arduino lcd display power consumption in stock

But the amount of heat and how much power it can supply before it fails depends on the overall current draw and the voltage being supplied to the barrel connector.

If you use the 5v USB connector for your power, you can supply quite a bit more current to attached devices with no regulator heat issues as it by passes the on board regulator.

Some of the 3rd party Arduino clones use a better design and do not have as much as an overheating issue when using a external power supply to power the Arduino clone board.

Verify your loads using spec/datasheets and/or a meter. If the loads are too high, try to use the 5v USB for the Arduino board and as else much as you can, then bring in the external power (potentially even a different voltage) for the bigger stuff like motors that can be isolated using transistors, relays, etc...

The datasheet says that it"s extremely low power. I hooked it up and was measuring a current of 2.0 to 2.25mA depending on whether it was active or sleeping. This didn"t make sense since it was advertised as being super low power. I realized that I had been given the 5V version which includes a 3.3v linear regulator (large 3-pin chip on left side of image). I removed the regulator since I"m running it at 3.3V, but that only reduced the current consumption by a small amount. The PCB I received has a Chinese font serial EPROM in the upper left corner (U1 - missing in the photo). Since I don"t intend to use it, I removed it and now the current measures from 0 (sleeping) to 276uA (active). This is nearly half the active current (400uA) of the Nokia 5110 and at a higher resolution. The backlighting is bright and evenly distributed and only draws an additional 4.8mA. If any of you have the same PCB that I bought and were wondering why it was drawing so much current, hopefully this info has helped you.

We have much merriment here when people refer to a "9v battery" if they mean the common "PP3" or "smoke alarm battery". It will not run an Arduino for very long at all.

You do not want to power the Arduino by "Vin" or the "barrel jack". The on-board regulator is not very capable and you are just wasting four volts out of nine. Four Ni-Mh "AA" cells in a holder would be far more appropriate, connected to the "5V" pin.

Now the backlight on the LCD draws about 20 mA (in most cases) while the LCD itself draws less than 1 mA. It will in fact draw only half of that if you correct a common mistake and remove the connection from the contrast potentiometer to 5 V, leaving it only connected to pin 3 and ground.

The Arduino itself however consumes as much or more power than the backlight, particularly a UNO or Nano etc. with a USB to serial chip. The Pro Mini does not have this USB to serial chip (you have to connect an adapter to program it) so is much better in this respect.

The 2-10ma range is about right for the LCD chip itself, I"ve seen about 15ma on quite a few, but the current varies depending on the state. i.e if you turn the pixels off, the base level current of the chip drops significantly.

The logger runs off battery power in a remote location for days on end, I need the LCD to be on when I check the unit every week, but for the rest of the time I want the LCD to be off just to save power.

I had thought that I could simply add an on/off switch to the 5v supply to the LCD (the Vdd line on the circuit diagram). For some reason, this doesn"t seem to work as expected. With the LCD on I can power up the data logger and it will happily boot up and start logging with the LCD working fine. If I flick the switch the LCD will turn off as expected and the logger will continue logging (I know this because the file it logs to continues to grow correctly)

The problem comes when I attempt to switch the LCD back on again, I flick the switch but the LCD remains blank, the only way I can turn the screen on again is to cycle the power for the whole unit, the logger and screen together. I seems I can"t just turn the screen on and off on it"s own.

Typically the LCD driver draws around 1mA or 1.1mA, not counting the external contrast voltage divider. They are fairly consistent between suppliers, as they are mostly based on an (originally) Hitachi-designed chip set HD44780/HD44100.

First you need to start by assembling the components onto the CT or onto your breadboard in order to create your current sensor which produces a signal which your Arduino can understand. An Arduino only has analogue voltage inputs which measure 0-5V DC, so you need to convert the current output from the CT into a voltage reference and then scale the voltage reference into a 0-5V range.

If you are going to be installing your power meter somewhere permanently then you may want to solder the resistors and capacitor directly onto the CT so that they cannot come loose. If you are simply trying this project for fun then a breadboard is perfect.

The LCD screen shield already picks up on the analogue inputs but only A0 is used by the shield. Simply solder the three leads from your current sensor onto the pin headers on the shield and use A1 as your sensor input as shown in the attached image.

NB – Be careful when connecting the power meter to you homes mains and make sure that the power to your board is switched off before doing anything in the mains box. Do not remove any wires or remove any screws before checking with your local authority, you may require a certified electrician to install the CT for you.

As a 2inch IPS display module with a resolution of 240 * 320, it uses an SPI interface for communication. The LCD has an internal controller with basic functions, which can be used to draw points, lines, circles, and rectangles, and display English, Chinese as well as pictures.

The 2inch LCD uses the PH2.0 8PIN interface, which can be connected to the Raspberry Pi according to the above table: (Please connect according to the pin definition table. The color of the wiring in the picture is for reference only, and the actual color shall prevail.)

The LCD supports 12-bit, 16-bit, and 18-bit input color formats per pixel, namely RGB444, RGB565, and RGB666 three color formats, this demo uses RGB565 color format, which is also a commonly used RGB format.

For most LCD controllers, the communication mode of the controller can be configured, usually with an 8080 parallel interface, three-wire SPI, four-wire SPI, and other communication methods. This LCD uses a four-wire SPI communication interface, which can greatly save the GPIO port, and the communication speed will be faster.

Note: Different from the traditional SPI protocol, the data line from the slave to the master is hidden since the device only has display requirement.

Framebuffer uses a video output device to drive a video display device from a memory buffer containing complete frame data. Simply put, a memory area is used to store the display content, and the display content can be changed by changing the data in the memory.

If you need to draw pictures, or display Chinese and English characters, we provide some basic functions here about some graphics processing in the directory RaspberryPi\c\lib\GUI\GUI_Paint.c(.h).

Set points of the display position and color in the buffer: here is the core GUI function, processing points display position and color in the buffer.

The fill color of a certain window in the image buffer: the image buffer part of the window filled with a certain color, usually used to fresh the screen into blank, often used for time display, fresh the last second of the screen.

Display time: in the image buffer,use (Xstart Ystart) as the left vertex, display time,you can choose Ascii visual character font, font foreground color, font background color.;

2. The module_init() function is automatically called in the INIT () initializer on the LCD, but the module_exit() function needs to be called by itself

Python has an image library PIL official library link, it do not need to write code from the logical layer like C, can directly call to the image library for image processing. The following will take 1.54inch LCD as an example, we provide a brief description for the demo.

Note: Each character library contains different characters; If some characters cannot be displayed, it is recommended that you can refer to the encoding set ro used.

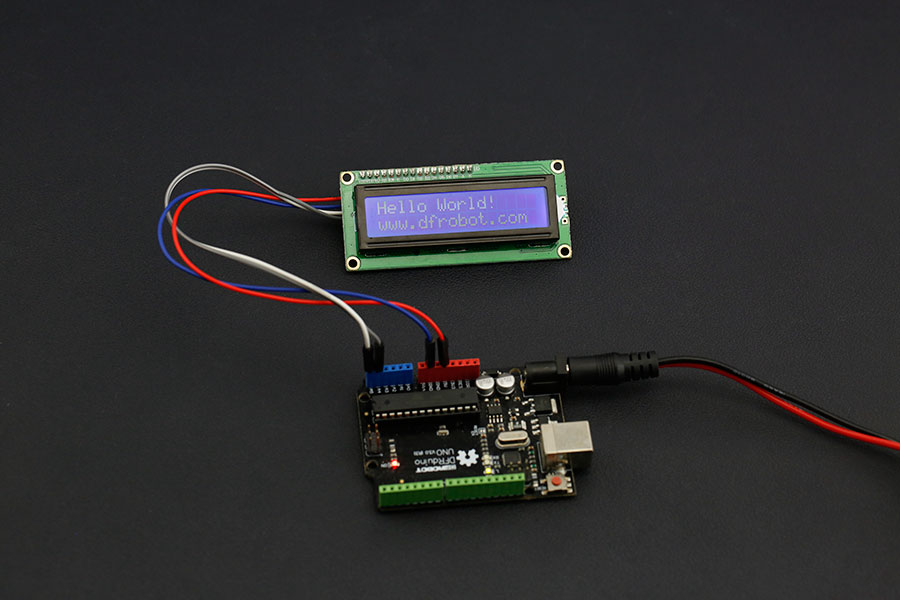

This is a 20x4 Arduino compatible LCD display module with high speed I2C interface. It is able to display 20x4 characters on two lines, whitecharacterson blue background.

Generally, LCD display will run out of Arduino pin resource. It needs 6 digital pins and 2 power pin for a LCD display. If you want to build a robot project, it will be a problem with Arduino UNO and LCD display.

This I2C 20x4 LCD display module is designed for Arduino microcontroller. It is using I2C communication interface, With this I2C interface, only 2 lines (I2C) are required to display the information on any Arduino based projects. It will save at least 4 digital / analog pins on Arduino. All connector are standard XH2.54 (Breadboard type). You can connect it with jumper wire directly.

This 1602 LCD module has 8 I2C address in all, from 0x20 to 0x27. You can set one according to your requirements, avoiding the confliction of I2C address. And its contrast can be adjusted manually.

This board is able to be powered by 5V or 3.3V which make it compatible with both Arduino 101 or Arduino DUE, intel edison 3.3V system and standard Arduino UNO/Arduino Mega 5V system.

Tired of using character LCD displays in your Arduino projects over and over? Well! They are, in fact, a thing of the past. Enter the fantastic OLED (Organic Light-Emitting Diode) displays! They’re extremely light, almost paper-thin, theoretically flexible, and produce a brighter, crisper image.

At the heart of the module is a powerful single-chip CMOS OLED driver controller – SSD1306. It can communicate with the microcontroller via I2C and SPI.

Because the SSD1306 controller is so versatile, the module comes in different sizes and colors, such as 128×64, 128×32, with white OLEDs, blue OLEDs, and dual-color OLEDs. The good news is that these displays are all interchangeable.

An OLED display, unlike a character LCD display, does not require a backlight because it generates its own light. This explains the display’s high contrast, extremely wide viewing angle, and ability to display deep black levels. The absence of a backlight reduces power consumption significantly. The display uses about 20mA on average, though this varies depending on how much of the display is lit.

The SSD1306 controller operates at 1.65V to 3.3V, while the OLED panel requires a 7V to 15V supply voltage. All of these various power requirements are fulfilled by internal charge pump circuitry. This makes it possible to connect the display to an Arduino or any other 5V logic microcontroller without requiring a logic level converter.

Regardless of the size of the OLED display, the SSD1306 driver includes a 1KB Graphic Display Data RAM (GDDRAM) that stores the bit pattern to be displayed on the screen. This 1 KB memory area is divided into 8 pages (from 0 to 7). Each page has 128 columns/segments (block 0 to 127). Furthermore, each column can store 8 bits of data (from 0 to 7). That certainly proves that we have:

As previously stated, regardless of the size of the OLED module, each module contains 1KB of RAM. The 128×64 OLED module displays the entire contents of 1KB of RAM (all 8 pages), whereas the 128×32 OLED module displays only half of the RAM (the first 4 pages).

Connect the SCL pin to the I2C clock pin and the SDA pin to the I2C data pin on your Arduino. It is important to note that each Arduino board has different I2C pins. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

Again, each Arduino board has different SPI pins that must be connected correctly. For Arduino boards such as the UNO/Nano V3.0, these pins are digital 13 (SCK), 12 (MISO), 11 (MOSI) and 10 (CS).

The SSD1306 controller in the OLED display has flexible but complex drivers. To use the SSD1306 controller, extensive knowledge of memory addressing is required. Fortunately, the Adafruit SSD1306 library was written to hide the complexities of the SSD1306 controller, allowing us to control the display with simple commands.

This Adafruit SSD1306 library is a hardware-specific library for low-level functions. To display graphics primitives such as points, lines, circles, and rectangles, it must be paired with the Adafruit GFX Library. Install this library as well.

This sketch will provide you with a thorough understanding of how to operate the OLED display and can serve as the foundation for more practical experiments and projects. Try out the sketch, and then we’ll go over it in detail.

The sketch begins with the inclusion of four libraries: SPI.h, Wire.h, Adafruit GFX.h, and Adafruit SSD1306.h. Although the SPI.h library is not required for I2C OLED displays, we must include it to compile our program.

The next step is to create an object of Adafruit_SSD1306.h. The Adafruit_SSD1306 constructor accepts 3 arguments: screen width, screen height, and the Arduino pin number to which the display’s reset pin is connected.

So, a couple of constants are defined to be passed to the constructor. Also, since the OLED display we are using doesn’t have a RESET pin, we will send -1 to the constructor to indicate that none of the Arduino pins are used to reset the display.

This sketch uses the I2C protocol for communicating with the display. However, the sketch is ready if you wish to use SPI. Simply uncomment the following lines of code.

In the setup function, we need to initialize the OLED object using the begin() function. This function accepts two parameters. The first parameter, SSD1306_SWITCHCAPVCC, turns on the internal charge pump circuitry, and the second parameter sets the OLED display’s I2C address. Most OLED display modules of this type have an I2C address of 0x3C, but some have 0x3D.

To display text on the screen, we must first set the font size. This can be accomplished by calling setTextSize() and passing a font size (starting from 1) as a parameter.

The final step is to use the display() command to instruct the library to bulk transfer the screen buffer to the SSD1306 controller’s internal memory and display the contents on the OLED screen.

To display inverted text, we use the setTextColor(FontColor,BackgroundColor) function once more. If you’ve been paying attention, you’ll notice that we previously passed only one parameter to this function, but now we’re passing two. This is possible due to function overloading.

The print() or println() functions can be used to display numbers on the OLED display. Because an overloaded implementation of these functions accepts 32-bit unsigned int values, you can only display numbers ranging from 0 to 4,294,967,295.

The print() and println() functions send data to the display as human-readable ASCII text, whereas the write() function sends binary data to the display. This function can thus be used to display ASCII symbols. For example, sending 3 displays a heart symbol.

You can scroll the display horizontally by calling the functions startscrollright() and startscrollleft(), and diagonally by calling the functions startscrolldiagright() and startscrolldiagleft(). All of these functions take two parameters: start page and stop page. Refer to the OLED Memory Map section for an explanation of the pages. Because the display has eight pages from 0 to 7, you can scroll the entire screen by scrolling all the pages, i.e. passing parameters 0x00 and 0x07.

Sometimes, we don’t want to scroll the whole display, but just a part of it. You can accomplish this by passing the appropriate start and stop page information to the scrolling functions.

Our last example shows how to draw bitmap images on the OLED display. This is useful for making sprites, exciting infographics, and splash screens with company logos.

The drawBitmap() function is used to display a bitmap image on an OLED display. This function accepts six parameters: top left corner X coordinate, top left corner Y coordinate, monochrome bitmap byte array, bitmap width in pixels, bitmap height in pixels, and color.

But, before we can use the drawBitmap() function, we need an image to draw. Remember that the OLED display’s screen resolution is 128×64 pixels, so images larger than that will not display properly. To get a properly sized image, open your favorite drawing program, such as Inkscape, Photoshop, or MS Paint, and set the canvas size to 128×64 pixels.

Once you have a bitmap, you must convert it into an array that the SSD1306 OLED controller can understand. This can be accomplished in two ways: online with image2cpp and offline with LCD Assistant.

The dimensions of your image will be displayed in the Canvas size option under Image Settings. If your image is larger than 128×64, change it to 128×64 by selecting the appropriate scaling option. You can see the result in the Preview section.

When you are satisfied with the results, you can proceed to generate the data array. Simply select Arduino Code as the code output format and press the Generate code button.

For your information, there is a setting called “Draw Mode”. It actually generates images based on the scanning pattern of the display. If your image appears distorted on your screen, try changing the mode.

There’s also a Windows application called LCD assistant that can turn your bitmap image into a data array. It is not as powerful as image2cpp, but it is still widely used by hobbyists.

For your information, there is a setting called Byte Orientation. It actually generates images based on the scanning pattern of the display. If your image appears distorted on your screen, try changing the mode.

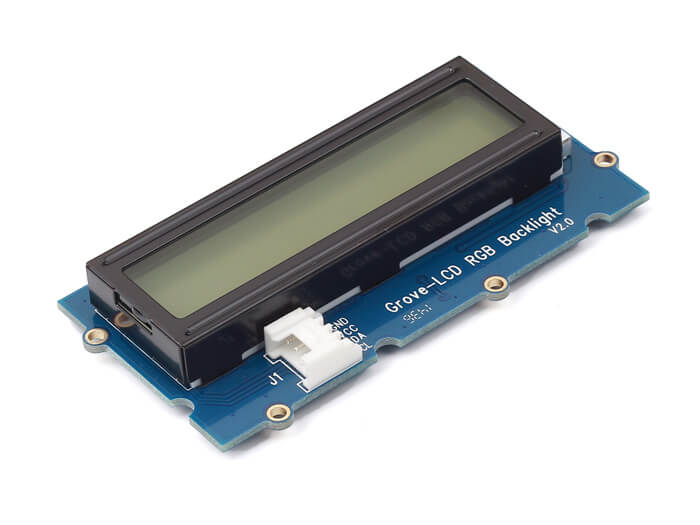

An easy way to add a simple visual interface to your project is by using an LCD Nanoshield. With it, you can display two lines of text with up to 16 characters. That allows you to show text messages or sensor data to the user, for example.

The internal LCD controller is compatible with the HD44780 chip from Hitachi, a de facto standard in the market for this kind of LCD. This is the same standard used in the LCD library that comes with the Arduino IDE.

The easiest way to use the LCd Nanoshield with an Arduino is to use the Base Board Uno or the Base Board L Uno. You just need to snap the boards together and upload our sample code to verify it"s working (see the code samples section below). This type of connection can be used with Arduino UNO, Mega R3, Duemilanove, and similar boards (contact us if you have questions about compatibility with other versions). The picture below shows how the final assembly looks like.

It is also possible to connect the LCd Nanoshield to our Arduino-compatible microcontroller board, the Base Boarduino. The connection is done in the same way as with the Base Board, as shown in the picture below. You just need to snap the boards together and upload our sample code to verify it"s working (see the code samples section below).

By using the Mini Terminal Nanoshield, it is possible to securely connect the LCD Nanoshield to an Arduino equipped with a Base Board or to a Base Boarduino. This connection uses only five wires, and is useful when the LCD needs to be mounted away from the Base Board – for instance when if must be mounted on a panel or case. The diagram below shows how to make that connection.

The LCD is equipped with a backlight that can be controlled via software by using the backlight() and noBacklight() methods in our Nanoshield_LCD software library.

Note: with the backlight on, the power consumption of the board is relatively high, and the voltage regulator can get quite hot when the system is powered from an external power supply. Don"t worry however, since the board and the components were designed to operate with much higher temperatures without a risk of overheating (but probably you fingers weren"t, so beware). For applications where the ambient temperature is consistently higher than 50ºC and there is no airflow, we recommend use of an external power supply with a maximum voltage of 9V, or our PowerLDO Nanoshield.

Power supply: the board power is supplied via the VIN and VCC pins: VIN is optional but VCC is required. The recommended voltage range for the VIN pin is 7 to 12V (absolute maximum of 20V); the range for the VCC pin is 4.5 to 5.5V (5V typical). When there is power available in both pins, the VIN pin has priority and will be selected automatically to power up the LCD module and the backlight; in cases where there is no VIN available, the VCC pin will power up the whole board. The I2C expander comes pre-configured to work with 5V levels, using the voltage available on the VCC pins, but can also be configured to use 3.3V levels when this voltage is selected in the VI2C jumper on the board - donwload the schematics below for more details).

OLED panels are made from organic materials that emit light when electricity is applied. Different from the LCD which needs backlight, the OLED does not need any backlight to display. Basically, the LCD does not emit light, it only “select ” the right color and intensity from the backlight and thus to display, while for OLED, each pixel of the OLED emits the light by themselves, the customer control all the pixels on/off and the intensity to show the images.

So far we"ve talked about how to reduce the power of the Arduino, but we haven"t talked about why it uses the power it does. Inside the ATmega328P, lies a series of circuits that work together to offload work from the processor, and each of these draws some amount of power. The Arduino"s analogWrite() function, for example, doesn"t have the processor create a PWM signal by counting the clock cycles itself. Instead, the Arduino uses one of the built in timers to count clock cycles and send an interrupt request to the processor. From there, the processor stops what it"s doing and handles the interrupt by switching the pin"s state. By offloading some of the work, the microcontroller is able to do multiple things at the same time. Some of the other circuitry built into the ATmega328P include:

Each of these independent components need power to work, and, unless you manually disable them, they will continue to draw power. The brown-out detection actively monitors the system voltage to ensure it doesn"t drop below its threshold. If it does, the controller powers down until the voltage is increased above that threshold. The analog to digital converter (ADC) does just as the name suggests, it take the analog voltage (which can be any value from 0V up to VCC) and converts it to a digital value that the microcontroller can use (0-1023 for 10-bit converters). If your project doesn"t need to use the ADC, disabling it will cut down on the power draw drastically.

But what if you still need the ADC? Thankfully there are registers where you can disable some of these circuits with software. Using software allows you to enable the circuits you need, when you need them, and, when you"re done, you can disable them again. All of the registers are well documented in the datasheet for the ATmega328p, but, if directly writing to registers makes you uncomfortable, there is a library available that you can download from the link below. For instructions on how to install an Arduino library, check out this tutorial.

This library allows you to set how long to enter into sleep mode, from a few milliseconds, up to indefinitely. It also allows you to specify which parts of the micro to disable, making it a pretty powerful and versatile library for your low-power needs.

In this first example, let"s load the sketch below onto our Arduino, which is running off of 5V at 16MHz. To see how little current is needed in sleep mode, I"m using a bare bones Arduino by using the ATmega328P on a breadboard to minimize the current I"m using.

In this sketch the Arduino blinks an LED on for two seconds and is then powered down for two seconds, and during that time the ADC and brown-out detect (BOD) are disabled. When powered down, the Arduino"s current drops from 14mA, down to just 6uA! If we use some of the other power saving tricks from previous sections, we can see in the table below just how low we can get the sleep current.

If you"re wondering why clock speed doesn"t affect the sleep current, during power down the clock is also disabled. Obviously you won"t want to keep the Arduino in low-power mode. But, in projects where you don"t need to take readings continuously, shutting the Arduino down 50% of the time, and using the techniques we covered, can allow the battery to last over seven times longer!

As electronics engineers, we always depend upon meters/instruments to measure and analyse the working of a circuit. Starting with a simple multimeter to a complex power quality analysers or DSOs everything has their own unique applications. Most of these meters are readily available and can be purchased based on the parameters to be measured and their accuracy. But sometimes we might end up in a situation where we need to build our own meters. Say for instance you are working on a solar PV project and you would like to calculate the power consumption of your load, in such scenarios we can build our own Wattmeter using a simple microcontroller platform like Arduino.

Building your own meters not only bring down the cost of testing, but also gives us room to ease the process of testing. Like, a wattmeter built using Arduino can easily be tweaked to monitor the results on Serial monitor and plot a graph on Serial plotter or add an SD card to automatically log the values of voltage, current and power at pre-defined intervals. Sounds interesting right!? So let’s get started...

For ease of understanding the arduino wattmeter circuit is split into two units. The upper part of the circuit is the measuring unit and the lower part of the circuit is the computation and display unit. For people who are new to this type of circuits followed the labels. Example +5V is label which means that all the pins to which label is connected to should be considered as they are connected together. Labels are normally used to make the circuit diagram look neat.

The circuit is designed to fit into systems operating between 0-24V with a current range of 0-1A keeping in mind the specification of a Solar PV. But you can easily extend the range once you understand the working of the circuit. The underlying principle behind the circuit is to measure the voltage across the load and current through it to calculate the power consumes by it. All the measured values will be displayed in a 16*2 Alphanumeric LCD.

Here the Input voltage is represent by Vcc, as told earlier we are designing the circuit for a voltage range from 0V to 24V. But a microcontroller like Arduino cannot measure such high values of voltage; it can only measure voltage from 0-5V. So we have to map (convert) the voltage range of 0-24V to 0-5V. This can be easily done by using a potential divider circuit as shown below. The resistor 10k and 2.2k together forms the potential divider circuit. The output voltage of a potential divider can be calculated using the below formulae. The same be used to decide the value of your resistors, you can use our online calculator to calculate value of resistor if you are re-designing the circuit.

The mapped 0-5V can be obtained from the middle part which is labelled as Voltage. This mapped voltage can then be fed to the Arduino Analog pin later.

Here the value of shunt resistor (SR1) is 0.22 Ohms. As said earlier we are designing the circuit for 0-1A so based on Ohms law we can calculate the voltage drop across this resistor which will be around 0.2V when a maximum of 1A current is passing through the load. This voltage is very small for a microcontroller to read, we use an Op-Amp in Non-Inverting Amplifier mode to increase the voltage from 0.2V to higher level for the Arduino to read.

Here in our case the value of Rf is 20k and the value of Rin is 1k which gives us a gian value of 21. The amplified voltage form the Op-amp is then given to a RC filter with resistor 1k and a capacitor 0.1uF to filter any noise that is coupled. Finally the voltage is then fed to the Arduino analog pin.

The last part that is left in the measuring unit is the voltage regulator part. Since we will give a variable input voltage we need a regulated +5V volt for the Arduino and the Op-amp to operate. This regulated voltage will be provided by the 7805 Voltage regulator. A capacitor is added at the output to filter the noise.

In the measuring unit we have designed the circuit to convert the Voltage and Current parameters into 0-5V which can be fed to the Arduino Analog pins. Now in this part of the circuit we will connect these voltage signals to Arduino and also interface a 16×2 alphanumeric display to the Arduino so that we can view the results. The circuit for the same is shown below

As you can see the Voltage pin is connected to Analog pin A3 and the current pin is connected to Analog pin A4. The LCD is powered from the +5V from the 7805 and is connected to the digital pins of Arduino to work in 4-bit mode. We have also used a potentiometer (10k) connected to Con pin to vary the contrast of the LCD.

Now that we have a good understanding of the hardware, let us open the Arduino and start programming. The purpose of the code is to read the analog voltage on pin A3 and A4 and calculate the Voltage, Current and Power value and finally display it on the LCD screen. The complete program to do the same is given at the end of the page which can be used as such for the hardware discussed above. Further the code is split into small snippets and explained.

As all programs we begin with, defining the pins that we have used. In out project the A3 and A4 pin is used to measure voltage and current respectively and the digital pins 3,4,8,9,10 and 11 is used for interfacing the LCD with Arduino

We also have included a header file called liquid crystal to interface the LCD with Arduino. Then inside the setup function we initialise the LCD display and display an intro text as “Arduino Wattmeter” and wait for two seconds before clearing it. The code for the same is shown below.

Inside the main loop function, we use the analog read function to read the voltage value from the pin A3 and A4. As we know the Arduino ADC output value from 0-1203 since it has a 10-bit ADC. This value has to be then converted to 0-5V which can be done by multiplying with (5/1023). Then again earlier in the hardware we have mapped the actual value of voltage from 0-24V to 0-5V and the actual value of current form 0-1A to 0-5V. So now we have to use a multiplier to revert these values back to actual value. This can be done by multiplying it with a multiplier value. The value of the multiplier can either be calculated theoretically using the formulae provided in hardware section or if you have a known set of voltage and current values you can calculate it practically. I have followed the latter option because it tends to be more accurate in real time. So here the value of multipliers is 6.46 and 0.239. Hence the code looks like below

So to improve the accuracy we can plot of set of measured ADC values with actual vales using a known set of values and then use that data to plot a graph and derive the multiplier equation using the linear regression method. You can refer the Arduino dB meter in which I have used a similar method.

Finally, once we have calculated the value of actual voltage and actual current through the load, we can calculate the Power using the formulae (P=V*I). Then we display all the three values on the LCD display using the code below.

For the sake of tutorial I have used a perf board to solder all the components as shown in the circuit. I have used a Phoenix screw terminal to connect the load and normal DC barrel Jack to connect my power source. The Arduino Nano board and the LCD are mounted on a Female Bergstik so that they can be re-used if required later.

After getting the hardware ready, upload the Arduino code to your Nano board. Adjust the trimmer pot to control the contrast level of the LCD until you see a clear intro text. To test the board connect the load to the screw terminal connector and the source to the Barrel jack. The source voltage should be more than 6V for this project to work, since the Arduino required +5V to operate. IF everything is working fine you should see the value of Voltage across the load and the current through it displayed in the first line of the LCD and the calculated power displayed on the second line of the LCD as shown below.

The fun part of building something lies in testing it to check how far it will work properly. To do that I have used 12V automobile indicator bubs as load and the RPS as source. Since the RPS itself can measure and display the value of current and voltage it will be easy for us to cross check the accuracy and performance of our circuit. And yes, I also used my RPS to calibrate my multiplier value so that I get close to accurate value.

This Arduino based Wattmeter project has many more upgrades that can be added to increase the performance to auto data logging, plotting graph, notifying over voltage or over current situations etc. So stay curious and let me know what you would use this for.

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

Next is the E pin which enables the writing to the registers, or the next 8 data pins from D0 to D7. So through this pins we are sending the 8 bits data when we are writing to the registers or for example if we want to see the latter uppercase A on the display we will send 0100 0001 to the registers according to the ASCII table. The last two pins A and K, or anode and cathode are for the LED back light.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below and don’t forget to check out my full collection of 30+ Arduino Projects.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey