bad lcd panel manufacturer

In 1991, a business unit called Samsung Display was formed to produce the panels used in products made by its parent company, Samsung Electronics. Afterward, it was a leading supplier of LCD panels not just for Samsung Electronics but for other companies in the industry as well.

The business received a stay of execution when the pandemic led to a global surge in demand for consumer electronics, but that demand is now declining, and projections aren"t good for LCD panel revenue.

Add to that the fact that emerging technologies like QD-OLED are the future for TV and monitors, and the case for keeping Samsung Display"s LCD business going becomes a hard one to make.

Samsung Display will now focus heavily on OLED and quantum dot. Most of the employees working in the LCD business will move to quantum dot, the publication claims.

Even if there isn"t a statement about a change in direction, the writing has been on the wall for Samsung"s LCD business. Unless something radical changes, it"s more a question of when than if at this point.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

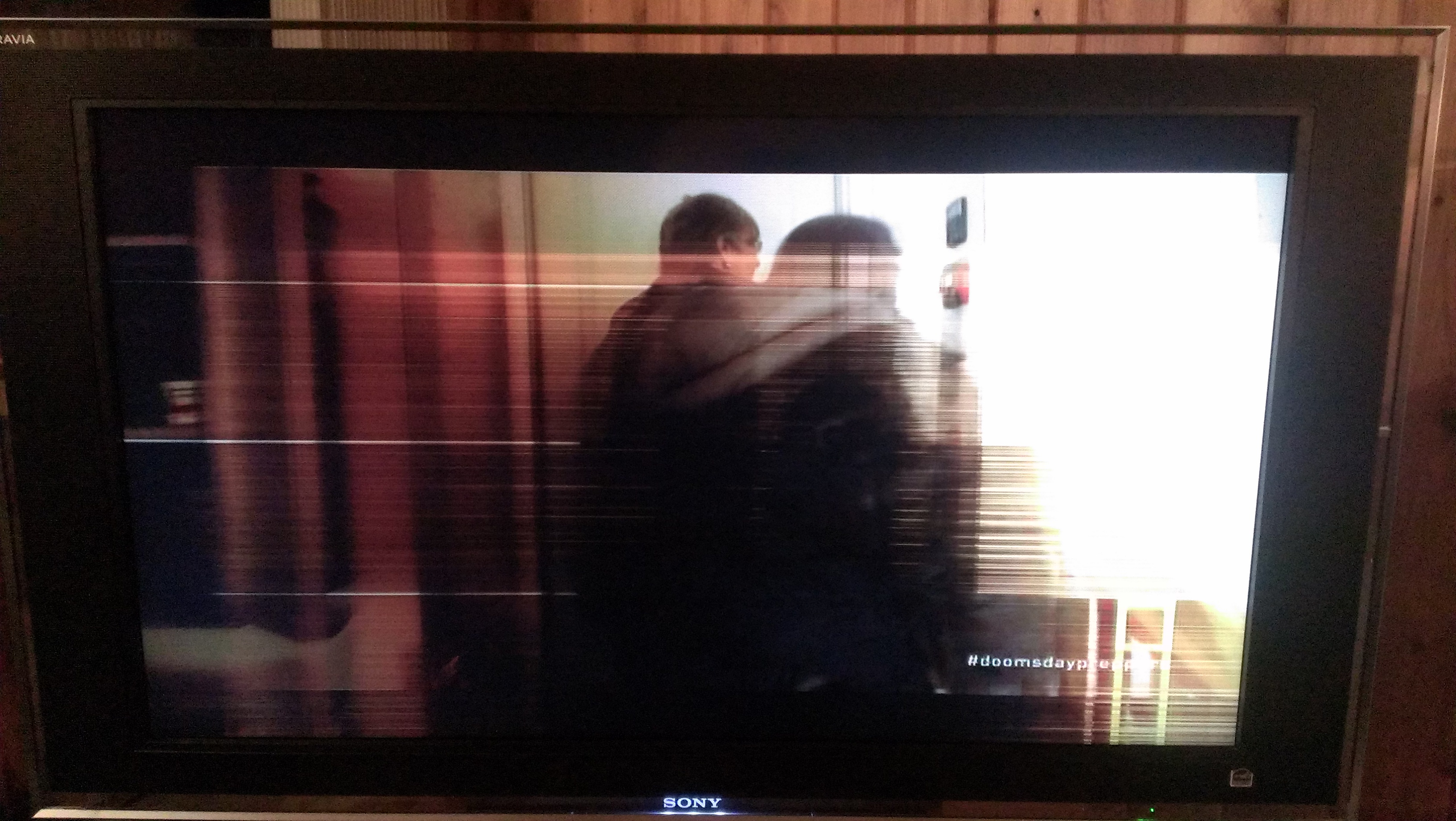

Unlike point defect, this larger scale defect is caused by the failure of external FPC or PCBA, or a bad connection between FPC and cell. Therefore, a bunch of pixels connected to these IC are out of control, and we see those defects.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

Mura is very common but it doesn’t affect the screen function severely, however it still bring bad look. Hence, many high end display manufacturers have their own standards of mura, and the displays without mura are of the best quality.

Because panels from LG and Samsung are of higher quality and more durable than chinese manufacturers. Previously, it was possible to see the panel model in a dell monitor, now this is not possible. Why dell decided to hide it is not clear. I understand that there are different price segments and it is not profitable to install more expensive panels everywhere, but if you pay attention to different specialized forums, people choose a monitor not only by brand, but also by the installed panel. It is important.

2. #Confirm whether the VAA is normal (normally about 17V). If abnormal, disconnect the RP32 to confirm whether it is caused by DC/DC loop or X-side COF: disconnect RP32, if the VAA is normal, the COF is bad, CO must be changed; COF can be Disconnect one by one to determine which NG disconnects RP32, VAA NG, try to change UP1; at the same time, confirm whether the continuity of the surrounding triode is OK.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

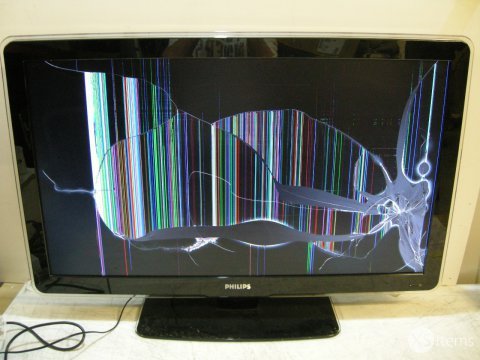

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

South Korean panel maker Samsung Display, a subsidiary of Samsung Electronics Co Ltd. that develops and manufactures display panels, have announced this week their intention to cease LCD panel production by the end of 2020. The company runs two LCD production lines at factories in South Korea and two LCD-only factories in China.

This would would mark the departure of one of the key panel providers from LCD desktop monitors as well as from the LCD TV space. Samsung currently make a range of LCD panels for monitors, primarily based on their SVA (VA-type) and PLS (IPS-type) technologies. Many of which (e.g. 49″ ultrawide) are fairly niche segments at this time for them. Much of this article is focused on the TV market and there is not much clarity on what this might mean for the desktop monitor market at this time.

Samsung Display will instead reportedly re-focus their production line on other technologies such as Quantum Dot, AMOLED and OLED reports say. Existing Samsung QLED-branded TV’s currently use LCD panels behind a Quantum Dot layer, with the “QLED” term being largely a marketing gimmick which makes them sound and read like “OLED”. Samsung dropped out of actual OLED (Organic Light Emitting Diode) production in 2015 leaving that segment to manufacturers like LG.Display who are the sold producer of OLED panels for TV’s at the moment.

Samsung had already suspended one of its two LCD production lines in South Korea in October 2019 amid falling demand for LCD panels and LCD panel prices declining worldwide as Chinese competitors ramp up production. LCD prices have plunged in recent years as Chinese makers, backed by generous state subsidies, aggressively expanded production capacity. Sluggish demand for large TV sets amid a global economic slowdown and the U.S.-China trade war has also weighed on prices.

Samsung will invest 13.1 trillion won (~$10.72 billion) in facilities and research to upgrade a production line, as it contends with oversupply amid weak global demand for smartphones and TVs. The investment for the next five years will be focused on converting one of its South Korean LCD lines into a facility to mass produce more advanced “quantum dot” screens. Samsung has not yet decided on the future operation of its factories in China.

In the meantime the production of the first iteration of new QD displays will begin in 2021, but will be QD-enabled OLED, which uses organic material as the light source and QD material as a film. It will be more similar to Samsung’s own AMOLED used for mobile phones and LG’s OLED TVs and will mark the company’s return to the OLED segment. It’s unclear how these new panels would be branded when they hit the market in TV’s, but it seems likely the term “QLED” would need to be changed given that is currently used for LCD+QD panels. “QD-OLED” seems a likely candidate.

It is expected that commercial products using the new panels will likely enter the market in 2022. The arrival of new OLED TV panel options from Samsung Display would mean competition for LG.Display of course, and provide alternative options for large TV manufacturers.

Digitimes reported earlier this week that Samsung Display reportedly plans to shut down four of its LCD panel production lines ahead of schedule as early as Q3 2020. Citing the ongoing coronavirus pandemic as a driver for this earlier closure due to reduced demand on TV’s due to major sporting events like the Olympics being postponed, as well causing downward pressure on panel prices. Digitimes reports that ” Samsung Display also plans to keep production at its 8.5G LCD fab in Suzhou, China in the meantime, while overhauling its L7-2 fab for production of POLED panels and its L8 fab for QD-OLED panels”

Digitimes goes on to report that “The Korean panel maker is also looking to halt the operations of the Suzhou 8.5G line by the third quarter of 2022 and is currently in talks to sell the LCD panel plant to Chinese panel makers, said the sources, adding that the completion of a deal will mark Samsung Display ‘s exit from the LCD TV panel market. “ – which actually implies someproduction would continue until Q3 2022, although some lines will end earlier in Q3 2020.

“We will supply ordered LCDs to our customers by the end of this year without any issues,” the company said in a statement. Although Samsung Display says that it will be able to continue supplying its existing LCD panel orders until the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. They have stated that for now nothing changes and they do not expect supply issues to affect their current “QLED branded” TV line up.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

Most of the reports about this change at Samsung Display are focused on the TV market, where OLED is already a commonly used technology. There are still questions around what this might mean for the desktop monitor market. We have yet to see any small/medium sized OLED panels of any notable mention in this segment, and it’s uncertain whether Samsung’s re-focus on QD-OLED and future QD technologies would extend to this space. It’s possible that they would begin to develop QD-OLED panels in smaller sizes to replace their current desktop monitor LCD panel line-up. Although it’s equally possible they would just move away from this segment and leave it to other providers like AUO, Innolux and new players like Panda for instance.

Samsung Display’s cross-town rival LG Display Co Ltd said earlier this year in January that it will halt domestic production in South Korea of LCD TV panels by the end of 2020. LG Display operates two LCD TV production sites, one in South Korea and another in China.

“We will be wrapping up our LCD TV production in South Korea by end of this year and focusing on our LCD TV production in China,”CEO Jeong Ho-young said at the annual CES trade show in Las Vegas. While terminating domestic LCD TV production, LG Display aims to shift its focus to organic light-emitting diode (OLED) technology in China.

According to Reuters, the continued losses suffered by the company is due to "sagging prices" for LCD panels across the board. The company also said its production plans in South Korea and China could be impacted by the emerging trade war between the U.S. and China.

LG Display cited "concern for the global smartphone market," as well as the long-term decline of LG"s LCD panel business. The company has been shifting its emphasis towards OLED panels.

A report earlier this month stated that Apple has ordered between 3 and 4 million OLED panels from LG Display, for use in the 2018 generation of iPhones, with LG expected to become the majority supplier of OLED panels for iPhones for 2019, overtaking its rival Samsung.

There had been reports in April of manufacturing delays on LG"s side affecting Apple"s panel diversifaction plans. As of June, LG was expected to deliver 2 million and 4 million OLED panels to Apple for "a future iPhone," although it"s unclear whether they would be used in this year"s or next year"s models.

LG Display has long been a supplier of 4K and 5K panels for the iMac. LG Display and Samsung both supply screens for the Apple Watch, while LG Display supplies Pad screens as well.

Back in 2016, to determine if the TV panel lottery makes a significant difference, we bought three different sizes of the Samsung J6300 with panels from different manufacturers: a 50" (version DH02), a 55" (version TH01), and a 60" (version MS01). We then tested them with the same series of tests we use in all of our reviews to see if the differences were notable.

Our Samsung 50" J6300 is a DH02 version, which means the panel is made by AU Optronics. Our 55" has an original TH01 Samsung panel. The panel in our 60" was made by Sharp, and its version is MS01.

Upon testing, we found that each panel has a different contrast ratio. The 50" AUO (DH02) has the best contrast, at 4452:1, followed by the 60" Sharp (MS01) at 4015:1. The Samsung 55" panel had the lowest contrast of the three: 3707:1.

These results aren"t really surprising. All these LCD panels are VA panels, which usually means a contrast between 3000:1 and 5000:1. The Samsung panel was quite low in that range, leaving room for other panels to beat it.

The motion blur results are really interesting. The response time of the 55" TH01 Samsung panel is around double that of the Sharp and AUO panels. This is even consistent across all 12 transitions that we measured.

For our measurements, a difference in response time of 10 ms starts to be noticeable. All three are within this range, so the difference isn"t very noticeable to the naked eye, and the Samsung panel still performs better than most other TVs released around the same time.

We also got different input lag measurements on each panel. This has less to do with software, which is the same across each panel, and more to do with the different response times of the panels (as illustrated in the motion blur section). To measure input lag, we use the Leo Bodnar tool, which flashes a white square on the screen and measures the delay between the signal sent and the light sensor detecting white. Therefore, the tool"s input lag measurement includes the 0% to 100% response time of the pixel transition. If you look at the 0% to 100% transitions that we measured, you will see that the 55" takes about 10 ms longer to transition from black to white.

All three have bad viewing angles, as expected for VA panels. If you watch TV at an angle, most likely none of these TVs will satisfy you. The picture quality degrades at about 20 degrees from the side. The 60" Sharp panel is worse than the other ones though. In the video, you can see the right side degrading sooner than the other panels.

It"s unfortunate that manufacturers sometimes vary the source of their panels and that consumers don"t have a way of knowing which one they"re buying. Overall though, at least in the units we tested, the panel lottery isn"t something to worry about. While there are differences, the differences aren"t big and an original Samsung panel isn"t necessarily better than an outsourced one. It"s also fairly safe to say that the same can be said of other brands. All panels have minute variations, but most should perform within the margin of error for each model.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

We are also a family owned and operated business out of Boca Raton, FL, and our business is refurbishing large volumes of salvageable combos (Cracked Glass Good LCD) such as the ones that you buy. We can give you a credit for each combo that we refurbish based on the units that you provide for us to work on. We have a very transparent process and would like the opportunity to serve you. We have the capacity to handle large volumes and would very much like to get in touch with you to discuss our capabilities and show you how we could improve the margins in your buyback business and possibly reduce your need for working capital. Please reply if interested so that we can set up a time to talk. I assure you that it will be a good use of your time.

@badalpriya " which the screen has got damaged" a physically damaged LCD display can not be repaired. It is not due to bad capacitors or anything else. It will be very difficult to find a new display. Even if it can be found it will most likely cost more than a new TV. You can always do an online search for a replacement but do not search by your TV model alone. Remove the back of your TV and check the label on the back of the LCD. It will have the manufacturer as well as the LCD panel number. Use that for your search. The only other thing you can try is to find the same model as your TV but broken other than the panel. Then harvest the panel from that TV.

To verify that this is a broken LCD post some images of what your screen shows with your question. Use this guide for that Adding images to an existing question

According to real LCD manufacturing conditions, the number of normal LCD panels exceeds greatly the number of defective LCD panels. Therefore, the normal PRs greatly outnumber the defective PRs. As a result, the collected data set for training would be imbalanced if a two-class classification approach is adopted, the SVM by Vapnik [4] for example, the class imbalance problem occurs.

In practice, in addition to the class imbalance problem, the LCD defect detection also suffers from another critical problem resulting from the absence of negative information. To facilitate the following problem description, the normal PR class and the defective PR class are defined as the positive class and negative class, respectively.

The main difference between a normal PR and a defective PR is that their appearances are apparently different, as can be observed from Figure 4. The color (or gray level) of a normal PR is nearly uniform, implying that the variation of the gray-level distribution of normal PRs is very small. On the contrary, the surfaces of defective PR not only contain various kinds of textures, but also vary greatly in color, implying that the variation of the true distribution for negative class in the data space is very large. Collecting a set of positive training data that can represent the true distribution of positive class is easy, because: (1) the variation of positive-class distribution is very small; and (2) most of the LCD panels are normal (the number of normal PRs is considerably large). Therefore, the positive class can be well-sampled during the data collection stage in real practice. However, representative defective PRs are difficult to obtain in practice for several reasons. For example, there are numerous types of defects in array process, more than 10 types at least. However, not all the defects would occur frequently. Some of the defects seldom appear, for example the defect caused by abnormal photo-resist coating (APRC). The defect “APRC” seldom occurs, because equipment/process engineers maintain the coating machines periodically. Even so, the coating machines might still break down occasionally. As a result, the number of available images containing the APRC defects is quite limited. But, the APRC defect has a large variation in color and texture. Unfortunately, limited APRC examples cannot stand for all kinds of APRC defects. Therefore, the collected negative training data are most likely under-sampled. Here, the “under-sampled” means that the collected negative training set cannot represent the true negative-class distribution in the data space, which is the problem of absence of negative information. Due to this problem, numerous false positive (i.e., missing defects) will be produced if a two-class classification approach (e.g., a binary SVM) is applied to the LCD defect detection, which has been evidenced by the results reported in [7]. Compared with two-class classification approach, novelty detection approach is a better choice.

Novelty detection is one-class classification [10,35], which is to solve the conventional two-class classification problems where one of the two classes is under-sampled, or only the data of one single class can be available for training [5,6,9–11,35–40]. As analyzed above, for the LCD defect detection application, the normal PRs can be well-sampled, while the defective PRs are in general undersampled. Therefore, the LCD defect detection can be treated as a typical novelty detection problem. Accordingly, one-class classification is a better solution.

To summarize, it can be seen that the LCD defect detection suffers from two problems simultaneously: one is the class imbalance problem, and the other is the problem of the absence of negative information. For the first problem, there have been many sophisticated solutions, including sampling, cost-sensitive learning, SVM-based, and one-class learning approaches. However, the only solution to the second problem is the novelty detection approach (i.e., one-class classification approach). Therefore, one-class classification would be a more appropriate approach to the LCD defect detection application.

There are several approaches for one-class classification, such as density approach (e.g., Gaussian mixture model [5]), boundary approach (e.g., SVDD [9] and one-class SVM [40]), neural network approach [6,36], and reconstruction-based approach (e.g., the kernel principal component analysis for novelty detection [35]). It has been proven in [9] that when a Gaussian kernel is used, the SVDD proposed by Tax and Duin [9] is identical to the one-class SVM proposed by Schölkopf et al. [40]. This paper focuses on the SVDD since it has been applied to the same application in the works of [7] and [10], and has shown to be effective in detecting defective PRs. However, as discussed in Section 1, generalization performance of SVDD is limited. Therefore, the intent of this paper is on proposing a method to improve generalization performance of SVDD, and applying the improved SVDD to the LCD defect detection treated as a novelty detection problem. The improved SVDD is called quasiconformal kernel SVDD (QK-SVDD). Note that the QK-SVDD and SVDD are not two independent classifiers. To obtain QK-SVDD, one has to train an SVDD first, which will be introduced in Section 2.4. In the following part of the paper, we first introduce the defect detection scheme, and then derive the proposed method in details.

This is a common problem in TVs and is a sign that your TV panel is failing. But before you call an expert to check the TV, you could try following these steps and check if they work:

If it continues to show lines, you may mostly have to get the panel replaced and replacing the panel can be a costly affair, depending on the TV and its model. LED panels range anywhere between Rs 8,000 to Rs 85,000, while LCD panels range between Rs 6,000 to Rs 25,000.

When the TV has speakers that work perfectly fine but it has no picture, there is mostly an issue with the back-lighting system or the power supply board, which will need to be replaced. In the case of an LCD TV, it works with the help of a backlight that is used to illuminate the picture on the screen. When the backlight begins to have problems, the screen turns blank.

To fix this issue, the backlight will have to be replaced by a TV expert. Another possible reason is that the backlight on the LCD TV which has a power inverter has failed. When this happens, you may need to replace the inverter or the capacitor.

Be it a panel issue or a major technical issue with the TV, resolving these problems is a costly affair. It’s best not to ignore any of these signs and call an authorized TV expert before the problem worsens.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey