tft lcd vs oled free sample

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation, which in turn changes the polarization of the liquid crystal which creates light or dark pixels on the display.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of our character LCD modules use a standard HD44780 controller, so they can be quickly integrated into a new product or used as a replacement in your existing products.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Because OLEDs are emissive, these displays can always be used in dark environments. There is usually a software command or hardware setting that will allow OLEDs to be dimmed.

Some OLED displays are bright enough to be sunlight readable–these models will typically take more current and may have a shorter rated lifetime. Additionally, OLEDs have extremely wide viewing angles.

What makes OLEDs useful for display construction is that they can be fabricated in bulk. Using OLED fabrication techniques, all the diodes can be made at the same time, at a much lower cost. OLEDs also come in a wide variety of colors.

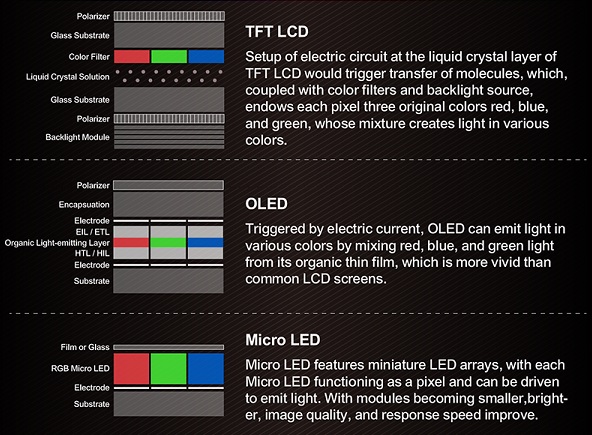

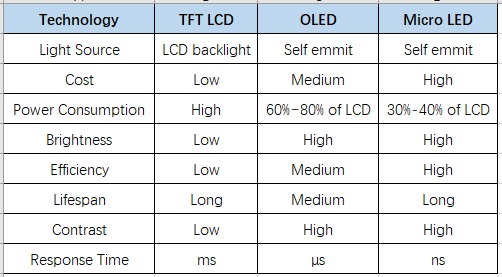

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

Note: this is an excerpt from a six-part series from Focus Display Solutions of Chandler, Ariz. The series will provide non-technical insights into why products such as cell phones use a color display, and other instruments, such as a blood pressure monitor, use 20-year-old non-color monochrome technology. This series will cover terms such as half-life, power budget, NRE, transflective, and others, and address the different LCD module options available when selecting a display for your product by being broken down into the following parts:Which color LCD technology is best for your application?

When choosing between a color LCD display and a monochrome display, there are several variables to consider. These include cost, EOL (end-of-life), power consumption, ability to customize, and appearance or perception of your product.

Three of the mainstream color LCD technologies currently in use are TFT, OLED and FSC. My goal is to help the OEMs understand and decide which display is best for their product and will appeal the most to their end customer.

TFTs (thin-film transistor) have been around for several years and control a large percentage of the color LCD market. Although this is the most popular color technology in use today, OLEDs (organic light-emitting diodes) looks like they will surpass TFT technology in the next few years.

TFTs and OLEDs can be seen in applications such as cell phones, laptop computers, and digital cameras. Video and high-resolution photos are also possible on both types.

Winner: OLEDs. OLEDs operate at temperatures as low as -40ºC (-40ºF) and as high as 85ºC (185ºF). TFTs perform poorly below -20ºC (-4ºF) and above +70ºC (158ºF).

Winner: TFT. The current size of TFTs range from 0.9 inches up to, and exceeding 19.2 inches, whereas OLEDs range from 0.5 inches to 7.7 inches (Samsung Galaxy Tab 7.7). It is important to note that these sizes are not absolute. There are TFT and OLED displays that are larger than the sizes listed above, but they are not in mass production at this time.

When choosing the size of your display, keep in mind two major factors: the popularity of the size and the number of suppliers that manufacture that size. Popular displays are LCDs that are manufactured in large quantities. The greater the popularity of the display, the less likely it will be discontinued in the near future, thus the lower the cost. The greater the number of manufactures for a particular size, the lower the cost, an the easier to second source.

Winner: TFTs. Half-life is a measurement of how many hours of use before a display becomes half-as-bright as when it was first turned on. The blue in the OLED has a half-life of 14,000 hours. This does not mean the display will burn out at that point, but will only be half-as-bright as when it was first turned on. There is much research in progress to increase the number of hours.

Keep in mind that not all products require the display to be on 24/7. Many products that require batteries, such as cell phones and digital cameras, only make use of the LCD for one to two hours a day. Many of these devices will be obsolete before the display reaches 14,000 hours.

Winner: OLEDs. OLEDs are estimated to be less than 0.01 mS (milliseconds). TFT is in the neighborhood of 15 mS. That"s milliseconds. The human eye blinks every 300 to 400 milliseconds. There are 86,400,000 milliseconds in one day. The eye can barely consciously detect a difference of 15 mS but the brain can tell there"s something up.

TFTs have been around longer then OLEDs. This head start has allowed TFT manufacturers more time to dominate the market, offer more sizes and lower the cost. The OLED has a few technical set backs at this time, but as technology improves, many or all of these issues may go away.

The VR Display we provide includes 2.1 inch, 2.54 inch, 2.9 inch, 2.95 inch, 3 inch, 3.5 inch, 3.81 inch, 5.55 inch, 6 inch. For micro OLED can be used on VR, we provide 0.71 inch 1920x1080 display.

Now LCD is the most common VR device screen on the market, and a few VR products use OLED screens and Mirco-OLED screens. Micro OLED is unfamiliar for VR players. Arpara 5K PC VR, the world"s first VR device, is using the micro-OLED display.

At present, the VR hamlet mostly uses "TFT-LCD" (thin film transistor liquid crystal display) technology, which consists of two glass substrates sandwiched with a layer of liquid crystal, the upper glass substrate is a color filter, and the lower glass layer is embedded with the transistor, When the electric field generated by the current passing through the transistor changes, the original rotating arrangement of the liquid crystal molecules will be reversed, which will change the rotation amplitude of the light through, and shine on the color filter in different proportions, and then generate different colors.

LCD technology has been quite mature, used in general computer and TV screens, also used in VR screens, and the cost is low, has become the basic technology of consumer products.

At present, the most fatal problem of LCD is that the liquid crystal layer can not be completely closed, so if the LCD shows black, some light will pass through the color layer, so the black of LCD is actually a gray mixture of white and black, compared to pure black.

OLED(Organic Light-emitting Diode), is based on an Organic light-emitting layer made of indium tin oxide (ITO) glass and covered with a low-work function metal electrode on the light-emitting layer. According to the driving mode, OLED includes AMOLED and PMOLED.

If the gray-scale response time is too long, the pixel in images fast sliding too late that resulting from the color 1 to 2 in the picture, will appear on the vision ghosting, ghosting extremely influence visual perception, the OLED screen is almost without any delay, and the LCD screen, even if it is apple"s top LCD, have a longer response time.

OLED is not the same as LCD screens with black color. Because OLED displays black, the pixels in the black area can be turned off directly to achieve an almost pure black effect. In contrast, OLEDs have excellent contrast and lower power consumption.

To sum up OLED color characters in one sentence: OLED is an oil painting, with pure and delicate colors, while LCD is a watercolor painting, with hazy and light colors. I think people can tell the difference between a high-end OLED and an LCD at a glance.

Although OLED presents a bright picture, has low power consumption, and can be bent, the organic materials will be oxidized, so the life is relatively short, and the color-burning problem does occur. Coupled with the high cost and high technology content, it is mostly suitable for small screens, such as mobile phone screens. In recent years, a handful of VR helmets have used OLED screens.

Mrico-Oled is a new high-level microdisplay technology. Micro OLEDs (silicon-based) consist of organic light-emitting materials sandwiched between two electrodes, diodes that emit light when an electric current flows through them. The desired color is then generated through the filter. The micro OLED light source module is generated by depositing the OLED onto the substrate using vapor deposition.

For example, to produce silicon-based OLED modules, OLED is deposited onto a silicon substrate or semiconductor wafer. In addition to being self-luminous like OLED, micro-OLED help makes thinner, smaller, and more energy-efficient panels. Their shorter response times and higher luminous efficiency also enable the production of high PPI(pixels per inch) displays.

Micro OLED microdisplay devices have the advantages of OLED self-lighting, thin, light, large viewing Angle, short response time, and high luminescence efficiency. Moreover, it is easier to achieve the application effect of high PPI (pixel density), small size, easy to carry, and low power consumption, which is especially suitable for near-eye display devices.

Although VR products on the market have been developed for many years, due to immature technology, they are prone to dizziness, have low resolution, are large in size, expensive. To avoid vertigo, the screen resolution had to be raised from 500 PPI to 2,000 PPI. Micro-OLEDs meet the needs of VR headsets and lenses. Therefore, after years of polishing, Arpara chose to launch the world"s first VR device based on micro-OLED display technology - Arpara 5K PC VR.

As we said earlier, micro-OLED uses pixel self-lighting technology to easily achieve a wide range of colors. For example, our Arpara 5K VR with Mirco-OLED screen covers 90% of the DCI-P3 range, which is the standard for evaluating display capabilities in the film industry. It can reflect the color expression of the product when watching film and television content.

Let"s go back and mention the comparison of the previous three screens. For LCD screen, there is a high density of LCD display, but because the LCD display device is a transparent type, its pixel driving circuit can only be placed in a pixel gap, this leads to a certain gap between pixels to place the drive circuit, so even if the high-resolution LCD screen, also cannot avoid the Screen Door Effect. The picture below is an example of a square RGB arrangement of LCD pixels, in which the black part is the driving circuit part (the picture is a schematic, in fact, we need to make a better look, please forgive me)

Relatively speaking, because the OLED material is a self-emitting device, the driver circuit can be placed on the underlying substrate, so there is no dark spot of the driver circuit between pixels.

For large-size OLED screens such as AMOLED, the current fill coefficient is still low, so there are blank areas between the screen pixels, as shown below:

The Micro OLED technology selected by Arpara can well control the pixel gap and greatly increase the pixel filling ratio. The schematic diagram is as follows:

Then again, micro-OLED has a big advantage in the small display market. As the applications of VR and AR displays gradually shift from gaming and military fields to healthcare, education, retail, and other fields, the market continues to expand, and more and more consumers demands resolution and avoidance of display lag. In this case, researchers will start to develop a new generation of display technology with high resolution, high brightness, high contrast, and fast response. At present, micro-OLED is most widely used in military, industrial and medical fields. VR is likely to be the next big thing.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

OLEDs are made from organic light-emitting materials that emit light when electricity is applied. OLED displays are emissive. That is the reason that OLED displays do not require backlight or filtering that are used in LCDs. As a result, OLEDs can be made flexible and transparent while providing the best images and great contrast and view angles.

Similar to LCD displays having two types: Passive Matrix LCD and Active-Matrix LCD, OLED displays also has two types: PMOLED and AMOLED. The difference is in the driving electronics – it can be either Passive Matrix (PM) or Active Matrix (AM).

Similar to passive matrix LCD, a PMOLED display uses a simple control scheme in which you control each row (or line) in the display sequentially (one at a time). PMOLED electronics do not contain a storage capacitor and so the pixels in each line are actually off most of the time. Because of this ,more voltage is needed to make PMOLED brighter. If you have 10 lines, for example, you have to make the one line that is on 10 times as bright (the real number is less than 10, but that’s the general idea).

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

where Tf is the frame time (e.g., Tf=16.67 ms for 60 fps). Using this equation, we can easily obtain an MPRT as long as the LC response time and TFT frame rate are known. The results are plotted in Figure 5.

From Figure 5, we can gain several important physical insights: (1) Increasing the frame rate is a simple approach to suppress image motion blur, but its improvement gradually saturates. For example, if the LC response time is 10 ms, then increasing the frame rate from 30 to 60 fps would significantly reduce the MPRT. However, as the TFT frame rate continues to increase to 120 and 240 fps, then the improvement gradually saturates. (2) At a given frame rate, say 120 fps, as the LC response time decreases, the MPRT decreases almost linearly and then saturates. This means that the MPRT is mainly determined by the TFT frame rate once the LC response time is fast enough, i.e., τ≪Tf. Under such conditions, Equation (1) is reduced to MPRT≈0.8Tf. (3) When the LC response is <2 ms, its MPRT is comparable to that of an OLED at the same frame rate, e.g., 120 fps. Here we assume the OLED’s response time is 0.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

High CR is a critical requirement for achieving supreme image quality. OLEDs are emissive, so, in theory, their CR could approach infinity to one. However, this is true only under dark ambient conditions. In most cases, ambient light is inevitable. Therefore, for practical applications, a more meaningful parameter, called the ACR, should be considered

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

A color filter array is another effective approach to enhance the color gamut of an OLED. For example, in 2017, AUO demonstrated a 5-inch top-emission OLED panel with 95% Rec. 2020. In this design, so-called symmetric panel stacking with a color filter is employed to generate purer RGB primary colors

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

The next type of lifetime is operational lifetime. Owing to material degradation, OLED luminance will decrease and voltage will increase after long-term drivingT50) can be as long as >80 000 h with a 1000 cd m−2 luminanceT50, half lifetime) with an initial luminance of 1000 nits. However, this is still ~20 × shorter than that of red and green phosphorescent OLEDs

To further enhance the lifetime of the blue OLED, the NTU group has developed new ETL and TTF-EML materials together with an optimized layer structure and double EML structureFigure 10a shows the luminance decay curves of such a blue OLED under different initial luminance values (5000, 10 000, and 15 000 nits). From Figure 10b, the estimated T50 at 1000 nits of this blue OLED is ~56 000 h (~6–7 years)

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

Power efficiency of white, red, green and phosphorescent blue and fluorescent/TTF blue OLEDs over time. Data are compiled from Refs. 41, 45, 114, 115, 116, 117, 118, 119, 120, 121, 122, 123, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

"Between 0.0001 and 0.00001 nits" "Sony claims an OLED contrast range of 1,000,000:1. When I asked how the contrast could be so high I was told that the surface is SO black the contrast is almost infinite. If the number representing the dark end of the contrast scale is nearly zero then dividing that number into the brightest value results in a very, very high contrast ratio."

Does not normally occur at 100% brightness level. At levels below 100% flicker often occurs with frequencies between 60 and 255 Hz, since often pulse-width modulation is used to dim OLED screens.

No native resolution. Currently, the only display technology capable of multi-syncing (displaying different resolutions and refresh rates without the need for scaling).Display lag is extremely low due to its nature, which does not have the ability to store image data before output, unlike LCDs, plasma displays and OLED displays.

Established in 2010, Topfoison has devoted itself to the manufacturing and development of high-quality products for the Wearable device, Smart Watch, VR, Medical device, Industrial LCD display including Color LCD modules/OLED/LCD display/Round lcd screen/Round AMOLED/ Square transflective lcd screen/ IPS full wide display/ 1080p fhd AMOLED and 2K 1440p lcd. Topfoison focus on1.22-7.0 inch small size displays, all the products produced in our company enjoys the most advanced production craft and technology as well as the strictly ISO quality management system.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey