sda in lcd module pricelist

The Analox SDA series is a range of fixed external chamber analyzers used to control levels of gases such as oxygen and carbon dioxide. The new products are designed to be more easily configured to meet the users’ needs, with interchangeable sensors and software.

More options are available for the Analox SDA O2 . Please call Amron"s award winning sales staff at (760) 208-6500 to assist you with your Analox SDA O2, get a quote, and place your order today!

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

As you can see in the picture the “backpack” is just soldered on anyway they could make it work. It’s sticking off the back at roughly 33 degrees instead of flat and inline with the device itself. I have others purchased elsewhere that are manufactured correctly. There is a “fin” on the back that needs to be flattened or removed prior to soldering. Clearly the people who assembled these were not aware of that, as they just soldered it on an angle making flush mount applications more difficult than necessary. Longer standoffs are required and if space is lacking this item will not work.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Adding a display to Raspberry PI Pico allows getting real time information from connected devices without using a computer from USB port. I2C LCD displays (with PCF8574 backpack) are one of best solution to keep wiring simple

I2C LCD displays are common LCD displays, usually composed of 16 columns x 2 rows blocks, but also different configurations can be found. Differently from simple LCD displays, they include a small panel soldered in its backside, including chips able to reduce their connection wires. The I2C LCD display usually has a PCF8574 chip, which is a device able to convert I2C serial communication into parallel connections.

To connect an I2C LCD Display with your Raspberry PI Pico, you just need to wire the Vcc and GND PINs from display to VSYS and a GND PINs of RPI Pico, then SDA and SCL PINs from the I2C Display to a couple of SDA and SCL PINs from Raspberry PI Pico, belonging to the same I2C bus, as shown in the picture on the following wiring diagram chapter.

A working solution uses the dhylands-python_lcd module including a generic API to interface to LCD displays. But this class implements commands to be sent to the LCD without caring about how to send them. The reason is that there are many different backpacks and every solution can be implemented in many different ways. The ones created with a PCF8574 use I2C as communication protocol, in this case, you need a sort of driver able to send commands via I2C. This function is implemented with a second module from T-622 user, also available from T-622 GitHub page.

As usual, I suggest adding from now to your favourite e-commerce shopping cart all the needed hardware, so that at the end you will be able to evaluate overall costs and decide if continue with the project or remove them from the shopping cart. So, hardware will be only:

Prepare cabling according to the previous paragraph. Connect RPI Pico to Thonny (you can refer to my tutorial about First steps with Raspberry PI Pico).

Before going into the usage explanation, you have to be sure that your LCD’s I2C address is correct. This is a unique address shared between I2C devices to make them able to talk on the same shared wire. This is usually a hexadecimal value and all devices connected to your RPI Pico can be scanned by copy-paste of the following code in your Thonny shell (you can copy all lines together):

As I2C LCD with PCF8574 backpack use PCF8574 chip for I2C communication, you will probably get its default address (0x27). But if your project includes more PCF8574-based chips, then you will need to identify the LCD one between those that will be shown. In case of missing devices, please check your cabling.

Starting to use your LCD device, you can run a generic test with the T-622 test script, which I have pre-configured for 16×2 LCDs using I2C0 channel (ports GP0 and GP1 according to my wiring diagram). This modified script can be get from my download area (use the following link: i2c_lcd_test). Save this file in your Raspberry PI Pico root folder or in your computer and open it with Thonny IDE.

If you will see nothing, please check your cabling. Another common issue with I2C LCD display is getting a clean screen which is only powering on and off. This means that your connection is correct and everything is working, you have only to adjust your LCD contrast by rotating the screw positioned in your LCD backside, which controls a potentiometer managing contrast:

The LCD API used has a flexible feature allowing users to display also complex icons inside a single cell. Some special characters are already available and depend on your LCD ROM (Read Only Memory, space not visible to the user). You can use these chars with “lcd.putchar(chr())” function.

The first 8 characters (from 0 to 7) character-generator RAM. This means that you can define and design any icon you want to display by identifying pixels to be put on/off for each char block, made of 8 rows and 5 columns of pixels. Each row A good description of how to define a generic icon is explained in https://github.com/dhylands/python_lcd.

I’ve also prepared a simple MS Excel file that can help you designing your personal icon and generating related code to use in your script. You can download it from this link: bytearray code generator.

With this file, while you set to 1 or 0 (zero) the cells in the drawing zone, these cells will change color according to their value and the code will be generated. In this way, you will have an immediate preview of what you are drawing and related code to use:

You can use the generated code with “lcd.custom_char()” command. An example usage is built in my pico_i2c_lcd script. Download and open it in your Thonny IDE.

Following part is where the custom icon is generated, using the code coming from my generator. This icon is associated to custom char (with id value going from 0 to 7):

A few weeks ago, we examined the features of ESP32 module and built a simple hello world program to get ourselves familiar with the board. Today, we will continue our exploration of the ESP32 on a higher level as we will look at how to interface a 16×2 LCD with it.

Displays provide a fantastic way of providing feedback to users of any project and with the 16×2 LCD being one of the most popular displays among makers, and engineers, its probably the right way to start our exploration. For today’s tutorial, we will use an I2C based 16×2 LCD display because of the easy wiring it requires. It uses only four pins unlike the other versions of the display that requires at least 7 pins connected to the microcontroller board.

ESP32 comes in a module form, just like its predecessor, the ESP-12e, as a breakout board is usually needed to use the module. Thus when it’s going to be used in applications without a custom PCB, it is easier to use one of the development boards based on it. For today’s tutorial, we will use the DOIT ESP32 DevKit V1 which is one of the most popular ESP32 development boards.

The schematics for this project is relatively simple since we are connecting just the LCD to the DOIT Devkit v1. Since we are using I2C for communication, we will connect the pins of the LCD to the I2C pins of the DevKit. Connect the components as shown below.

Due to the power requirements of the LCD, it may not be bright enough when connected to the 3.3v pin of the ESP32. If that is the case, connect the VCC pin of the LCD to the Vin Pin of the ESP32 so it can draw power directly from the connected power source.

At this point, it is important to note that a special setup is required to enable you to use the Arduino IDE to program ESP32 based boards. We covered this in the introduction to ESP32 tutorial published a few weeks go. So, be sure to check it out.

To be able to easily write the code to interact with the I2C LCD display, we will use the I2C LCD library. The Library possesses functions and commands that make addressing the LCD easy. Download the I2C LCD library from the link attached and install on the Arduino IDE by simply extracting it into the Arduino’s library folder.

Before writing the code for the project, it’s important for us to know the I2C address of the LCD as we will be unable to talk to the display without it.

While some of the LCDs come with the address indicated on it or provided by the seller, in cases where this is not available, you can determine the address by using a simple sketch that sniffs the I2C line to detect what devices are connected alongside their address. This sketch is also a good way to test the correctness of your wiring or to determine if the LCD is working properly.

This sketch basically uses a “for” loop to generate a list of addresses and then sends a begin transmission request to the address. The return value of the Write.endTransmission() function shows if a device exists on that particular address. The address at which a response was received is the address we are a looking for.

If you keep getting “no devices found”, it might help to take a look at the connections to be sure you didn’t mix things up and you could also go ahead and try 0x27 as the I2C address. This is a common address for most I2C LCD modules from China.

Our task for today’s tutorial is to display both static and scrolling text on the LCD, and to achieve that, we will use the I2C LCD library to reduce the amount of code we need to write. We will write two separate sketches; one to displaystatic textsand the other to display both static and scrolling text.

To start with the sketch for static text display, we start the code by including the library to be used for it, which in this case, is the I2C LCD library.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

With that done, we proceed to the void setup() function. Here we initialize the display and issue the command to turn the backlight on as it might be off by default depending on the LCD.

Next is the void loop() function. The idea behind the code for the loop is simple, we start by setting the cursor to the column and row of the display where we want the text to start from, and we proceed to display the text using the lcd.print() function. To allow the text to stay on the screen for a while (so its visible) before the loop is reloaded, we delay the code execution for 1000ms.

For the scrolling text, we will use some code developed by Rui Santos of RandomNerdTutorials.com. This code allows the display of static text on the first row and scrolling text on the second row of the display at the same time.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

Next, we create the function to display scrolling text. The function accepts four arguments; the row on which to display the scrolling text, the text to be displayed, the delay time between the shifting of characters, and the number of columns of the LCD.

Next is the void setup() function. The function stays the same as the one for the static text display as we initialize the display and turn on the backlight.

With that done, we move to the void loop() function. We start by setting the cursor, then we use the print function to display the static text and the scrollText() function is called to display the scrolling text.

Ensure your connections are properly done, connect the DOIT Devkit to your PC and upload either of the two sketches. You should see this display come up with the text as shown in the image below.

That’s it for today’s tutorial guys. Thanks for following this tutorial. This cheap LCD display provides a nice way of providing visual feedback for your project and even though the size of the screen and the quality of the display is limited, with the scrolling function you can increase the amount of text/characters that can be displayed.

In this guide we’re going to show you how you can use the 1.8 TFT display with the Arduino. You’ll learn how to wire the display, write text, draw shapes and display images on the screen.

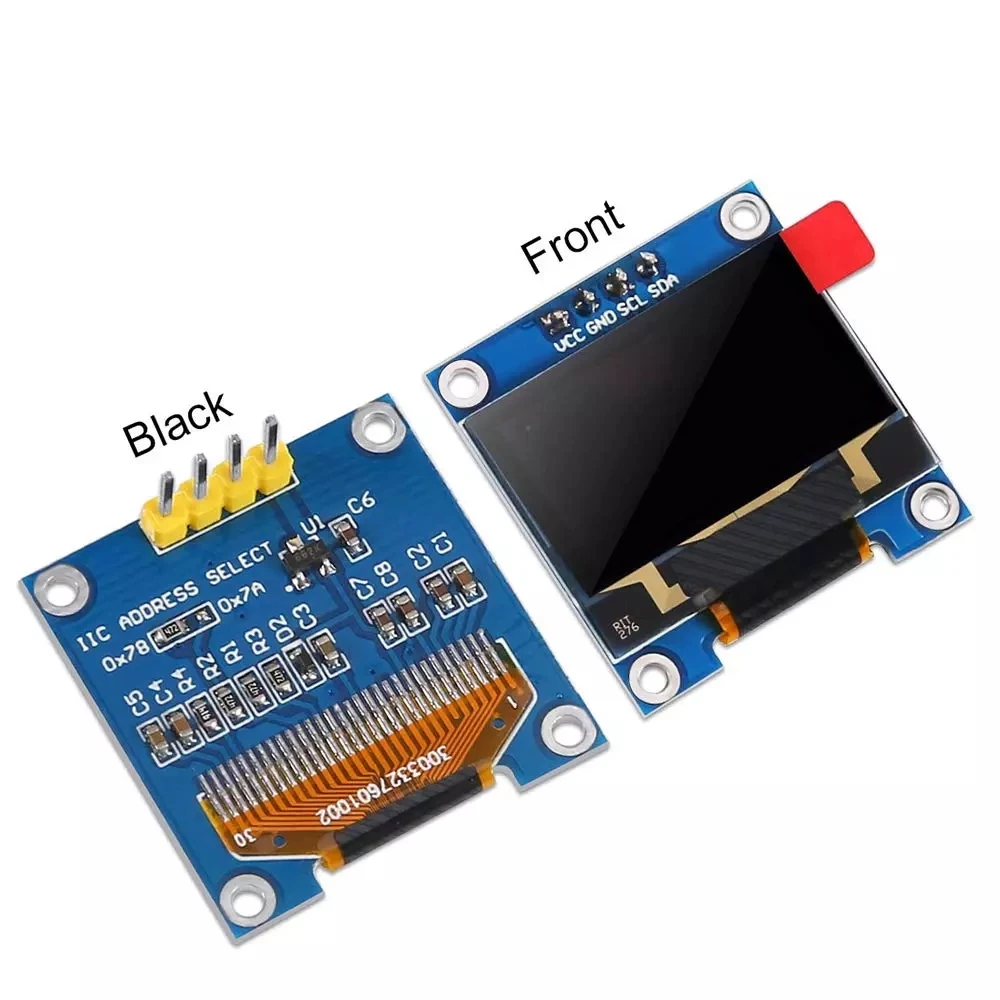

The 1.8 TFT is a colorful display with 128 x 160 color pixels. The display can load images from an SD card – it has an SD card slot at the back. The following figure shows the screen front and back view.

This module uses SPI communication – see the wiring below . To control the display we’ll use the TFT library, which is already included with Arduino IDE 1.0.5 and later.

The TFT display communicates with the Arduino via SPI communication, so you need to include the SPI library on your code. We also use the TFT library to write and draw on the display.

In which “Hello, World!” is the text you want to display and the (x, y) coordinate is the location where you want to start display text on the screen.

The 1.8 TFT display can load images from the SD card. To read from the SD card you use the SD library, already included in the Arduino IDE software. Follow the next steps to display an image on the display:

Note: some people find issues with this display when trying to read from the SD card. We don’t know why that happens. In fact, we tested a couple of times and it worked well, and then, when we were about to record to show you the final result, the display didn’t recognized the SD card anymore – we’re not sure if it’s a problem with the SD card holder that doesn’t establish a proper connection with the SD card. However, we are sure these instructions work, because we’ve tested them.

In this guide we’ve shown you how to use the 1.8 TFT display with the Arduino: display text, draw shapes and display images. You can easily add a nice visual interface to your projects using this display.

In this project, we"ll see how to hook up a 16x2 Character I2C LCD module with a ProtoStax Enclosure for Raspberry Pi to display interesting information like the Pi"s IP Address, Date & Time, or any other information you would like to display!

TheProtoStax LCD Kit V2is a new Extension Kit from ProtoStax. It can be used to add a 16x2 Character I2C LCD module to any ProtoStax Enclosure. You simply replace the top of your existing ProtoStax Enclosure with the one from the kit with the LCD module installed, and you"ll have an enclosure with an LCD screen!

Firstly, mount the LCD screen from the kit to the Top Plate from the kit using the mounting hardware. Then, unscrew and remove the Top Plate from your ProtoStax Enclosure Raspberry Pi (A+/B+, 4B/Zero) and replace it with the LCD Kit Top Plate.

Since the LCD module that is used has an I2C adapter, you only need 2 I2C pins to communicate with it. Wiring is super easy.RPi 5v pin (physical pin 2) - LCD VCC

Next, we want to enable I2C on the Raspberry Pi (if it is not already enabled). You can do that using the raspi-config utility. Here are the steps to do so. You will first run$ sudo raspi-config

We are going to interact with the LCD using Python. To do that, we are going to use the install the necessary python packages - we use RPLCD and smbus (to use I2C to communicate with the LCD module).$ sudo pip3 install RPLCD

We"ll demonstrate printing the IP address and Date and Time on the LCD screen, using the Python program below. You can find the source code on the GitHub link below.

Assuming you"ve installed it in ProtoStax_RPi_LCD_Example/ under your home directory, launch the program thus:$ python3 /home/pi/ProtoStax_RPi_LCD_Example/lcd_ip.py

This displays the Date and Time on the first line, and the second line of the 16x2 display shows the IP address and hostname of the Raspberry Pi in a scrolling fashion (as the character count is longer than 16 characters, we have to resort to scrolling). The

If the network is down on unreachable, then the IP address and hostname will be empty - therefore with a quick glance you can tell about the connection status of your Raspberry Pi as well as know how to connect to it, if it is headless. Just use the IP address or use

Now we want to make sure that this script gets run when we boot up the computer. We therefore create a service (which we call lcd.service) and make sure that the service is enabled (this assumes that the lcd_ip.py Python script is in the /home/pi/ProtoStax_RPi_LCD_Example directory - adjust the path accordingly in the WorkingDirectory below)

When shutting down the computer, the service gets stopped, and the python script as part of cleanup will clear the LCD screen and turn off the backlight.

Of course, you can also use the LCD display to display other information. For example, you cancreate a stock ticker that shows a scrolling ticker of stock prices you are interested in

Since the use of an LCD requires many microcontroller pins, we will reduce that number using serial communication, which is basically sending "packages" of data one after another, using only two pins of our microcontroller , pins SDA and SCL which are the analog pins A4 and A5 of the Arduino NANO or pro mini.

First of all we connect i2c pins module as shown in the schematic. Power the LCD module to 5 volts and connect the ground as well. The SDA pin of the i2c module conected to arduinio A5 and the SCL pin to A4. We connect the arduino to USB and we are ready to program. In order to make the LCD work we need to inport the LCD library for arduino.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

In addition, there is a jumper on the board that supplies power to the backlight. To control the intensity of the backlight, you can remove the jumper and apply external voltage to the header pin that is marked ‘LED’.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1 and A2) are placed at the end of the 7-bit I2C address register.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x20. The range of all possible addresses spans from 0x20 to 0x27. Please see the illustration below.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1 and A2) are also placed at the end of the 7-bit I2C address register. But the other bits in the address register are different.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x38. The range of all possible addresses spans from 0x38 to 0x3F. Please see the illustration below.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

To install the library navigate to Sketch > Include Libraries > Manage Libraries… Wait for Library Manager to download the library index and update the list of installed libraries.

Filter your search by typing ‘liquidcrystal‘. There should be some entries. Look for the LiquidCrystal I2C library by Frank de Brabander. Click on that entry, and then select Install.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

To use createChar() you first set up an array of 8 bytes. Each byte in the array represents a row of characters in a 5×8 matrix. Whereas, 0 and 1 in a byte indicate which pixel in the row should be ON and which should be OFF.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

Your imagination is limitless. The only limitation is that the LiquidCrystal library only supports eight custom characters. But don’t be discouraged, look at the bright side, at least we have eight characters.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

Let’s examine the Heart[8] array as an example. You can see how the bits (0s and 1s) are forming a heart shape. 0 turns the pixel off and 1 turns the pixel on.

In setup, a custom character is created using the createChar() function. This function takes two parameters. The first parameter is a number between 0 and 7 to reserve one of the 8 supported custom characters. The second is the name of the array.

As we all know, though LCD and some other displays greatly enrich the man-machine interaction, they share a common weakness. When they are connected to a controller, multiple IOs will be occupied of the controller which has no so many outer ports. Also it restricts other functions of the controller. Therefore, LCD1602 with an I2C bus is developed to solve the problem.

I2C bus is a type of serial bus invented by PHLIPS. It is a high performance serial bus which has bus ruling and high or low speed device synchronization function required by multiple-host system. The blue potentiometer on the I2C LCD1602 (see the figure below) is used to adjust the backlight for better display. I²C uses only two bidirectional open-drain lines, Serial Data Line (SDA) and Serial Clock Line (SCL), pulled up with resistors. Typical voltages used are +5 V or +3.3 V although systems with other voltages are permitted.

Step 3:Since in some code, the libraries needed are not included in Arduino, so you need to add them before compiling. Unzip the downloaded file. Copy the folders under the Library folder to the libraries folder in Arduino (if you cannot find the path in Arduino, open Arduino IDE, click File ->Preferences, and you can see the path in the Browse box, as shown in the following diagram). Compile the program.

LCD screens are useful and found in many parts of our life. At the train station, parking meter, vending machines communicating brief messages on how we interact with the machine they are connected to. LCD screens are a fun way to communicate information in Raspberry Pi Pico projects and other Raspberry Pi Projects. They have a big bright screen which can display text, numbers and characters across a 16 x 2 screen. The 16 refers to 16 characters across the screen, and the 2 represents the number of rows we have. We can get LCD screens with 20x2, 20x4 and many other configurations, but 16x2 is the most common.

In this tutorial, we will learn how to connect an LCD screen, an HD44780, to a Raspberry Pi Pico via the I2C interface using the attached I2C backpack, then we will install a MicroPython library via the Thonny editor and learn how to use it to write text to the display, control the cursor and the backlight.

2. Import four librariesof pre-written code. The first two are from the Machine library and they enable us to use I2C and GPIO pins. Next we import the sleep function from Time enabling us to pause the code. Finally we import the I2C library to interact with the LCD screen.from machine import I2C, Pin

3. Create an objecti2c to communicate with the LCD screen over the I2C protocol. Here we are using I2C channel 0, which maps SDA to GP0 and SCL to GP1.i2c = I2C(0, sda=Pin(0), scl=Pin(1), freq=400000)

4. Create a variableI2C_ADDR,which will store the first I2C address found when we scan the bus. As we only have one I2C device connected, we only need to see the first [0] address returned in the scan.I2C_ADDR = i2c.scan()[0]

5. Create an objectlcdto set up the I2C connection for the library. It tells the library what I2C pins we are using, set via the i2c object, the address of our screen, set via I2C_ADDRand finally it sets that we have a screen with two rows and 16 columns.lcd = I2cLcd(i2c, I2C_ADDR, 2, 16)

6. Create a loopto continually run the code, the first line in the loop will print the I2C address of our display to Thonny’s Python Shell.while True:

8. Write two lines of textto the screen. The first will print “I2C Address:” followed by the address stored inside the I2C_ADDR object. Then insert a new line character “\n” and then write another line saying “Tom’s Hardware" (or whatever you want it to say). Pause for two seconds to allow time to read the text.lcd.putstr("I2C Address:"+str(I2C_ADDR)+"\n")

9. Clear the screenbefore repeating the previous section of code, but this time we display the I2C address of the LCD display using its hex value. The PCF8574T chip used in the I2C backpack has two address, 0x20 and 0x27 and it is useful to know which it is using, especially if we are using multiple I2C devices as they may cause a clash on the bus.lcd.clear()

11. To flash the LED backlight, use a for loopthat will iterate ten times. It will turn on the backlight for 0.2 seconds, then turn it off for the same time. The “Backlight Test” text will remain on the screen even with the backlight off.for i in range(10):

12. Turn the backlight back onand then hide the cursor. Sometimes, a flashing cursor can detract from the information we are trying to communicate.lcd.backlight_on()

13. Create a for loopthat will print the number 0 to 19 on the LCD screen. Note that there is a 0.4 second delay before we delete the value and replace it with the next. We have to delete the text as overwriting the text will make it look garbled.for i in range(20):

Save and runyour code. As with any Python script in Thonny, Click on File >> Saveand save the file to your Raspberry Pi Pico. We recommend calling it i2c_lcd_test.py. When ready, click on the Green play buttonto start the code and watch as the test runs on the screen.

In this illustration we will going to wire the I2C or 2 wire connection in our Aruduino Board with the 16x2 Liquid Crystal Display, you can also use the 20x4 LCD, but on this de…

UtilitySmart Phone Link Display Audio (SDA) 7" Touchscreen, Tuner, Bluetooth, USB-Port, Compatible with Apple CarPlay and Android AutoSpeakers: 4Keyless Operation System (Engine Push Start)Remote Trunk Opener/Trunk lid SwitchRear View CameraWelcome Home LightComing Home Light

PerformanceFront Brakes: 14-inch Ventilated DiscRear Brakes: 8-inch Leading and Trailing Drums1.2-Liter 3 In-Line DOHC MIVEC Gasoline (3A92) Euro 4Fuel tank : Capacity 42LFront Suspension: MacPherson Strut Coil Spring with StabilizerRear Suspension: Torsion Beam185 / 55 R15 Tires15" Alloy WheelINVECS-III CVT

InteriorMulti-Information Display Monitor: (Drive Range, Fuel Consumption Meter, Service Reminder, Trip Meter and Outside Temperature)ECO LampRear Center Armrest: Equipped with cupholders x2

SafetyAnti-Lock Braking System (ABS)Electronic Brakeforce Distribution (EBD)Brake Override SystemImmobilizerFront SRS Airbags (Driver and Passenger)Front Seatbelts: 3P ELR with Pretensioner (Double for Driver, Single for Passenger)Rear Seatbelts: 3P ELR x3

Mitsubishi Motors Philippines Corporation (MMPC) places utmost importance and respects your right to privacy. MMPC shall handle with utmost care all personal and sensitive information that you may provide or those that we may collect from you upon your use of the website in accordance with our Privacy Policy. By closing this banner, scrolling this page or clicking any part of it, you hereby acknowledge that you have read and understood our Privacy Policy and expressly consent to it.

The library includes a bunch of examples, which you can load in the usual way, and one interesting thing about this library is that the backlight can be turned on or off, programmatically :)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey