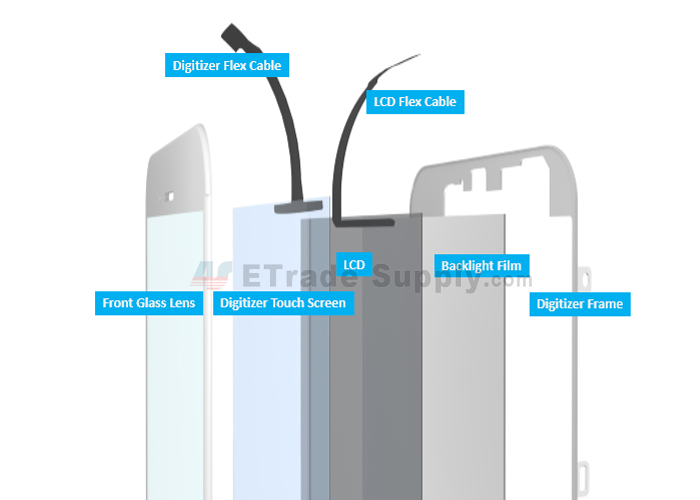

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

Your iPod, iPhone and tabletare commonly known to have three key components: a glass panel, digitizer (aka touch screen) and LCD. What are the differences? Let’s clearly define these layers:

Digitizer –The digitizer is located just under the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer. The digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa. UEGoffers a Front Glass (Digitizer Touch Screen) Repair Service on tablets.

Touch Screen – The term touch screen is interchangeable with the term digitizer. You’ll often see the combined terms Digitizer Touch Screen offered as a repair service.

LCD – LCD is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. UEGoffers LCD repairs on tablets, iPhonesand iPods.

A touch screen display is usually made with three main parts. The protective glass sheet, the digitizer sheet, and the LCD. The digitizer is a thin transparent sheet that is adhered to the protective glass sheet with a transparent conductive adhesive. The digitizer is the only part of the display assembly that is responsible for sensing touch. Since the human touch is conductive it allows the screen to sense the location you touch. The LCD is only responsible for displaying the image on the screen. If the screen is not responding to touch then usually the digitizer is damaged or faulty. Usually a damaged or cracked LCD will display a distorted image or no image at all. So if the phone displays a good image but does not respond to touch then you may have the option of only replacing the digitizer. It"s not as easy of a repair as replacing the whole display but is cheaper. A new digitizer part already has the digitizer sheet adhered to a protective sheet of glass. If a person can remove the faulty digitizer from the phone without damaging the LCD then it is surely more cost effective repair. Some displays have the digitizer fused to the LCD which makes it hard not to damage the LCD if trying to remove the digitizer. If that is the case with your phone"s display it is a lot easier to just replace the whole display. Hope this information is helpful.

Touchscreen devices consist of numerous different components that must work cohesively together in order to make it functional. The touch sensor, controller, and the software all play important roles. But there’s one component that’s often overlooked in the equation and that’s the touchscreen digitizer. This is the component that allows users to directly interact with what’s on the screen and issue commands.

As you know, touchscreen devices consist of multiple layers each of which serve a different purpose and carry out various functions. The purpose of the touchscreen digitizer glass layer is essentially to translate or convert physical touch commands into digital signals that the device can understand and then carry out.

Commercial and industrial displays such as capacitive and resistive screens all feature touchscreen digitizers that are placed on top of and connected to the LCD layer using a flex cable. While the LCD layer is responsible for displaying sharp and crystal-clear images on the screen, the LCD touchscreen digitizer reads, understands, and translates the commands given so that the device can perform the appropriate functions.

Touchscreen digitizers are fairly common components of modern LCD displays, but not all of them are equipped with one. The sole purpose of an LCD display touchscreen digitizer is to convert touch commands on the top layer into digital data that the device can understand and perform. Once the touch commands are converted into digital data, the device can then perform the required function and change the images displayed on the screen accordingly.

Touchscreen digitizers are made of a single glass layer, which means they can be susceptible to damage if the device is dropped or comes into contact with a brute force. Although the device can still marginally function depending on the extent of the damage to the touchscreen digitizer glass, its functionality and ability to comprehend touch commands may be limited. If the glass is completely shattered, then the device won’t be able to interpret touch commands at all.

The LCD and touchscreen digitizer layers of a device display serve completely different functions, but they work in tandem to maximize user experience and device performance. Since both of these components are made of thin glass layers, they’re not impervious to damages such as cracks or scratches as a result of being dropped or coming into contact with external physical stressors.

If it’s only the touchscreen digitizer that’s broken, you’ll still be able to make out what’s being displayed on the screen by the LCD component for the most part. The only difference is that parts of the screen or the entire screen might be unresponsive to your touch commands as a result of the damages. Moreover, blobs or splotchy images may appear in certain parts of the screen.

This indicates that there’s a disconnection between the touchscreen digitizer and the LCD display, which is preventing the device from performing the desired functions issued by touch commands.

The LCD screen is responsible for the visual component of your device. Pixelation in the form of multicoloured splotches or dots throughout the screen indicates that the LCD component has sustained a certain level of damage. It can be caused by wear and tear over time or if your device sustains physical damage.

A black screen indicates that the LCD layer of the device is damaged. The device itself will most likely still turn on and function like normal, but you won’t be able to see what it’s doing on the screen itself. Typically, this just means that the LCD layer needs to be repaired or replaced. Depending on the extent of the damage, it might be more practical and cost-effective to simply purchase a new device altogether unless you’re still within the warranty period.

As an official phone repair provider who has been in the business for almost a decade, one unique question people ask when they visit our service centres to replace their phone screen is: "what"s the difference between original and copy phone screen?"

Well, the answer is, there are many differences between these two screens, which is mostly in their quality. And while “copy” phone screens are somewhat cheaper than the originals, it doesn’t justify the difference in quality. So, before you regret replacing your phone screen with a forbidden part, the tips below will tell you the critical differences between original and copy phone screens.

Generally, phone screens manufactured from your brand"s factory are the original ones while ‘Copy’screens are the ones designed and produced by third-party manufacturers and factories that are not related to your brand.

Many people usually like to go for copy screens because of their cheaper price. However, the "real" differences between original and copy screens lie in their quality, and here’s what you need to know about them.

One of the principal issues with "copied" phone screens and why it differs from the originals is touch and digitizer problems. And that"s a big problem since you"re going to control the device with the touchscreen anyway.

As far as we could remember, phone manufacturers build the touch panel/digitizer with the LCD itself, while the copied screen manufacturer build it separately on the surface glass. Hence, there"s a difference in touch sensitivity. Additionally, copied phone screens usually drop the high touch sampling rate, meaning your screen may not respond to your touches faster.

Here"s also another major issue with the digitizer on copied phone screens. When you crack a copied screen accidentally, the touchscreen stops working, stopping you from accessing the device until you fix it again. Meanwhile, the touch on the original phone screen works perfectly, even after undergoing severe cracking.

Besides having touch problems, most copy phone screens usually have poor display properties. That means you get lower brightness, colour accuracy, sharpness, contrast, etc. And when the display isn"t great, watching movies and viewing other content becomes boring.

For instance, if the original screen is supposed to have 480 nits of brightness, but the copy screen has just 200 nits, the screen becomes unusable under bright lights. Moreso, copied phone screen seems to have more blue light, which, in return, affect your sight and disrupts your sleep at night.

Among others, copied phone screens drop higher refresh rates, and that"s a bummer since most phones come with at least 90Hz refresh rate screens. What that means is the copied screen won’t feel smooth as it’s supposed to be.

It"s not all about the display quality. A copy phone screen may also affect other parts of the phone system if its specifications don"t tally with the original one. In such a case, it could drain your battery at an alarming rate, or at worse, damage your backlight.

If you happen to have a phone with an in-display fingerprint sensor, then replacing its screen with a copied one is not an option – it’s going to mess with your fingerprint accuracy.

We know copied phone screens for their poor quality, and it also extends to the fingerprint sensor. Hence, it takes a longer time to unlock your device. And in other cases, the security of the sensor is not accurate. We"ve seen situations where phones get unlocked with many unregistered fingers after replacing the screen with a copied one.

If you care about your phone"s security and you don"t want a sluggish fingerprint sensor, then we recommend you only go for the original phone screen replacement.

That brings us to the last difference we’re going to mention between copied and original phone screens. They manufacture copied phone screens with poor glass materials. Hence, they break quicker than the originals. And when they do, you’ll be left with only one option: to replace the screen again.

The major reason for choosing the official service centre over third-party/local repair shops summarizes what we"ve said earlier. The official service centre is the reliable place to get original phone screen replacement parts.

Besides offering you the original screen spare parts, the official service centres also have other advantages. These include certified and well-experienced technicians to fix the screen, the use of modern tools that won"t damage your phone further, and most importantly, a reliable warranty. Local repair shops usually don"t offer these features; most especially a reliable warranty, which means you"re on your own if the replaced screen gets faulty afterwards.

As far as choosing the official service centre is concerned for genuine screen replacement, then you shouldn"t shy away from Carlcare Service if you own a TECNO, Infinix, or itel phone with a cracked screen.

We"re the official service center for these three brands to cater for your mobile repair needs. And for screen replacement, Carlcare delivers excellently. Our brand-trained technicians replace your cracked screen with genuine OEM parts at affordable rates.

We understand you have a busy schedule; and yes, we"ll replace your screen in the shortest possible time. Start by checking how much it cost to fix your cracked phone screen, then you can book an online reservation service with us to reduce your waiting time and also become a VIP customer.

Projected capacitive touch screen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

Resistive touch screens still reign in cost-sensitive applications. They also prevail in point-of-sale terminals, industrial, automotive, and medical applications.

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

If you have any questions about Orient Display capacitive touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

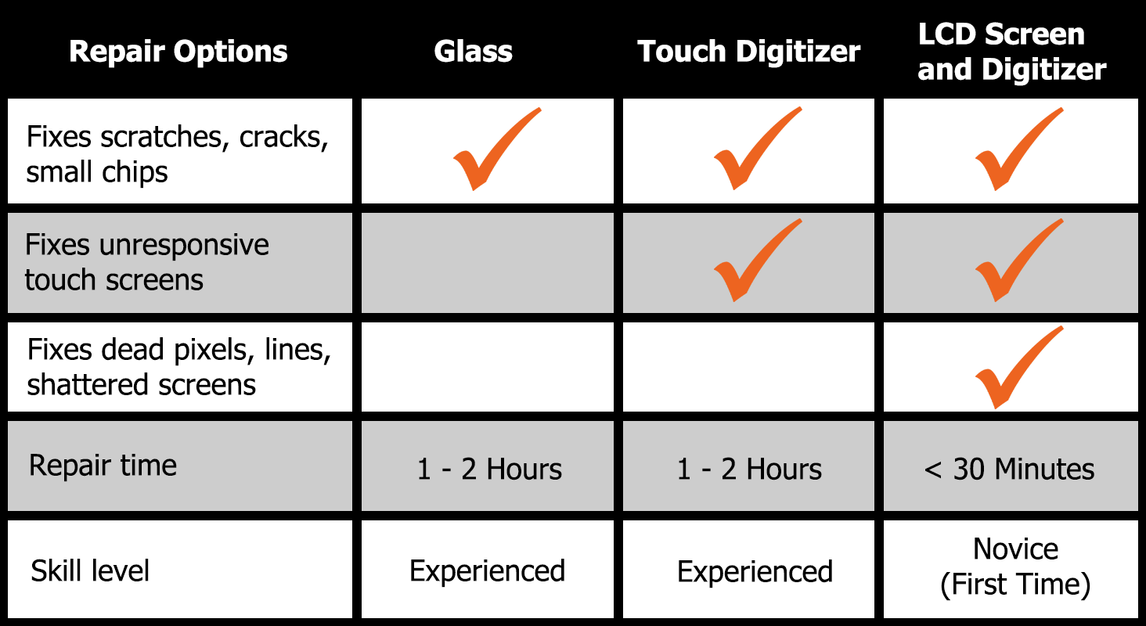

The easiest repair for mobile phones to complete is the LCD assembly replacement. This repair takes less than an hour and requires the least amount of technical ability. For some devices the LCD assembly can be replaced simply by removing a few screws and cables. Also, as the assembly includes the glass, touch screen and the LCD, you can be confident it will fix all common screen issues.

For iPad and other tablets, if the screen parts aren"t fused, then you can do a glass touch digitizer only replacement. Otherwise, the full assembly is the easiest repair. Either way, it usually takes 1-2 hours.

While it can be significantly cheaper repair, If the screen parts are fused, the screens must be heated to loosen the adhesive between the screen and LCD and you need special equipment. This includes all iPhone and most other mobile phones and some iPads or tablets. A heat gun or hair dryer can be used for this. The screen is then gently and very slowly pried apart from LCD. DIYers need to use care to insure the LCD is not damaged in the process.

Tip: Transferring the home button on an iPhone or an iPad can be the most tricky part. It takes a little patience and heat. You can purchase screens that have the home button pre-installed (along with other small parts) and this is the easiest of all repair. This can take 15-30 minutes. However, Touch ID function only works with the original home button so you have to transfer if you want to retain it. Note: some of the iPads don"t have a screen replacement option that includes the home button like the iPad Pro and newer iPad Mini. iPad 1st Gen to 9th Gen screens, have a home button pre-installed option.

Manufacturer of standard & custom operator interface terminals, industrial computers, panel personal computers, software, LCD displays, VFD displays & accessories. Types of operator interface terminals include touch screen operator interface terminals, graphic operator interface terminals, PLC & motion controller interfaces, ASCII & motion controller interfaces, high speed operator interface terminals & widescreen operator interface terminals. Accessories such as controller cables, power cables, power supplies, memory cards, adapters & power isolators are also available. Types of software include industrial process control software, process monitoring software, utility software & operator interface software. Products are used in retail, kiosk, packaging, transportation, plastic manufacturing, medical, pharmaceutical, printing, security, water treatment, petrochemical, bottling & power generation applications. Products are UL® listed, CE certified & RoHS compliant.

Simply put, the industrial touch screen can be clicked directly, easily, and quickly. It is the tactile feedback function of the industrial touch screen LCD display screen system. Commercial monitors are flat, ultra-thin displays made up of a fixed number of color or black and white pixels that sit in front of a light source or reflector commonly used in televisions and desktop computers in offices.

At the LCD level, LCDS use ordinary displays, while industrial touch screens use high-brightness, industrial-grade LCDs, which require more backlighting than displays. Its storage temperature and the working temperature are high, the grade is strict. Industrial touch displays can withstand both high and low temperatures. As a result, when commercial monitors work long hours, the image becomes blurry and gets worse and worse. Their performance also depends on how well they are produced on-screen. A new Display uses industrial panels with a higher level of detection on its industrial displays, which are more stable than commercial displays.

Different driver schemes, such as display motherboard schemes are different. A new model insists on using an industrial-grade motherboard for display when dealing with moving images, while industrial touch screens require long-term work. Therefore, a professional drive board or motherboard must be used to ensure higher brightness and ultra-high temperature resistance, so as to reduce the use of the screen base loss. If the ordinary display is used for a long time, its brightness and contrast will rapidly decline, affecting its service life. That’s why most LCDs display fine images right after a project is debugged, but some screen bases turn dark after a sustained period of power.

Industrial touch screens have wide viewing angles, with maximum visibility up to 178 degrees, while ordinary LCD screens can only see one or 40/40 views from left to right. It is also an important standard to identify industrial touch screens and LIQUID crystal displays. There are also differences between the two input signals, mainly the input video signal. In order to meet the interface requirements of different front-end devices, the interface of the display will be much richer than that of the display. There are VGA, RGB, HDMI, DVI, and display ports. A variety of other interfaces can meet the input requirements of different signals, while the display mainly inputs VGA signals. Commercial monitors cannot meet the signal input requirements of various monitoring equipment.

So, do you know the difference between an industrial touch display and a commercial one? Choosing a monitor for your project depends on your application’s working environment. If used in harsh environments, opting for industrial touch displays could save you significant costs and time in the future.

We hope you found these touchscreen or panel PC fundamentals informative. Goldenmargins offers a broad selection of Industrial Touchscreen Monitors and Touch Panel PCs in various sizes and configurations, including medical touch screens, sunlight-readable touch screens, open-frame touch screens, and waterproof touch panels, as well as other unique touch screen or panel PC designs. You can learn more about our services HERE or by calling us at +86 755 23191996 or sales@goldenmargins.com

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey