sda in lcd module quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

What is the purpose of declaring LiquidCrystal_I2C lcd(0x27, 2, 1, 0, 4, 5, 6, 7, 3, POSITIVE); if we are using pins A4 and A5? I know that 0x27 is the ic address but what is the rest for?

there is a bit more but i"ll leave that for you to look into. in a more sophisticated IDE you normally can right click to a sub menu that will take you to the definition. it"s a great way to help you get a deeper understanding of how things work.0

I am getting a error while i m going to add zip file of lcd library error id this zip file does not contains a valid library please help me to resolve this issue as soon as possible.....

Hey guys. My LCD works fine using the above instructions (when replacing the existing LCD library in the Arduino directory) but I can"t get the backlight to ever switch off. Suggestions?

This article includes everything you need to know about using acharacter I2C LCD with Arduino. I have included a wiring diagram and many example codes to help you get started.

In the second half, I will go into more detail on how to display custom characters and how you can use the other functions of the LiquidCrystal_I2C library.

Once you know how to display text and numbers on the LCD, I suggest you take a look at the articles below. In these tutorials, you will learn how to measure and display sensor data on the LCD.

Makerguides.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to products on Amazon.com.

Each rectangle is made up of a grid of 5×8 pixels. Later in this tutorial, I will show you how you can control the individual pixels to display custom characters on the LCD.

They all use the same HD44780 Hitachi LCD controller, so you can easily swap them. You will only need to change the size specifications in your Arduino code.

The 16×2 and 20×4 datasheets include the dimensions of the LCD and you can find more information about the Hitachi LCD driver in the HD44780 datasheet.

Note that an Arduino Uno with the R3 layout (1.0 pinout) also has the SDA (data line) and SCL (clock line) pin headers close to the AREF pin. Check the table below for more details.

After you have wired up the LCD, you will need to adjust the contrast of the display. On the I2C module, you will find a potentiometer that you can turn with a small screwdriver.

The LiquidCrystal_I2C library works in combination with the Wire.h library which allows you to communicate with I2C devices. This library comes pre-installed with the Arduino IDE.

To install this library, go to Tools > Manage Libraries (Ctrl + Shift + I on Windows) in the Arduino IDE. The Library Manager will open and update the list of installed libraries.

*When using the latest version of the LiquidCrystal_I2C library it is no longer needed to include the wire.h library in your sketch. The other library imports wire.h automatically.

Note that counting starts at 0 and the first argument specifies the column. So lcd.setCursor(2,1) sets the cursor on the third column and the second row.

Next the string ‘Hello World!’ is printed with lcd.print("Hello World!"). Note that you need to place quotation marks (” “) around the text since we are printing a text string.

The example sketch above shows you the basics of displaying text on the LCD. Now we will take a look at the other functions of the LiquidCrystal_I2C library.

This function turns on automatic scrolling of the LCD. This causes each character output to the display to push previous characters over by one space.

I would love to know what projects you plan on building (or have already built) with these LCDs. If you have any questions, suggestions or if you think that things are missing in this tutorial, please leave a comment down below.

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

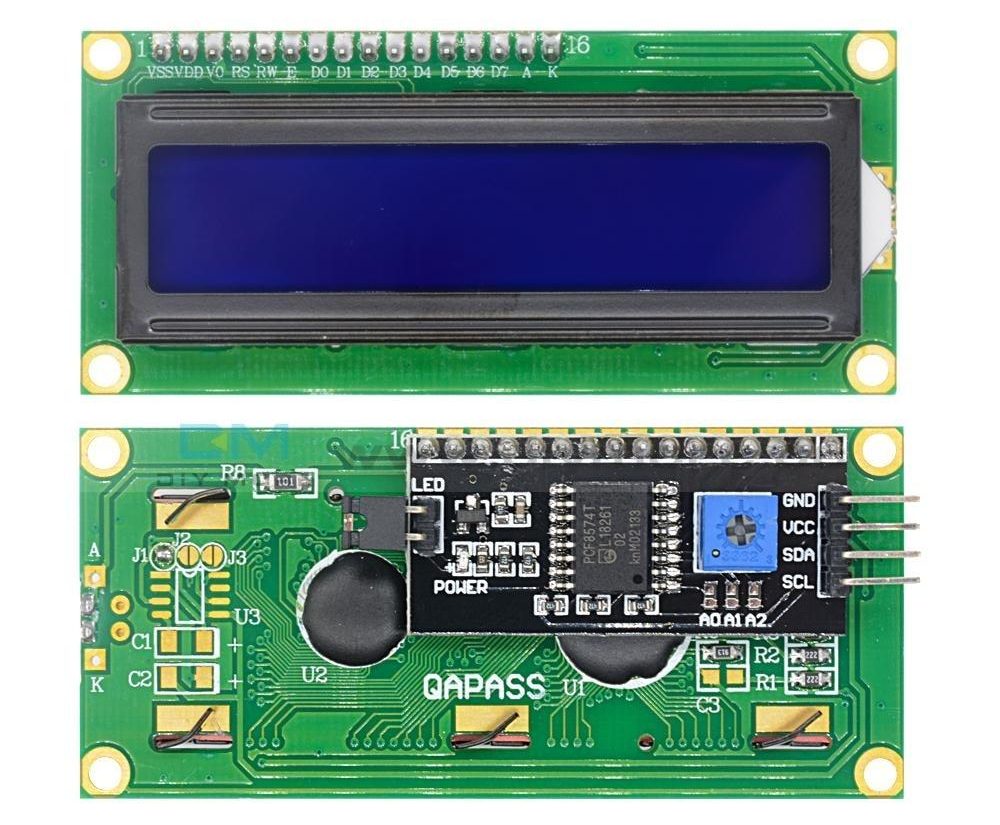

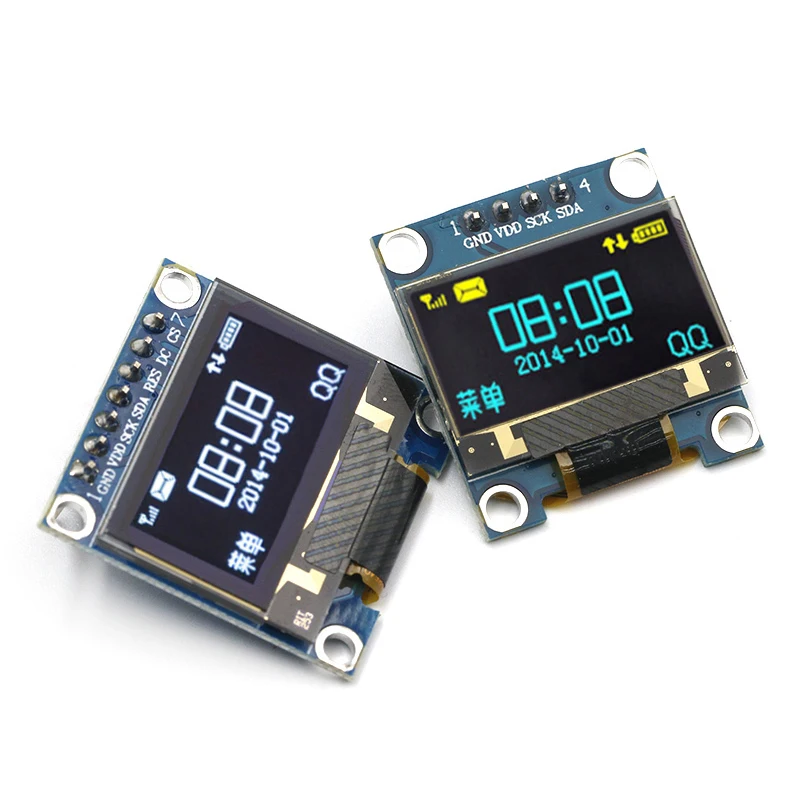

A few weeks ago, we examined the features of ESP32 module and built a simple hello world program to get ourselves familiar with the board. Today, we will continue our exploration of the ESP32 on a higher level as we will look at how to interface a 16×2 LCD with it.

Displays provide a fantastic way of providing feedback to users of any project and with the 16×2 LCD being one of the most popular displays among makers, and engineers, its probably the right way to start our exploration. For today’s tutorial, we will use an I2C based 16×2 LCD display because of the easy wiring it requires. It uses only four pins unlike the other versions of the display that requires at least 7 pins connected to the microcontroller board.

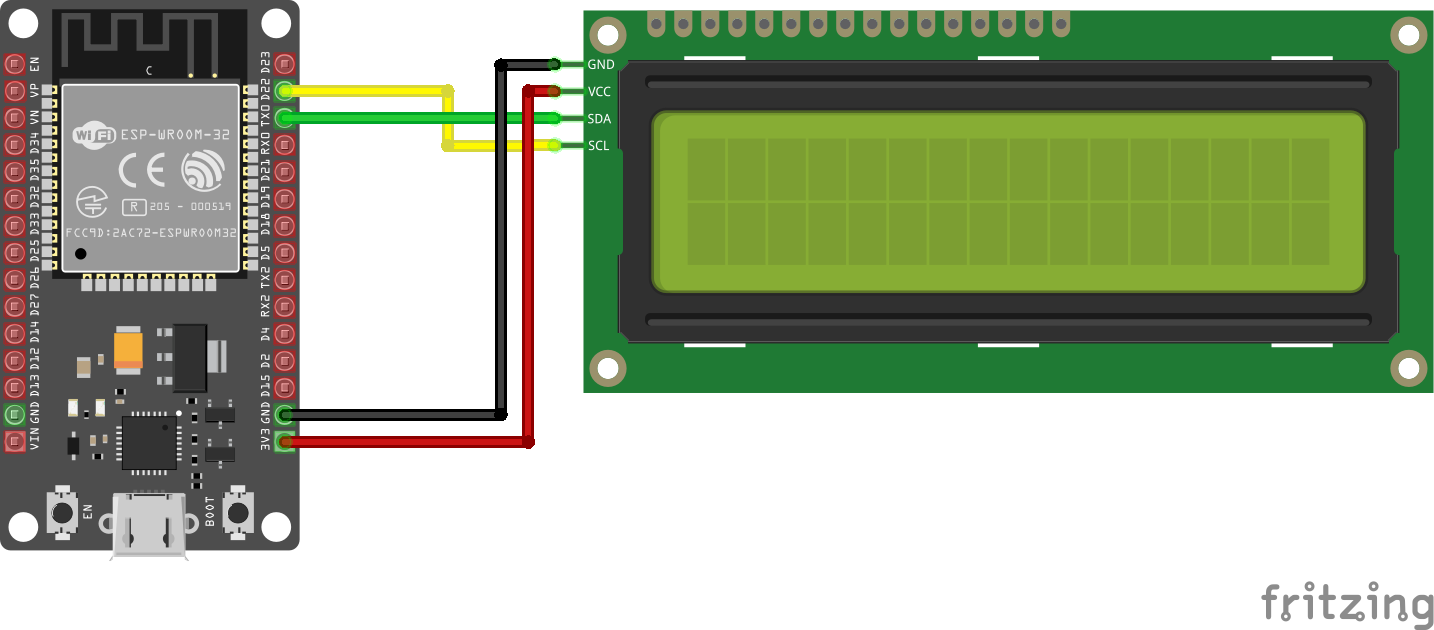

ESP32 comes in a module form, just like its predecessor, the ESP-12e, as a breakout board is usually needed to use the module. Thus when it’s going to be used in applications without a custom PCB, it is easier to use one of the development boards based on it. For today’s tutorial, we will use the DOIT ESP32 DevKit V1 which is one of the most popular ESP32 development boards.

The schematics for this project is relatively simple since we are connecting just the LCD to the DOIT Devkit v1. Since we are using I2C for communication, we will connect the pins of the LCD to the I2C pins of the DevKit. Connect the components as shown below.

Due to the power requirements of the LCD, it may not be bright enough when connected to the 3.3v pin of the ESP32. If that is the case, connect the VCC pin of the LCD to the Vin Pin of the ESP32 so it can draw power directly from the connected power source.

At this point, it is important to note that a special setup is required to enable you to use the Arduino IDE to program ESP32 based boards. We covered this in the introduction to ESP32 tutorial published a few weeks go. So, be sure to check it out.

To be able to easily write the code to interact with the I2C LCD display, we will use the I2C LCD library. The Library possesses functions and commands that make addressing the LCD easy. Download the I2C LCD library from the link attached and install on the Arduino IDE by simply extracting it into the Arduino’s library folder.

Before writing the code for the project, it’s important for us to know the I2C address of the LCD as we will be unable to talk to the display without it.

While some of the LCDs come with the address indicated on it or provided by the seller, in cases where this is not available, you can determine the address by using a simple sketch that sniffs the I2C line to detect what devices are connected alongside their address. This sketch is also a good way to test the correctness of your wiring or to determine if the LCD is working properly.

This sketch basically uses a “for” loop to generate a list of addresses and then sends a begin transmission request to the address. The return value of the Write.endTransmission() function shows if a device exists on that particular address. The address at which a response was received is the address we are a looking for.

If you keep getting “no devices found”, it might help to take a look at the connections to be sure you didn’t mix things up and you could also go ahead and try 0x27 as the I2C address. This is a common address for most I2C LCD modules from China.

Our task for today’s tutorial is to display both static and scrolling text on the LCD, and to achieve that, we will use the I2C LCD library to reduce the amount of code we need to write. We will write two separate sketches; one to displaystatic textsand the other to display both static and scrolling text.

To start with the sketch for static text display, we start the code by including the library to be used for it, which in this case, is the I2C LCD library.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

With that done, we proceed to the void setup() function. Here we initialize the display and issue the command to turn the backlight on as it might be off by default depending on the LCD.

Next is the void loop() function. The idea behind the code for the loop is simple, we start by setting the cursor to the column and row of the display where we want the text to start from, and we proceed to display the text using the lcd.print() function. To allow the text to stay on the screen for a while (so its visible) before the loop is reloaded, we delay the code execution for 1000ms.

For the scrolling text, we will use some code developed by Rui Santos of RandomNerdTutorials.com. This code allows the display of static text on the first row and scrolling text on the second row of the display at the same time.

Next, we create an instance of the I2C LCD library class with the address of the display, the number of columns the display has (16 in this case), and the number of rows (2 in this case) as arguments.

Next, we create the function to display scrolling text. The function accepts four arguments; the row on which to display the scrolling text, the text to be displayed, the delay time between the shifting of characters, and the number of columns of the LCD.

Next is the void setup() function. The function stays the same as the one for the static text display as we initialize the display and turn on the backlight.

With that done, we move to the void loop() function. We start by setting the cursor, then we use the print function to display the static text and the scrollText() function is called to display the scrolling text.

Ensure your connections are properly done, connect the DOIT Devkit to your PC and upload either of the two sketches. You should see this display come up with the text as shown in the image below.

That’s it for today’s tutorial guys. Thanks for following this tutorial. This cheap LCD display provides a nice way of providing visual feedback for your project and even though the size of the screen and the quality of the display is limited, with the scrolling function you can increase the amount of text/characters that can be displayed.

Should have seen that you said I2C! You need to use the I2C display selection, not the 4bit selection. You also need to make sure you have the correct version of the LiquidCrystal_I2C with no conflicting named libraries. Get it here…

https://bitbucket.org/fmalpartida/new-liquidcrystal/downloads/ or use the Arduino IDE’s Library Manager to download Bill Perry’s “hd44780” library. The latter will get auto-updated and it searches for the I2C address making configuration easier.

Using a Liquid Crystal Display or LCD is a great and cheap way to add monitoring capabilities to your Arduino projects. It’s a very handy way to get feedback on what’s happening with your project. Many appliances and gadgets are using LCDs to communicate with the end-users. It is used in many useful applications such as digital thermometers, cash registers, calculators, and so many more.

LCD (Liquid Crystal Display) is a type of flat panel display which uses liquid crystals to form characters through a set of instructions or code. The liquid crystals in an LCD produce an image using a backlight.

I2C (IIC) means inter-integrated communication protocol. This is usually used to communicate between one master and multiple slaves. This setup eliminates the need for having to use many digital pins in the Arduino board. I2C is a serial communication protocol, so data is transferred bit by bit along a single wire (the SDA line).

You will know that your LCD has I2C because you will see pins labeled SDA and SCL. These are the connections going to the Arduino board:I2C PINS ARDUINO BOARD

Libraries are ready-mode codes that you just need to include in your Arduino sketch in order for your LCD to work. The LCD module I’m using is a generic 16x2 LCD with I2C. I have tried to include several libraries but I keep receiving errors. After many trials, I was able to make it work using 2 libraries, the LiquidCrystal_V1.2.1 library, and the Wire library. You can download these files at the bottom of this page.

Step 3. Browse to where you saved the zip files and select one file at a time, then click Open. In this case, we select the LiquidCrystal_V1.2.1 zip file first.

Now that you have installed the libraries, you are now ready to make your first LCD project. For your first project, let’s have the inevitable "Hello World!" project which simply displays the text Hello World! on the LCD.

The LiquidCrystal_I2C() function sets the pins the Arduino uses to connect to the LCD. You can use any of Arduino’s digital pins to control the LCD. Also, in this function, you need to specify the name of your LCD module, in this case, the name is LCD.

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program.

This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program. In this case, the cursor is placed at the first column, first row. Remember that the column is written first before the row. 0 means the first column and the second 0 means the first row.

This function is used to print text to the LCD. It can be used in the void setup() sections or the void loop() section of the program. The text enclosed inside the double quotes is exactly what will be displayed.

This simply waits for 1 second before the next set of text is displayed. The delay here also produces a nice fading effect. This is completely optional.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

In addition, there is a jumper on the board that supplies power to the backlight. To control the intensity of the backlight, you can remove the jumper and apply external voltage to the header pin that is marked ‘LED’.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1 and A2) are placed at the end of the 7-bit I2C address register.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x20. The range of all possible addresses spans from 0x20 to 0x27. Please see the illustration below.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1 and A2) are also placed at the end of the 7-bit I2C address register. But the other bits in the address register are different.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x38. The range of all possible addresses spans from 0x38 to 0x3F. Please see the illustration below.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

To install the library navigate to Sketch > Include Libraries > Manage Libraries… Wait for Library Manager to download the library index and update the list of installed libraries.

Filter your search by typing ‘liquidcrystal‘. There should be some entries. Look for the LiquidCrystal I2C library by Frank de Brabander. Click on that entry, and then select Install.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

To use createChar() you first set up an array of 8 bytes. Each byte in the array represents a row of characters in a 5×8 matrix. Whereas, 0 and 1 in a byte indicate which pixel in the row should be ON and which should be OFF.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

Your imagination is limitless. The only limitation is that the LiquidCrystal library only supports eight custom characters. But don’t be discouraged, look at the bright side, at least we have eight characters.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

Let’s examine the Heart[8] array as an example. You can see how the bits (0s and 1s) are forming a heart shape. 0 turns the pixel off and 1 turns the pixel on.

In setup, a custom character is created using the createChar() function. This function takes two parameters. The first parameter is a number between 0 and 7 to reserve one of the 8 supported custom characters. The second is the name of the array.

I have problems with teensy 3.1 and I2C serial lcd adapter. The adapter has a PCF8574P mounted on it and I"m trying to execute a simple software thai initialize the lcd and prints the hello world. I"m using also LiquidCrystal_I2C 1.1 library.

I don"t know why, but when the code arrives to lcd.init(), the sketch doesn"t continue (i put a blink before and after the init). The code works well on arduino.

So, what is the problem? I tried also with 4.7kohm pullup resistor from sda and scl to gnd but nothing. I tried also with 3.3v instead of 5v but nothing.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this tutorial, you will see how to connect i2c LCD display (Liquid Crystal Display) to Arduino using the i2c module. Before starting this article we will see what is i2c. I2C (I-square-C i.e IIC) means inter-integrated communication protocol. This is usually used to communicate between one master and multiple slaves. One of the best things about using I2C is we can reduce the connections (wiring). If you use normal LCD display, you need a total number of connections are 12. If you use I2C LCD display, you need only just 4 connection. By seeing the example you may know the advantage of I2C protocol. I2C protocol is also known as 2 line protocol.

Of course it is very wasteful on our Digital Pin on Arduino, to overcome this problem we need an I2C LCD that works like the Shift Register so that the interface pins can be less.

I2c LCD Backpack Module has 16pin Output that can be connected with LCD pins 1602/2004 directly (permanently soldered) and has 4pin inputs (VCC, GND, SDA, SCL) .

The Mx-O-SDA-S-6D237 from Mobotix is a 6MP day sensor module with B237 Lens contains a B237 lens and image sensor and is compatible with MOBOTIX DualDome camera modules to deliver up to 3072 x 2048 (6MP) resolution.

I2C (Inter-Integrated Circuit, eye-squared-C), alternatively known as I2C or IIC, is a synchronous, multi-controller/multi-target (master/slave), packet switched, single-ended, serial communication bus invented in 1982 by Philips Semiconductors. It is widely used for attaching lower-speed peripheral ICs to processors and microcontrollers in short-distance, intra-board communication.

Several competitors, such as Siemens, NEC, Texas Instruments, STMicroelectronics, Motorola,Nordic Semiconductor and Intersil, have introduced compatible I2C products to the market since the mid-1990s.

System Management Bus (SMBus), defined by Intel in 1995, is a subset of I2C, defining a stricter usage. One purpose of SMBus is to promote robustness and interoperability. Accordingly, modern I2C systems incorporate some policies and rules from SMBus, sometimes supporting both I2C and SMBus, requiring only minimal reconfiguration either by commanding or output pin use.

Describing connectable devices via small ROM configuration tables to enable plug and play operation, such as in serial presence detect (SPD) EEPROMs on dual in-line memory modules (DIMMs), and Extended Display Identification Data (EDID) for monitors via VGA, DVI and HDMI connectors.

A particular strength of I2C is the capability of a microcontroller to control a network of device chips with just two general-purpose I/O pins and software. Many other bus technologies used in similar applications, such as Serial Peripheral Interface Bus (SPI), require more pins and signals to connect multiple devices.

Note that the bit rates are quoted for the transfers between controller (master) and target (slave) without clock stretching or other hardware overhead. Protocol overheads include a target address and perhaps a register address within the target device, as well as per-byte ACK/NACK bits. Thus the actual transfer rate of user data is lower than those peak bit rates alone would imply. For example, if each interaction with a target inefficiently allows only 1 byte of data to be transferred, the data rate will be less than half the peak bit rate.

The number of nodes which can exist on a given I2C bus is limited by the address space and also by the total bus capacitance of 400 pF, which restricts practical communication distances to a few meters. The relatively high impedance and low noise immunity requires a common ground potential, which again restricts practical use to communication within the same PC board or small system of boards.

In addition to 0 and 1 data bits, the I2C bus allows special START and STOP signals which act as message delimiters and are distinct from the data bits. (This is in contrast to the start bits and stop bits used in asynchronous serial communication, which are distinguished from data bits only by their timing.)

The controller is initially in controller transmit mode by sending a START followed by the 7-bit address of the target it wishes to communicate with, which is finally followed by a single bit representing whether it wishes to write (0) to or read (1) from the target.

If the target exists on the bus then it will respond with an ACK bit (active low for acknowledged) for that address. The controller then continues in either transmit or receive mode (according to the read/write bit it sent), and the target continues in the complementary mode (receive or transmit, respectively).

The address and the data bytes are sent most significant bit first. The start condition is indicated by a high-to-low transition of SDA with SCL high; the stop condition is indicated by a low-to-high transition of SDA with SCL high. All other transitions of SDA take place with SCL low.

If the controller wishes to write to the target, then it repeatedly sends a byte with the target sending an ACK bit. (In this situation, the controller is in controller transmit mode, and the target is in target receive mode.)

If the controller wishes to read from the target, then it repeatedly receives a byte from the target, the controller sending an ACK bit after every byte except the last one. (In this situation, the controller is in controller receive mode, and the target is in target transmit mode.)

An I2C transaction may consist of multiple messages. The controller terminates a message with a STOP condition if this is the end of the transaction or it may send another START condition to retain control of the bus for another message (a "combined format" transaction).

In a combined transaction, each read or write begins with a START and the target address. The START conditions after the first are also called repeated START bits. Repeated STARTs are not preceded by STOP conditions, which is how targets know that the next message is part of the same transaction.

Pure I2C systems support arbitrary message structures. SMBus is restricted to nine of those structures, such as read word N and write word N, involving a single target. PMBus extends SMBus with a Group protocol, allowing multiple such SMBus transactions to be sent in one combined message. The terminating STOP indicates when those grouped actions should take effect. For example, one PMBus operation might reconfigure three power supplies (using three different I2C target addresses), and their new configurations would take effect at the same time: when they receive that STOP.

With only a few exceptions, neither I2C nor SMBus define message semantics, such as the meaning of data bytes in messages. Message semantics are otherwise product-specific. Those exceptions include messages addressed to the I2C general call address (0x00) or to the SMBus Alert Response Address; and messages involved in the SMBus Address Resolution Protocol (ARP) for dynamic address allocation and management.

In practice, most targets adopt request-response control models, where one or more bytes following a write command are treated as a command or address. Those bytes determine how subsequent written bytes are treated or how the target responds on subsequent reads. Most SMBus operations involve single-byte commands.

One specific example is the 24C32 type EEPROM, which uses two request bytes that are called Address High and Address Low. (Accordingly, these EEPROMs are not usable by pure SMBus hosts, which support only single-byte commands or addresses.) These bytes are used for addressing bytes within the 32 kbit (or 4 kB) EEPROM address space. The same two-byte addressing is also used by larger EEPROMs, like the 24C512 which stores 512 kbits (or 64 kB). Writing data to and reading from these EEPROMs uses a simple protocol: the address is written, and then data is transferred until the end of the message. The data transfer part of the protocol can cause trouble on the SMBus, since the data bytes are not preceded by a count, and more than 32 bytes can be transferred at once. I2C EEPROMs smaller than 32 kbit, like the 2 kbit 24C02, are often used on the SMBus with inefficient single-byte data transfers to overcome this problem.

A single message writes to the EEPROM. After the START, the controller sends the chip"s bus address with the direction bit clear (write), then sends the two-byte address of data within the EEPROM and then sends data bytes to be written starting at that address, followed by a STOP. When writing multiple bytes, all the bytes must be in the same 32-byte page. While it is busy saving those bytes to memory, the EEPROM will not respond to further I2C requests. (That is another incompatibility with SMBus: SMBus devices must always respond to their bus addresses.)

To read starting at a particular address in the EEPROM, a combined message is used. After a START, the controller first writes that chip"s bus address with the direction bit clear (write) and then the two bytes of EEPROM data address. It then sends a (repeated) START and the EEPROM"s bus address with the direction bit set (read). The EEPROM will then respond with the data bytes beginning at the specified EEPROM data address — a combined message: first a write, then a read. The controller issues an ACK after each read byte except the last byte, and then issues a STOP. The EEPROM increments the address after each data byte transferred; multi-byte reads can retrieve the entire contents of the EEPROM using one combined message.

At the physical layer, both SCL and SDA lines are an open-drain (MOSFET) or open-collector (BJT) bus design, thus a pull-up resistor is needed for each line. A logic "0" is output by pulling the line to ground, and a logic "1" is output by letting the line float (output high impedance) so that the pull-up resistor pulls it high. A line is never actively driven high. This wiring allows multiple nodes to connect to the bus without short circuits from signal contention. High-speed systems (and some others) may use a current source instead of a resistor to pull-up only SCL or both SCL and SDA, to accommodate higher bus capacitance and enable faster rise times.

An important consequence of this is that multiple nodes may be driving the lines simultaneously. If any node is driving the line low, it will be low. Nodes that are trying to transmit a logical one (i.e. letting the line float high) can detect this and conclude that another node is active at the same time.

When used on SCL, this is called clock stretching and is a flow-control mechanism for targets. When used on SDA, this is called arbitration and ensures that there is only one transmitter at a time.

When idle, both lines are high. To start a transaction, SDA is pulled low while SCL remains high. It is illegal: 14 to transmit a stop marker by releasing SDA to float high again (although such a "void message" is usually harmless), so the next step is to pull SCL low.

Except for the start and stop signals, the SDA line only changes while the clock is low; transmitting a data bit consists of pulsing the clock line high while holding the data line steady at the desired level.

While SCL is low, the transmitter (initially the controller) sets SDA to the desired value and (after a small delay to let the value propagate) lets SCL float high. The controller then waits for SCL to actually go high; this will be delayed by the finite rise time of the SCL signal (the RC time constant of the pull-up resistor and the parasitic capacitance of the bus) and may be additionally delayed by a target"s clock stretching.

Once SCL is high, the controller waits a minimum time (4 μs for standard-speed I2C) to ensure that the receiver has seen the bit, then pulls it low again. This completes transmission of one bit.

After every 8 data bits in one direction, an "acknowledge" bit is transmitted in the other direction. The transmitter and receiver switch roles for one bit, and the original receiver transmits a single "0" bit (ACK) back. If the transmitter sees a "1" bit (NACK) instead, it learns that:

(If controller transmitting to target) The target is unable to accept the data. No such target, command not understood, or unable to accept any more data.

One of the more significant features of the I2C protocol is clock stretching. An addressed target device may hold the clock line (SCL) low after receiving (or sending) a byte, indicating that it is not yet ready to process more data. The controller that is communicating with the target may not finish the transmission of the current bit, but must wait until the clock line actually goes high. If the target is clock-stretching, the clock line will still be low (because the connections are open-drain). The same is true if a second, slower, controller tries to drive the clock at the same time. (If there is more than one controller, all but one of them will normally lose arbitration.)

The controller must wait until it observes the clock line going high, and an additional minimal time (4 μs for standard 100 kbit/s I2C) before pulling the clock low again.

Although the controller may also hold the SCL line low for as long as it desires (this is not allowed since Rev. 6 of the protocol – subsection 3.1.1), the term "clock stretching" is normally used only when targets do it. Although in theory any clock pulse may be stretched, generally it is the intervals before or after the acknowledgment bit which are used. For example, if the target is a microcontroller, its I2C interface could stretch the clock after each byte, until the software decides whether to send a positive acknowledgment or a NACK.

Clock stretching is the only time in I2C where the target drives SCL. Many targets do not need to clock stretch and thus treat SCL as strictly an input with no circuitry to drive it. Some controllers, such as those found inside custom ASICs may not support clock stretching; often these devices will be labeled as a "two-wire interface" and not I2C.

To ensure a minimal bus throughput, SMBus places limits on how far clocks may be stretched. Hosts and targets adhering to those limits cannot block access to the bus for more than a short time, which is not a guarantee made by pure I2C systems.

Every controller monitors the bus for start and stop bits and does not start a message while another controller is keeping the bus busy. However, two controllers may start transmission at about the same time; in this case, arbitration occurs. Target transmit mode can also be arbitrated, when a controller addresses multiple targets, but this is less common. In contrast to protocols (such as Ethernet) that use random back-off delays before issuing a retry, I2C has a deterministic arbitration policy. Each transmitter checks the level of the data line (SDA) and compares it with the levels it expects; if they do not match, that transmitter has lost arbitration and drops out of this protocol interaction.

If one transmitter sets SDA to 1 (not driving a signal) and a second transmitter sets it to 0 (pull to ground), the result is that the line is low. The first transmitter then observes that the level of the line is different from that expected and concludes that another node is transmitting. The first node to notice such a difference is the one that loses arbitration: it stops driving SDA. If it is a controller, it also stops driving SCL and waits for a STOP; then it may try to reissue its entire message. In the meantime, the other node has not noticed any difference between the expected and actual levels on SDA and therefore continues transmission. It can do so without problems because so far the signal has been exactly as it expected; no other transmitter has disturbed its message.

If the two controllers are sending a message to two different targets, the one sending the lower target address always "wins" arbitration in the address stage. Since the two controllers may send messages to the same target address, and addresses sometimes refer to multiple targets, arbitration must sometimes continue into the data stages.

Arbitration occurs very rarely, but is necessary for proper multi-controller support. As with clock stretching, not all devices support arbitration. Those that do, generally label themselves as supporting "multi-controller" communication.

One case which must be handled carefully in multi-controller I2C implementations is that of the controllers talking to each other. One controller may lose arbitration to an incoming message, and must change its role from controller to target in time to acknowledge its own address.

In the extremely rare case that two controllers simultaneously send identical messages, both will regard the communication as successful, but the target will only see one message. For this reason, when a target can be accessed by multiple controllers, every command recognized by the target either must be idempotent or must be guaranteed never to be issued by two controllers at the same time. (For example, a command which is issued by only one controller need not be idempotent, nor is it necessary for a specific command to be idempotent when some mutual exclusion mechanism ensures that only one controller can be caused to issue that command at any given time.)

While I2C only arbitrates between controllers, SMBus uses arbitration in three additional contexts, where multiple targets respond to the controller, and one gets its message through.

Although conceptually a single-controller bus, a target device that supports the "host notify protocol" acts as a controller to perform the notification. It seizes the bus and writes a 3-byte message to the reserved "SMBus Host" address (0x08), passing its address and two bytes of data. When two targets try to notify the host at the same time, one of them will lose arbitration and need to retry.

An alternative target notification system uses the separate SMBALERT# signal to request attention. In this case, the host performs a 1-byte read from the reserved "SMBus Alert Response Address" (0x0C), which is a kind of broadcast address. All alerting targets respond with a data bytes containing their own address. When the target successfully transmits its own address (winning arbitration against others) it stops raising that interrupt. In both this and the preceding case, arbitration ensures that one target"s message will be received, and the others will know they must retry.

SMBus also supports an "address resolution protocol", wherein devices return a 16-byte "universal device ID" (UDID). Multiple devices may respond; the one with the lowest UDID will win arbitration and be recognized.

There are several possible operating modes for I2C communication. All are compatible in that the 100 kbit/s standard mode may always be used, but combining devices of different capabilities on the same bus can cause issues, as follows:

Fast mode is highly compatible and simply tightens several of the timing parameters to achieve 400 kbit/s speed. Fast mode is widely supported by I2C target devices, so a controller may use it as long as it knows that the bus capacitance and pull-up strength allow it.

Fast mode plus achieves up to 1 Mbit/s using more powerful (20 mA) drivers and pull-ups to achieve faster rise and fall times. Compatibility with standard and fast mode devices (with 3 mA pull-down capability) can be achieved if there is some way to reduce the strength of the pull-ups when talking to them.

High speed mode (3.4 Mbit/s) is compatible with normal I2C devices on the same bus, but requires the controller have an active pull-up on the clock line which is enabled during high speed transfers. The first data bit is transferred with a normal open-drain rising clock edge, which may be stretched. For the remaining seven data bits, and the ACK, the controller drives the clock high at the appropriate time and the target may not stretch it. All high-speed transfers are preceded by a single-byte "controller code" at fast or standard speed. This code serves three purposes:

Ultra-Fast mode is essentially a write-only I2C subset, which is incompatible with other modes except in that it is easy to add support for it to an existing I2C interface hardware design. Only one controller is permitted, and it actively drives data lines at all times to achieve a 5 Mbit/s transfer rate. Clock stretching, arbitration, read transfers, and acknowledgements are all omitted. It is mainly intended for animated LED displays where a transmission error would only cause an inconsequential brief visual glitch. The resemblance to other I2C bus modes is limited to:

In all modes, the clock frequency is controlled by the controller(s), and a longer-than-normal bus may be operated at a slower-than-nominal speed by underclocking.

I2C is popular for interfacing peripheral circuits to prototyping systems, such as the Arduino and Raspberry Pi. I2C does not employ a standardized connector, however, board designers have created various wiring schemes for I2C interconnections. To minimize the possible damage due to plugging 0.1-inch headers in backwards, some developers have suggested using alternating signal and power connections of the following wiring schemes: (GND, SCL, VCC, SDA) or (VCC, SDA, GND, SCL).

The vast majority of applications use I2C in the way it was originally designed—peripheral ICs directly wired to a processor on the same printed circuit board, and therefore over relatively short distances of less than 1 foot (30 cm), without a connector. However using a differential driver, an alternate version of I2C can communicate up to 20 meters (possibly over 100 meters) over CAT5 or other cable.

the 10-pin iPack connector carries I2C;6P6C Lego Mindstorms NXT connector carries I2C;Ethernet physical layer to instead carry differential-encoded I2C signals2C signals;HDMI and most DVI and VGA connectors carry DDC2 data over I2C.

When there are many I2C devices in a system, there can be a need to include bus buffers or multiplexers to split large bus segments into smaller ones. This can be necessary to keep the capacitance of a bus segment below the allowable value or to allow multiple devices with the same address to be separated by a multiplexer. Many types of multiplexers and buffers exist and all must take into account the fact that I2C lines are specified to be bidirectional. Multiplexers can be implemented with analog switches, which can tie one segment to another. Analog switches maintain the bidirectional nature of the lines but do not isolate the capacitance of one segment from another or provide buffering capability.

Buffers can be used to isolate capacitance on one segment from another and/or allow I2C to be sent over longer cables or traces. Buffers for bi-directional lines such as I2C must use one of several schemes for preventing latch-up. I2C is open-drain, so buffers must drive a low on one side when they see a low on the other. One method for preventing latch-up is for a buffer to have carefully selected input and output levels such that the output level of its driver is higher than its input threshold, preventing it from triggering itself. For example, a buffer may have an input threshold of 0.4 V for detecting a low, but an output low level of 0.5 V. This method requires that all other devices on the bus have thresholds which are compatible and often means that multiple buffers implementing this scheme cannot be put in series with one another.

Alternatively, other types of buffers exist that implement current amplifiers or keep track of the state (i.e. which side drove the bus low) to prevent latch-up. The state method typically means that an unintended pulse is created during a hand-off when one side is driving the bus low, then the other drives it low, then the first side releases (this is common during an I2C acknowledgement).

Advantages are using targets devices with the same address at the same time and saving connections or a faster throughput by using several data lines at the same time.

SMBus reserves some additional addresses. In particular, 0001 000 is reserved for the SMBus host, which may be used by controller-capable devices, 0001 100 is the "SMBus alert response address" which is polled by the host after an out-of-band interrupt, and 1100 001 is the default address which is initially used by devices capable of dynamic address assignment.

Although MSB 1111 is reserved for Device ID and 10-bit target (slave) addressing, it is also used by VESA DDC display dependent devices such as pointing devices.

An I2C transaction consists of one or more messages. Each message begins with a start symbol, and the transaction ends with a stop symbol. Start symbols after the first, which begin a message but not a transaction, are referred to as repeated start symbols.

Each message is a read or a write. A transaction consisting of a single message is called either a read or a write transaction. A transaction consisting of multiple messages is called a combined transaction. The most common form of the latter is a write message providing intra-device address information, followed by a read message.

Many I2C devices do not distinguish between a combined transaction and the same messages sent as separate transactions, but not all. The device ID protocol requires a single transaction; targets are forbidden from responding if they observe a stop symbol. Configuration, calibration or self-test modes which cause the target to respond unusually are also often automatically terminated at the end of a transaction.

The data is sampled (received) when SCL rises for the first bit (B1). For a bit to be valid, SDA must not change between a rising edge of SCL and the subsequent falling edge (the entire green bar time).

In order to avoid false marker detection, there is a minimum delay between the SCL falling edge and changing SDA, and between changing SDA and the SCL rising edge. Note that an I2C message containing n data bits (including acknowledges) contains n + 1 clock pulses.

I2C lends itself to a "bus driver" software design. Software for attached devices is written to call a "bus driver" that handles the actual low-level I2C hardware. This permits the driver code for attached devices to port easily to other hardware, including a bit-banging design.

Below is an example of bit-banging the I2C protocol as an I2C controller (master). The example is written in pseudo C. It illustrates all of the I2C features described before (clock stretching, arbitration, start/stop bit, ack/nack).

Since OpenBSD 3.9 (released 1 May 2006; 16 years ago(2006-05-01)), a central i2c_scan subsystem probes all possible sensor chips at once during boot, using an ad hoc weighting scheme and a local caching function for reading register values from the I2C targets;general-purpose off-the-shelf i386/amd64 hardware during boot without any configuration by the user nor a noticeable probing delay; the matching procedures of the individual drivers then only has to rely on a string-based "friendly-name" for matching;2C sensor drivers are automatically enabled by default in applicable architectures without ill effects on stability; individual sensors, both I2C and otherwise, are exported to the userland through the sysctl hw.sensors framework. As of March 20192C that export some kind of a sensor through the hw.sensors framework, and the majority of these drivers are fully enabled by default in i386/amd64 GENERIC kernels of OpenBSD.

In NetBSD, over two dozen I2C target devices exist that feature hardware monitoring sensors, which are accessible through the sysmon envsys framework as property lists. On general-purpose hardware, each driver has to do its own probing, hence all drivers for the I2C targets are disabled by default in NetBSD in GENERIC i386/amd64 builds.

In Linux, I2C is handled with a device driver for the specific device, and another for the I2C (or SMBus) adapter to which it is connected. Hundreds of such drivers are part of current Linux kernel releases.

In Mac OS X, there are about two dozen I2C kernel extensions that communicate with sensors for reading voltage, current, temperature, motion, and other physical status.

In Microsoft Windows, I2C is implemented by the respective device drivers of much of the industry"s available hardware. For HID embedded/SoC devices, Windows 8 and later have an integrated I²C bus driver.

There are a number of I2C host adapter hardware solutions for making a I2C controller or target connection to host computers, running Linux, Mac or Windows. Most options are USB-to-I2C adapters. Not all of them require proprietary drivers or APIs.

I2C protocol analyzers are tools that sample an I2C bus and decode the electrical signals to provide a higher-level view of the data being transmitted on the bus.

When developing and/or troubleshooting the I2C bus, examination of hardware signals can be very important. Logic analyzers are tools that collect, analyze, decode, and store signals, so people can view the high-speed waveforms at their leisure. Logic analyzers display time stamps of each signal level change, which can help find protocol problems. Most logic analyzers have the capability to decode bus signals into high-level protocol data and show ASCII data.

On low-power systems, the pull-up resistors can use more power than the entire rest of the design combined. On these, the resistors are often powered by a switchable voltage source, such as a DIO from a microcontroller. The pull-ups also limit the speed of the bus and have a small additional cost. Therefore, some designers are turning to other serial buses, e.g. I3C or SPI, that do not need pull-ups.

The assignment of target addresses is a weakness of I2C. Seven bits is too few to prevent address collisions between the many thousands of available devices. What alleviates the issue of address collisions between different vendors and also allows to connect to several identical devices is that manufacturers dedicate pins that can be used to set the target address to one of a few address options per device. Two or three pins is typical, and with many devices, there are three or more wiring options per address pin.

Automatic bus configuration is a related issue. A given address may be used by a number of different protocol-incompatible devices in various systems, and hardly any device types can be detected at runtime. For example, 0x51 may be used by a 24LC02 or 24C32 EEPROM, with incompatible addressing; or by a PCF8563 RTC, which cannot reliably be distinguished from either (without changing device state, which might not be allowed). The only reliable configuration mechanisms available to hosts involve out-of-band mechanisms such as tables provided by system firmware, which list the available devices. Again, this issue can partially be addressed by ARP in SMBus systems, especially when vendor and product identifiers are used; but that has not really caught on. The Rev. 3 version of the I2C specification adds a device ID mechanism.

I2C supports a limited range of speeds. Hosts supporting the multi-megabit speeds are rare. Support for the Fm+ 1 Mbit/s speed is more widespread, since its electronics are simple variants of what is used at lower speeds. Many devices do not support the 400 kbit/s speed (in part because SMBus does not yet support it). I2C nodes implemented in software (instead of dedicated hardware) may not even support the 100 kbit/s speed; so the whole range defined in the specification is rarely usable. All devices must at least partially support the highest speed used or they may spuriously detect their device address.

Devices are allowed to stretch clock cycles to suit their particular needs, which can starve bandwidth needed by faster devices and increase latencies when talking to other device addresses. Bus capacitance also places a limit on the transfer speed, especially when current sources are not used to decrease signal rise times.

Because I2C is a shared bus, there is the potential for any device to have a fault and hang the entire bus. For example, if any device holds the SDA or SCL line low, it prevents the controller from sending START or STOP commands to reset the bus. Thus it is common for designs to include a reset signal that provides an external method of resetting the bus devices. However many devices do not have a dedicated reset pin, forcing the designer to put in circuitry to allow devices to be power-cycled if they need to be reset.

Because of these limits (address management, bus configuration, potential faults, speed), few I2C bus segments have even a dozen devices. It is common for systems to have several such segments. One might be dedicated to use with high-speed devices, for low-latency power management. Another might be used to control a few devices where latency and throughput are not important issues; yet another segment might be used only to read EEPROM chips describing add-on cards (such as the SPD standard used with DRAM sticks).

I2C is the basis for the ACCESS.bus, the VESA Display Data Channel (DDC) interface, the System Management Bus (SMBus), Power Management Bus (PMBus) and the Intelligent Platform Management Bus (IPMB, one of the protocols of IPMI). These variants have differences in voltage and clock frequency ranges, and may have interrupt lines.

High-availability systems (AdvancedTCA, MicroTCA) use 2-way redundant I2C for shelf management. Multi-controller I2C capability is a requirement in these systems.

TWI (Two-Wire Interface) or TWSI (Two-Wire Serial Interface) is essentially the same bus implemented on various system-on-chip processors from Atmel and other vendors.2C is not a registered trademark as of 2014-11-07.2C have now lapsed.Microchip Technology, TWI and I2C have a few differences. One of them is that TWI does not support START byte.

In some cases, use of the term "two-wire interface" indicates incomplete implementation of the I2C specification. Not supporting arbitration or clock stretching is one common limitation, which is still useful for a single controller communicating with simple targets that never stretch the clock.

US Patent 4689740, "Two-Wire Bus-System Comprising A Clock Wire And A Data Wire For Interconnecting A Number Of Stations", issued 1987-08-25, assigned to U.S. Philips Corporation

"8-Kbit serial I2C bus EEPROM (PDF)" (PDF). STMicroelectronics. October 2017. Archived (PDF) from the original on 2019-10-18. Retrieved 19 November 2019.

Using The ZONE_READ And ZONE_WRITE Protocols (PDF) (Application Note). Revision 1.0.1. System Management Interface Forum. 2016-01-07. AN001. Archived (PDF) from the original on 2017-09-22.

Ferrari, Mario; Ferrari, Giulio (2018-04-29). Building Robots with LEGO Mindstorms NXT. pp. 63–64. ISBN 9780080554334. Archived from the original on 2018-04-29.

Gasperi, Michael; Hurbain, Philippe (2010), "Chapter 13: I2C Bus Communication", Extreme NXT: Extending the LEGO MINDSTORMS NXT to the Next Level, ISBN 9781430224549

"I2C Address Allocation Table" (PDF) (Selection Guide). Philips Semiconductors. 1999-08-24. Archived from the original (PDF) on 2017-10-16. Retrieved 2017-10-01.

"System Management Bus (SMBus) Specification" (PDF). Version 3.0. System Management Interface Forum. 2014-12-20. pp. 81–82. Archived (PDF) from the original on 2016-01-29. Retrieved 2017-12-01.

"VESA Display Data Channel Command Interface (DDC/CI) Standard" (PDF). Version 1.1. VESA. 2004-10-29. pp. 15–16. Archived (PDF) from the original on 2016-09-09. Retrieved 2017-12-01.

"Intelligent Platform Management Interface Specification Second Generation V2.0" (PDF). Document Revision 1.1. Intel, NEC, Hewlett-Packard & Dell. 2013-10-01. p. 563. Archived (PDF) from the original on 2016-03-27. Retrieved 2017-12-01. The 7-bit portion of the slave address for the BMC is 0010_000b

Theo de Raadt (2015-05-29). "/sys/dev/i2c/i2c_scan.c#probe_val". Super User"s BSD Cross Reference. OpenBSD. Retrieved 2019-03-04. static u_int8_t probe_val[256];

Constantine A. Murenin (2010-05-21). "5.2. I2C bus scan through i2c_scan.c". OpenBSD Hardware Sensors — Environmental Monitoring and Fan Control (MMath thesis). University of Waterloo: UWSpace. hdl:10012/5234. Document ID: ab71498b6b1a60ff817b29d56997a418.

Linear Technology"s LTC4151 Archived 2017-08-09 at the Wayback Machine has two pins for address selection, each of which can be tied high or low or left unconnected, offering 9 different addresses.

Maxim"s MAX7314 Archived 2017-07-13 at the Wayback Machine has a single pin for address selection to be tied high or low or connected to SDA or SCL, offering 4 different addresses.

Delvare, Jean (2005-08-16). "Re: [PATCH 4/5] add i2c_probe_device and i2c_remove_device". linux-kernel (Mailing list). Archived from the original on 2016-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey