difference between lcd touch screen digitizer manufacturer

Your iPod, iPhone and tabletare commonly known to have three key components: a glass panel, digitizer (aka touch screen) and LCD. What are the differences? Let’s clearly define these layers:

Digitizer –The digitizer is located just under the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer. The digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa. UEGoffers a Front Glass (Digitizer Touch Screen) Repair Service on tablets.

Touch Screen – The term touch screen is interchangeable with the term digitizer. You’ll often see the combined terms Digitizer Touch Screen offered as a repair service.

LCD – LCD is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. UEGoffers LCD repairs on tablets, iPhonesand iPods.

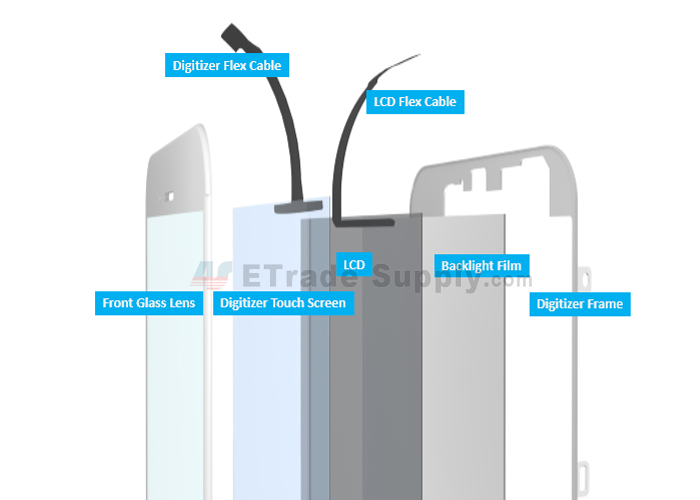

A touch screen display is usually made with three main parts. The protective glass sheet, the digitizer sheet, and the LCD. The digitizer is a thin transparent sheet that is adhered to the protective glass sheet with a transparent conductive adhesive. The digitizer is the only part of the display assembly that is responsible for sensing touch. Since the human touch is conductive it allows the screen to sense the location you touch. The LCD is only responsible for displaying the image on the screen. If the screen is not responding to touch then usually the digitizer is damaged or faulty. Usually a damaged or cracked LCD will display a distorted image or no image at all. So if the phone displays a good image but does not respond to touch then you may have the option of only replacing the digitizer. It"s not as easy of a repair as replacing the whole display but is cheaper. A new digitizer part already has the digitizer sheet adhered to a protective sheet of glass. If a person can remove the faulty digitizer from the phone without damaging the LCD then it is surely more cost effective repair. Some displays have the digitizer fused to the LCD which makes it hard not to damage the LCD if trying to remove the digitizer. If that is the case with your phone"s display it is a lot easier to just replace the whole display. Hope this information is helpful.

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

Touchscreen devices consist of numerous different components that must work cohesively together in order to make it functional. The touch sensor, controller, and the software all play important roles. But there’s one component that’s often overlooked in the equation and that’s the touchscreen digitizer. This is the component that allows users to directly interact with what’s on the screen and issue commands.

As you know, touchscreen devices consist of multiple layers each of which serve a different purpose and carry out various functions. The purpose of the touchscreen digitizer glass layer is essentially to translate or convert physical touch commands into digital signals that the device can understand and then carry out.

Commercial and industrial displays such as capacitive and resistive screens all feature touchscreen digitizers that are placed on top of and connected to the LCD layer using a flex cable. While the LCD layer is responsible for displaying sharp and crystal-clear images on the screen, the LCD touchscreen digitizer reads, understands, and translates the commands given so that the device can perform the appropriate functions.

Touchscreen digitizers are fairly common components of modern LCD displays, but not all of them are equipped with one. The sole purpose of an LCD display touchscreen digitizer is to convert touch commands on the top layer into digital data that the device can understand and perform. Once the touch commands are converted into digital data, the device can then perform the required function and change the images displayed on the screen accordingly.

Touchscreen digitizers are made of a single glass layer, which means they can be susceptible to damage if the device is dropped or comes into contact with a brute force. Although the device can still marginally function depending on the extent of the damage to the touchscreen digitizer glass, its functionality and ability to comprehend touch commands may be limited. If the glass is completely shattered, then the device won’t be able to interpret touch commands at all.

The LCD and touchscreen digitizer layers of a device display serve completely different functions, but they work in tandem to maximize user experience and device performance. Since both of these components are made of thin glass layers, they’re not impervious to damages such as cracks or scratches as a result of being dropped or coming into contact with external physical stressors.

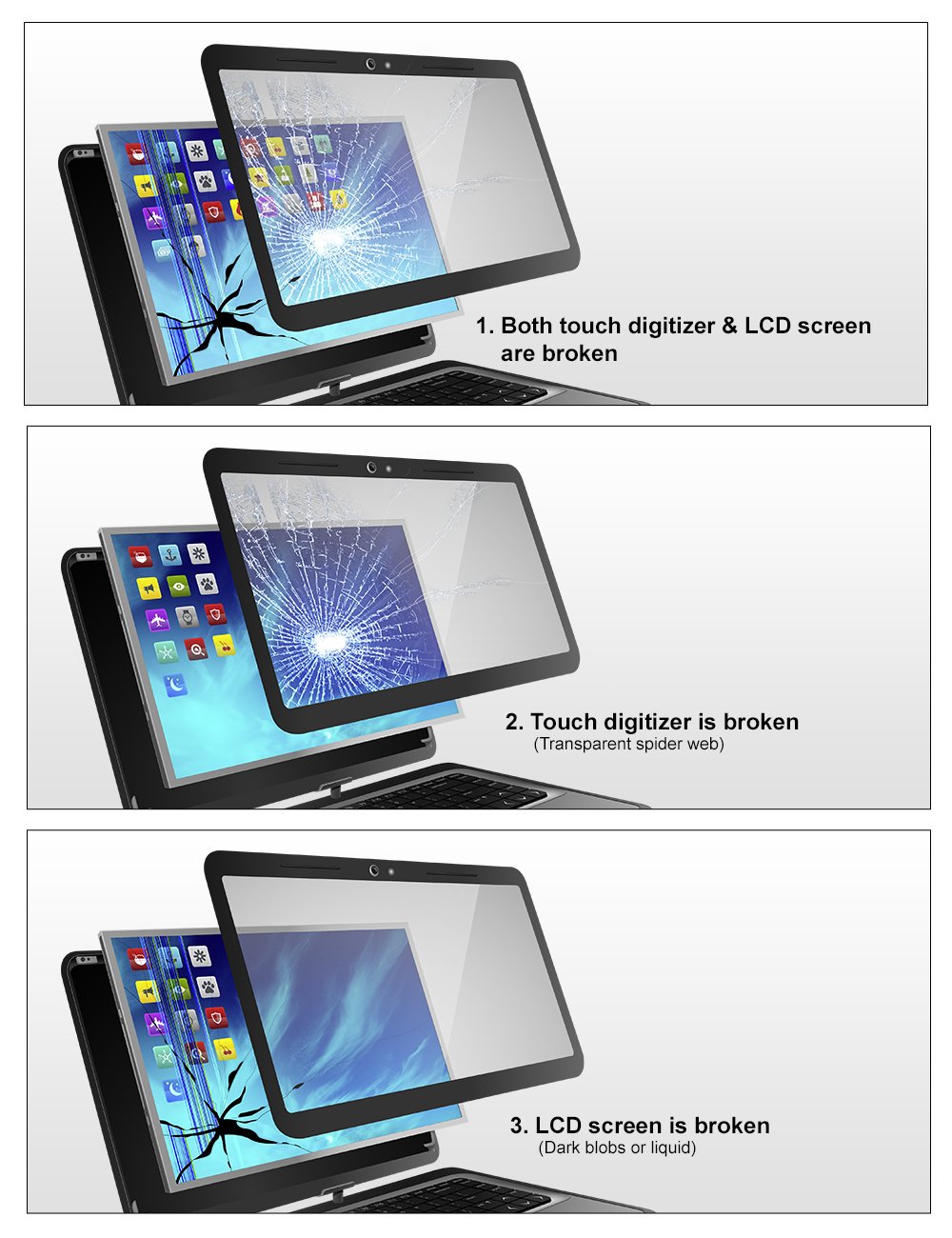

If it’s only the touchscreen digitizer that’s broken, you’ll still be able to make out what’s being displayed on the screen by the LCD component for the most part. The only difference is that parts of the screen or the entire screen might be unresponsive to your touch commands as a result of the damages. Moreover, blobs or splotchy images may appear in certain parts of the screen.

This indicates that there’s a disconnection between the touchscreen digitizer and the LCD display, which is preventing the device from performing the desired functions issued by touch commands.

The LCD screen is responsible for the visual component of your device. Pixelation in the form of multicoloured splotches or dots throughout the screen indicates that the LCD component has sustained a certain level of damage. It can be caused by wear and tear over time or if your device sustains physical damage.

A black screen indicates that the LCD layer of the device is damaged. The device itself will most likely still turn on and function like normal, but you won’t be able to see what it’s doing on the screen itself. Typically, this just means that the LCD layer needs to be repaired or replaced. Depending on the extent of the damage, it might be more practical and cost-effective to simply purchase a new device altogether unless you’re still within the warranty period.

Most of the time people don’t know the difference between a touchscreen and a LCD screen. When there are dark black blobs on your screen, it’s not because the display screen is damaged, it is the caused due to the damage in the LCD of your mobile phone whereas when there are cracks on your screen its mainly due to the damaged caused to your touchscreen and as compared to an LCD screen it is easier to fix as you only need to replace the display screen of you mobile phone.

An LCD is the part of a phone that displays the image we see on screen. It is the layer which produces and displays the image, therefore if the LCD is damaged you can still use the touchscreen although the panel would have either the aforementioned dark black blobs or the spider web type dark cracks on the display or both it would still function normally. To repair the LCD, a technician would have to pull apart the phone part by part to reach the LCD and assess the damage done which is not required for a touch screen. LCD, which is a liquid crystal display, is widely used in mobile phones as it uses low power and produces good quality images.

The images which are displayed in a LCD are produced through small elements which are called pixels. Pixel is a word everybody is familiar with but what exactly is a pixel? Pixel is made up of a layer of molecules lined up between two transparent electrodes and polarizing filters. There are several types of LCDs, reflective, transmissive and transflective, each has a specific function. A transmissive LCD can produce a clear and good quality image in low light while Reflective screen can produce a very good image in bright light. The transflective screen as the name indicates can produce a good quality image in both conditions, hence it is a mixture of both transmissive and reflective LCD.

Touchscreen is now a part of almost every digital gadget in the 21st century. From mobile phones and laptops to TVs and switch boards, it is now used almost everywhere your eyes fall on. But what exactly is a touchscreen? A touchscreen is basically a device which allows us to directly interact by using our fingers or a stylus. The stylus is a special kind of pen whose tip is covered with a unique coating which allows it to directly interact with the computer. We can use one finger or multiple gestures to interact with a touchscreen device. It doesn’t require a mouse or any alternative device such as a keyboard for navigation. A touchscreen can use several methods to sense our finger, it can use a grid which consists of infrared beams or it can use touch sensitive units to sense our gestures.

With touchscreen, there are several gestures that we can make which would be quite tiresome if we use a mouse or a keyboard like when we double tap the screen while using gallery or while reading a pdf file the screen tends to zoom in and when we double tap again it zooms out similarly we can easily drag different icons and swipe to scroll upwards, downwards even sideways. A touch screen is also referred to as an input device as it takes input directly from the user. The computers require a mouse which makes them hard to use but touchscreen is very simple to use as you are directly interacting with the icons, it is also cost efficient to manufacture touchscreen as it does not require buttons for each icon.

In conclusion it can be said that LCD and Touch Screen have very different functions which makes them different from each other. One deals with production of images and the other deals with receiving the input from the user directly. Although they are different, they are equally important for a digital device.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

My T-Mobile Revvlry screen is broken & i want to fix it, but i am confused on which part of the screen module do i need to fix it. Do i need the Front Glass Only or the Touch Screen or the LCD Display or the LCD + Touch Combo?

The T-Mobile Revvlry screen module is known to have three key components: Glass Panel, Digitizer & Display. To know the differences between different type of parts available for T-Mobile Revvlry, we first need to know what is the function of each of these 3 components of the screen module.

* The Glass Panel or The Front Glass (Top Layer) - This is the top glass layer in the front, which you can touch and feel. Typically less than one millimeter thick, the glass panel does not have a functionality and mostly serves as a protective layer to the screen module.

* The Digitizer (Middle Layer) - A film like component, pasted just below the front glass. When you tap your fingertip or swipe it across the screen, the digitizer senses it and sends data to the phone processor. The digitizer pasted to the front glass together is called as a "Touch Screen".

* The Display or The LCD (Bottom Layer) - The bottom layer which produces the image. The display is the visual component underneath the glass that displays the image on the screen.

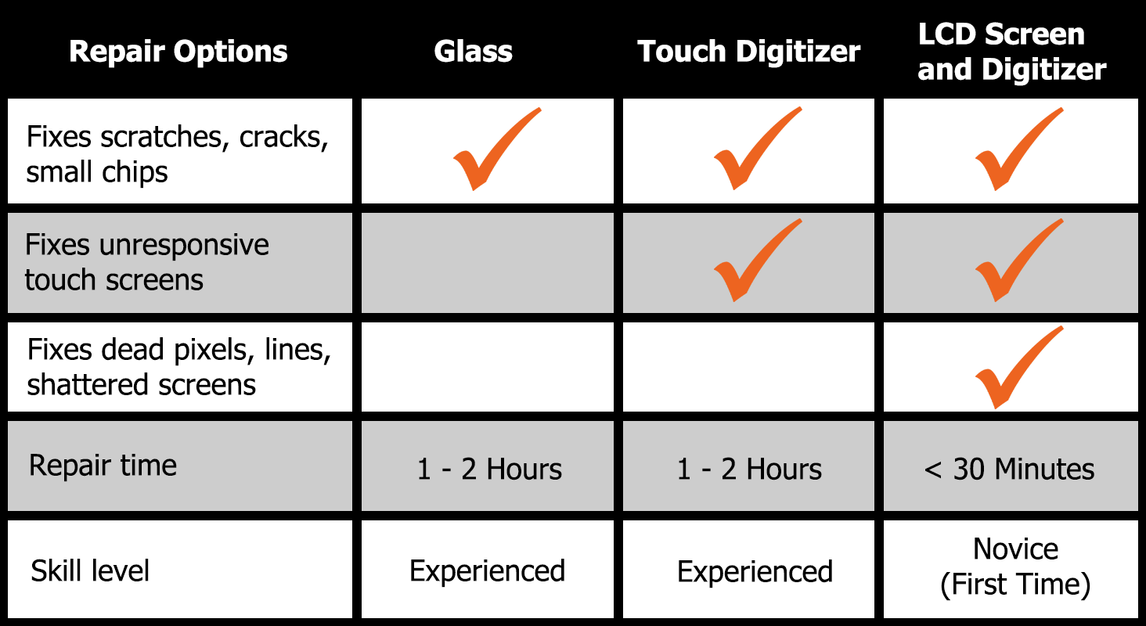

Front Glass Only:You need Front Glass when only the front glass is broken / cracked. Means When your phone is working perfectly fine and you can see the display clearly with no black spots & the touch is working fine for all portion of your screen, then you can just buy the front glass and get it replaced in your phone.

Replacing the front glass of a screen module is a very technical procedure and requires lots of experience and machinery. If you don"t know what you need, then better look for other product type.

Touch Screen Digitizer:You need to replace Touch Screen Digitizer for your T-Mobile Revvlry when the phone is working fine, but the phone stops responding to touch. This can happen when you broke the front panel of your phone and it together damaged the digitizer also. If the display your phone is working fine and there is no black spot on your screen, then replacing the Touch Screen is the best alternative.

Again, replacing the touch screen of T-Mobile Revvlry screen module requires technical know how. This procedure also needs some machinery to perform the procedure as the touch is closely pasted on top of the display.

LCD Display:In rare cases the T-Mobile Revvlry display stop functioning properly. This can be due to internal malfunction, water logging, manufacturing defect, etc. In this case, you can replace the LCD Display from the screen module.

Replacing LCD from the screen module will again require technical know how & set of machinery, as you again need to remove the pasted touch digitizer from the LCD display.

LCD with Touch Combo (Folder):This is the complete screen module, means LCD with Touch for T-Mobile Revvlry contains all components of the screen module and is ready for installation in your phone. You can use this part if the screen is broken / cracked or the display stops working.

The easiest repair for mobile phones to complete is the LCD assembly replacement. This repair takes less than an hour and requires the least amount of technical ability. For some devices the LCD assembly can be replaced simply by removing a few screws and cables. Also, as the assembly includes the glass, touch screen and the LCD, you can be confident it will fix all common screen issues.

For iPad and other tablets, if the screen parts aren"t fused, then you can do a glass touch digitizer only replacement. Otherwise, the full assembly is the easiest repair. Either way, it usually takes 1-2 hours.

While it can be significantly cheaper repair, If the screen parts are fused, the screens must be heated to loosen the adhesive between the screen and LCD and you need special equipment. This includes all iPhone and most other mobile phones and some iPads or tablets. A heat gun or hair dryer can be used for this. The screen is then gently and very slowly pried apart from LCD. DIYers need to use care to insure the LCD is not damaged in the process.

Tip: Transferring the home button on an iPhone or an iPad can be the most tricky part. It takes a little patience and heat. You can purchase screens that have the home button pre-installed (along with other small parts) and this is the easiest of all repair. This can take 15-30 minutes. However, Touch ID function only works with the original home button so you have to transfer if you want to retain it. Note: some of the iPads don"t have a screen replacement option that includes the home button like the iPad Pro and newer iPad Mini. iPad 1st Gen to 9th Gen screens, have a home button pre-installed option.

As an official phone repair provider who has been in the business for almost a decade, one unique question people ask when they visit our service centres to replace their phone screen is: "what"s the difference between original and copy phone screen?"

Well, the answer is, there are many differences between these two screens, which is mostly in their quality. And while “copy” phone screens are somewhat cheaper than the originals, it doesn’t justify the difference in quality. So, before you regret replacing your phone screen with a forbidden part, the tips below will tell you the critical differences between original and copy phone screens.

Generally, phone screens manufactured from your brand"s factory are the original ones while ‘Copy’screens are the ones designed and produced by third-party manufacturers and factories that are not related to your brand.

Many people usually like to go for copy screens because of their cheaper price. However, the "real" differences between original and copy screens lie in their quality, and here’s what you need to know about them.

One of the principal issues with "copied" phone screens and why it differs from the originals is touch and digitizer problems. And that"s a big problem since you"re going to control the device with the touchscreen anyway.

As far as we could remember, phone manufacturers build the touch panel/digitizer with the LCD itself, while the copied screen manufacturer build it separately on the surface glass. Hence, there"s a difference in touch sensitivity. Additionally, copied phone screens usually drop the high touch sampling rate, meaning your screen may not respond to your touches faster.

Here"s also another major issue with the digitizer on copied phone screens. When you crack a copied screen accidentally, the touchscreen stops working, stopping you from accessing the device until you fix it again. Meanwhile, the touch on the original phone screen works perfectly, even after undergoing severe cracking.

Besides having touch problems, most copy phone screens usually have poor display properties. That means you get lower brightness, colour accuracy, sharpness, contrast, etc. And when the display isn"t great, watching movies and viewing other content becomes boring.

For instance, if the original screen is supposed to have 480 nits of brightness, but the copy screen has just 200 nits, the screen becomes unusable under bright lights. Moreso, copied phone screen seems to have more blue light, which, in return, affect your sight and disrupts your sleep at night.

Among others, copied phone screens drop higher refresh rates, and that"s a bummer since most phones come with at least 90Hz refresh rate screens. What that means is the copied screen won’t feel smooth as it’s supposed to be.

It"s not all about the display quality. A copy phone screen may also affect other parts of the phone system if its specifications don"t tally with the original one. In such a case, it could drain your battery at an alarming rate, or at worse, damage your backlight.

If you happen to have a phone with an in-display fingerprint sensor, then replacing its screen with a copied one is not an option – it’s going to mess with your fingerprint accuracy.

We know copied phone screens for their poor quality, and it also extends to the fingerprint sensor. Hence, it takes a longer time to unlock your device. And in other cases, the security of the sensor is not accurate. We"ve seen situations where phones get unlocked with many unregistered fingers after replacing the screen with a copied one.

If you care about your phone"s security and you don"t want a sluggish fingerprint sensor, then we recommend you only go for the original phone screen replacement.

That brings us to the last difference we’re going to mention between copied and original phone screens. They manufacture copied phone screens with poor glass materials. Hence, they break quicker than the originals. And when they do, you’ll be left with only one option: to replace the screen again.

The major reason for choosing the official service centre over third-party/local repair shops summarizes what we"ve said earlier. The official service centre is the reliable place to get original phone screen replacement parts.

Besides offering you the original screen spare parts, the official service centres also have other advantages. These include certified and well-experienced technicians to fix the screen, the use of modern tools that won"t damage your phone further, and most importantly, a reliable warranty. Local repair shops usually don"t offer these features; most especially a reliable warranty, which means you"re on your own if the replaced screen gets faulty afterwards.

As far as choosing the official service centre is concerned for genuine screen replacement, then you shouldn"t shy away from Carlcare Service if you own a TECNO, Infinix, or itel phone with a cracked screen.

We"re the official service center for these three brands to cater for your mobile repair needs. And for screen replacement, Carlcare delivers excellently. Our brand-trained technicians replace your cracked screen with genuine OEM parts at affordable rates.

We understand you have a busy schedule; and yes, we"ll replace your screen in the shortest possible time. Start by checking how much it cost to fix your cracked phone screen, then you can book an online reservation service with us to reduce your waiting time and also become a VIP customer.

We have all heard of an LCD and touchscreen, some people do not know the difference, and some do not even know there is a difference, but what exactly is the difference? Many of us have had to deal with a broken touchscreen or LCD at one time or another, especially with smartphones. But how well do you know this device? You should know it pretty well since we use them everyday in our phones, laptops, and even radios!

A radio touchscreen is defined as "a display device which allows the user to interact with a computer by touching areas on the screen". In a radio, the touch screen or digitizer is the input portion of the radio. This thin piece of resistive or capacitive electrically charged glass is as thin as 1.1 mm. Using your finger allows for haptic responses to control the radio and some vehicle functions. A ribbon cable allows for integration into the main circuit board that powers the LCD, touch screen and any buttons built into the radio.

When the touchscreen is broken, you will still see what is on the screen, the screen should operate as normal. Like when you break your phone screen and can still operate the device. While it’s design may seem delicate and fragile, they are made to withstand the constant vibrations of daily driving. Any force greater than a finger tap is more likely to cause damage in the form of a spider web crack. Other foreign objects such as car keys, 2x4s, and the occasional matchbox race car can dent or completely shatter the touchscreen; even the LCD!

The Liquid Crystal Display (LCD) is the output portion of the radio that displays all radio functions and features. An LCD screen is what displays the image from inside of the device. Without the LCD, the radio brain or module cannot be used to its full potential. Today’s car and truck radios act as infotainment hubs providing both in-vehicle entertainment and live information.

When the LCD is broken and/or damaged, you may still be able to use the touchscreen depending on how bad the damage is. When broken, the panel will have dark blobs or a viscous substance and most likely will have a spider web type crack. While the touchscreen seems to act as a protective barrier, any defect can cause secondary damage to the LCD deeming both pieces scrap. Isolated LCD damage with no damage to the touch screen is possible and has been witnessed by our techs; the cause of which is due to some dropping or the impact from a car wreck. The LCD has a thin ribbon cable that connects into a circuit board that powers the LCD, touchscreen and any buttons built into the radio.

Luckily for you, at Factory Radio Parts, we provide many OEM replacement parts such as DVD and Navigation mechanisms, touch screens, spindle motors, LCD displays, main printed circuit boards, flex cables, hard disk drives-YOU NAME IT! All of our products have been sourced from the suppliers who help manufacturer these factory radios. All products are delivered to our warehouse where they are thoroughly tested and stored in a clean and secure environment. We, at Factory Radio Parts, value our customers and will go above and beyond to provide the best quality replacement parts at the lowest prices and superior customer experience. CLICK THIS TO VIEW OUR LCDs AND TOUCHSCREENS!

If you find yourself with a broken touchscreen or LCD, don’t let mechanics and dealerships try to sell you a new radio, instead of the more cost-effective alternative: REPAIR! Click here to check out our DIY replacement parts

In the work, I often encounter some friends to consult the difference between LED display and LCD touch display. There are always some misunderstandings in choosing these two displays.

JFCVISION has more than 10 years of experience in the production and sales of LCD capacitive touchscreen. We gives a brief analysis of the difference between LCD touch display and LED display.

1. The principle of LED and LCD illumination is different, and the manufacturing process is different. The LED is composed of a dense dot matrix composed of light-emitting diodes, and the image definition depends on the resolution of the light-emitting point. The LCD is composed of liquid crystal cells. This process is mainly manufactured by major manufacturers such as Samsung, LG, AUO, BOE.

Remanufacturer and distributor of liquid crystal, panel and touch screen displays. Available with 100 VAC to 240 VAC power supply. Features include front bezels, USB support, windows, auto-adjust buttons, built-in power supply and USB cable brackets. AutoCAD files accepted. Most items available in stock. 24/7 services provided. RoHS compliant. UL and cUL listed. CE certified. Two year warranty.

Manufacturer of standard and custom liquid crystal display (LCD) displays. Thin film transistor (TFT) and graphical displays are available. Offered with LED backlight and integrated capacitive or resistive touchscreen. Suitable for medical devices, embedded systems, airplanes, amusement parks, golf carts and vehicles. Serves automotive, automation, gaming, security and OEM industries.

Distributor of touch screen panel liquid crystal displays (LCDs). Available in 10.1 in. sizes. Inventory management services are also offered. Serves the electronics, computer, telecommunications, aerospace, aviation, medical, automotive and transportation industries. ITAR registered. Stock items available.

Manufacturer of optically bonded, non-touch and touchscreen displays. Features vary depending upon model, including vision 2 display controllers with quad-core multimedia processors, liquid crystal displays, auto-dimmable display backlights, housings with powder-coated die-cast front, horizontal and vertical viewing angles, membrane keyboards, internal temperature sensors, programmable software and resistive touch screens. Meets ASME and OHSAS 18001 standards. CSA and NFPA approved. API registered. CE certified.

Manufacturer of flat-panel industrial monitors and displays rated for Division 1 and Division 2 environments. Custom engineered, designed, and manufactured to handle the dust, dirt, debris and chemical exposure common to rugged and hazardous applications in the oil and gas, pharmaceutical and food processing, manufacturing and chemical industries. Types of monitors include military grade, LCD, rugged, washdown, high definition, wide screen, panel mount, rack mount, flush mount, gas purged, and more.

Manufacturer of resistive touchscreen HMI displays with anodized aluminum housings, USB and Ethernet. Available in four screen sizes, 6.102 to 11.535 in. width, 2.283 in. depth and 5.315 to 8.78 in. height. Surrounding air operating temperature ranges up to +55 degrees C. Serves the automotive, railway system, power engineering, building, lighting, marine, offshore and process industries. Most items available in stock. RoHS compliant. UL listed. CE certified. JIT delivery.

Distributor of integrated touch screen displays. LCD, sunlight readable TFT, monochrome, chip on glass, TFT LCD, LED, automotive rear seat and OLED displays are also available. Vendor managed inventory (VMI) programs and stock items available. Meets AS9100 Rev C standards. Kanban and JIT delivery.

Manufacturer of Industrial touchscreen displays suitable for railway sign, airport control tower, digital signage, agriculture, factory automation, kiosk and retail applications. Available in 10.4 to 21.5 in. display size, -10 to 60 degrees C operating temperature and 9 to 50 volts DC voltage. Some monitors are offered with fanless and rugged design, LCD display, front panel IP65 waterproof, dual speakers, resistive and capacitive (PCAP) touch options available. EPA registered.

Manufacturer of touchscreen panel displays for medical and industrial applications. Available in 10.1 to 27 in. display sizes. Features vary depending upon model, including LED backlights, plastic design, USB, flat, power connectors, optional side brackets, input video signal interfaces and terminals. Accessories such as power adaptors, cords, cables and stands offered. Meets EN 60601-1-2 standards. Custom options depending upon applications are also provided.

Manufacturer of standard and custom thin film transistor liquid crystal displays (LCD) including human machine interface diagonal touchscreens. Available in 5 VDC power at 200 mA current, 4.3 in. screen sizes, 0.92 in. depth, 4.75 in. width and 3.70 in. height. Features include programmable, graphical operating systems, front panel mountable enclosures, protective overlays, built-in copy protection options and power management controllers. Serves the pharmaceutical packaging identification, instrumentation, emergency response service, recording and bioprocessing industries. Made in the USA.

Manufacturer of custom rugged displays for military, marine, industrial, avionic, medical, transportation, commercial and other applications. Diverse engineering team able to design to fit any enclousure. Many types of touch screen technologies available, including surface capacitive, projected capacitive, resistive, SAW, infrared, optical, DST. Other features include sunlight readable, NVIS, waterproof, flip-up, flip-down, rack mount drawer, panel or rack mount, and much more. All sizes are available, from small to large. Suitable for workstations, cockpits, medical devices and other safety- or mission-critical applications. Manufactured, serviced, and supported in the USA.

Manufacturer and distributor of touchscreen, sound, video and theatrical displays. Types include counter top, back-up, extension, dual USB charger, heads up and four sided color changing displays. Available in a variety of configurations. Features vary depending upon model and include LED light strips, wireless remote control, LCD widescreen rear view mirrors and license plate cameras.

Manufacturer of touchscreen displays for home automation, video intercom and door entry system. Features include up to 16 control functions, intuitive operation and capacitive touch display. Lifecycle management, engineering, consulting, installation, maintenance, replacement and training services are provided. Serves the automotive, chemical, marine, metal, food, beverage, mining, power generation or distribution, solar power, printing, aluminum, cement, automation, water, wind power, pulp and paper industries.

Manufacturer of alphanumeric, touchscreen and LCD displays. Features vary depending upon model, including built-in Ethernet ports, hand-held versions, single port multi access (SPMA), integrated simulation functions, analog resistive touch, multiple communications, compact flash memory cards and FTP web interfaces. Serves the automotive, food/packaging, electronics, life sciences, material handling, machine tool, oil and gas, water, wastewater, security, detection, entertainment and other industries. 24/7 predictive maintenance services also provided.

ISO 9001 certified worldwide manufacturer of touchscreen terminals, monitors & displays. Graphics touchscreen terminals enable operating, monitoring & control of large scale projects with different PLC"s simultaneously. Features include plain text messages & graphical overview screens for user-friendly diagnostics. Touchscreen terminals are available in sizes of 5.7 in., 6.5 in., 10.4 in. 12.1 in. & 15 in. Terminal features also include Microsoft Windows ® CE.net operating system, USB interfaces, serial interfaces, Ethernet interface, IP65 front, IP20 back & PCMCIA slots.

Custom manufacturer of touchscreen LCD displays. Various capabilities include design, testing, engineering, cutting, plating and potting. Electronics, medical, telecommunications, gaming and other industries served. Meets IPC standards. JIT delivery.

Six Sigma capable, ISO 9001:2008 & ISO 14000 certified manufacturer of touchscreen displays including flat panel monitors. Types of flat panel monitors include DVI/RGB and hazardous location compatible. Flat panel monitors feature front USB interface, 256K or 16 million color display, analog resistive touch panel, serial/USB touch interfaces, on-screen-display menu for brightness & contrast control, & VESA standard wall mounts. Available with a 2-year warranty. Markets served include industrial, automotive, oil & gas, water/wastewater, semiconductors & agriculture. Modbus-IDA, OMAC & ODVA affiliated. Products are UL® listed, CSA® approved, and ATEX & CE certified. Products are RoHS compliant.

Precision CNC machining, sheet metal fabrication and assembly services. Repair services are also provided. Fiber optic junction boxes, converters, latches and switches are offered. Uninterruptible power supplies (UPS), liquid crystal displays (LCD), racks, consoles, multiplexers, control panels and quad-core processors and servers are also available. Serves aerospace and defense industries.

Custom manufacturer of touchscreen displays for stationary storage, equipment, electric and hybrid vehicles. Battery management systems and vehicle control systems are offered. Fleet management software is also provided. Consulting is available as value added service. Serves the e-mobility, automotive and mobile robotics industries.

Manufacturer of standard and custom digital signage, including a large variety of displays. Display types such as LCD, digital sign, animated, touchscreen, video, and a large array of point of purchase (POP) displays are offered. Industries served include retail, convenience, and healthcare.

Your smartphone"s screen is the part of the phone that lets you see everything and interact with the device. If it gets a crack or receives some other damage, you might not be able to use it as intended. You can browse through eBay"s huge selection of inexpensive cell phone screen repair tools to find a kit that will help you fix mobile phone screens.

Cell phone screen repair kits are available from eBay in a variety of types. Some types have a general mix of tools, and others are made with a specific purpose in mind. You can use the helpful categories on eBay to sort through the hundreds of cell phone screen repair options you"ll find there. Some common types that are available to you include:

Many cell phones have screens that come in two parts. The LCD display is the part you see in the first layer. It shows you images, videos, and texts that are on the screen. A second layer over the first has sensors that allow you to interact with the screen using your fingertips. During cell phone screen repair, it is sometimes necessary to use an LCD separator to take apart the two layers of the device. You may need to replace one or both of them to repair your phone.

You can find all-in-one cell phone repair kits on eBay. These kits include all the tools and parts you might need for screen repair work on phones. They are intended to work with as many phone models as possible. The main items you will find in one of these kits are adhesive strips and suction cups to help you separate the phone"s layers, various screwdrivers to deal with the small screws, prying tools, and pliers to hold the phone open. These parts are designed to be safe for the delicate parts you"ll find in your phone, but you should exercise care when performing any repairs.

Touch screens offer ease of use, speed, accuracy, and negate the need to become proficient with a handheld device. General Digital offers the option of equipping your LCD monitor with a variety of touch technologies, such as:

In 1977, we created the world’s first touch responsive industrial terminal, the VuePoint™. It didn’t have a true touch screen; rather, the VuePoint was equipped with a circuit board onto which infrared LEDs were mounted. The LEDs were arranged to form a 12 x 40 grid and when the screen was touched, the infrared beams were broken, indicating the touch location to the terminal. Thus, an operator could control a system right at the terminal.

As touch screen technology evolved (along with monitor technology), we incorporated various touch panels into our LCD monitors, starting with our SlimLine™ series of flip-up LCD monitors. Over time and based on demand, our Saber RackMount, PanelMount and Standalone Series became the next logical candidates for touch integration. This was due to increased use of flat panel technology in human-machine interface applications.

Featuring pure glass construction, Surface Acoustic Wave (SAW) touch screens will almost never physically “wear out” due to a superior scratch-resistant coating. Excellent light transmission ensures that the image clarity of the display remains sharp and vibrant. The stable, “drift-free” operation means that the touch response is always accurate. They work well with a finger, gloved hand or a soft stylus. And SAW touch screens have a sensitive touch response—they recognize the touch location and the amount of pressure applied.

Being an all-glass design, light transmission of surface capacitive touch screens is improved, when compared to resistive touch screens. This improves display viewability and reduces eye fatigue. Featuring a scratch-resistant top coat, durability in heavy-use environments is easily maintained. This type of touch screen is ideally suited for rugged, industrial or military applications.

Infrared touch technology doesn’t rely on an overlay or a substrate to register a touch, so it cannot physically “wear out,” thus ensuring a long product life cycle. Possessing superior optical performance and excellent gasket-sealing properties, an infrared touch screen is ideal for harsh industrial environments and outdoor kiosks. They work with a finger, gloved hand, stylus, and most any object wider than 1/10". They adjust to changing light conditions, even direct sunlight. And they benefit from stable, no-drift calibration performance.

Working in tandem, two optical sensors track the movement of an object close to the surface by detecting the interruption of the touch screen’s infrared light source, which is emitted in a plane across the display surface and can be either active (infrared LED) or passive (special reflective surfaces).

Optical touch screens use a controller board that receives signals from the optical sensors, then compensates for optical distortions and triangulates the position of the touching object with extreme accuracy.

The infrared light source and optical sensors of the touch screen are synchronized using a sophisticated algorithm that also reduces the effect of ambient light, thus creating a very clear, accurate touch selection.

Developed specifically for interactive digital signage applications, Dispersive Signal Technology determines a touch point by measuring the mechanical energy (bending waves) within a substrate created by the pressure of a finger or stylus. As these bending waves radiate away from the touch location, the signal spreads out over time due to the phenomena of dispersion. The “smeared” signals are then interpreted by a complex set of algorithms to precisely pinpoint the exact touch location on the screen.

DST is a passive technology, waiting for a signal created by a touch impact. Therefore, contaminants such as dirt, grease, and other solids can accumulate on the surface and edges of the display screen without significantly affecting touch responsiveness. In addition, surface damage, such as scratches, has no significant impact on touch performance.

The sophisticated and optimized controller that continuously monitors for a touch impact is the fastest and most responsive technology available for large format displays, offering greater than 99% touch location accuracy.

Projected capacitive touch screen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

Resistive touch screens still reign in cost-sensitive applications. They also prevail in point-of-sale terminals, industrial, automotive, and medical applications.

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

If you have any questions about Orient Display capacitive touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

The construction of a capacitive touch screen,mainly to plate a transparent film conductor layer on the glass screen,then add a protective glass to the outside of the conductor layer,plate narrow electrodes on all four sides of the touch screen,a low voltage alternating electric field is formed in the electrical conductor.When you touch the screen,due to the existence of the human body electric field,a coupling capacitor is formed between the finger and the conductor layer,the current from the four electrodes will flow to the contacts,the current strength is proportional to the distance from the finger to the electrode,the controller behind the touch screen can calculate the ratio and strength of the current,then can accurately calculate the location of the touch point.

Compared with the resistive touch screens that are common in the market at that time,capacitive touch screen has obvious advantages,no pressure is needed to generate the signal,while the resistive touch screen is activated by pressure.Second,the capacitive touch screen has a long average life.Third,for the resistive touch screen, the upper film needs to be thin enough to be elastic so as to be bent downward to contact the underlying film, so it is easily damaged.And the covers of capacitive touch screen can be thicker, also have glass protection and have good scratch resistance, which can better protect conductors and sensors.In addition, capacitive touch screen is more durable, not easy to aging, high temperature resistance.Moreover, the double-glass design of capacitive touch screen can effectively prevent the impact of external environmental factors on the touch screen,even if the screen is stained with dirt, dust or oil stains, the capacitive touch screen can still accurately calculate the touch position.the more important thing is,at this time, the touch screen has evolved from an early analog touch screen to a digital touch screen, can achieve multi-touch.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey