lcd panel failure reasons in stock

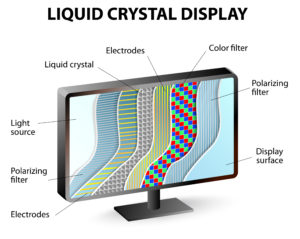

Unlike older cathode ray tube (CRT) displays that scan an electron beam over a phosphor screen to create light, LCD displays are composed of a fixed grid of tricolor pixels that change transparency based on a range of voltage levels provided by the monitor"s controller. Without a voltage the pixel is opaque and blocks the screen"s backlight from transferring through it, and when a full voltage is applied then the pixel allows full transmittance of the backlight. When this is done over the entire pixel grid in patterns, then you see those patterns on the screen.

This pixel-based setup for LCD monitors provides many advantages over CRT displays, but does have potential drawbacks arising from the fact that the image is dependent on millions of independent electrical components as opposed to a single scanning beam, so if faults occur in these components then the display output can be affected. The resulting problems include stuck or dead pixels, as well as a residual image effect.

One of the more common problems with LCD displays is the potential for stuck or broken pixels, where the pixel either does not receive a voltage and remains black, or does not respond to voltage changes and stays at a set luminance level. Sometimes this can happen for individual pixels, suggesting a problem with the pixel itself, or it can happen to groups of pixels, suggesting the possibility of problems with the display"s controller or a defect in a portion of the pixel grid.

LCD monitors can also be affected by another problem called "transient persistence" that is reminiscent of CRT burn-in. Classic burn-in would happen because the phosphor coating on the screen would get depleted by the persistent bombardment of electrons from the CRT, resulting in the inability of those sections of the display to convert the electron beam to visible light. This meant that if you kept a specific pattern showing on the screen then over time it could become a permanent residual image on the display that would show even when the display was turned off. This was a reason why screensavers were developed--to keep the wear on the screen"s phosphor coating as even as possible.

The physical burn-in of displays is no longer an issue now that LCD displays have taken over, but while transient image persistence is not a physical burn of the device, it is an alteration of the pixel response to voltage changes (usually temporary) that prevents pixels from getting as bright as others on the screen.

Similar to CRT burn-in, LCD image persistence generally happens after you have displayed a pattern of intense colors on screen; however, unlike CRT burn-in, LCD persistence can sometimes set in after only a few hours of displaying the image, as opposed to the weeks or even months that it can take for burn to set in on a CRT monitor. Additionally, unlike CRT burn-in, image persistence can often be reversed.

What happens with LCD monitors is the affected pixels have lost their ability to respond to the full range of voltages that the display gives them, resulting in a limited range of colors that can be output. This can happen if the pixel is acting like a capacitor and is retaining a residual charge, or if it is not able to reach the level of luminance that is desired when given a specific voltage. Either way, the pixel is not able to reach its full range of possible intensities.

Unlike stuck or dead pixels that may benefit from having the monitor turned on and off rapidly to produce rapid voltage changes, image persistence will benefit from a lengthy stretching of the pixel"s range. Therefore, instead of using tools like JScreenFix to run random patterns over the affected screen area, you might instead place a pure white window (such as an empty TextEdit window, or what you get using the "White" option in the LCD Repair tool listed above) over the affected area for a few hours or even a few days if necessary. Doing this will force those pixels to be fully on, and over time their intensities may increase to be the same as the surrounding pixels.

Likewise, try turning off the pixels fully by shutting down the display for a long period of time or placing a pure black texture over the affected area (see the LCD Repair tool listed above for this option as well). This will turn the pixels completely off and allow residual voltage in them to drain slowly over time.

So far we have discussed pixel-based problems with LCD displays, but the system"s backlight can also suffer some common problems that include the backlight randomly blinking off, not turning on, or only illuminating part of the screen.

If only the backlight is malfunctioning, then the LCD panel itself should still be working just fine and should be rendering the text and images of your computer"s output. To test for this, use a bright flashlight and shine it on your screen at an angle in an area where you expect images and text to be (such as the Dock or menu bar). On Apple"s laptop systems, you can shine the flashlight through the Apple logo on the back to illuminate the screen on the front and better detect text and images that way.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

4. #The fault of the product is basically caused by the above reasons. If the appearance is fault-free, the lamp bar can be crossed to confirm whether the phenomenon follows the lamp bar, or the voltage of the lamp bar and the conduction condition between the lamp beads can be measured.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Before we get into specifics about how this would work, it is important to understand that liquid crystal display panels and polarizers utilize organic compounds that are susceptible to high heat and light energy stress. These organic compounds will eventually break down if deployed in high stress environments. One such contributing factor to LCD panel failure is the use of a high energy unfiltered illuminator. The near IR and shorter UV wavelengths not only add excess heat that may overheat the liquid crystal and prevent them from working properly, but they also add UV band energy that is destructive to organic compounds.

Over time the UV and IR will degrade and damage the LCD panel and polarizers to the point that they produce an unacceptably poor performance. In most applications this is observed to be color shift, washed out images and an observable raise in the darkness levels produced by a damaged LCD panel.

In order to help prolong the onset of such damage a set of UV and IR band filters and mirrors can be used to minimize the amount of harmful energy that is conveyed to the LCD panel from the illuminator. In order to determine what combination of filters and mirrors are best for any particular application it is important to know how each material reacts to the various intensities of bandwidths emitted by your chosen illuminator.

Frequently the Illuminators used in LCD systems are gas discharge lamps such as xenon arc lamps and metal halide light sources. A standard hot mirror that reflects energy between 750 and 1200 nm can be used to mitigate the majority of IR energy being conveyed to the LCD panel. In addition a UV blocker can be used to mitigate the damage from energy below 400 nm.

Other thin film coatings and substrates can be utilized to reduce the IR and UV damage to an LCD panel. Any solution must be well researched to minimize concerns so that a sufficient cooling mechanism is planned and allowed for in the application.

Troubleshooting CRTs versus LCDs begins with similar steps, but diverges due to the differing natures of the two display types. The first troubleshooting steps are similar for either display type: power down the system and display and then power them back up; make sure the power cable is connected and that the outlet has power; verify that the signal cable is connected firmly to both video adapter and display and that there are no bent pins; verify that the video adapter is configured properly for the display; try the problem display on a known-good system, or try a known-good display on the problem system; and so on. Once you"ve tried the "obvious" troubleshooting steps, if the problem persists, the next step you take depends on the type of display. The following sections cover basic troubleshooting for CRTs and LCDs.

Catastrophic CRT failure is imminent. The noises are caused by high-voltage arcing, and the smell is caused by burning insulation. Unplug the CRT from the wall before it catches fire, literally.

If your LCD displays no image at all and you are certain that it is receiving power and video signal, first adjust the brightness and contrast settings to higher values. If that doesn"t work, turn off the system and LCD, disconnect the LCD signal cable from the computer, and turn on the LCD by itself. It should display some sort of initialization screen, if only perhaps a "No video signal" message. If nothing lights up and no message is displayed, contact technical support for your LCD manufacturer. If your LCD supports multiple inputs, you may need to press a button to cycle through the inputs and set it to the correct one.

Unlike CRTs, where increasing the refresh rate always reduces flicker, LCDs have an optimal refresh rate that may be lower than the highest refresh rate supported. For example, a 17" LCD operating in analog mode may support 60 Hz and 75 Hz refresh. Although it sounds counterintuitive to anyone whose experience has been with CRTs, reducing the refresh rate from 75 Hz to 60 Hz may improve image stability. Check the manual to determine the optimum refresh rate for your LCD, and set your video adapter to use that rate.

First, try setting the optimal refresh rate as described above. If that doesn"t solve the problem and you are using an analog interface, there are several possible causes, most of which are due to poor synchronization between the video adapter clock and the display clock, or to phase problems. If your LCD has an auto-adjust, auto-setup, or auto-synchronize option, try using that first. If not, try adjusting the phase and/or clock settings manually until you have a usable image. If you are using an extension or longer than standard video cable, try connecting the standard video cable that was supplied with the display. Long analog video cables exacerbate sync problems. Also, if you are using a KVM switch, particularly a manual model, try instead connecting the LCD directly to the video adapter. Many LCDs are difficult or impossible to synchronize if you use a KVM switch. If you are unable to achieve proper synchronization, try connecting the LCD to a different computer. If you are unable to achieve synchronization on the second computer, the LCD may be defective. Finally, note that some models of video adapter simply don"t function well with some models of LCD.

Not all analog video cards synchronize perfectly with flat panels. The gray Shutdown screen exaggerates the problem, so don"t worry if very tiny movements are visible after you"ve adjusted clock and phase as well as possible. After you"ve set the clock and phase controls for the best image possible on the gray screen, cancel Shutdown and the image should be optimized.

Your video card is supplying a video signal at a bandwidth that is above or below the ability of your LCD to display. Reset your video parameters to be within the range supported by the LCD. If necessary, temporarily connect a different display or start Windows in Safe Mode and choose standard VGA in order to change video settings.

This occurs when you run an LCD at other than its native resolution. For example, if you have a 19" LCD with native 1280x1024 resolution but have your display adapter set to 1024x768, your LCD attempts to display those 1024x768 pixels at full screen size, which physically corresponds to 1280x1024 pixels. The pixel extrapolation needed to fill the screen with the smaller image results in artifacts such as blocky or poorly rendered text, jaggy lines, and so on. Either set your video adapter to display the native resolution of the LCD, or set your LCD to display the lower-resolution image without stretching the display (a feature sometimes referred to as display expansion), so that pixels are displayed 1:1, which results in the lower resolution using less than the entire screen.

This is a characteristic of LCDs, particularly older and inexpensive models, caused by defective pixels. Manufacturers set a threshold number below which they consider a display acceptable. That number varies with the manufacturer, the model, and the size of the display, but is typically in the range of 5 to 10 pixels. (Better LCDs nowadays usually have zero dead pixels.) Nothing can be done to fix defective pixels. Manufacturers will not replace LCDs under warranty unless the number of defective pixels exceeds the threshold number.

Some people claim that leaving the unit powered off for a day or two will "erase" a persistent after-image. Others suggest leaving a neutral gray screen (like the one used for phase adjustment) up on the screen to "equalize" the display. I dunno. FWIW, I"ve seen this problem on older Samsung panels but never on the Sony or NEC/LaCie panels I use.

Again, this is a characteristic of LCDs, particularly older and inexpensive models. The after-image occurs when the display has had the same image in one place for a long time. The after-image may persist even after you turn the display off.

Transistor-based pixels in an LCD respond more slowly than the phosphors in a CRT. The least-expensive LCDs exhibit this problem even with slow image movement, as when you drag a window. Better LCDs handle moderately fast image movement without ghosting, but exhibit the problem on fast-motion video. The best LCDs handle even fast-motion video and 3D gaming very well. The only solution to this problem is to upgrade to an LCD with faster response time.

These steps are as generic as possible, since most LCD displays use a similar design. However, you will need to think carefully about how to take the display apart so you can put it back together, and have it still work!

The images are from Repair ViewSonic VX924 LCD Monitor Blinking Green power Button (youtube). You should watch it through once to get an idea for what it"s like.

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

1Case 6-Abnormal Display. Bad components in power section of t-con.Case 7-Noise. Solder defect or shorted components on t-con.Case 8-Abnormal Display. Bad components in power section of t-con.Case 9-Noise. Solder defect or shorted components on t-con.Case 10-Abnormal Display. Bad components in power section of t-con.Case 11-Abnormal Display. Bad components in power section of t-con.Case 12-Noise. Bad solder connections, shorted or open components on t-con.Case 13-Noise. Bad solder connections, shorted or open components on t-con.Case 14-No display and back lights are lit. T-con Fuse Open or Bad components in power section of t-con. No voltage to t-con from main board or power supply(main board or power supply failure).Case 15-No back light. Inverter failure or power supply failure.Case 16-Dim back light. Inverter failure.Case 17-Dim back light. Inverter failure.Case 18-Dim back light. Inverter failure.

2Case 19-Uneven display. cell defect.Case 20-Uneven display. cell defect.Case 21-Damage from applied pressure to panel. Bad panelCase 22-Crosstalk. cell defect.Case 23-Crosstalk. cell defect.Case 24-Panel cracked.Case 25-Vertical block. Failed driver IC, TCP/COF failed ACF bonding to panel bad connectionfrom driver IC to TCP/COF.Case 26-Vertical line. Failed driver IC, TCP/COF failed ACF bonding to panel, bad connectionfrom driver IC to TCP/COF.Case 27-Vertical block. Failed driver IC, TCP/COF failed ACF bonding to panel, bad connectionfrom driver IC to TCP/COF.Case 28-Vertical block. Failed driver IC, TCP/COF failed ACF bonding to panel, bad connectionfrom driver IC to TCP/COF.Case 29-Horizontal block. Failed driver IC, TCP/COF failed ACF bonding to panel, bad connectionfrom driver IC to TCP/COF.Case 30-Horizontal block. Failed driver IC, TCP/COF failed ACF bonding to panel, bad connectionfrom driver IC to TCP/COF.Case 31-Horizontal line. Driver IC abnormal output. Failed driver IC, TCP/COF failed ACF bonding topanel, bad connection from driver IC to TCP/COF.

3Case 32-Horizontal block. Failed driver IC, TCP/COF failed ACF bonding to panel bad connectionfrom driver IC to TCP/COF.Case 33-Horizontal block. Failed driver IC, TCP/COF failed ACF bonding to panel bad connectionfrom driver IC to TCP/COF.

COF= Chip on film/flexTCP= Tape carrier packageIC= Integrated circuitT-con= Timing controller(board)LCD= Liquid crystal displayACF= Anisotropic conductive film

one is a hardware fault, the other is a software problem. Although only these two big aspects but involved in the details of the aspect is very much, the following details about the display color abnormal possible reasons and solutions.

Monitor color is not normal, we recommend the first use of the elimination method, as far as possible to eliminate some simple problems. There are many reasons leading to the abnormal display of the display color, such as checking whether the display data line is normal, the display color control panelis not set well, poor contact, or rust of the display wire may lead to such problems.

A kinescope-tube failure can cause this problem, but it is not irreparable – minor electric shocks, serious rewound filament power supply windings, and sometimes the visual discharge power supply resistance of a particular electron gun is miswelded or broken or the resistance value is increased.

In addition, there is easier to let people detour the cause of failure – screen dust caused by too much screen white when red! This kind of fault often happens in the monitor that color temperature slants warm (a lot of monitors can set color temperature by oneself), say so, encounter white (and similar color) slants red when the fault you had better be cleaned the first screen later undertake other checks, if the fault disappears, mean you won’t because of this and “unlucky” detour. Of course, too low brightness values on some models can also cause this “fault” phenomenon.

Some half professionals see the two faults as a tube in life, some of the maintenance personnel to see will say adjust the contrast and the focusing extremely potentiometer and accelerate the potentiometer on the ignition coil will be good, others say it’s caused by a hardware failure or graphics driver damage of graphics, these point of failure judgment is wrong.

The aging of the kinescope and the decline, in contrast, will not cause such failure phenomenon, as for the adjustment of the collector and the acceleration of the electrode potentiometer is not correct, this is palliative, and it is difficult to adjust to a satisfactory degree, the most troublesome is that the fault will soon return, even accelerate the aging of the kinescope.

The real failure point of the type 1 fault phenomenon is usually due to the aging of the focusing knob of the FBT. You can try to replace an FBT first. Of course, if the monitor has been in use for more than six years, then we need to take into account the possibility of tube aging. In addition, it may be the tube seat of the picture tube and the large area of the negative copper foil leakage phenomenon caused by the displacer (after analysis like design problems), so sometimes into a maintenance dilemma after the replacement of a genuine tube seat try.

The poor contact of the video card usually causes the failure of starting up and there is an alarm sound or the system is unstable resulting in a crash and other failures. The reason for the poor contact of the graphics card is that the gold finger of the graphics card is oxidized, dust, the quality of the graphics card is poor or the baffle of the case has a problem. For the golden finger oxidation caused by poor contact, can use an eraser to wipe the golden finger to solve; For dust caused by poor contact, general removal of dust can be solved; For the hardware quality caused by poor contact, usually through the replacement method to detect, generally replace the video card to solve; For the case baffle problem caused by poor contact, usually the video card can not be fully inserted into the video card slot, can be replaced by the case to eliminate.

Compatibility failure will usually cause the computer can not to start up and alarm sound, the system is not stable crash or screen abnormal miscellaneous phenomenon. Display card compatibility fault generally occurs in the computer just installed or upgrade, more in the motherboard and display card is not compatible or motherboard slot and display card gold finger can not completely contact. The video card compatibility fault usually USES the replacement method to detect, generally USES the replacement video card to troubleshoot the fault.

The failure of the components of the graphics card will usually cause the failure of the computer can not startup, the system is not stable crash, flower screen, and other fault phenomena. The damage of graphics components generally includes the damage of graphics chip, BIOS, memory, capacitance, or field-effect tube. For the damage and failure of graphics card components, it is generally necessary to carefully measure the signals in the graphics card circuit to judge the damaged components. After finding the damaged components, replace them.

The failure of the graphics driver usually causes the system unstable crash, flower screen, text image graphics card is not complete, and other fault phenomena. The video driver’s fault mainly includes the loss of the video driver, the video driver is incompatible with the system, the video driver is damaged, and the video driver cannot be installed. For the video card, driver failure generally first enter the “device manager” to see whether there is a video card driver, if not, re-install. If so, but the graphics driver has a “!”, the video card driver is not installed, the driver version is not correct, the driver and the system are not compatible. Generally, remove the video card driver reinstall, if installed after there are “!”, you can download the new version of the driver installation. If you cannot install a graphics driver, there is usually a problem with the driver or with the registry.

CMOS setup failure is caused by the error of displaying related options in CMOS. Common CMOS setup failures mainly include: integrated graphics card motherboard, CMOS graphics card shielding options setting error; For example, the “AGP Driving Control” option is incorrectly set (usually “AUTO”), “AGP Aperture Size” option is incorrectly set, and “FAST Write Supported” option is incorrectly set.CMOS error is generally modified by loading the default BIOS value.

Video card over frequency problem refers to the time spent to improve the video card speed, improve the video card’s working frequency, and lead to computer failure. When a problem occurs, the frequency can be restored to the factory default.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Brightness issues can be both hardware failures or simply settings that need to be adjusted, below are a few steps to help determine the point of failure.

Lines on the LCD BISTin this case point to the LCD Screen itself. If the lines are not seen during the LCD BIST we would then look to the Video Card, System Board, or the LCD Cable

If the issue persists on the external monitor, it may be an issue with the video card (GPU) or video settings and not the laptop LCD panel. Go to verify display or video issues in Windows Safe Mode. Otherwise, go to the next step.

Performance issues may occur if there is any damage to the LCD screen. The display may stop working, work intermittently, flicker, display horizontal or vertical lines, and so on, if there is damage to the display screen.

Dell laptops have integrated diagnostic tools that can determine if the screen abnormality is an inherent problem with the LCD screen of the Dell laptop or with the video card (GPU) and computer settings.

When you notice screen abnormalities like flickering, distortion, clarity issues, fuzzy or blurry images, horizontal or vertical lines, color fade, running a diagnostic test on the LCD helps identify if the issue is with the LCD panel.

Press and hold the D key and turn on the computer to enter the LCD built-in self-test (BIST) mode. Continue to hold the D key until you see the entire screen change colors.

If you do not detect any screen abnormalities in the integrated self-test mode, the LCD panel of the laptop is functioning properly. Go to the Update the video card (GPU) driver, monitor driver, and BIOS section.

If you notice any abnormalities in the LCD built-in self-test mode, contact Dell Technical Support to learn more about repair options that are available in your region.

Display settings like brightness, refresh rate, resolution, and power management may affect the performance of the LCD screen on your Dell laptop. Changing or adjusting the display settings can help resolve several types of video issues.

If the diagnostic tests on the LCD panel and the video card (GPU) passed, it is most definitely an issue that is related to software that is installed on the computer. If the above troubleshooting steps did not resolve the issue, you may try to restore the computer to factory default settings as a last resort.

It is estimated that there are around one billion personal computers around the world, and with every single desktop computer, there is also a monitor attached to it. Every day, hundreds of computer monitors break down, and if you have a LCD monitor that you bought fairly recently and have questioned why it won"t turn on anymore, it"s most likely a power problem that can be fixed to save you hundreds of dollars. This guide will specialize on the computer monitor model LG L196WTQ-BF, but most monitors will follow similar design and can generally be fixed using the same instructions.

Recently, the LCD screen started to show some artifacts, like flickering, screen freeze in dark image and corner starts to get brighter. Most of the flickering happens in a horizontal pattern (horizontal lines, parts)

Searching in the web, I concluded this could be a screen inverter failure, but I have no idea if another piece of hardware could be responsible of this.

There are many reasons why a screen could be flickering, including physical damages to hardware, software problems and bugs in specific applications. Changes in settings and malware can also cause your computer or mobile screen to perform poorly.

The new technology that makes Prius so valued and coveted, however, comes with its own myriad of potential headaches. A lot of the technology is new or still in the early years of development and is mostly untested until it gets into the hands of consumers. One headache that many post-2004 Prius model owners experience is the failure of their Multi-Function Display (MFD).

Multi function displays are a great leap forward in automotive innovation, and many other vehicle makers have followed suit with their own versions in recent years. However, certain Prius models are prone to MFD failures. With these failures comes a wide array of symptoms, some a minor frustration, some a major bane in your Prius ownership. Some of the most common symptoms of MFD failure include:

If your MFD does not provide you with a readout of your miles, energy flow, or any other standard need-to-knows, you are experiencing multi function display failure and should have your unit inspected by a certified, experienced mechanic immediately.

If your radio suddenly turns itself off without your physical command to do so, this is a seemingly innocuous sign that can quickly compound into full-on MFD failure. The same is true if you suddenly find yourself unable to turn your music up, down, or off.

If you are unable to access your built-in GPS from your MFD, this is a clear sign of MFD failure. Which this is not a catastrophic event most of the time, not having a GPS for those who depend on them can make life much harder.

If your Toyota Prius is experiencing any of these symptoms of multi function display failure, it’s time to bring it in to your local Mechanics Direct for a diagnosis and repair. Mechanics Direct services a wide area of Massachusetts, including North Chelmsford, Chelmsford, Dracut, Tyngsborough, Westford, and Lowell, MA. Mechanics Direct staffs only the most experienced, qualified technicians on salary, ensuring your vehicle will be given the proper time and attention it needs to get you up and running again.

Some TV displays, such as LCD screens, use a backlight to illuminate the picture. If the backlight burns out or stops working, it will result in a blank TV screen.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey