lcd panel failure reasons factory

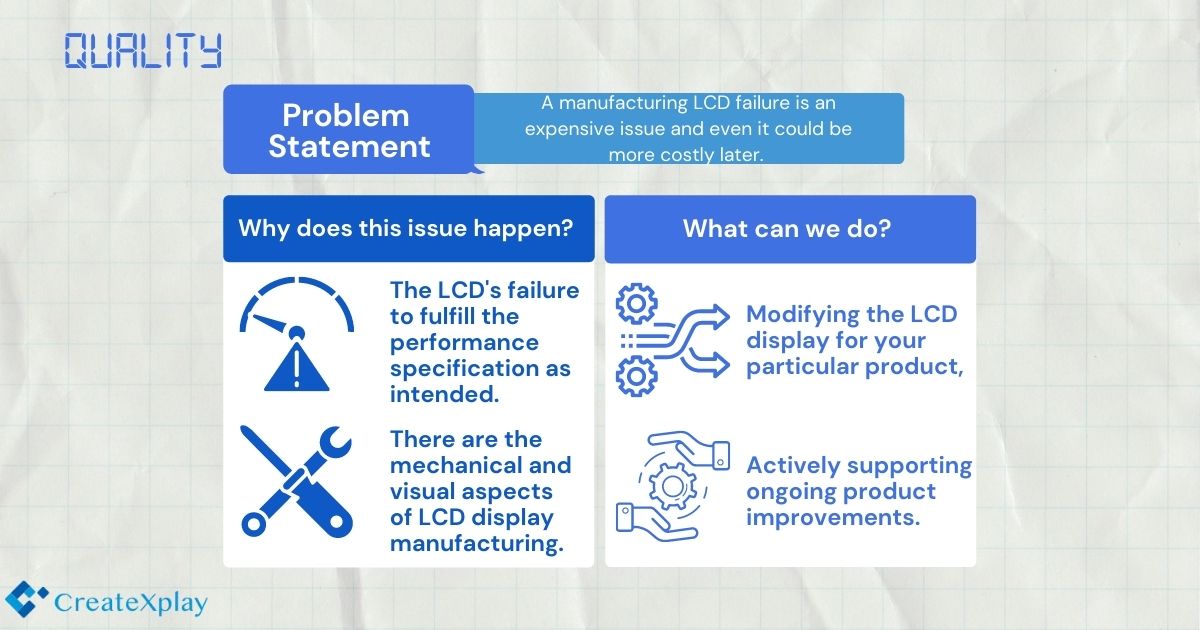

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

Unfortunately, it is common for some failures to make it through final testing. After the vibration and thermal effects from the shipping process, these defects can be exposed and result in an out of box failure at the assembly line.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

Performing a failure analysis is next. Then, linking that analysis to the customer’s field environment. You’ll need to determine (1) whether the failure is caused by the environment and (2) whether a product improvement can better support the application, or whether there’s a way to limit the environmental extremes.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

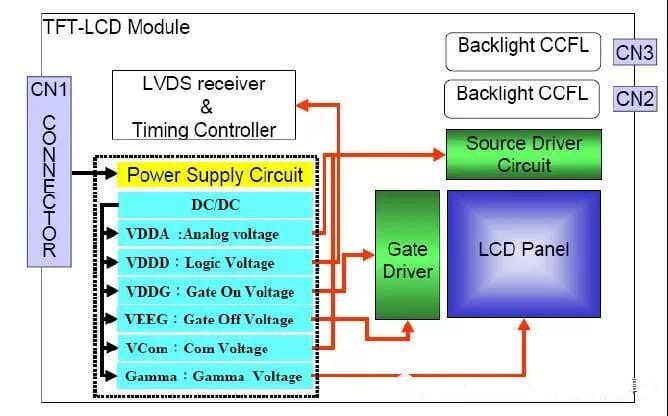

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

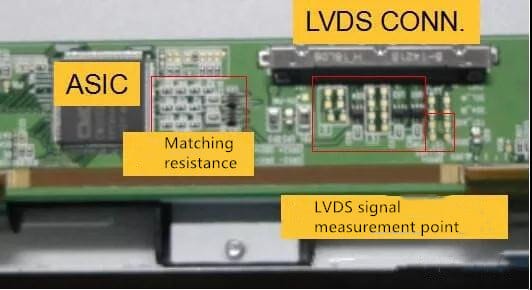

Unlike point defect, this larger scale defect is caused by the failure of external FPC or PCBA, or a bad connection between FPC and cell. Therefore, a bunch of pixels connected to these IC are out of control, and we see those defects.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

There you have it, the pros and cons of different display types and some of their common failures. Remember, if you suffer a failure of any display type, we are here to help. Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!

Before we get into specifics about how this would work, it is important to understand that liquid crystal display panels and polarizers utilize organic compounds that are susceptible to high heat and light energy stress. These organic compounds will eventually break down if deployed in high stress environments. One such contributing factor to LCD panel failure is the use of a high energy unfiltered illuminator. The near IR and shorter UV wavelengths not only add excess heat that may overheat the liquid crystal and prevent them from working properly, but they also add UV band energy that is destructive to organic compounds.

Over time the UV and IR will degrade and damage the LCD panel and polarizers to the point that they produce an unacceptably poor performance. In most applications this is observed to be color shift, washed out images and an observable raise in the darkness levels produced by a damaged LCD panel.

In order to help prolong the onset of such damage a set of UV and IR band filters and mirrors can be used to minimize the amount of harmful energy that is conveyed to the LCD panel from the illuminator. In order to determine what combination of filters and mirrors are best for any particular application it is important to know how each material reacts to the various intensities of bandwidths emitted by your chosen illuminator.

Frequently the Illuminators used in LCD systems are gas discharge lamps such as xenon arc lamps and metal halide light sources. A standard hot mirror that reflects energy between 750 and 1200 nm can be used to mitigate the majority of IR energy being conveyed to the LCD panel. In addition a UV blocker can be used to mitigate the damage from energy below 400 nm.

Other thin film coatings and substrates can be utilized to reduce the IR and UV damage to an LCD panel. Any solution must be well researched to minimize concerns so that a sufficient cooling mechanism is planned and allowed for in the application.

LCDs used in outdoor situations have many concerns to deal with in addition to any that they might normally encounter during indoor use. Initially some concerns are weather related such as moisture in the air or extreme temperatures. Another concern that is often not understood or just not known about at all is sunlight damage.

Liquid crystal displays use organic components that are susceptible to UV (<400 nm) and IR (>750 nm). These bandwidths of radiation have an observable impact on the organic components in LCDs. Extended exposure has been known to cause a color shift and a washed out look to images displayed with the LCD.

In any case it is important to protect your display from the elements, especially if it is going to be exposed to harsh environments not intended by the manufacturer. One way to do this would be to utilize a Hot Mirror with a UV blocker. This will significantly reduce the amount of IR radiation between 750 nm and 1200 nm, as well as the UV radiation below 400 nm. If the LCD is going to be used outdoors for extended periods then an extended hot mirror may be necessary, which extends the bandwidth protection out to 1600 nm and will help reduce some of the longer wavelength IR damage.

Another concern with liquid crystal displays are their susceptibility to overheating due to excess IR radiation. The LCD is intended to operate within a certain range of temperatures according to the manufacturer’s instructions and outdoor use can lead to higher than normal temperatures. The display being exposed to excessive heat can cause the crystal to become isotropic and fail to perform properly. A hot mirror can help alleviate these concerns as well by reducing the amount of infrared radiation that heats the display.

A state report on Foxconn’s Wisconsin factory depicts a project gone far off course. The report, issued this month by Wisconsin’s Division of Executive Budget and Finance and obtained through a records request, confirms that the company has not built the enormous Gen 10.5 LCD factory specified in its contract. It also says that the building the company claims is a smaller Gen 6 LCD factory shows no signs of manufacturing LCDs in the foreseeable future and “may be better suited for demonstration purposes.”

The report notes that Foxconn received a permit to use its so-called “Fab” for storage, which The Verge first reported this week. Furthermore, according to an industry expert consulted by the state, Foxconn has not ordered the equipment that would be needed to make LCDs. If the building were to be used as an LCD manufacturing facility, the expert notes it would be the smallest Gen 6 in the world and “would appear to be more of a showcase than a business viable for the long term.”

If any LCD-related manufacturing were to take place in the building, the analysis says, it would likely only be the final assembly of components produced elsewhere and imported to Wisconsin. Such a project would have a vastly smaller impact on local supply chains and employ nowhere near the 13,000 workers anticipated in Foxconn’s contract with the state.

Regarding the company’s failure to build LCDs and two years spent veering from idea to idea (co-working, fish farming, building giant glass spheres), the company said “Foxconn’s progress in Wisconsin has been achieved despite many growing pains that includes the need to explore new business opportunities, adjust to changes in global customer requirements, and a constantly evolving global technology industry.”

A defective pixel is a pixel on a liquid crystal display (LCD) that is not functioning properly. The ISO standard ISO 13406-2 distinguishes between three different types of defective pixels,

Similar defects can also occur in charge-coupled device (CCD) and CMOS image sensors in digital cameras. In these devices, defective pixels fail to sense light levels correctly, whereas defective pixels in LCDs fail to reproduce light levels correctly.

A dark dot defect is usually caused by a transistor in the transparent electrode layer that is stuck "on" for TN panels or "off" for MVA, PVA, and IPS panels. In that state, the transistor places the liquid crystal material so that no light ever passes through to the RGB layer of the display.

A bright dot defect or hot pixel is a group of three sub-pixels (one pixel) all of whose transistors are "off" for TN panels or stuck "on" for MVA and PVA panels.

A tape automated bonding fault (TAB fault) is caused by a connection failure from the TAB that connects the transparent electrode layers to the video driver board of an LCD.

TAB is one of several methods employed in the LCD-manufacturing process to electrically connect hundreds of signal paths going to the rows and columns of electrodes in layer 6 (the transparent electrode layer) in the LCD to the video integrated circuits (ICs) on the driver board that drives these electrodes.

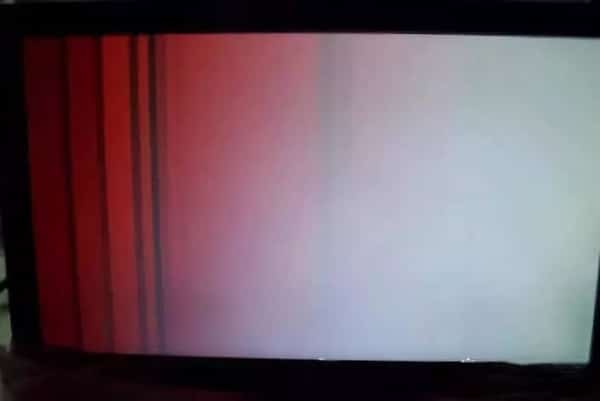

If an LCD is subjected to physical shock, this could cause one or more TAB connections to fail inside the display. This failure is often caused by horizontally flexing the chassis (e.g., while wall-mounting or transporting a display face up/down) or simple failure of the adhesive holding the TAB against the glass. TAB faults require the replacement of the LCD module itself. If these connections were to fail, the effect would be that an entire row or column of pixels would fail to activate. This causes a horizontal or vertical black line to appear on the display while the rest of the display would appear normal. The horizontal failure runs from edge to edge; the vertical failure runs from top-to-bottom.

In LCD manufacture, it is common for a display to be manufactured with several sub-pixel defects (each pixel is composed of three primary-colored sub-pixels). The number of faulty pixels tolerated before a screen is rejected, is dependent on the class that the manufacturer has given the display (although officially described by the ISO 13406-2 standard, not all manufacturers interpret this standard the same way, or follow it at all).

Some manufacturers have a zero-tolerance policy with regard to LCD screens, rejecting all units found to have any number of (sub-)pixel defects. Displays meeting this standard are deemed Class I. Other manufacturers reject displays according to the number of total defects, the number of defects in a given group (e.g., one dead pixel or three stuck sub-pixels in a five-by-five pixel area), or other criteria.

A defective pixel is a pixel on a liquid crystal display (LCD) that is not functioning properly. The ISO standard ISO 13406-2 distinguishes between three different types of defective pixels,

Similar defects can also occur in charge-coupled device (CCD) and CMOS image sensors in digital cameras. In these devices, defective pixels fail to sense light levels correctly, whereas defective pixels in LCDs fail to reproduce light levels correctly.

A dark dot defect is usually caused by a transistor in the transparent electrode layer that is stuck "on" for TN panels or "off" for MVA, PVA, and IPS panels. In that state, the transistor places the liquid crystal material so that no light ever passes through to the RGB layer of the display.

A bright dot defect or hot pixel is a group of three sub-pixels (one pixel) all of whose transistors are "off" for TN panels or stuck "on" for MVA and PVA panels.

A tape automated bonding fault (TAB fault) is caused by a connection failure from the TAB that connects the transparent electrode layers to the video driver board of an LCD.

TAB is one of several methods employed in the LCD-manufacturing process to electrically connect hundreds of signal paths going to the rows and columns of electrodes in layer 6 (the transparent electrode layer) in the LCD to the video integrated circuits (ICs) on the driver board that drives these electrodes.

If an LCD is subjected to physical shock, this could cause one or more TAB connections to fail inside the display. This failure is often caused by horizontally flexing the chassis (e.g., while wall-mounting or transporting a display face up/down) or simple failure of the adhesive holding the TAB against the glass. TAB faults require the replacement of the LCD module itself. If these connections were to fail, the effect would be that an entire row or column of pixels would fail to activate. This causes a horizontal or vertical black line to appear on the display while the rest of the display would appear normal. The horizontal failure runs from edge to edge; the vertical failure runs from top-to-bottom.

In LCD manufacture, it is common for a display to be manufactured with several sub-pixel defects (each pixel is composed of three primary-colored sub-pixels). The number of faulty pixels tolerated before a screen is rejected, is dependent on the class that the manufacturer has given the display (although officially described by the ISO 13406-2 standard, not all manufacturers interpret this standard the same way, or follow it at all).

Some manufacturers have a zero-tolerance policy with regard to LCD screens, rejecting all units found to have any number of (sub-)pixel defects. Displays meeting this standard are deemed Class I. Other manufacturers reject displays according to the number of total defects, the number of defects in a given group (e.g., one dead pixel or three stuck sub-pixels in a five-by-five pixel area), or other criteria.

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

If you ever notice multi-coloured or single-coloured vertical lines on your laptop screen, it may be a result of a hardware failure or due to damage to the screen. To try fixing it yourself, first unplug your laptop, hold the power button for 30 seconds and restart the laptop. If you continue to see coloured lines, the issue is probably with the LCD screen, which will need to be replaced from the brand’s service center. To be sure about the LCD screen problem, try connecting your laptop to another monitor and see if the issue persists. If it does, the issue is certainly in the LCD panel.

Firstly, check if your laptop’s brightness level is set to maximum. If the display is still dim, try restarting the device. This could just be a system error that can be resolved by restarting the device. Also, check if the AC adapter cord is loose and firmly connect it to the outlet and laptop. If the issue still persists, it is mostly due to a failure of the LCD. Behind the LCD, there is an inverter board and backlight bulb which control the picture.

The inverter board converts the low voltage your laptop uses, into higher voltage required by the long bulb that lights up the LCD screen. If the inverter board or bulb fail, you will experience the problem of a dimmed display. Even if one of these two components fail, the screen will need to be replaced, unless the service center can help by just replacing the bulb. We wouldn’t recommend you try resolving it yourself, as this is more complex and you could end up damaging the circuit board and the backlight lamp. So, it’s best to leave this job to an expert.

My touch screen is not working.All touch panels must be connected to a computer via USB or RS232 cable. This allows the touch panel to communicate with the computer.

If you recently downloaded a new touch panel driver, you must also delete the old driver and reboot your computer. Make sure you have deleted any old touch panel drivers and then restart your computer.

My touch screen is not registering correctlyAll non-HID compliant touch panels will need to be calibrated during the initial start-up and may need recalibrating at some other point in the future. This is accomplished via the touch panel software installed on your computer. For a detailed walk through, please contact us.

Certain touch panels are susceptible to issues due to grease/dust/water and therefore may need added care. If this is a constant problem, please contact us for further assistance.

For heavier duty cleaning, create a solution of 80% alcohol mixed with 20% water and use the damp, not wet, cloth to clean the screen and panel surface.

one is a hardware fault, the other is a software problem. Although only these two big aspects but involved in the details of the aspect is very much, the following details about the display color abnormal possible reasons and solutions.

Monitor color is not normal, we recommend the first use of the elimination method, as far as possible to eliminate some simple problems. There are many reasons leading to the abnormal display of the display color, such as checking whether the display data line is normal, the display color control panelis not set well, poor contact, or rust of the display wire may lead to such problems.

A kinescope-tube failure can cause this problem, but it is not irreparable – minor electric shocks, serious rewound filament power supply windings, and sometimes the visual discharge power supply resistance of a particular electron gun is miswelded or broken or the resistance value is increased.

In addition, there is easier to let people detour the cause of failure – screen dust caused by too much screen white when red! This kind of fault often happens in the monitor that color temperature slants warm (a lot of monitors can set color temperature by oneself), say so, encounter white (and similar color) slants red when the fault you had better be cleaned the first screen later undertake other checks, if the fault disappears, mean you won’t because of this and “unlucky” detour. Of course, too low brightness values on some models can also cause this “fault” phenomenon.

Some half professionals see the two faults as a tube in life, some of the maintenance personnel to see will say adjust the contrast and the focusing extremely potentiometer and accelerate the potentiometer on the ignition coil will be good, others say it’s caused by a hardware failure or graphics driver damage of graphics, these point of failure judgment is wrong.

The aging of the kinescope and the decline, in contrast, will not cause such failure phenomenon, as for the adjustment of the collector and the acceleration of the electrode potentiometer is not correct, this is palliative, and it is difficult to adjust to a satisfactory degree, the most troublesome is that the fault will soon return, even accelerate the aging of the kinescope.

The real failure point of the type 1 fault phenomenon is usually due to the aging of the focusing knob of the FBT. You can try to replace an FBT first. Of course, if the monitor has been in use for more than six years, then we need to take into account the possibility of tube aging. In addition, it may be the tube seat of the picture tube and the large area of the negative copper foil leakage phenomenon caused by the displacer (after analysis like design problems), so sometimes into a maintenance dilemma after the replacement of a genuine tube seat try.

The poor contact of the video card usually causes the failure of starting up and there is an alarm sound or the system is unstable resulting in a crash and other failures. The reason for the poor contact of the graphics card is that the gold finger of the graphics card is oxidized, dust, the quality of the graphics card is poor or the baffle of the case has a problem. For the golden finger oxidation caused by poor contact, can use an eraser to wipe the golden finger to solve; For dust caused by poor contact, general removal of dust can be solved; For the hardware quality caused by poor contact, usually through the replacement method to detect, generally replace the video card to solve; For the case baffle problem caused by poor contact, usually the video card can not be fully inserted into the video card slot, can be replaced by the case to eliminate.

Compatibility failure will usually cause the computer can not to start up and alarm sound, the system is not stable crash or screen abnormal miscellaneous phenomenon. Display card compatibility fault generally occurs in the computer just installed or upgrade, more in the motherboard and display card is not compatible or motherboard slot and display card gold finger can not completely contact. The video card compatibility fault usually USES the replacement method to detect, generally USES the replacement video card to troubleshoot the fault.

The failure of the components of the graphics card will usually cause the failure of the computer can not startup, the system is not stable crash, flower screen, and other fault phenomena. The damage of graphics components generally includes the damage of graphics chip, BIOS, memory, capacitance, or field-effect tube. For the damage and failure of graphics card components, it is generally necessary to carefully measure the signals in the graphics card circuit to judge the damaged components. After finding the damaged components, replace them.

The failure of the graphics driver usually causes the system unstable crash, flower screen, text image graphics card is not complete, and other fault phenomena. The video driver’s fault mainly includes the loss of the video driver, the video driver is incompatible with the system, the video driver is damaged, and the video driver cannot be installed. For the video card, driver failure generally first enter the “device manager” to see whether there is a video card driver, if not, re-install. If so, but the graphics driver has a “!”, the video card driver is not installed, the driver version is not correct, the driver and the system are not compatible. Generally, remove the video card driver reinstall, if installed after there are “!”, you can download the new version of the driver installation. If you cannot install a graphics driver, there is usually a problem with the driver or with the registry.

CMOS setup failure is caused by the error of displaying related options in CMOS. Common CMOS setup failures mainly include: integrated graphics card motherboard, CMOS graphics card shielding options setting error; For example, the “AGP Driving Control” option is incorrectly set (usually “AUTO”), “AGP Aperture Size” option is incorrectly set, and “FAST Write Supported” option is incorrectly set.CMOS error is generally modified by loading the default BIOS value.

Video card over frequency problem refers to the time spent to improve the video card speed, improve the video card’s working frequency, and lead to computer failure. When a problem occurs, the frequency can be restored to the factory default.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

The LCD screen is vital for operating the printer. Should you encounter any kind of trouble, such as a dead screen, corrupted text, or other issues, please refer to the guide below.

First of all, unscrew the LCD screen from the printer frame, remove both M3x10 screw holding it the LCD board in the plastic casing, and remove it from the casing. See if the problem still appears when the LCD is not pressed by the casing.

Firmware updates are necessary to keep your printer up to date. However, the installation of incorrect firmware can lead to letter corruption on the LCD screen. There"s an easy fix, though:

There is a small chance the printer"s LCD screen can glitch out by electrostatic discharge when inserting the SD card. Try to turn the printer off and on again.

This problem usually appears only on user-assembled printers. If your printer"s LCD screen remains blank or displays corrupted symbols after you turn on the printer, there is a chance it is caused by incorrect wiring. Follow these steps to fix the issue.

If you suspect that the LCD ribbon cables connectors are not firmly seated in the slots, disconnect the LCD ribbon cables and check the slots for any bent pins. If there are bent pins, you can use tweezers to fix them. However, be very careful not to break the pin(s) completely.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey