lcd panel shortage for sale

COVID-19 has had a dramatic effect on the electronics industry. The worldwide drive for people to work and educate from home and the increase in demand for medical products have taken the supply of electronics components from overcapacity to shortage and extended lead times. This was multiplied by the shutdown of manufacturing and the attempt to catch up with previous demand. The industrial market has also gotten hit by the loss of small gen fab capacity due to the shutting down of older, less competitive fabs.

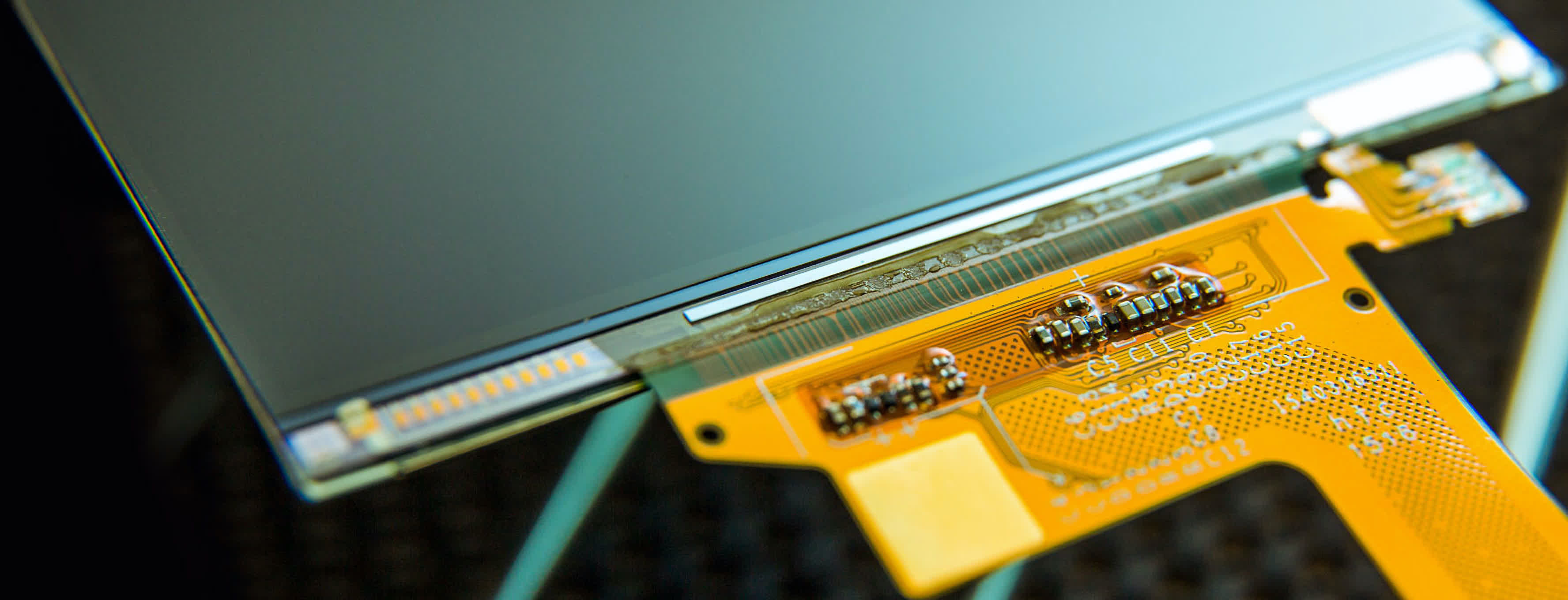

Before COVID-19, the display market had been in an oversupply with the slowdown in cell phone demand. With the increased demand for laptops, monitors, and even TVs has backfilled this capacity and driven us into a shortage situation. This shortage of electronic components is not only in the display market but extends to basic components like resistors and capacitors.

A shortage of large LCDs, which has lasted for almost a year, and which has resulted in the biggest panel price increases in the history of the industry, has begun to turn into an oversupply, according to research by consulting firm DSCC.

The shortage was driven by strong demand for TVs in the US during the Covid-19 pandemic, but increasing vaccination rates and higher inventory levels have led to a weakening in this market.

While every country has been affected by the pandemic and demand for LCD panels in IT applications remains high, the surge in demand for big TVs at premium prices in the US has had the biggest impact on LCD panel prices, feeding healthy profit margins at all major TV brands. But the surge of demand that started in Q2, 2020 is now slowing, as US consumers begin to spend more on travel and other activities that were restricted during lockdown.

DSCC expects the panel price for LCD TVs to begin to fall during the second half of 2021, but tight supply for various components such as driver ICs and glass substrates will continue for the time being.

However, you won’t be pleased that the shortage will increase, and it will likely persist until the following year due to some developments that have affected manufacturing.

The actual quantity of the damaged goods and products was not specified, but you’d be impressed to know that AUO’s facility in Taiwan produces millions of panels. It made more than 10 million large modules for TVs and a little less than 9.5 million small to medium screens meant for monitors last month. An hour of stoppage means that several thousand will get delayed, but that doesn’t count the number of broken panels that are already fragile or sensitive, to begin with.

Foundries for other parts such as memory modules or processors aren’t as affected even if they suspended operations as well. TrendForce reported that they were indeed halted by the earthquake, but the damage to their equipment and product was limited since they aren’t as fragile as LCD panels.

It also doesn’t get any better at this point since existing shortages for boards and ICs have already affected supply and pricing. Factor in the effect of the pandemic, and you will get a level of uncertainty for manufacturing and sales in 2021. These two massive disruptions seem like they will make the shortage we are experiencing now worse, so we have no choice but to recommend grabbing what you can as soon as possible.

Half of the ill effects we mentioned are speculation at this point, and even the CEO of AU Optronics has not yet commented regarding the effects on pricing. However, basic economics will dictate that a large-scale shortage like this will lead to price hikes, especially at a time where demand and the growth of the display and monitor market are steadily expanding.

The outlook for your ability to get the 2021 model TV you might have your eyes on, and the price you might have to pay for it isn’t good right now, following reports of component shortages limiting production yields this year.

According to reports out of Asia, widespread component supply shortages could impact availability on LCD TV panels from TCL owned panel maker China Star Optoelectronics Technology (CSoT) and Innolux, two of the world’s largest LCD panel suppliers.

The display panel manufacturers were reported by Korean electronics business news site The Elec on Mondayas warning that supplies of panels are expected to be “tight throughout the year.”

TCL chairman Li Dongsheng used a media briefing last week to announce that panel shortages will continue in the first half of 2021, following conditions already hampered last year during the start of the Covid-19 pandemic.

The Elec article also cited Innolux president James Yang warning of a shortage in LCD panels caused by strong demand for LCD coming out of the global Covid-19 crisis, and he also added the conditions are expected to continue through 2021.

Innolux has seen shortages in LCD components including power semiconductors, driver ICs and glass substrates that have kept production below capacity. Shortages of integrated circuits and semiconductors could continue right up to the first half of 2022, Yan cautioned.

Ironically, prior to the run on LCD panel supplies, manufacturers were also faced with the dilemma of overproduction causing a glut in inventory, which was driving prices artificially lower. This was the result of giant new LCD fabs coming online in China and other areas of Asia.

TV manufacturers reportedly have been moving aggressively to replenish inventories of LCD panels to meet strong sales of TVs and other devices to meeting escalating demand, particularly in the United States and Europe.

At the same time, Samsung Display LCD monitor panel supplies for monitors are on course to terminate by the end of the first quarter 2021, and supply of IT panels overall will only continue to tighten up as demand increases for TVs and notebook panels, according to Asian analyst reports.

China-based Sigmaintell last week estimated the average selling price for a 21.5-inch LCD module for monitors would rise $3 to $55 this month, compared to a $2.50 increase for 23.8-inch panels and $2 increase for 27-inch monitor panels.

Global monitor panel shipments declined in the first quarter of the year, a report showed on Wednesday, mainly due to Samsung Displays exit from the monitor LCD display manufacturing business and a shortage of semiconductors.

The worldwide monitor panel shipments fell 8.6 percent on-quarter to 39.9 million units in the January-March period, according to the latest report from market researcher TrendForce.

"TrendForce indicates that SDC will exit the monitor LCD panel manufacturing business after it reaches its shipment target of 1.2 million panels in 1H21," it said. "This figure represents a staggering 93.8 percent decline compared to the 19.3 million units of LCD panels that SDC shipped throughout last year."

Samsung Display, the world"s top mobile display panel maker, has been focusing on its migration to next-generation quantum-dot (QD) displays, while withdrawing from the LCD business, reports Yonhap news agency.

But for large LCD panels for TVs, the company recently said it is mulling extending its manufacturing for one more year due to soaring demand from TV makers and rising panel prices.

TrendForce said the global monitor panel market also suffered a setback in the first quarter due to a shortage of components, such as integrated circuits and timing controllers.

"In addition, since TV and notebook (laptop) panels have higher profit margins compared to monitor panels, panel suppliers generally allocate less of their production capacities for manufacturing monitor panels relative to other products," it said.

"TrendForce believes that panel suppliers will likely in turn allocate more production capacities to clients in the monitor segment in 4Q21," it said.

"More specifically, the current shortage of components in the upstream supply chain, which has been exerting significant downward pressure on monitor panel shipments, will be gradually alleviated in 2H21."

Based on Omdia’s Large Area Display Price Tracker, April 2021, Sanju Khatri, director of consulting for displays, ProAV and consumer devices at research and consultancy firm Omdia, provided some analysis on disruption in the display supply chain due to component shortage and high demand. Impact will be mostly felt on LCD technology, as strong demand and component shortage will lead to the following price cycles for LCD panels.

EDITOR’S NOTE: Three distinct terms are used below. Components (display driver IC, glass, and polarizer); panel (raw LCD panels) and brands/finished sets/device vendors (TV, monitor/laptops/ProAV vendors).

Strong consumer demand for TVs/IT displays. The “at home” trends are including work at home, learn at home, entertain at home and shop at home. The LCD TV, Notebook, LCD monitor, and tablet PC products continue to have the strong demand thanks to the “at home” trends.

Display panel makers are increasing prices sharply to take the fast turnaround on profitability. The LCD TV open cell prices have been increasing by 40%-50% from June 2020 to December 2020. And it is expected there will be another 20% increase from January 2021 to May 2021.

Component shortage(Glass substrate, Display Driver IC, T-con, PMIC, Polarizer films) are frustrating the supply chain from time to time, making the set makers to be more nervous thus giving more orders. Three display components are especially tight in 2021, represented by “P.I.G.”

P: Polarizer, protective/release films and surface treatment capacity are in tightness due to the production bottleneck and the retreat of the makers. However, the polarizer shortage is viewed as a short term as the long-term polarizer supply is sufficient.

I: IC, Display Driver IC supply is expected to loosen from 2H21however, limited foundry capacity and allocation competition with other IC applications may continue to complicate display panel shipments into the future. Even with the incremental display driver IC wafer foundry in the second half of 2021 (2H21), it is possible the wafer capacity allocation will be shifting to other IC applications.

G: Glass substrate is in tightness due to the unexpected accidents happened in the suppliers from 4Q20 to 1Q21. The glass substrate shortage is viewed as a short term but especially serious within these couple of months due to some accidents that happened in NEG and AGC. The recovery schedule is expected to take 6 months in Omdia’s estimation. In April 2021, there were also some yield rate challenges in glass tanks in Korea, which caused the short-term tightness in 2Q21.

Monitor prices may soon be on the rise, or at least there’s potential for that happening, with existing LCD panel shortages likely to worsen thanks to a couple of recent unfortunate events.

The earthquake was problematic for AU Optronics, a prolific producer of LCDs and a name you’ll often see mentioned in conjunction with monitor panels. It took out some of the firm’s assembly lines for a period of time, resulting in lost production as per a DigiTimes(opens in new tab) report (with word coming from the chairman of AU Optronics, Paul Peng).

Output is back to normal now, but the impact from those supply losses will be felt in conjunction with the event in Japan. That was a power outage in Takatsuki which affected a Nippon Electric Glass (NEG) production facility that makes glass substrates for flat panel displays.

NEG’s production comprises of around 10% of the world’s glass substrate manufacturing, and it supplies the makers of various LCD panels, so the issues with glass substrates will have a knock-on effect in the monitor supply chain.

Why it matters: The global semiconductor industry was worth $439 billion in 2020, and is on track to grow even bigger this year. However, that growth potential is being eroded by a shortage of $1 chips that are essential for every display panel that needs to be manufactured.

A global shortage of chips has wreaked havoc on the supply chains of the tech and auto industries. This has caused many companies to scale back production at a time when demand is soaring for their products. This is the result of a combination of factors, and the current situation will probably not change until the end of next year.

According to a Bloomberg report, there is now a serious shortage of display driver chips that is creating headaches for manufacturers of LCD and OLED panels. This in turn will affect all manner of consumer devices, from the lowly smartwatch to smartphones, tablets, laptops, computer monitors, TVs, smart appliances, and infotainment systems. Every new car or plane comes with one or more display panels, which only adds to the demand.

Nevertheless, the shortage of these driver chips will likely cause further delays and price hikes for products that are currently in high demand, and the manufacturers of these chips don"t see a solution in sight.

The shortfall is already visible in the doubling of prices for large LCD panels over the last year. Himax Technologies CEO Jordan WU told Bloomberg "I have never seen anything like this in the past 20 years since our company"s founding."

A long-standing supply crunch for liquid-crystal display panels is starting to lift, providing hope that prices for flat-panel monitors will begin falling again later this year.

"We see supply of LCD panels beginning to loosen from the shortage we saw the last three quarters of last year," Ross Young, president of research firm DisplaySearch, said Friday.

The majority of LCD panels that are 10 inches or more in diagonal width are used in computer monitors, Young said. But suppliers focused on notebook and TV applications last year because those products have higher profit margins, he said. Monitors "sort of got the short end of the stick during the shortage," he added.

Thanks partly to decreased demand for televisions after the holiday season, prices for large LCD panels for televisions are falling, Young said. But the average price for 15-inch panels for monitor use is expected to climb from $218 in January to $224 in March, he said.

Not surprisingly, that"s translating into continued price increases in actual monitor products in the United States. "Those prices haven"t started going down again yet" on average, said Samantha Nebrich, an analyst at iSuppli/Stanford Resources. Nebrich said that after steady declines in what it cost to buy an LCD monitor, prices started rising in the third quarter of 2003. The average price of a 15-inch LCD monitor in the United States in the fourth quarter was $327, up from $302 in the third quarter, Nebrich said.

A reversal in the pricing trend will probably happen in the latter half of this year, she said. That prediction is in keeping with DisplaySearch"s forecast for increased LCD panel supplies. Young said the first quarter should see a 2 percent surplus of panels in the market, and that should expand to 4 percent in the second quarter and 5 percent in the third quarter.

Key to additional supplies is a major increase in capacity from LCD panel suppliers, which include Samsung. Young said suppliers are set to invest $10 billion in new equipment this year, which is 50 percent more than the greatest amount ever invested in a single year.

Strong demand for LCD panels in the wake of the coronavirus pandemic has created shortages that will remain in the entire 2021, according to Innolux president James Yang.

Global production capacity for LCD panels exceeds global demand currently, but actual output is much less than the capacity due to continued shortages of key components including polarizers, power ICs, driver ICs and glass substrates, Yang said at a March 3 investors conference.

Shortage of ICs is the most serious and may remain until first-half 2022, Yang noted. Japan-based Nippon Electric Glass and Asahi Glass, two main suppliers of glass substrates, have seen factory accidents and the glass supply is expected to be tight in first-half 2021, Yang indicated.

In view of potential demand for high value-added automotive displays along with development of smart cockpits and integration of various digital information, Innolux has worked with clients developing high-end free-form miniLED-backlit LCD automotive displays of over 20 inches for use in high-end car models, Yang said, adding Innolux has begun small-volume shipments for such displays, and aims to become the market leader in 2023.

Due to the pandemic and along with increasing deployments of 5G infrastructure, global demand for online education is growing fast, and Innolux’s shipment for notebook-use LCD panels in 2020 hiked 50% on year to become the second-largest supplier worldwide, Yang indicated.

Of global demand for Chromebooks used in online education, 30% was met in 2020 and 70% is not yet satisfied, and Innolux is optimistic about shipments for notebook-use LCD panels in 2021, Yang noted.

In view of fast increasing application of AI, IoT and 5G, Innolux has stepped into business other than LCD panels. Based on TFT-LCD manufacturing technology, Innolux has worked with US-based Kymeta to produce liquid crystal meta-surface antennas and with InnoCare Optoelectronics, its subsidiary, to produce X-ray flat panel detectors for medical diagnosis.

In recent weeks, all leading PC makers have complained about the tight supply of LCD panels due to shortages of components and complicated logistics. As it turns out, the situation might get worse in the coming weeks and months due to an earthquake in Taiwan and a power outage in Japan, eventually resulting in higher prices at retail.

Last week an earthquake struck Taiwan. This isn"t an extraordinary event for the country, but it does have repercussions. AU Optronics (AUO), one of the leading makers of LCD panels, said this week that some of its production lines had been impacted by the quake, and it had taken it "at least a few hours" to clean up and repair them before resuming operations. Some of the output was lost because of the disaster, reports DigiTimes, citing Paul Peng, the chairman of AU Optronics.

Mr. Peng did not quantify the company"s losses, but AUO makes hundreds of thousands of LCD panels every day, so the earthquake will clearly impact the supply of display panels. Back in November, AUO produced 10.81 million large-sized panels for LCD TVs, desktops, and notebooks as well as 9.35 million small-and-medium-sized panels. AUO says it has now resumed normal operations.

On November 10, a power outage in Takatsuki, Japan, disrupted operations at Nippon Electric Glass"s Shiga-Takatsuki plant that manufactures glass substrates for flat-panel displays. The outage lasted for five hours and damaged some of NEG"s production equipment, the company revealed in its statement.

NEG owns about 10% of the world"s glass substrate manufacturing capacity and supplies glass substrates for LCD panels to numerous panel makers, according to the chairman of AUO. Consequently, NEG"s production problems will impact the whole market as customers that buy from NEG will have to source components from other suppliers.

The chairman of AU Optronics did not reveal his expectations concerning prices of LCD panels and displays in the coming months. Still, it is evident that shortages usually lead to price hikes. The only question is how significant the hikes will be.

A boy looks at a prototype model of the world"s largest 108-inch sized LCD TV, produced by Japan"s electronics giant Sharp in 2007. Electronics makers worldwide face a shortage of liquid crystal displays used for large-screen televisions due to soaring demand, particularly in emerging markets such as China, Sharp said Monday.

Electronics makers worldwide face a shortage of liquid crystal displays used for large-screen televisions due to soaring demand, particularly in emerging markets such as China, Sharp said Monday.

Rising demand for three-dimensional televisions and light-emitting diode (LED) televisions is adding pressure on an already strained supply chain as makers look towards using higher-performance panels, the company said.

Last week the maker said it expects to sell 15 million LCD televisions worldwide for the current fiscal year, up from 10 million units the previous year.

The company, which pioneered the technology behind LCDs, will double its production capacity faster than expected at its newest Japanese factory in Sakai city, considered the world"s most advanced display plant.

Demand for light emitting diodes, which are used as backlights in recently launched LCD models, is also increasing at a faster-than-expected pace, the company said.

SEOUL, Oct 27 (Reuters) - South Korea"s LG Display Co Ltd (034220.KS) on Wednesday saw its third-quarter operating profit more than triple as strong television demand boosted panel prices but said it expects the buying spree prompted by the pandemic to slow next year.

"Panel shipments in the fourth quarter are expected to increase by mid-10% compared to the third quarter, with the delayed shipments affected by the industry’s component shortage ...while the prices of LCD TV panels are expected to remain on a downward trend," LG Display said in a statement.

"Panel makers including LG Display have enjoyed strong demand of their panels for both TVs and IT devices, including monitors and laptops, because people spent extra time amid COVID shutdowns, but such demand will likely ease as vaccinated people already have begun to spend less time in front of screens," said Park Sung-soon, an analyst at Cape Investment & Securities.

Prices of LG Display"s mainstay 55-inch liquid crystal display (LCD) panels for TV sets increased by about 57% in the third quarter year on year, market data from TrendForce"s WitsView showed.

HSINCHU, Taiwan (Reuters) May 17 - AU Optronics Corp, Taiwan’s No. 2 LCD maker, said an LCD panel shortage is likely to last into the second half of this year on robust demand for PCs and TVs, even though fears linger about a weak euro.A woman walks past an Au Optronics LCD monitor at the company"s headquarters in Hsinchu May 17, 2010. AU Optronics Corp, Taiwan"s No. 2 LCD maker, said an LCD panel shortage is likely to last into the second half of this year on robust demand for PCs and TVs, even though fears linger about a weak euro. REUTERS/Nicky Loh

“Clients have requested a large amount (of panels), but we are not able to deliver,” Lee, 58, said at the company’s headquarters in the Hsinchu science park, Taiwan’s high-tech center.

“Monitor (panel) is tight, and notebook and especially TV (as well),” said Lee, adding that he sees no impact from a weak euro now. AU returned to profit in the first quarter after strong demand boosted sales and prices of its displays.

Major LCD makers in Asia have reported brisk demand recently as economies recover, with China leading the way. However, some analysts say the sector might be saddled with oversupply later this year if display makers aggressively ramp up output.

AU has applied to the Taiwan government for approval to set up a new LCD factory in China, with an investment of about $3 billion, as it aims to strengthen its competitiveness in China, which could soon become the world’s largest TV consumer.

Other LCD rivals, including LG Display of South Korea, also have similar plans to build new plants on the mainland, and relaxed investment laws may help usher high-generation production there.

“Competitors are competing with volume, but we should compete on value. How much value a panel can create is a key,” Lee said, who was named AU’s chairman in 2001 when the company was created by a merger of Acer Display and Unipac Optoelectronics.

You might want to hold off on any major LCD panel purchases for the next few months, whether it’s a notebook, desktop monitor or big-screen TV — a shortage is threatening to keep prices high and cut into coming seasonal discounts.

The shortage won’t be long; market research firm iSuppli said the crunch should ease up by the third quarter and supply will be plentiful by the fourth quarter, just in time for Christmas. But in the meantime, the shortage in LCD panels is poised to play havoc with prices.

Glass makers “all cut down production because they did not see a big opportunity in 2009,” Sweta Dash, senior director of LCD research at iSuppli, told InternetNews.com. “By the beginning of 2009, what happened was the inventory all got cleared up because some brand manufacturers were selling at a clearance rate. They wanted to get rid of it.”

An American firm, Corning (NYSE: GLW), is the dominant player in the glass panel market, with more than 60 percent of the space. Japan’s Asahi Glass and Nippon Electric Glass (NEG) are also in the glass panel business.

The concern now is that if there is a shortage of glass in second and third quarters, it will keep costs in the panel market high — and impact TV set, notebook and monitor price reductions for the holiday season or the back-to-school season.

“The market will ease up in Q3 and prices will go down in Q4, but it is cutting it close,” she said. “Right now, the notebook panel prices will go up,” and this is the time for notebook makers to be making notebooks that will ship with Windows 7 in October.

The company predicts that pricing for 32-inch 720p progressive scan LCD TVs could drop from an average of $634 in June to $480 by November, with Black Friday specials possibly as low as $299. A 42-inch full High-Definition (HD) set could be $628, with Black Friday specials as low as $499, it said.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey