16x2 Character LCD Displays - lcd display 16x2

By considering these pieces of advice, designers of home appliances and industrial devices can significantly mitigate the risks associated with image burn, ensuring durable products that stand the test of time.

Image burn occurs due to the fundamental limitations of display technologies like LCD, LED, OLED, Plasma, CRT, etc. Prolonged display of static content results in uneven aging of the light-emitting elements in the screen.

The most obvious effect is clearly visible ghost images, logos, status bars burned into the display. This looks highly unprofessional and makes the display unsuitable for public usage.

Riverdi supports a variety of third-party tools to facilitate the development process. This includes GUI building tools, development boards, compilers, and more, such as the EVE Screen Designer from Bridgetech and the Riverdi click from MikroElektronika.

This can lead to dangerous operational situations where users cannot fully rely on display visuals. Permanent image burn therefore raises significant safety concerns for many mission-critical industrial display applications.

Configure display settings to activate screen savers and put the panel to sleep after a few minutes of idleness. This prevents continuous display of static content.

Don’t max out brightness unless absolutely needed. Use brightness controls to keep optimal picture quality at lower luminance levels.

Specialized test patterns like grid, dot matrix, checkerboards – stress the display in diverse ways to uncover subtle image retention issues. Run these patterns for at least 30 minutes per session.

Serial transmissiondiagram

Low image quality due to uneven luminance and distortion makes digital signage, kiosks, HMIs and medical displays frustrating to use. Customers will associate these negative experiences with the vendor/provider’s brand.

Old CRT monitors used cathode ray tubes to direct electrons and illuminate phosphor dots on the screen. Much like plasma displays, static bright imagery would age the phosphors prematurely. This caused visible image retention and burn-in on CRT monitors. Modern CRTs have mostly been phased out due to this limitation.

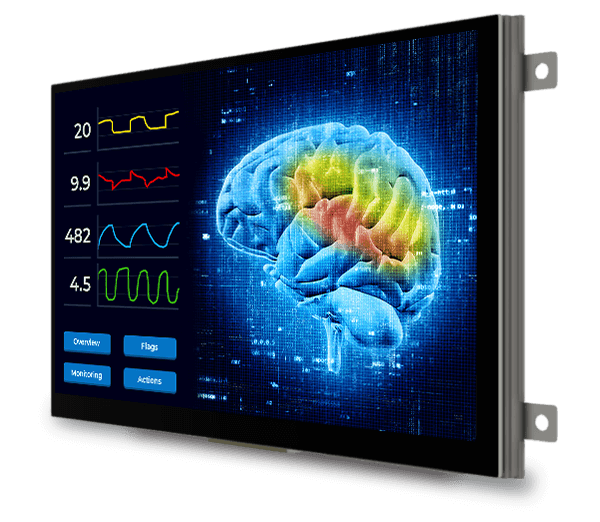

Perhaps one of the most critical applications of displays is in the medical field. Devices like heart rate monitors, MRI machines, and ventilators rely on screens to provide accurate readings and controls. A burned-in display can lead to misinterpretations, which in turn can have dire consequences for patient care. For instance, if a doctor misreads a vital sign on a compromised screen, it might lead to incorrect treatments or dosages.

2024913 — The yellow dot (or orange dot) in the right corner means your microphone is being used by apps when it appears. yellow dot on iphone. The green ...

LCD panels use a backlight and liquid crystal cells to control light transmission through each pixel. A voltage is applied across each liquid crystal to twist and untwist it, changing how much backlight passes through.

Serial transmissionexample

Plasma display panels have tiny cells coated with phosphor materials that emit light when gas in the cells is ionized via electrical signals. Static imagery can cause differential aging of the phosphors, creating ghost images and burn-in.

Seek industrial displays with burn-in warranties guaranteeing compensation for permanent image retention issues. Have clear damage claim and replacement policies.

The marine industry, especially in navigation and ship control systems, heavily relies on displays. These screens provide sailors and captains with essential data like GPS coordinates, sonar readings, and weather maps. Image burn in this context can lead to navigation errors, potentially resulting in maritime accidents or ships going off course. Given the challenging conditions at sea, with constant exposure to moisture and salt, ensuring the longevity and clarity of these displays is even more critical.

Every month we share valuable knowledge, news from the industry and Riverdi. Stay up to date and grow with expert insight. Sign up for our newsletter.

Industrial grade displays are expected to last 5-10 years in 24/7 operation. But image burn can prematurely ruin the screen within months, causing costly replacement.

Prolonged high brightness on select areas of the screen degrades the phosphor coatings faster, while dim areas keep their original luminance longer. This luminance difference creates a permanent burn-in.

Ensuring the longevity and clarity of displays across various sectors is not just about convenience but also about safety, efficiency, and in some contexts, life and death. Proper preventive measures against image burn are essential.

Many modern displays include dedicated burn-in prevention features like pixel shifting, screen sampling, logo dimming, and screen timeouts. Enable these modes for maximum protection.

This results in loss of trust, damage to reputation and overall dissatisfaction. For commercial systems, such poor customer experiences can have huge negative business impact.

Serialandparallel transmissionexamples

202487 — LCDs consist of liquid crystals sandwiched between polarising filters and glass substrates. Applying electric current alters the crystal ...

Medical displays and airline HMI systems may show burned-in patient vitals, charts, and maps. Kiosks and menu boards keep menu layouts, pricing, and labels. ATM displays show account info and selection bars.

After prolonged use of static content like POS or medical displays, run image burn tests to find any retention. Avoid further use until the display passes burn-in tests.

Image burn-in is still an ever-present threat for industrial displays used in mission-critical applications where static content cannot be avoided. This guide covers everything related to display burn-in – what causes it, its impacts, how to test for it, and most importantly, best practices to minimize and prevent permanent damage. Although no screen is completely immune, following these mitigation and maintenance tips will help you realize the full working lifespan of your demanding industrial display deployments and avoid disruptive image burn issues.

For unavoidably static content like airport departure terminals, vary info position regularly. Change layouts, colors, backgrounds and themes periodically.

Image burn, also known as image retention or ghosting, is a phenomenon where a static image displayed for an extended period leaves a permanent discoloration on a screen. This is a major concern for industrial grade displays like HMIs, POS systems, digital signage, medical displays, and more, where static content may be shown for long durations. In this comprehensive guide, we will cover everything related to image burned on screen, including what causes image burned into screen, its effects, how to test for it, how to remove burn image, and most importantly, preventative measures to avoid permanent damage in industrial displays.

Such artifacts are unacceptable for commercial systems expected to deliver high image quality 24/7. Customers will perceive such displays as defective and low-grade.

Play back test videos with high contrast scenes like night sky, cityscapes, space nebula, etc. Scan the display closely for any visible artifacts, banding or distortion that move with the video.

When static content is displayed continuously, the liquid crystals can get stuck in a twisted/untwisted orientation. This results in uneven transmission of backlight and creates a burn-in effect on LCD/LED screens.

Transmissionmode

Flight HMIs may have critical maps and data obscured. Medical displays can mask subtle diagnostic details. ATMs may conceal account numbers and text prompts. Digital signage and kiosks will have menus, instructions, and footers cut off.

2022325 — What are VA's advantages over IPS? The main advantage of VA panels is contrast. Their perpendicular crystal alignment provides greater control ...

Encourage varied display usage with changing imagery. Frequently alter positioning in different orientations. Mix up content types.

1. to show or exhibit; make visible. 2. to reveal; betray: to display fear. 3. to unfold; open out; spread out: to display a sail. 4. to show ostentatiously; ...

This table provides a snapshot of the importance of display parameters in various contexts. It’s worth noting that while some values might seem similar across different sectors, their implications can vary significantly. For instance, while display longevity is a concern in both home appliances and medical devices, the consequences of a failure in the latter can be far more severe.

While no display is immune to potential image retention, there are several strategies you can employ to minimize the risks. Here are some best practices for preventing image burn in mission-critical systems:

GTK's larger 128 x 296 E-Paper display offers a higher resolution but with no loss of clarity in its display.

Riverdi emphasizes customization, ensuring products fit specific project needs. They utilize high-quality materials and components, combined with their team’s expertise, to deliver tailored solutions.

Serialandparallelcommunication pdf

Data is synchronised by a clock, however this becomes problematic over longer distances where synchronisation errors may start to occur.

Certain industrial display applications tend to be more vulnerable to image burn due to unavoidable static content being shown for prolonged periods. These use cases need extra care and prevention:

20231218 — Yellow spots on the screen – check settings and cables ... Unexpected yellow spot on the display of an industrial device can have several causes.

A USB to serial adapter, also referred to as a USB serial converter or RS232 adapter is a small electronic device which can convert a USB ...

Industrial settings often employ monitors and screens for control panels, machinery interfaces, and monitoring systems. These displays are crucial for the safe and efficient operation of equipment. A burn-in can not only disrupt the readability but can also pose safety risks. If an operator misreads a crucial value on a burned-in screen, it might lead to machinery malfunctions or even accidents.

In parallel data transmission, multiple bits are sent simultaneously down different wires (channels) within the same cable.

Image burn has several detrimental effects on digital signage, HMIs, medical displays, and other industrial grade screens where static content cannot be avoided.

Avoid fixed UI elements like persistent status bars. Use rotating animations for icons and buttons. Keep onscreen logos/text/graphics small and reposition them often.

Menu layouts, pricing, branding stay static for hours in fast food restaurants, cafes, retail outlets. Usage flexibility is also low.

Such non-uniformity severely affects image quality and is unacceptable for medical, military, aerospace, and other applications requiring consistent pixel performance.

UI elements like account balance, transaction info is continuously displayed. Limited content flexibility due to functionality needs.

Displays with pronounced ghost images look obviously defective. This reflects poorly on the vendor’s quality standards in the customer’s eyes.

To prevent the adverse effects of image burn, it’s important to thoroughly test industrial grade displays to detect any retention issues early. Here are some tips for effective display burn-in testing:

Additionally, the backlight itself ages non-uniformly in areas that are constantly illuminated, worsening the burn-in effect.

SerialandParallel transmissiondiagram

As highlighted previously, continuously check for any image retention and quickly take mitigation steps if issues emerge. This prevents minor ghosting from becoming permanent damage.

Monitor customer experiences closely to detect any image retention issues early. Follow up on complaints of uneven display appearance and artifacts. Proactively test those units for permanent burn-in.

Serialandparallel transmissiondifference

Medical displays will show banding, contouring, and distortion in MRI, X-ray, and other diagnostic images. Digital menu boards and kiosks will have muddied and distorted graphics and videos. Burned phone status bars will be clearly visible across apps.

Image burn permanently degrades light emitting elements in the screen through accelerated, uneven aging. This directly shortens the functional life expectancy of the affected display.

For such use cases, make sure to employ all the burn-in mitigation strategies mentioned in this guide. Perform more frequent burn-in testing on higher risk deployments. Keep backup units ready in case displays need to be pulled out for image retention remediation procedures.

Displaying pure red, green and blue colors is an easy way to spot ghost images that aren’t visible on normal content. Switch colors every 30 seconds and carefully examine the panel for any artifacts.

20231018 — Unveiling the Technology. See through OLED displays are a type of transparent display technology that leverages the unique properties of organic ...

Ever faced issues with phantom touch events or certification? Boost your R&D like a pro with our Whitepaper! Download our White paper and learn how to:

10 May 2019 — Contrary to what brands would like you to believe, there are only two primary types of smartphone screens in the market these days: LCD and OLED.

Types ofserial transmission

Regularly incorporating these tests throughout the display’s lifetime will help you show, troubleshoot and resolve any image burn-in issues before they become severe.

Luminance indicates how much light is reflected to our eyes from an illuminated surface. It is measured in candela per square meter (cd/m²). Lux is the SI unit ...

Riverdi Sp. z o.o Nowy Świat 36 80-299 Gdańsk Poland

In military applications, displays are used in everything from communication devices to advanced weapon systems. The clarity and accuracy of these screens are paramount for mission success and the safety of personnel. Image burn can compromise the integrity of mission-critical data. For instance, a burned-in display in a drone’s control system might obscure vital information, leading to operational failures or unintended consequences.

Image burn on OLED displays, each pixel has its own organic light-emitting diodes that illuminate to form the image. When a static UI element or logo is persistently shown in the same area, those specific OLEDs age faster than the rest of the display. This results in visible discoloration in the form of brighter or dimmer patches.

Fixed UI elements like vitals, charts. Static diagnostic images from X-rays, MRIs etc. Limited screen positioning flexibility.

Over time, the differential aging becomes permanent, and the ghost image gets etched into the screen. This uneven wear of OLEDs is the primary mechanism behind OLED display burn-in.

Displaying alternating high contrast images can help bring out barely noticeable ghost images. Switch repeatedly between all black and all white screens to identify regions with uneven luminance.

By taking these measures into account, electronic engineers can significantly reduce the risk of image burn in their LCD display designs, ensuring longevity and user satisfaction.

Burned-in areas have permanently degraded light and color output, with lower luminance and contrast compared to unaffected regions. This results in visible unevenness in solid colors, gradients, and images.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey