future of lcd displays brands

Since no backlight is used, the display requires very little energy in order to operate. This means: a lot of money can be saved over time. Think about the costs of a drive thru menu that stays running all year for sixteen whole hours a day. Those costs add up. Can you imagine spending $20k a year – just to power your display? That would cut your profits in a very noticeable way. So, I bet you’d be pretty pleased to find such a low-energy alternative.

Reflective displays really are a unique thing. You don’t have to hide them from the sun. You don’t have to shield your screen with your hand in order to eliminate glare. You don’t have to tilt it at funny angles that cause your neck to throb in pain, just so that you can read what’s on the screen. Funny, because those are our natural reactions whenever LCD and sunlight combine. Not with a reflective display though.

You could almost compare a reflective display to a piece of paper in the way that it becomes more visible when light is shining directly on it. It’s really bizarre to see, and you almost have to witness it in order to wrap your head around it, because it’s totally unlike what you’re used to.

Screens in private use are already highly diverse; in terms of size alone, they range from smartwatches to huge flatscreen TVs. And with many innovations on the way, the number of different formats and device types will increase significantly in the coming years. This includes virtual and augmented reality glasses, folding screens, 3D holograms, and direct projections, e.g. onto car windscreens. Consumers will be able to use these displays to control their appliances as much as for enjoying media content. New screen types will also influence the presentation of the content itself: Storytelling, camera style, and content length will adapt to each format. In addition, stakeholder behavior – from hardware manufacturers to consumers and advertising agencies – will also shape developments.

Successful innovations, groundbreaking business decisions, consumer behavior: Where exactly these aspects are going remains an open question. The future of displays cannot be predicted with any accuracy, so how can companies decide on sensible preparations for the uncertainties of the future? The Deloitte Center for the Long View has made the scenario analysis approach its own and refined it. The Center experts analyze and extrapolate the most important drivers, then use these to develop four strikingly different foundational scenarios for the year 2030 and assess the likelihood of their occurrence. The results should not be considered forecasts, but plausible narrative reference frames for strategy planning, implementation, and monitoring.

![]()

In January 2010, Taiwanese AU Optronics Corporation (AUO) announced that it had acquired assets from Sony"s FET and FET Japan, including "patents, know-how, inventions, and relevant equipment related to FED technology and materials".Nikkei reported that AUO plans to start mass production of FED panels in the fourth quarter of 2011, however AUO commented that the technology is still in the research stage and there are no plans to begin mass production at this moment.

IMOD displays are now available in the commercial marketplace. QMT"s displays, using IMOD technology, are found in the Acoustic Research ARWH1 Stereo Bluetooth headset device, the Showcare Monitoring system (Korea), the Hisense C108,Freestyle Audio and Skullcandy. In the mobile phone marketplace, Taiwanese manufacturers Inventec and Cal-Comp have announced phones with Mirasol displays, and LG claims to be developing "one or more" handsets using Mirasol technology. These products all have only 2-color (black plus one other) "bi-chromic" displays. UniPixel"s TMOS and Pixtronix"s DMS display technologies utilize vertically and horizontally moving MEMS structures to modulate a backlight, respectively.

The technology is still in its nascent stages, and the project is unusual for Microsoft, which is not in the display business. There is a possibility that Microsoft will collaborate with a display manufacturer, but commercial production will not begin until at least 2013.

Although MicroLED displays have not been mass-produced for home use, after pioneering the technology in 2012,China Star Optoelectronics Technology (CSoT) demonstrated a 3.3" transparent microLED display with around 45% transparency, also co-developed with PlayNitride.Plessey Semiconductors Ltd demonstrated a GaN-on-Silicon wafer to CMOS backplane wafer bonded native Blue monochrome 0.7" active-matrix microLED display with an 8-micron pixel pitch.Ostendo Technologies, Inc. demonstrated a vertically integrated LED that can emit light from red to blue, including white – from a monolithic InGaN-based LED device.

Many expect that quantum dot display technology can compete or even replace liquid crystal displays (LCDs) in near future, including the desktop and notebook computer spaces and televisions. These initial applications alone represent more than a $8-billion addressable market by 2023 for quantum dot-based components. Other than display applications, several companies are manufacturing QD-LED light bulbs; these promise greater energy efficiency and longer lifetime.

In recent years, China and other countries have invested heavily in the research and manufacturing capacity of display technology. Meanwhile, different display technology scenarios, ranging from traditional LCD (liquid crystal display) to rapidly expanding OLED (organic light-emitting diode) and emerging QLED (quantum-dot light-emitting diode), are competing for market dominance. Amidst the trivium strife, OLED, backed by technology leader Apple"s decision to use OLED for its iPhone X, seems to have a better position, yet QLED, despite still having technological obstacles to overcome, has displayed potential advantage in color quality, lower production costs and longer life.

Zhao: We all know display technologies are very important. Currently, there are OLED, QLED and traditional LCD technologies competing with each other. What are their differences and specific advantages? Shall we start from OLED?

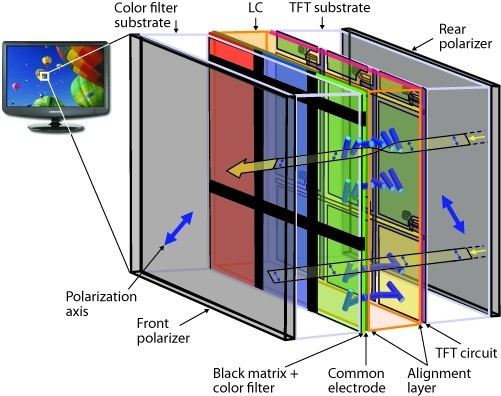

Huang: OLED has developed very quickly in recent years. It is better to compare it with traditional LCD if we want to have a clear understanding of its characteristics. In terms of structure, LCD largely consists of three parts: backlight, TFT backplane and cell, or liquid section for display. Different from LCD, OLED lights directly with electricity. Thus, it does not need backlight, but it still needs the TFT backplane to control where to light. Because it is free from backlight, OLED has a thinner body, higher response time, higher color contrast and lower power consumption. Potentially, it may even have a cost advantage over LCD. The biggest breakthrough is its flexible display, which seems very hard to achieve for LCD.

Liao: Actually, there were/are many different types of display technologies, such as CRT (cathode ray tube), PDP (plasma display panel), LCD, LCOS (liquid crystals on silicon), laser display, LED (light-emitting diodes), SED (surface-conduction electron-emitter display), FED (filed emission display), OLED, QLED and Micro LED. From display technology lifespan point of view, Micro LED and QLED may be considered as in the introduction phase, OLED is in the growth phase, LCD for both computer and TV is in the maturity phase, but LCD for cellphone is in the decline phase, PDP and CRT are in the elimination phase. Now, LCD products are still dominating the display market while OLED is penetrating the market. As just mentioned by Dr Huang, OLED indeed has some advantages over LCD.

Huang: Despite the apparent technological advantages of OLED over LCD, it is not straightforward for OLED to replace LCD. For example, although both OLED and LCD use the TFT backplane, the OLED’s TFT is much more difficult to be made than that of the voltage-driven LCD because OLED is current-driven. Generally speaking, problems for mass production of display technology can be divided into three categories, namely scientific problems, engineering problems and production problems. The ways and cycles to solve these three kinds of problems are different.

At present, LCD has been relatively mature, while OLED is still in the early stage of industrial explosion. For OLED, there are still many urgent problems to be solved, especially production problems that need to be solved step by step in the process of mass production line. In addition, the capital threshold for both LCD and OLED are very high. Compared with the early development of LCD many years ago, the advancing pace of OLED has been quicker.While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen?

Liao: I want to supplement some data. According to the consulting firm HIS Markit, in 2018, the global market value for OLED products will be US$38.5 billion. But in 2020, it will reach US$67 billion, with an average compound annual growth rate of 46%. Another prediction estimates that OLED accounts for 33% of the display market sales, with the remaining 67% by LCD in 2018. But OLED’s market share could reach to 54% in 2020.

Huang: While different sources may have different prediction, the advantage of OLED over LCD in small and medium-sized display screen is clear. In small-sized screen, such as smart watch and smart phone, the penetration rate of OLED is roughly 20% to 30%, which represents certain competitiveness. For large size screen, such as TV, the advancement of OLED [against LCD] may need more time.

Xu: LCD was first proposed in 1968. During its development process, the technology has gradually overcome its own shortcomings and defeated other technologies. What are its remaining flaws? It is widely recognized that LCD is very hard to be made flexible. In addition, LCD does not emit light, so a back light is needed. The trend for display technologies is of course towards lighter and thinner (screen).

But currently, LCD is very mature and economic. It far surpasses OLED, and its picture quality and display contrast do not lag behind. Currently, LCD technology"s main target is head-mounted display (HMD), which means we must work on display resolution. In addition, OLED currently is only appropriate for medium and small-sized screens, but large screen has to rely on LCD. This is why the industry remains investing in the 10.5th generation production line (of LCD).

Xu: While deeply impacted by OLED’s super thin and flexible display, we also need to analyse the insufficiency of OLED. With lighting material being organic, its display life might be shorter. LCD can easily be used for 100 000 hours. The other defense effort by LCD is to develop flexible screen to counterattack the flexible display of OLED. But it is true that big worries exist in LCD industry.

LCD industry can also try other (counterattacking) strategies. We are advantageous in large-sized screen, but how about six or seven years later? While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen? People may not watch TV and only takes portable screens.

Some experts working at a market survey institute CCID (China Center for Information Industry Development) predicted that in five to six years, OLED will be very influential in small and medium-sized screen. Similarly, a top executive of BOE Technology said that after five to six years, OLED will counterweigh or even surpass LCD in smaller sizes, but to catch up with LCD, it may need 10 to 15 years.

Xu: Besides LCD, Micro LED (Micro Light-Emitting Diode Display) has evolved for many years, though people"s real attention to the display option was not aroused until May 2014 when Apple acquired US-based Micro LED developer LuxVue Technology. It is expected that Micro LED will be used on wearable digital devices to improve battery"s life and screen brightness.

Micro LED, also called mLED or μLED, is a new display technology. Using a so-called mass transfer technology, Micro LED displays consist of arrays of microscopic LEDs forming the individual pixel elements. It can offer better contrast, response times, very high resolution and energy efficiency. Compared with OLED, it has higher lightening efficiency and longer life span, but its flexible display is inferior to OLED. Compared with LCD, Micro LED has better contrast, response times and energy efficiency. It is widely considered appropriate for wearables, AR/VR, auto display and mini-projector.

However, Micro LED still has some technological bottlenecks in epitaxy, mass transfer, driving circuit, full colorization, and monitoring and repairing. It also has a very high manufacturing cost. In short term, it cannot compete traditional LCD. But as a new generation of display technology after LCD and OLED, Micro LED has received wide attentions and it should enjoy fast commercialization in the coming three to five years.

Peng: It comes to quantum dot. First, QLED TV on market today is a misleading concept. Quantum dots are a class of semiconductor nanocrystals, whose emission wavelength can be continuously tuned because of the so-called quantum confinement effect. Because they are inorganic crystals, quantum dots in display devices are very stable. Also, due to their single crystalline nature, emission color of quantum dots can be extremely pure, which dictates the color quality of display devices.

Interestingly, quantum dots as light-emitting materials are related to both OLED and LCD. The so-called QLED TVs on market are actually quantum-dot enhanced LCD TVs, which use quantum dots to replace the green and red phosphors in LCD’s backlight unit. By doing so, LCD displays greatly improve their color purity, picture quality and potentially energy consumption. The working mechanisms of quantum dots in these enhanced LCD displays is their photoluminescence.

For its relationship with OLED, quantum-dot light-emitting diode (QLED) can in certain sense be considered as electroluminescence devices by replacing the organic light-emitting materials in OLED. Though QLED and OLED have nearly identical structure, they also have noticeable differences. Similar to LCD with quantum-dot backlighting unit, color gamut of QLED is much wider than that of OLED and it is more stable than OLED.

Another big difference between OLED and QLED is their production technology. OLED relies on a high-precision technique called vacuum evaporation with high-resolution mask. QLED cannot be produced in this way because quantum dots as inorganic nanocrystals are very difficult to be vaporized. If QLED is commercially produced, it has to be printed and processed with solution-based technology. You can consider this as a weakness, since the printing electronics at present is far less precision than the vacuum-based technology. However, solution-based processing can also be considered as an advantage, because if the production problem is overcome, it costs much less than the vacuum-based technology applied for OLED. Without considering TFT, investment into an OLED production line often costs tens of billions of yuan but investment for QLED could be just 90–95% less.

Given the relatively low resolution of printing technology, QLED shall be difficult to reach a resolution greater than 300 PPI (pixels per inch) within a few years. Thus, QLED might not be applied for small-sized displays at present and its potential will be medium to large-sized displays.

Zhao: Quantum dots are inorganic nanocrystal, which means that they must be passivated with organic ligands for stability and function. How to solve this problem? Second, can commercial production of quantum dots reach an industrial scale?

Peng: Good questions. Ligand chemistry of quantum dots has developed quickly in the past two to three years. Colloidal stability of inorganic nanocrystals should be said of being solved. We reported in 2016 that one gram of quantum dots can be stably dispersed in one milliliter of organic solution, which is certainly sufficient for printing technology. For the second question, several companies have been able to mass produce quantum dots. At present, all these production volume is built for fabrication of the backlighting units for LCD. It is believed that all high-end TVs from Samsung in 2017 are all LCD TVs with quantum-dot backlighting units. In addition, Nanosys in the United States is also producing quantum dots for LCD TVs. NajingTech at Hangzhou, China demonstrate production capacity to support the Chinese TV makers. To my knowledge, NajingTech is establishing a production line for 10 million sets of color TVs with quantum-dot backlighting units annually.China"s current demands cannot be fully satisfied from the foreign companies. It is also necessary to fulfill the demands of domestic market. That is why China must develop its OLED production capability.

Huang: Based on my understanding of Samsung, the leading Korean player in OLED market, we cannot say it had foresight in the very beginning. Samsung began to invest in AMOLED (active-matrix organic light-emitting diode, a major type of OLED used in the display industry) in about 2003, and did not realize mass production until 2007. Its OLED production reached profitability in 2010. Since then, Samsung gradually secured a market monopoly status.

So, originally, OLED was only one of Samsung"s several alternative technology pathways. But step by step, it achieved an advantageous status in the market and so tended to maintain it by expanding its production capacity.

Also, Samsung has spent considerable time and efforts on the development of the product chain. Twenty or thirty years ago, Japan owned the most complete product chain for display products. But since Samsung entered the field in that time, it has spent huge energies to cultivate upstream and downstream Korean firms. Now the Republic of Korea (ROK) manufacturers began to occupy a large share in the market.

Liao: South Korean manufacturers including Samsung and LG Electronics have controlled 90% of global supplies of medium and small-sized OLED panels. Since Apple began to buy OLED panels from Samsung for its cellphone products, there were no more enough panels shipping to China. Therefore, China"s current demands cannot be fully satisfied from the foreign companies. On the other hand, because China has a huge market for cellphones, it would be necessary to fulfill the demands through domestic efforts. That is why China must develop its OLED production capability.

Huang: The importance of China"s LCD manufacturing is now globally high. Compared with the early stage of LCD development, China"s status in OLED has been dramatically improved. When developing LCD, China has adopted the pattern of introduction-absorption-renovation. Now for OLED, we have a much higher percentage of independent innovation.

Then it is the scale of human resources. One big factory will create several thousand jobs, and it will mobilize a whole production chain, involving thousands of workers. The requirement of supplying these engineers and skilled workers can be fulfilled in China.

Although we cannot say that our advantages triumph over ROK, where Samsung and LG have been dominating the field for many years, we have achieved many significant progresses in developing the material and parts of OLED. We also have high level of innovation in process technology and designs. We already have several major manufacturers, such as Visionox, BOE, EDO and Tianma, which have owned significant technological reserves.

Peng: As mentioned above, there are two ways to apply quantum dots for display, namely photoluminescence in backlightingFor QLED, the three stages of technological development [from science issue to engineering and finally to mass production] have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

units for LCD and electroluminescence in QLED. For the photoluminescence applications, the key is quantum-dot materials. China has noticeable advantages in quantum-dot materials.

After I returned to China, NajingTech (co-founded by Peng) purchased all key patents invented by me in the United States under the permission of US government. These patents cover the basic synthesis and processing technologies of quantum dots. NajingTech has already established capability for large-scale production of quantum dots. Comparatively, Korea—represented by Samsung—is the current leading company in all aspects of display industry, which offers great advantages in commercialization of quantum-dot displays. In late 2016, Samsung acquired QD Vision (a leading quantum-dot technology developer based in the United States). In addition, Samsung has invested heavily in purchasing quantum-dot-related patents and in developing the technology.

China is internationally leading in electroluminescence at present. In fact, it was the 2014 Nature publication by a group of scientists from Zhejiang University that proved QLED can reach the stringent requirements for display applications. However, who will become the final winner of the international competition on electroluminescence remains unclear. China"s investment in quantum-dot technology lags far behind US and ROK. Basically, the quantum-dot research has been centered in US for most of its history, and South Korean players have invested heavily along this direction as well.

For electroluminescence, it is very likely to co-exist with OLED for a long period of time. This is so because, in small screen, QLED’s resolution is limited by printing technology.

Peng: If electroluminescence can be successfully achieved with printing, it will be much cheaper, with only about 1/10th cost of OLED. Manufacturers like NajingTech and BOE in China have demonstrated printing displays with quantum dots. At present, QLED does not compete with OLED directly, given its market in small-sized screen. A while ago, Dr. Huang mentioned three stages of technological development, from science issue to engineering and finally to mass production. For QLED, the three stages have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

Huang: When OLED was compared with LCD in the past, lots of advantages of OLED were highlighted, such as high color gamut, high contrast and high response speed and so on. But above advantages would be difficult to be the overwhelming superiority to make the consumers to choose replacement.

It seems to be possible that the flexible display will eventually lead a killer advantage. I think QLED will also face similar situation. What is its real advantage if it is compared with OLED or LCD? For QLED, it seems to have been difficult to find the advantage in small screen. Dr. Peng has suggested its advantage lies in medium-sized screen, but what is its uniqueness?

Peng: The two types of key advantages of QLED are discussed above. One, QLED is based on solution-based printing technology, which is low cost and high yield. Two, quantum-dot emitters vender QLED with a large color gamut, high picture quality and superior device lifetime. Medium-sized screen is easiest for the coming QLED technologies but QLED for large screen is probably a reasonable extension afterwards.

Huang: But customers may not accept only better wider color range if they need to pay more money for this. I would suggest QLED consider the changes in color standards, such as the newly released BT2020 (defining high-definition 4 K TV), and new unique applications which cannot be satisfied by other technologies. The future of QLED seems also relying on the maturity of printing technology.

Peng: New standard (BT2020) certainly helps QLED, given BT2020 meaning a broad color gamut. Among the technologies discussed today, quantum-dot displays in either form are the only ones that can satisfy BT2020 without any optical compensation. In addition, studies found that the picture quality of display is highly associated with color gamut. It is correct that the maturity of printing technology plays an important role in the development of QLED. The current printing technology is ready for medium-sized screen and should be able to be extended to large-sized screen without much trouble.

Xu: For QLED to become a dominant technology, it is still difficult. In its development process, OLED precedes it and there are other rivaling technologies following. While we know owning the foundational patents and core technologies of QLED can make you a good position, holding core technologies alone cannot ensure you to become a mainstream technology. The government"s investment in such key technologies after all is small as compared with industry and cannot decide QLED to become mainstream technology.

Peng: Domestic industry sector has begun to invest in these future technologies. For example, NajingTech has invested about 400 million yuan ($65 million) in QLED, primarily in electroluminescence. There are some leading domestic players having invested into the field. Yes, this is far from enough. For example, there are few domestic companies investing R&D of printing technologies. Our printing equipment is primarily made by the US, European and Japan players. I think this is also a chance for China (to develop the printing technologies).

Xu: Our industry wants to collaborate with universities and research institutes to develop kernel innovative technologies. Currently they heavily rely on imported equipment. A stronger industry-academics collaboration should help solve some of the problems.

Liao: Due to their lack of kernel technologies, Chinese OLED panel manufacturers heavily rely on investments to improve their market competitiveness. But this may cause the overheated investment in the OLED industry. In recent years, China has already imported quite a few new OLED production lines with the total cost of about 450 billion yuan (US$71.5 billion).Lots of advantages of OLED over LCD were highlighted, such as high color gamut, high contrast and high response speed and so on …. It seems to be possible that the flexible display will eventually lead a killer advantage.

The short of talent human resources perhaps is another issue to influence the fast expansion of the industry domestically. For an example, BOE alone demands more than 1000 new engineers last year. However, the domestic universities certainly cannot fulfill this requirement for specially trained OLED working forces currently. A major problem is the training is not implemented in accordance with industry demands but surrounding academic papers.

Huang: The talent training in ROK is very different. In Korea, many doctoral students are doing almost the same thing in universities or research institutes as they do in large enterprises, which is very helpful for them to get started quickly after entering the company. On the other hand, many professors of universities or research institutes have working experience of large enterprises, which makes universities better understand the demand of industry.

Liao: However, Chinese researchers’ priority pursuit of papers is in disjunction from industry demand. Majority of people (at universities) who are working on organic optoelectronics are more interested in the fields of QLED, organic solar cells, perovskite solar cells and thin-film transistors because they are trendy fields and have more chances to publish research papers. On the other hand, many studies that are essential to solve industry"s problems, such as developing domestic versions of equipment, are not so essential for paper publication, so that faculty and students shed from them.

Xu: It is understandable. Students do not want to work on the applications too much because they need to publish papers to graduate. Universities also demand short-term research outcomes. A possible solution is to set up an industry-academics sharing platform for professionals and resources from the two sides to move to each other. Academics should develop truly original basic research. Industry wants to collaborate with professors owning such original innovative research.

Zhao: Today there are really good observations, discussions and suggestions. The industry-academics-research collaboration is crucial to the future of China"s display technologies. We all should work hard on this.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0/), which permits non-commercial reuse, distribution, and reproduction in any medium, provided the original work is properly cited. for commercial re-use, please contact journals.permissions@oup.com

Over the years, many high-tech screen technologies have come and gone. From traditional tube televisions to projectors, plasma screens to LCD and now oLEDs, the consumer market has seen all manner of screen formats, definitions, and materials.

Usually, these factors are measured as single percentage point differences–until now. The advent of MicroLED technology promises to radically redefine how screens are made, what specs can be packed into screens of all different sizes, and the level of resolution LED screens are capable of.

MicroLED technology is, at least in name, relatively straightforward. Engineers have created dramatically smaller Light-Emitting Diodes (LEDs) and crammed more of them onto the same surface area than previous generations of LED screens. Millions more.

So, microLEDs are a multifaceted improvement in the technology that links LEDs and images produced on a screen. MicroLEDs shrink the size of LEDs by a lot, which means more of them can fill the same space previously occupied by one diode.

This increases resolving power and ability to render detail, but comes at the expense of brightness. That has historically been the sticking point for shrinking LEDs in screen applications. Making microLEDs as bright as their traditional counterparts requires more power, greater diode efficiency, or both. Cranking more energy into more, smaller LEDs means more heat, greater battery drain, and more manufacturing complexity.

To-date, there’s been a limit to how small manufacturers could make LED boards, not only because of the size of diodes, but because of the ‘pitch’ size, which is the space between each LED and what that spacing means for the screen’s resolution.

Hardware technology and manufacturing processes are often limiting factors, because LEDs could only be made so small and mounted to circuitry of a certain size and efficiency. Instead of the few dozen yellow-blue traditional LEDs in today’s LED screens, microLED screens containmillionsof LEDs, or one for each pixel.

This number is then tripled, because microLED screens utilize red, green, and blue LEDs. Each RGB trio delivers one ‘pixel,’ which you can imagine adds up quickly on a TV-sized 1080p screen. Thousands of pixels comprise individual modules, and multiple modules make up a given screen.

The first MicroLED TV to debut is Samsung’s ‘The Wall,’ a frame-less, modular screen that offers industry-leading resolution and an industry-first modular capability that could allow end users to expand their TVs as applications change.

At CES 2018, Jonghee Han, President of Visual Display Business at Samsung Electronics, said, “At Samsung, we are dedicated to providing consumers with a wide range of cutting-edge screen experiences. As the world’s first consumer modular MicroLED television, ‘The Wall’ represents another breakthrough. It can transform into any size, and delivers incredible brightness, color gamut, color volume and black levels. We’re excited about this next step along our road map to the future of screen technology, and the remarkable viewing experience it offers to consumers.”

These points highlight many of the promising breakthroughs and benefits of microLED technology, from the ability to deliver brightness and resolutionandclearly defined black levels, all issues with generations of plasma and LED HD TVs.

Even most of today’s LED screens are actually hybrid LCD/LED screens that use one element (Liquid Crystal Diodes) to create the picture and another (the LEDs behind them) to backlight the screen.

In essence, this is an extremely high-tech take on old projector TV screens, and they come with their own set of problems, including image distortion or blackout from wide viewing angles, light bleed in dark sections of the screen, thick screens that require two different layers, and limitations on maximum brightness due to the pass-through nature of the screen element.

The Samsung Wall is a massive screen, making its debut in 120-inch format. It’s easy to think that this was simply a case of wanting to make a splash with a large-scale screen at a major trade show, but there is a more complicated backstory.

The manufacturer has not mastered microLED technology at smaller screen sizes. The complications surrounding scale of LEDs, power and heat generation, and cost and complexity mean that for now microLED is only being presented as a solution for massive, high-end screens. However, like many other technologies, what starts as a premium niche product may soon become the norm.

It has been widely reported that Apple is working on its own microLED display research, and on the opposite end of the spectrum. Apple believes that microLEDs could make future iPhones even thinner and brighter than the latest-generation organic LED (OLED) displays that recently replaced LCD screens. MicroLEDs are currently regarded as the sort of futuristic technology that OLEDs were considered three to five years ago.

It also means they are limited in maximum brightness as materials cannot be pushed further; similarly, extreme applications like always-on displays suffer from burn-in similar to early plasma screens.

The future of screen technology is almost certainly MicroLEDs. As with every cutting-edge technology, there is a learning curve for manufacturers as materials science and manufacturing processes struggle to catch up to the theoretical potential of this technology.

Once manufacturing potential catches up to the rendering benefits of microLEDs, the leap from OLED to microLED could be rapid, leaving OLEDs behind as a single-generation technology that served as an interesting bridge to a new standard for screens from smartphones to televisions.

As with all technological advances, if the first few products are successful, the floodgates will soon open. Combined with more efficient batteries, microLEDs will soon power all screen-dominated devices, bringing stunning resolution and brightness from the palm of your hand to filling an entire wall in your home.

I’ve been in the display industry for the past 17 years, and I never cease to be amazed by the ability of LCD to reinvent itself. Time and again, as alternative display technologies emerge, questions arise about LCD’s future, prompting new developments that defy expectations and demonstrate its versatility.

Over the last 20 years, LCD displays have become thinner and lighter, and have expanded to larger sizes, as well as offering huge increases in screen performance, including resolution, colour, contrast, brightness and refresh rate. The next evolution is set to bring these developments to more products than ever before – the future lies with flexible displays.

Our organic LCD (OLCD) technology makes use of carbon-based, rather than silicon, transistors, allowing us to sidestep the limitations of flat screens and embrace curved surfaces. This novel feature will bring many benefits to both existing and future products, and there are three key areas where our technology stands to make a significant positive impact. The most obvious application for flexible OLCD is as a replacement for glass LCD screens in products – such as tablets, laptops and TVs – that will benefit from thinner, lighter or unbreakable displays. There’s also the potential to make borderless screens without the bezel or border around their edge, which enlarges the usable screen space, as well as simply being more aesthetically pleasing.

Finally, there is the limitless possibility of adding displays to everyday objects or surfaces that can’t make effective use of glass displays. This will introduce new, previously unattainable, functionality into our homes, offices and cars. One particular application that is gaining traction is using OLCD displays on the inside of the A-pillar in your car. Combined with an external camera, you can make the pillar ‘invisible’, increasing visibility and improving safety.

OLCD is set to transform the world around us. Thanks to the existing, low-cost manufacturing supply chain for LCDs, it’s a small step for designers to begin developing the next generation of products that take advantage of the flexibility afforded by this innovative technology.

There"s a new TV tech on the horizon, and it promises incredible picture quality and even more incredible sizes. You can buy one right now if you"ve got deep pockets. It"s called MicroLED, and it combines the best features of the current TV technologies into something new -- and huge. Using millions of tiny individually addressable LEDs, MicroLED promises to rival the picture quality of

Although super-expensive now, MicroLED is on the cusp of being the next great display technology. And it could end up in your home sometime in the future, even if you"re not rich. Here"s what you need to know.

With MicroLED, on the other hand, the LEDs themselves directly create the image. The picture you watch is composed of individually-addressable LEDs, which makes it more like how OLED works. No more LCDs.

Here"s how it works. As the name suggests, MicroLED is made of millions of micro, well, LEDs. Tinier versions of what"s in your current LCD TV, or newer flashlights, light bulbs and what myriad other devices

Turns out that process is a lot harder than it sounds. One problem is that when you shrink LEDs, the total amount of light they produce goes down. So you either need to drive them harder, increase their efficiency, or both. Just driving them harder introduces new issues. The TV will need a lot more electricity and have to dissipate a lot more heat. The dozens of LEDs in your current TV don"t emit that much heat, certainly not compared to older technologies like plasma and CRT, but put millions of them right next to each other and things can get toasty.

Sure, wall-size TVs are cool, but no one will buy them. If a manufacturer wants to make a profit on its new tech, it needs something easy to make in the 60-inch range, or smaller. If they can do that, the big sizes will get even cheaper.

To put it another way, current LCD and OLED TVs have different size pixels for different screen sizes. So a 4K 75-inch LCD has larger pixels, but the same number, as a 4K 50-inch LCD. MicroLED could, possibly, just add more pixels of the same size to make a larger, and higher resolution, TV. This could turn out easier than changing the tiny LED pixel sizes, from a manufacturing standpoint. We"ll have to wait and see if it happens that way. Right now though, Samsung"s three sizes have the same resolution, meaning the 88-inch has the smallest pixels of the lot.

LG is the latest company to announce MicroLED displays, though not every model from their DVLED Home Cinema line is MicroLED. Sizes range from 108-inches to 393-inches, with HD, 4K, and even 8K resolutions. You can even get 32:9 models that allow two full-sized 16:9 shows or games running simultaneously side-by-side.

It wasn"t long ago that OLED was a far-off future tech that never seemed to leave the prototype stage. Now there are multiple sizes and resolutions that would have seemed impossible in the tech"s early days. It"s possible we"re now in the early days of microLED. It"s a technology that holds a lot of promise, in both picture quality, screen size and myriad other uses -- but it"s not without its issues. Heat and price are stumbling blocks, but engineers love a challenge. The fact that you can, if you"ve got $100,000 or so to burn, buy one now says a lot. Could this replace LCD TVs in many homes? Maybe. Could it give OLED a run for its money? Possibly. Will it replace projectors? Could be. As I said, it"s an interesting technology.

Most modern computer monitors, and even televisions, have an edge-lit LCD display that’s fundamentally similar to the first such displays sold decades ago, but that’s not where the future is headed. The twin threats of Mini-LED and OLED want to conquer the world of PC displays for themselves.

Which will win, and where is the future headed? I spoke with Ross Young, CEO of Display Supply Chain Consultants, and David Wyatt, CTO of Pixel Display (and inventor of Nvidia G-Sync), for the inside scoop.

Modern OLED displays rarely exceed 1,000 nits of brightness, and when they do, are incapable of sustaining it. LG’s C9 OLED television, for example, can’t sustain a peak brightness above 160 nits (according to testing by Rtings). Mini-LED displays like Apple’s Liquid Retina XDR, Samsung’s Odyssey Neo G9, and Samsung’s QN90A television can hit peak brightness well above 1,000 nits and sustain at least 600 nits.

Wyatt points to this as a key advantage. The best HDR standards call for up to 10,000 nits of brightness. Current consumer Mini-LED displays don’t achieve this, but it’s possible future displays will.

And Micro-LED, which uses individual LEDs as per-pixel lighting elements, can reach even greater heights. Wyatt says his company’s VividColor NanoBright technology will be capable of reaching up to one million nits.

Such brightness is not necessary for computer monitors or home televisions and instead targets demanding niche components, such as avionics displays. Still, it hints that we’ve only seen a sliver of HDR’s real potential – and that Mini-LED and Micro-LED, not OLED, will lead the charge.

OLED’s greatest strength is the opposite of Mini-LED’s incredible brightness. The self-emissive nature of OLED means each pixel can be turned on or off individually, providing a deep, inky, perfect black level.

“Mini-LED has clear advantages in sources of supply and brightness,” Young said in an email, “but OLEDs have advantages in regards to contrast, particularly off-axis contrast, response times, and no halo effect.” The “halo effect,” also known as blooming, is the halo of luminance that often surrounds bright objects on a Mini-LED display.

The advantages of OLED add up to superior contrast and depth. You’ve likely noticed this when viewing an OLED television at your local retailer. High-quality content has an almost three-dimensional look, as if the display is not a flat panel but a window into another world.

Modern Mini-LED displays often claim to rival OLED. Apple’s Liquid Retina Display XDR, for example, lists a maximum contrast ratio of 1,000,000:1. In reality, Mini-LED still noticeably lags the contrast performance of OLED because it can’t light pixels individually. This will remain true at least until Micro-LED, which can light pixels individually, goes mainstream.

Mini-LED improves on traditional edge-lit LCD displays by improving the backlight. The LCD panel itself, however, is much the same as before and retains some flaws common to the technology.

Display quality can shift significantly depending on viewing angle, and significant blur will be visible when displaying fast motion. Both problems are inherent to LCD technology. The liquid crystals do not block light uniformly, so the image looks different from different angles, and require a few milliseconds to respond to a charge, causing blur or ghosting in rapidly changing images.

OLED is different from LCD technology. There’s no liquid crystals to twist or move. Each pixel is an organic element that creates its own light when a charge is applied. The light is emitted in a relatively uniform pattern and can turn on or off extremely quickly, removing the viewing angle and motion performance issues of LCD entirely.

The last few points—contrast, black levels, viewing angles, and response times—highlight the strengths of OLED technology. But, OLED has a weakness: durability.

This problem is most often discussed in the context of burn-in or image retention. Burn-in happens when specific pixels on an OLED panel degrade differently from those around them, creating a persistent shadow in the image.

Want to see the effects yourself? I recommend Rting’s burn-in testing page, which shows results over a period of eight years (though, unfortunately, Rtings has not updated its result since February of 2020). This testing shows OLED degradation is indeed a thing, though its severity depends on how you use your display.

Monitor pricing remains a sore point for PC enthusiasts. As explained in my deep-dive on upcoming OLED monitors, pricing is tied to the efficiency of production.

This advantage will likely continue in the near future. OLED pricing is reliant on availability of OLED panels, which are not as widely produced as LCD panels. Companies looking to build Mini-LED displays can design the backlight somewhat independently of the LCD panel and choose panels as needed based on the panel’s capabilities and pricing.

Because of this, there’s more ways for manufacturers to deliver Mini-LED displays in notebooks and monitors, which may lead to a more aggressive reduction in price.

The current OLED vs. Mini-LED battle is give-and-take. Mini-LED wins in brightness, HDR, durability, and pricing (of full-sized monitors). OLED wins in contrast, black levels, viewing angles, and motion performance.

OLED’s big break may come with the introduction of new fabs. Young says they will “lower costs significantly for 10-inch to 32-inch panels, giving OLED fabs the same flexibility as G8.5 LCD fabs, meaning the ability to target multiple applications from a single fab.” The first of these new fabs should start producing panels by 2024.

Affordable OLED seems alluring, but Wyatt champions a different approach. He believes the Micro-LED technology championed by Pixel Display will meld the strengths of LCD and OLED while ditching the weaknesses of both.

However, Micro-LED is a technology more relevant to the latter half of this decade. The more immediate fight will see OLED attempt to improve brightness and durability while Mini-LED pursues increasingly sophisticated backlights to mimic the contrast of OLED.

Personally, I think Mini-LED shows more promise—when it comes to PC displays, at least. The static images, long hours, and sustained brightness of Mini-LED displays pinches on OLED pain points, which will remain even if pricing becomes more affordable.

As consumers expectations for televisions increase, panel makers are utilizing technology and process improvements to design brighter, higher resolution, and larger displays.

For example, panel makers are economically achieving 8K resolution with backplanes that seemed impossible only a few years ago, such as oxide TFTs. And to improve the color and light output of LCD TVs, panel makers are using increasingly advanced quantum dot films to augment traditional LCD designs, as seen in QLED sets.

In the past few years, the global center of LCD panel manufacturing has shifted from Korea to China. The shift was somewhat expedited because of COVID-19, but this dynamic did not happen overnight.

Korean panel manufacturers adjusted to industry and macroeconomic dynamics by sourcing LCD panels from other locations and turning their resources toward next-generation display technologies.

Ultimately, what drives end-market demand drives glass demand – which is what we at Corning are focused on. As we continue to expand glass capacity, with supply agreements for three out of four announced Gen 10.5 plants, Corning is well positioned to support our customers’ market growth.

In the first part of this feature on the future of displays, we outlined some of the emerging technologies set to have an impact. Here manufacturers make the case for the improvement of existing formats and remark on the increase in creativity of content, unusual shapes and multi-screen formations.

Thomas Issa, corporate and education solution marketing manager for Sony Professional Solutions Europe suggests that there is still a lot of life left in the current types of display. “While there are some superb solutions on the market already, both LED and LCD technologies still have a lot of room to grow before we need to start thinking about the next big innovations. There is scope for a number of advances: from improving resolution and picture quality, to creating new designs with reduced bezels, to increasing their overall reliability. So, while we will see some impressive innovations in the short time, the future still very much belongs to new and improved iterations of LED and LCD technologies.

“Even more important than how new and innovative the technology is, is whether it actually meets the needs of the end-users. There is a lot of demand for display integration with wider AV solutions at the moment, which is driving demand for versatility in display solutions these days, whether we’re talking about a corporate environment and meeting rooms, or an education setting like lecture theatres in universities.”

Applications and content are crucial to the success of every digital screen-based communication campaign or installation. “Content has also become a vital part of in-house displays, across all sectors,” says Nigel Roberts, IT solutions sales head for LG Electronics UK Business Solutions. “Applications have advanced accordingly, like our WebOS platform, which allows marketing teams to quickly generate responsive online campaigns that can now remotely sync almost immediately with the displays, keeping the brand on message and engaging up to the minute rather than the weekly rotation.”

The prevalence of screens throughout our lives and in almost every conceivable location has led us to ignore them to a great extent, something that manufacturers and owners are fighting against by installing screens in less traditional places. Roberts: “The 16:9 ratio will be the norm for corporate applications so that BYOD can be enabled rapidly and displays can quickly be used as a standard format for all content from every user. However with the increase in creativity of content, unusual shapes and multi-screen formations are growing in popularity and impact. There is strong uptake for our UltraStretch and Open Frame OLED technologies, both of which encourage creative application and placing of the displays, creating real impact for the end user.”

Large LED displays are increasingly found in public areas and can be moulded to suit the available space or structure – whether flat, curved or irregular – allowing even more creativity in application and gaining attention from viewers. LED pitch is reducing every year, enabling LED matrix displays to be used in a wider range of applications and locations. It is a business that has accelerated rapidly, registering sales last year of over $5.3 billion. “The introduction of MicroLED by Sony in 2016 caused a great stir of excitement in the industry, but it was thought to be a measure of what was possible, not what was viable in the near term,” comments Chris McIntyre-Brown, associate director at Futuresource Consulting. “However, this year has seen far more buzz around new chip-on-board (COB) solutions, MiniLED and glue-on-board. All offer different benefits, but it is really the potential of MiniLED, with a pixel pitch of 100 micrometers or less, that has the industry excited. Troublingly though, are the lack of standards around MiniLED, MicroLED and indeed the LED industry as a whole. This is creating confusion, and that certainly needs to be addressed.”

As LED screens take a more prominent place in the mainstream display market, large corporations are installing LED displays in areas which could previously only accommodate projection. This is resulting in new manufacturing techniques, such as COB, to cater for changing requirements, including increased resolution and the creation of more robust displays for high footfall locations.

“There is a clear trend is the move away from LCD and plasma technology, and towards LED becoming the technology at the heart of displays in the next decade,” believes Paul Brown, VP sales UK, at SiliconCore Technology. “LED will be ubiquitous across all verticals, and as the price point comes down and quality rises, the application horizon will widen. Command and control rooms are a major area of change at the moment with the removal of tiled displays and rear projection in favour of LED displays. We expect to see this pick up pace over the coming year. Indoor retail and public areas in which projection and seamed videowalls will most commonly be replaced by seamless LED displays.

“To meet this demand, we have developed technology over the last three years that addresses the durability issues found in LED displays. This year we launched LISA, LED in Silicon Array, which introduces a unique process in manufacturing, as the next step forward for fine pixel pitch displays. It will become standard across our range, and we believe, over time the industry standard. Common Cathode technology, which we patented over five years ago, is also taking off as it becomes more widely accepted as a method of creating more power-efficient LED technology.”

Further examples of COB technology that are already commercially available are the new Crystal LED range from Sony and the LED LiFT range from NEC. With each LED taking up just 0.003sqmm in a pixel of 1.4sqmm, it is possible to create very high resolution displays in small overall sizes, giving them greater scope for use in control rooms, retailing, product design studios and other applications that traditionally needed LCD displays or projectors. The large black area around each chip contributes greatly to a highly acceptable contrast level of 1,000,000:1. “Bringing new technologies to market is ultimately about offering customers choice. A retailer’s requirements for signage and display solutions differs from those of a design studio, post-production house or sports venue, for example,” explains Issa. “Based on individual, bezel-less display units, organisations can create a display tailored to their exact specifications.”

Futureproof pathsIt is notoriously difficult to predict the future in the AV world in the face of rapid technological evolution and the frequent introduction of newer, better, solutions to meet an ever-widening range of applications. Integrators need to be conversant with all types of display technologies and be able to guide and advise their customers in selecting the best system for them today, as well as ensuring there is a futureproof path to upgrade and develop as the technology improves even further.

This, Thomas Walter, section manager strategic product marketing, NEC Display Solutions Europe, believes, is why: “System integrators who offer a wide choice of technologies from projection, LCD-based displays to direct view LED will be the ones that can holistically serve their customers and will win in the long run with a consultative expert approach. To get to this point needs training and expertise and help by providing intense training to our partners in order to give them the necessary technical skill and knowledge to gain competitive advantage.”

Those integrators must also be conversant in associated IT technologies and networking if they are to meet the complexities and demands of a rapidly changing world. There is a trend toward integrated displays that no longer require external media players to function and as screens become more modular and adaptable new commercial opportunities will open up.

Purchasing models are also changing, as buyers move toward leased service provision rather than capital purchase wherever possible. Data storage, software and even remote processing are already offered on a product-as-a-service model and hardware is increasingly offered that way too. Integrators and manufacturers need to be able to respond to client requests to provide leased equipment accompanied by ongoing support, maintenance and upgrade contracts that ensure the end customer, and hence the viewer, is always supplied with the latest and greatest technology and solutions.

However, the biggest changes in the AV market will be driven by the changing work and leisure habits of today’s workers, driven by the expectations of today’s consumers for a certain quality of technology experience. With the consumer market moving so rapidly, the AV market needs to keep pushing the boundaries and innovating to stay relevant.

During the summer it was my pleasure to work with two interns from local universities. As part of their instruction I asked each of them to pick a topic of their choice, and to generate a patent landscape report on the area. For each project the interns were asked to research the technical aspects of their topic, suggest a patent search strategy for identifying documents, reduce their collections to remove family duplicates, cleanup various data fields, categorize the collection into a variety of facets, conduct relevant analytics on the data, and finally generate both a written report and a PowerPoint presentation to summarize their results. I am excited to publish the first of these projects produced by Riley Collins who did his project on Flexible Electronic Displays. So without further ado here"s Riley"s project:

Unlike traditional flat panel displays OLEDs, one of the more popular types of flexible electronic displays are solid-state devices composed of thin films of organic molecules that create light with the application of electricity. OLEDs can provide brighter, crisper displays on electronic devices and use less power than conventional light-emitting diodes (LEDs) or liquid crystal displays (LCDs) used according to HowStuffWorks.com. Using glass substrates, flexible technology OLED‘s utilizes plastic substrates, which allow the display to bend and twist. Flexible OLED‘s only need one sheet of substrate while LCD‘s require two and a separate backlight. Because of this, OLED‘s are able to be paper thin and lightweight, a perfect candidate for mobile phones and wearable electronics. The challenge for manufacturers currently is allowing the device to be repeatedly deformed while keeping the internals intact. Currently, electronic flexible displays are being used to make curved phones and televisions. This is possible because while the display may be “flexible”, the internal components remain fixed. Figure 1 shows a diagram of the layers in different types of displays. Samsung refers to their flexible OLED display as FAMOLED.

Electronic paper displays are the oldest type of flexible display. They differ in that they reflect light and have a wider viewing angle. E-paper is used predominately in E-readers and signage because text can be read in direct sunlight without fading. Similar to flexible OLED and LCD, it also uses plastic substrates, allowing display to bend like paper. E-paper displays are not ideal for phones and tablets because they have a very low refresh rate, ghosting problems, and are yet to be mass-produced in color.

As flexible displays become cheaper to manufacture we will likely see new functions of this technology. While curved devices are the first to hit the market, recent patent filings by top display manufacturers suggest that foldable, bendable, and rollable devices are not that far away. Foldable displays will likely come first to accommodate the growing demand for larger displays and the need for portability. As the wearable device market grows, bendable displays could be used to wraparound an individual’s wrist. Finally, displays that can be rolled up may be used in televisions and eventually a tubular device with a retractable roll out display.

Some benefits of flexible displays are better durability, lighter weight, thinner dimensions, and unique software commands. The use of a plastic substrate and the ability to flex locally when dropped makes the device less likely to crack, saving the users the trouble of having their screen replaced or being forced to buy a new device. Flexible devices will also be lighter and thinner than their rigid counterparts because they use plastic instead of glass. The ability to deform the device may allow the user to access a set of commands in their devices user interface. For example, when the device is folded it will go into sleep mode.

Demand for flexible displays is on the verge of a sharp increase. According to a new IHS report, “Global Flexible Display Technology and Market Forecast” (Figure 2 above). It is estimated that the flexible display market will grow to $1.1 billion in 2015 and will continue to develop at rate of 226% to $42 billion by the end of 2020. Units sold are projected to rise from 3.2 million in 2013 to 792 million in 2020. This means that in 2020, flexible display market will have captured 13% of the total display market. Even though smartphones with flexible displays have not yet achieved their desired potential, it is probable that they will soon capture the market by storm.

The search was started by locating as many Cooperative Patent Classification (CPC) codes that referred to flexible displays.. A sample of highly relevant documents were used to cross-reference and make sure that no CPC codes were left out.. The codes used were are:

OLEDA family reduction was conducted, but all unique US application numbers were retained. Foreign inventions were reduced to one invention per extended family. This list of CPC codes produced 2156 documents. After manually sorting the files, 177 were on E-Paper, and 1218 were Flexible OLED/LCD technologies. Many of the relevant documents included the key words flex*, deform, roll*, curve, bend* or bent, fold*, and a flexible or plastic substrate.

The objective of preforming this research is to complete an analysis

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey