make your own lcd screen in stock

If you have ever wondered what it took to make your own custom graphic LCD from scratch, this video from [Applied Science] is worth a watch. It’s concise and to the point, while still telling you what you need to know should you be interested in rolling your own. There is also a related video which goes into much more detail about experimenting with LCD technology.

[Applied Science] used microscope slides and parts purchased online to make an LCD that displays a custom graphic when activated. The only step that home experimenters might have trouble following is coating the glass slides with a clear conductive layer, which in the video is done via a process called sputtering to deposit a thin film. You don’t need to do this yourself, though. Pre-coated glass is readily available online. (Search for Indium-Tin Oxide or ‘ITO’ coated glass.)

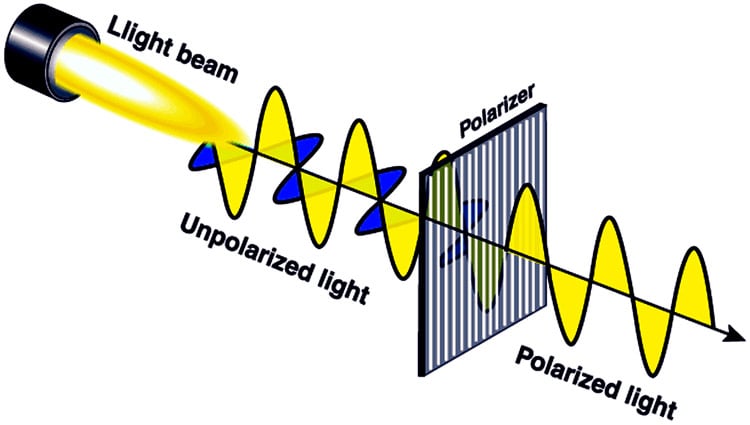

The LCD consists of a layer of liquid crystal suspended between two layers of conductive glass. An electrical field is used to change the orientation of crystals in the suspension, which modulate the light passing through them. Polarizing filters result in a sharp contrast and therefore a visible image. To show a particular shape, some of the conductive coating is removed from one of the layers in the shape of the desired image. The process [Applied Science] uses to do this is nearly identical to etching a custom PCB.

Parts of LCD technology can be quite hackable. Neither of these videos are brand-new, either. Have any of you taken on the challenge of DIY LCD displays? We’ve seen experiments with electrochromatic glass using old LCD displays, as well as experiments in playing with polarized light to hide secret messages on LCD screens.

The process to take your LCD idea from a concept to having prototype samples in hand is simple and requires just the few steps listed below. (Download PDF)

In many cases, FocusLCDs’ lead time for custom LCD samples is as little as 6-7 weeks after you approve our counter drawings and data sheet. This lead time increases by 4-6 weeks between November to early February due to Chinese New year. Standard production orders for custom displays have a lead time of 10-12 weeks, which can increase by 2-4 weeks during Chinese New year.

Focus Display Solutions offers several LCD technologies. The majority of these displays can be customized to fit your need. Below is a short introduction to each type of LCD.

Character LCDs have been around since the 1950s and are still very common. These displays offer 256 selectable characters and are available with several different font tables to show a variety of languages. They are most commonly known for their ease of programming wide variety of sizes, character arrays and colors.

Mimo Monitors can create a custom-size LCD monitor to almost any specification. Whether it is a minor modification to an existing design, or by utilizing our extensive experience in the industry, we can almost always build what you need.

Viewing Angle - This will depend on the technology of the LCD panel. TN vs. VA vs. IPS. More here (http://www.tnpanel.com/tn-vs-ips-va/) . In general, the better the viewing angle, the more expensive the resulting display. Typical are 150x140, 170x170 and 179x179. Or more commonly wide viewing angle or standard viewing angle.

Brightness or Luminance - It is the level of light emitted by an LCD display monitor. Luminance is reported in nits or cd/m2. They are actually the same thing. This matters for indoor and outdoor viewing and also if you want to draw people toward the display for advertising. Typical indoor brightness is 150 nits, indoor advertising is 300, bright indoor advertising is 700 and outdoor panels are 1000+

Single Cable –DisplayLink has an advantage that video information, touch information, and power are transmitted over a single USB connection. Read 5 Reasons to Choose a USB Powered Monitor to learn how they can meet your needs.

Touch panel - Optional human interface for interactivity. Typical choices are Display Only, Resistive (4 or 5 wire), and Capacitive touch options. Our blog discusses the advantages and disadvantages of capacitive touchscreens. SAW is another touch technology that is becoming less and less common.

In addition to custom LCD displays, we provide custom PCB assemblies and turnkey solutions for products that feature a Displaytech LCD. As a display manufacturer, our engineering and production staff are experienced in handling the design and manufacturing of printed circuit board assemblies for front panels, rack mount equipment, handheld devices and many other products.

Orient Display is a company that specializes in manufacturing LCD displays, touch panels, OLED displays with competitive prices. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years, Orient Display factory is now the world’s leading custom LCD manufacturer in flat panel industry and is listed as a public company in China stock market. Now, Orient Display factory has 2 production lines that can produce PMOLED and AMOLED custom display modules. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. Orient Display takes around 18% market share in global automotive market and is No.1 in automotive capacitive touch screen.

Orient Display has supported customers with custom LCD displays for tens of thousands of types and models for automotive, appliances, medical, smart homes, point of sales, industrial advices, etc. Whether your design requires a small custom LCD display glass, or a fully customized LCD module, or custom monitors and displays equipped with complicated embedded control board with touch panels, our experienced engineers in North America, Europe or in China factory will assist you in designing your customized displays.

Orient Display customer service sends quotation to you (might come with technical suggestions according to your targeted applications). The time will depend on the complexity of the project and the time to source components, normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

Orient Display engineers provide custom LCD display counter-drawings for you to approve with your signature on the drawing. The drawings might be modified several times until the designs are fully achieved your technical requirements. There can be a lot of technical discussions at this stage. The time our engineers take to arrange drawings also depend on the complexity of the project. Normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

After your drawing approval, Orient Display will start to make samples or prototypes for you to test. The lead time also varies depending on the production complexity and component/material sourcing. Normally, it takes 4-6 weeks for custom LCD glass panels, 8-10 weeks for custom LCD display modules or touch panels.

After your sample / prototype approval, Orient Display is ready for production. Orient Display welcomes trial production between the prototypes to large scale production so that you have the opportunity to fully test the custom LCD display or touch panel to run well in your designed products.

Congratulations! You have accomplished the journey of the idea, design, prototype and production in the market. The journey can take from 3 months to 3 years. Whatever the voyage, Orient Display’s engineers, customer services are proud to be part of your design. Our happiness is based on your success.

Dimensions (Specification / Drawing / Sketch of the LCD, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Fully custom made TFT LCD display module can be very expensive, the NRE ranges from $80,000 to $1M depending on the size and the resolution of the LCD display and the generation of the production line the LCD display to be produced. For over 99% of our projects, we are talking about the modifications of the standard TFT LCD display. There are a lot of standard color TFT displays available in the market. You are highly likely to find one matching your requirement. If you can’t find a suitable one on our website, please check with our engineers, we have a database in factory with much more types.

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop replacement, it is great to provide files in dwg. or dxf. format.

The above information can be overwhelming. Actually, we design a lot of touch panel and LCD custom display projects without being provided detailed information. Our engineers and customer service can quickly decide the parameters based on the customer’s application. Please feel free to contact our engineers for details.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

In Layman’s language, when an electric current is applied to the electrodes, i.e. to the segment line and common line, it twists the Liquid Crystals w.r.t to the polarizing filter, obstructing the light in that particular area as shown in the figure below. Hence, that area becomes darker and prominent.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

COG can be used as it is cheaper and makes the assembly process simpler, but if the dimensions are a constraint, then the COB is also a viable option.

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

/img/iea/LBGR1VDEO2/youtube-duo-build-see-through-lcd-computer-screen-like-its-the-year-3020.jpg)

Every LCD screen eventually fails, usually due to the backlight behind the screens. That is why we have a backlight solution for every LCD screen on the market. Plazmo currently has the single largest global stock of drop-in CCFL and LED backlight assemblies.

Each of our assemblies comes complete with a pre-wired harness, OEM connector plug, silicone end caps and an optional metal rail. Nearly every LCD screen has a unique model design and we have developed the molds and manufacturing specifically to fit more than 200,000 LCD screen models in use today.

Plazmo also has robust manufacturing capabilities and specializes in perfectly replicating OEM backlight assemblies. Using our LED and CCFL backlight assemblies, we pass on savings to our customers while helping keep their LCD screens running smoothly.

Custom-designed backlight solutions are also available through Plazmo. Our experts will work with you to design, prototype and manufacture custom LED and CCFL backlight assemblies. Our custom LED and CCFL backlight assemblies can help you save thousands of hours in labor and ultimately help you lower your equipment operating costs. Contact us today and let us find the best solution to meet your needs!

Unused electronics are the bane of the modern life. Perfectly functional gadgets sit quietly in a corner of the store room, doing nothing. If you"re wondering what to do with old computer monitors, here are a few easy ideas to repurpose unused screens.

In this guide, it doesn"t matter if your old monitor is still working or not. Even if it isn"t, you can use its parts to make a great new gadget. From turning it into a super-tiny computer or dashboard to refashioning into a smart mirror, here are some of the most productive ways to repurpose a computer monitor.

The Raspberry Pi 4 is an incredible device. While it has a wide range of uses, at its core, it is a tiny, low-cost, full-fledged computer. And that means your old monitor can be turned into a PC for less than $60.

Perhaps the best thing to do with an old flat-screen monitor is a DIY DAKboard. The DAKboard is a LCD wall display that shows the current time, weather forecast, calendar events, stock quotes, fitness data, and news headlines. It"s all displayed on a soothing photo. You could buy an official DAKboard, but the makers themselves have shown how to build your own wall display with a Raspberry Pi. when you can build one for far less money and a little geeky fun, the choice is obvious.

Attach your old monitor to a Pi and it can be put in your kitchen as a recipe and video source. Make a Pi-based retro video game console as a treat for your kid (or the kid in you).

Sometimes, you"re working on something private in an open office, or browsing certain *cough* sites *cough* at home. You can"t have your colleagues or kids see what"s on the screen. To keep snooping eyes at bay, make a "your-eyes-only" monitor from an old one.

Basically, you will be cutting out the polarizing film of the old LCD monitor. This film will then be put on a simple pair of glasses. Now your screen appears white, but the glasses can "see" the content. It"s one of the best ways to keep prying eyes out of your PC.

If you have a broken old LCD monitor, it can be re-purposed into a usable mirror; but if you have a working old LCD monitor, adding a Raspberry Pi can turn it into a smart magic mirror!

If you"re on a tight budget for a first-time DIY project, consider the $100 smart mirror. It"s not the best version of turning an LCD monitor into a smart mirror, but you"ll get the basic features and not spend a bomb.

If you have the space available, the best thing you can do with an extra monitor is to boost your productivity with a dual-monitor setup. A second monitor has many potential purposes, such as extended screen space, a dashboard for your social media or news updates, or a dedicated video conferencing screen.

Make it a dedicated screen for Nintendo Wii:The Nintendo Wii can connect to a VGA monitor, so if you don"t have a Wii, buy one. In fact, buy a used one, they"re pretty cheap on Craigslist.

Like any gadget, monitors have a limited shelf life. If you"re looking to upgrade, you now have a few ideas of what to do with your old monitor. And that age should influence which project you chose. For example, given the effort involved in building a smart mirror, don"t go with a screen that"s already shown signs of trouble. The Raspberry Pi-based projects are usually the easiest to keep changing.

Use our “Get an Estimate” tool to review potential costs if you get service directly from Apple. If you go to another service provider, they can set their own fees, so ask them for an estimate. For service covered by AppleCare+, your fee per incident will be the same regardless of which service provider you choose. We"ll inspect your product when we receive it. If additional damage is found, you could pay an additional fee.

The Apple Limited Warranty covers your Apple Display and the Apple-branded accessories that come in the box with your product against manufacturing issues for one year from the date you bought them. Apple-branded accessories purchased separately are covered by the Apple Limited Warranty for Accessories. This includes adapters and spare cables.

If your situation isn’t covered, you’ll pay a fee. If the issue with your Apple Display is ineligible for service, you might pay the full replacement value.

We guarantee our service, including replacement parts, for 90 days or the remaining term of your Apple warranty or AppleCare plan, whichever is longer. This is in addition to your rights provided by consumer law.

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

If you are concerned about pixel anomalies on your display, take your Apple product in for closer examination at an Apple Store, Apple Authorized Service Provider, or an Independent Repair Provider. There may be a charge for the evaluation. Genuine Apple parts are also available for out-of-warranty repairs through Self Service Repair.*

When your embedded device needs a display, that product becomes one of the most important parts of the device. I have helped build hundreds of embedded devices with screens in my career. I share expert tips and my insights for what to consider when choosing one.

An embedded display is a screen that connects to an embedded device. The screen provides information about how the device is working and allows users to interact with it.

Sometimes called embedded touch, these displays allow users to interact with the device by touching the screen"s surface. Smartphones, including the iPhone, were among the first products to use this technology. Retail displays increasingly use embedded touch screens.

The basic standard screens for embedded systems might include a liquid crystal display (LCD). Embedded systems use two types of LCD modules: character LCD and Graphic LCD. A character LCD only shows characters and is the simplest and cheapest LCD technology. A graphic LCD is more advanced and displays images.

Provides a custom look: You can design a display to fit the design of the embedded device. This option can be crucial if your device needs physical buttons along with the digital or touch screen buttons. A custom screen also means users have a more integrated and satisfying experience with the device.

The display won"t go off the market: When you create a display, you can make arrangements with your manufacturer to continue making it while continually improving it. That partnership can last the life of your embedded device, which might be longer than that of some off-the-shelf displays.

Slow to market: Designing a display takes more time and can delay the point at which you can produce your embedded device for the market. You"ll need to create drivers for the display controller. You"ll also need to do the work to ensure the display can provide basic graphic functions like drawing lines and boxes. Then everything must be tested and debugged. The entire process might add five or six months or more to production time.

Can initially be more expensive: The work to design and build a custom display will make the display—and the embedded device—more expensive at the outset.

Faster to market: Since off-the-shelf displays have been tested and improved and work well, you can usually get your embedded device finished and ready for the market faster.

Reduced cost: If you are producing a large number of your embedded device, per-unit costs for a custom display might become low enough for them to be more economical. In any other situation, your cost-per-unit is likely to be less expensive with an off-the-shelf display.Advantages of an Off-the-shelf Embedded Display:

"The lower the volume, the less likely it is that you"ll do a custom design—that you design yourself," says Burkhard Stubert, an independent software developer and consultant specializing the embedded systems."

Consumer perception of your product: An off-the-shelf display that looks different than or otherwise doesn"t fit well with your device can be a negative. Consumers can see your product as less finished or professional.

Display support: An off-the-shelf display may need support from its manufacturer to continue to perform well. The product may also undergo continual changes and development. Those changes, or lack of support, can cause problems when integrating the display into your embedded device.

Becoming obsolete: Many off-the-shelf displays will have a life of only a few years before consumers expect to replace them with new and better units. That can be a significant problem if you expect your embedded devices to last much longer than that.

Poor Consumer Perception:An off-the-shelf display that doesn"t seem to fit with the device will make consumers think less of the product and your company.

Obsolescence:Some off-the-shelf displays will have a life of only a few years; that could be a problem if you expect the life of your device will be longer.

Some embedded devices may only need a basic display that the user doesn"t interact with at all—a display showing the level of battery power for the device, for example. Other embedded devices will have a screen that has more user interaction.

Many displays operate within embedded systems that are critical for safety. Devices include medical equipment, automotive components, and parts in other critical infrastructure. All aspects of your system, including the display, will need to meet certain safety requirements. Be sure to consider safety in all aspects of choosing or building the display for these types of embedded devices.

You might choose to have users interact with the screen mainly through physical buttons rather than through a touch screen. Using buttons will be cheaper; touch screens are much more expensive than a simple display. However, physical buttons can wear down and stop working, and most users expect touch screens with devices these days.

"People are just used to touchscreens from their phones," Stubert says. “If users don"t have that, they become very impatient. They want to know why the product doesn"t work like their phone."

Touch screens also allow engineers to reprogram the display interactions later if they want to change or add features, explains Horine. "Whereas it"s hard to add a (physical) button to a system after it"s been deployed," he adds.

Some embedded devices may need more than one screen. You can learn more about howfor your device. You can also see a Qt demonstration of the future of embedded displays thatto provide an exceptional user experience.

Off-the-shelf or custom?Probably the most important early decision you"ll make is whether to build a custom display or buy an off-the-shelf model that will work with your device.

Horine says some devices may need a simple LCD that"s two inches by one inch. "I can find someone who manufactures that. Then it"s just a function of building and doing the interface that"s necessary to make it work," he shares.

With certain devices and situations, such as vehicles and agricultural and construction machines, you"ll want to ensure your device"s display is not distracting, explains Stubert.

Some displays in those machines and vehicles may have rotary knobs or joysticks that allow users to control the device. "You have a second method of input, which is important because a touchscreen always means that you have to look where you touch. So, you are distracted, which is not good in vehicles," says Stubert.

The working conditions of the embedded device might quickly wear out a display that isn"t durable. You"ll also want to consider how people will use the screen and how often they might be touching or using it in general. If users will touch the display often, it needs to be able to handle that interaction.

Custom or off-the-shelf displays will have software within them. You"ll want to make sure you can access development tools and other resources to maintain that software.

For an off-the-shelf display, find out how long the manufacturer will be making this particular unit. If you plan to use the screen in a device that you expect to produce for six years or more, you’ll have issues if the display will only be available for three years.

Industry requirementsYou will want to consider whether the industry in which people will be using the embedded device has specific operating requirements. Will there be lighting conditions, such as darkness or bright sunlight, that might affect the screen?

Be sure to test how easy it is to read the display in various environments. Consider the contrast between the type of the screen and its background and the angle at which the users will view it, and if that affects their experience.

Qt"s Embedded Product Planning and Requirements Guide provides engineers with more details about the top embedded displays. The guide compares key features of the displays to help make your decision easier.

Displays are an important part of many embedded devices and can often be the most expensive element in your design. Choosing the right one is vital for the success of your device. Once you"ve selected a display, you"ll want to learn how to streamline the user interface design for the embedded device.

Qt Design Studiohelps you create beautiful user interfaces once you"ve chosen the right display for your embedded device. Qt Design Studio closes the gap between designers and developers allowing you to work simultaneously with one unifying framework, one common language, fewer feedback loops, and faster iterations.

1. Before you can download any software upgrades, make sure your appliance is connected to WiFi and our SmartHQ app. If you haven’t already set up your appliance with your WiFi, follow our instructions and you’ll be on your way.

2. Once your appliance is fully connected, open your SmartHQ app on your mobile device. You’ll see a notification that your appliance has an upgrade available. You can choose to download immediately or later.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey