fluorescent lamp in lcd panel testing manufacturer

Plazmo is the largest supplier of CCFL backlights (Cold Cathode Fluorescent Lamp) in North America. We currently have more 1 million CCFL backlights in stock and ready to ship.

The CCFL products we carry consist of hundreds of different sizes of raw Cold Cathode Fluorescent Lamps (CCFLs) available in diameters from 1.8mm - 6.0mm, and lengths from 40mm all the way up to 1,400mm. We also have more than 200,000 complete LCD backlight assemblies in stock in addition to the millions of CCFL backlights Plazmo has in stock.

We specialize in precision color-matching technology and use the latest in testing equipment that allows us to both analyze and produce any color CCFL backlight you want. This includes the full spectrum of white lamps commonly used in various LCD screens as well as specialty color, UV, and infrared lamps that are used in a wide range of applications.

In addition to our standard CCFL backlight offerings, we have complete engineering and manufacturing capabilities for custom designs. We can make any type of CCFL backlight you might need. If you have an old, obsolete LCD or even a new, yet uncommon, LCD requiring a specific or custom-made backlight, we can help. We make new, specialty backlight lamps for any and all LCD applications, including straight and shaped lamps. Some of the CCFL backlight shapes Plazmo offers are: C, U, L, and M shape lamps. In short, if you don"t find the perfect solution for your LCD backlighting needs on our website,CCFLWarehouse.comorPlazmo.com, just give us a call or send us an email with your specific needs.

To go with the vast array of CCFL backlights we have in stock, we also offer the most common CCFLwire harnessesused in LCD backlighting. We stock UL-rated wire harnesses which include connector types from brands like JST, JAE, Molex, Honda, and many more. We also stock all of the components you would need to make your own, custom harnesses. Those components include High Voltage CCFL lamp wire, terminals, connectors and shrink tube, to name a few. If you need a CCFL wire harness that isn’t found atPlazmo.com, give our experts a call or send us an email. We can custom design and make practically any CCFL wire harnesses you might need. Whether you are a small LCD repair facility or a large OEM, we are CCFL backlight and LED backlight experts, and we are here to help.

Silicone end caps for CCFL backlights are a necessary component in making LCD backlight repairs. That’s why Plazmo carries hundreds of different models of silicone end caps. These include a variety of single, dual and triple LCD backlight lamp assembly varieties. However, not all of the end cap possibilities out there are available directly from our website, but we are able to help you find one that would be compatible with your needs. Send our experts an email or give us a call and we will help you find the right end cap, or, in the rare occurrence that we can not find the right end cap, we can custom manufacture the ones you need. For more information on custom CCFL silicone end caps, our contact information is below; we are here to help.

CCFLs have been used for years as a backlight source. These backlights usually have a hollow glass cylinder - 2 to 10 mm in diameter, that’s internally coated with a phosphorescent material and filled with a noble gas (most commonly argon). The tube is then sealed at both ends with an iron-nickel electrode located at each end of the tube.

CCFLs operate on high-voltage alternating current (AC). When the high voltage is applied the resulting arc ionizes the internal noble gas which produces ultraviolet energy. The ultraviolet energy excites the phosphorescent lining which then produces light in the visible range (400 to 700 nm). The phosphorus make-up determines the color temperature of the visible light output. Typically, the resulting temperature color is in the 2800 - 3200K range, which looks like a warm to standard white light.

Most systems that have LCD panels run on direct current (DC), the DC has to be converted to AC in order power the lamp. An inverter is typically used to create the high-voltage AC. In addition, CCFL backlights require constant current, not constant voltage. Also, the strike voltage or the voltage required to start the light of the CCFL is different than the sustaining voltage. The inverter that’s designed to power an LCD CCFL will typically run at about 50 kHz. The inverter has to be matched to the specifications of the CCFL, particularly the current, strike voltage, and operating voltage.

When power is applied to the inverter, it starts by ramping up the output voltage until the CCFL turns on (an arc strikes). The strike voltage may be several hundred volts higher than the sustaining voltage, just to get the CCFL to light up. After the tube strikes which is identified by current flowing, the inverter then drops the voltage until the rated current is flowing which is typically around 5 to 7 mA. For example, a CCFL may have a strike voltage of approximately 1200 V, an operating voltage of approximately 800 V, and an operating current of 6 mA. Using this example, the power draw would then be 4.8 watts. The inverter switch has built-in protection so that if the tube does not strike after it’s gotten a few hundred volts more than the normal strike voltage, the tube is considered dead.

The life expectancy of CCFLs used as backlights is now around 50,000 - 60,000 hours. CCFLs rarely exhibit catastrophic failure unlike incandescent bulbs. Rather, the tube slowly dims over time due to phosphor erosion. The useful life for all backlights is defined by when the light output from the tube reaches half of its initial brightness. Increasing the current will decrease the life expectancy, but will increase the brightness. The color temperature of the tube doesn’t usually change as the bulb gets older.

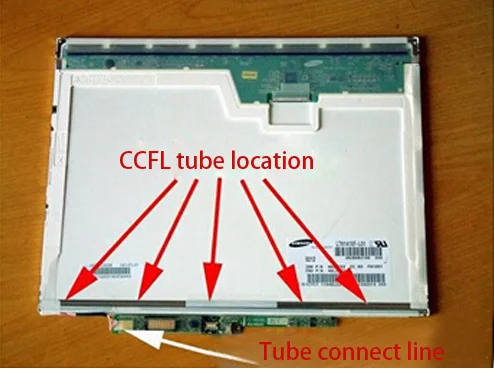

In many LCD panels, the CCFLs may be replaced when they reach the end of their useful life. CCFLs typically have low heat generation, about 6 - 8 watts per tube. The heat is spread over the surface area of the tube easing heat dissipation. Most LCDs in the embedded market use 4 tubes or less. However, when many CCFLs, more than 4, are used together in an enclosed panel, overall heat dissipation should be taken into account. The optimum ambient temperature range for the highest efficiency and brightness is 77 to 104°F (25 to 40°C). Depending on the design of the tube, it may operate at temperatures from -22 to +185°F (-30 to +85°C); however, performance may be affected at either end of the spectrum, especially the lower end. At low temperatures the brightness decreases and the strike voltage increases. The typical efficiency of CCFLs is in the range of 70 to 90 lumens-per-watt, although with the competition of LED backlights, new advances are being made to boost efficiency.

LCD Lighting produces both hot-cathode (HCFL) and cold cathode (CCFL) fluorescent lamps for many OEM’s worldwide. Hot cathode lamps are found in many applications from home and retail to the the highly custom/ task oriented lamps for business and industrial applications. Custom fluorescent lamps in business are found in OEM applications such as scanners, vision /inspection systems, graphic arts and medical devices and even the outdoor sign industry. The HFCL style lamps can be made with internal reflectors or apertures for when more directional control is required.

CCFL style fluorescent lamps use an electrode (cylindrical metal shell) instead of a filament the hot cathode HCFL style uses. Cold cathode fluorescent lamps also include the family of neon lamps that are custom made by sign benders all over the world. Like HCFL, CCFL’s use mercury vapor to excite the phosphor coating on the inside of the lamp to emit visable light. Large diameter CCFL’s are most often used as architectural accents for interior alcove and general lighting applications. Smaller diameter 15mm and under are found in neon signs, back lighting, graphic arts, scanners and other specialized applications.

LCD Lighting manufactures a wide variety of standard and custom linear fluorescent lamp. We manufacturer lamps used worldwide in the retail and industrial settings from the curing and graphic arts industry to supplying the needs of professionals in the aquarium and transportation market. Need help customizing a standard lamp or designing new lamp style- give us a call. Our experience is deep from designing lamps for quality control visions systems to new style of medical lamps, we work with designers to make it. Give us a call.

LCD Lighting manufactures miniature lampsfor avionic displays and cabin lighting in HFCL and CCFL styles. Typically these are custom multiple bend lamp configuration used to backlight liquid crystal displays (LCD), as well as indirect cabin lighting, passenger and crew reading lights, galley and lavatory lighting, entry lighting, cockpit applications, cargo areas, wing inspection lights, exterior emergency lighting, landing lights and many other locations.

Smaller miniature and subminiature cold cathode (CCFL) “straw” lamps and are the premier choice for backlighting, entertainment, and liquid crystal displays (LCDs) in numerous commercial, civil, military, and space avionics information systems. These lamps allow for new opportunities for low profile applications where straight or various bent U, L, S, or rectangular fluorescent lamps are needed.

Compact fluorescent lamps for specialty lamps provide high light output (lm/watt) without consuming high energy or producing excessive heat as compared to incandescent lamps of comparable light output- helps reduce maintenance costs.

We offer many standard and custom designs. With the flexibility of a dual /twin tube design – lamp designers have access to many custom configurations – Clients can choose wattage, shape, size, and standard or special arc lengths and the full range of specialty phosphors from UVA/ UVB and actinic phosphors to lamps OEM styles with two different phosphors (one in each tube)- It’s like having two bulbs in one! Let us know what you want to design.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

The Lighting Facts label gives shoppers the information they need to buy the most energy-efficient bulb to meet their lighting needs. The label includes a bulb’s brightness, energy cost, life, light appearance, and wattage. In addition, the principal display panel on the front of packaging focuses on lumens, a measure of brightness, rather than on watts, a measure of the amount of energy used, and includes the estimated yearly energy cost for each bulb. Bulbs themselves also feature lumens, and in the case of CFLs, a mercury disclosure.

The FTC enforces the Energy Labeling Rule. To help you comply with the labeling and reporting requirements for common household light bulbs, FTC staff have prepared answers to some common questions we’ve been asked.

The FTC Lighting Facts label and principal display panel information must appear on packaging for most general service “lamps” with medium screw bases, including most incandescent, compact fluorescent (CFL) and light-emitting diode (LED) light bulbs. The Energy Labeling Rule has several exceptions for various lamp types, so it’s a good idea to review specific definitions for answers about coverage. See 16 CFR § 305.2 and § 305.5.

the correlated color temperature of each lamp included in the package, measured in degrees Kelvin, expressed as “Light Appearance” and by a number and a marker placed proportionately on a scale ranging from 2,600 K on the left to 6,600 K on the right

the ENERGY STAR logo for qualified products, if you wish. Manufacturers who have a signed Memorandum of Understanding with the Department of Energy or the Environmental Protection Agency may add the ENERGY STAR logo to labels on qualifying covered products that are covered by the Memorandum of Understanding

the lamp"s average initial lumens, expressed as a number rounded to the nearest five, next to the word “lumens,” both in minimum eight point font, and

If the total surface area of the product package available for labeling is less than 24 square inches, and the package shape or size cannot accommodate the standard label, you may provide the information using asmaller linear label. See 16 CFR § 305.15.

Specialty consumer lamps include most lamps with a medium screw, candelabra screw, a GU-10, or GU-24 base and a lumen range between 310 lumens and no more than 2,600 lumens, or a rated wattage between 30 and 199. The term does not cover any lamp that qualifies as a general service lamp. The Energy Labeling Rule has several exceptions for various lamp types, so it’s a good idea to review specific definitions for answers about coverage. See sections305.5and305.23of the Rule for details about the coverage.

Manufacturers may use the Lighting Facts label required for general service lamps or the smaller version of the Lighting Facts label for most specialty consumer lamps, as long as it appears on the principal display panel. However, a specialty consumer lamp that is a vibration-service lamp, rough service lamp, appliance lamp or shatter resistant lamp must use the Lighting Facts labels (and follow all other requirements) applicable for general service lamps.

If the required disclosures (i.e., either the abbreviated specialty bulb disclosure or the standard general service lamp label) would not be legible on the front of a single-card blister package due to its size, you may use a smaller label on the principal display panel that says “See Back for Lighting Facts,” and include the full Lighting Facts label on the back of the package.

You must ensure that you enter the correct data for your products. If you have signed a Memorandum of Understanding with the Department of Energy or the Environmental Protection Agency, you may use labels with the ENERGY STAR logo, but only on certified models listed on the ENERGY STAR website. SeeEnergystar.govfor more information.

You must use Department of Energy (DOE) test procedures for any lamps (e.g., general service lamps), covered by those procedures. You may find themhere. See 10 CFR Part 430, 10 CFR Part 431, and 10 CFR § 429.11.

If a lamp is not covered by DOE tests, you must have competent and reliable scientific evidence to support the representations you make on the required label. See 16 CFR § 305.8.

Here is asample of a bilingual label. All the required information must appear in both languages, but you don’t need to repeat numeric characters that are identical in both languages. The amendments don’t allow a trilingual label. See 16 CFR § 305.23.

No. The Rule doesn’t require you to get FTC approval before you label and sell the products. However, you must meet the FTC reporting requirements before you distribute products that are covered by the Rule. You also must comply with the Rule’s testing requirements. See the previous question: What test procedures must I use to support the content of my Lighting Facts label?

If you are a manufacturer of general service lamps or specialty consumer lamps covered by the labeling requirements, you must post images of the Lighting Facts labels for the products on a publicly available website so website retailers can hyperlink to the labels or download them. The label for each model must remain on the website for six months after production of that model ends. See 16 CFR § 305.6.

A manufacturer, distributor, retailer, or private labeler who advertises a general service lamp on a website or in a print catalog that contains the terms of sale, retail price, and ordering instructions for consumers, must disclose clearly and conspicuously, on the page listing the lamp, an image of the Lighting Facts label.

The labels must be clear and conspicuous, and appear in close proximity to the lamp’s price on each page that contains a detailed description of the lamp.

The Rule requires reports for general service incandescent lamps and CFLs. It does not require reports for general service light-emitting diode (LED or OLED) lamps or specialty consumer lamps. See 16 CFR § 305.8.

You can submit the reports required by the FTC through the Department of Energy’s Compliance Certification Management System (CCMS) atregulations.doe.gov/ccms. The reports must contain the same content the Department of Energy requires under its certification rules. See 16 CFR § 305.8 and 10 CFR Part 429.

Yes. You have the option to use the Lighting Facts label on lamps that do not meet the definition of general service lamp or specialty consumer lamp, as long as you comply with all the Rule’s requirements for specialty consumer lamps.

Family Owned & Operated for over 65+ years, H. H. Fluorescent & LED Products, Inc. has supplied customers with superior fluorescent fixture parts. Located in Montgomery County, Pennsylvania, we continue to serve the fluorescent lighting industry with reliable, high quality products. As an independently-owned company, we also know what it takes to deliver excellent customer service.

Family Owned & Operated for over 65+ years, H. H. Fluorescent & LED Products, Inc. has supplied customers with superior fluorescent fixture parts. Located in Montgomery County, Pennsylvania, we continue to serve the fluorescent lighting industry with reliable, high quality products. As an independently-owned company, we also know what it takes to deliver excellent customer service.

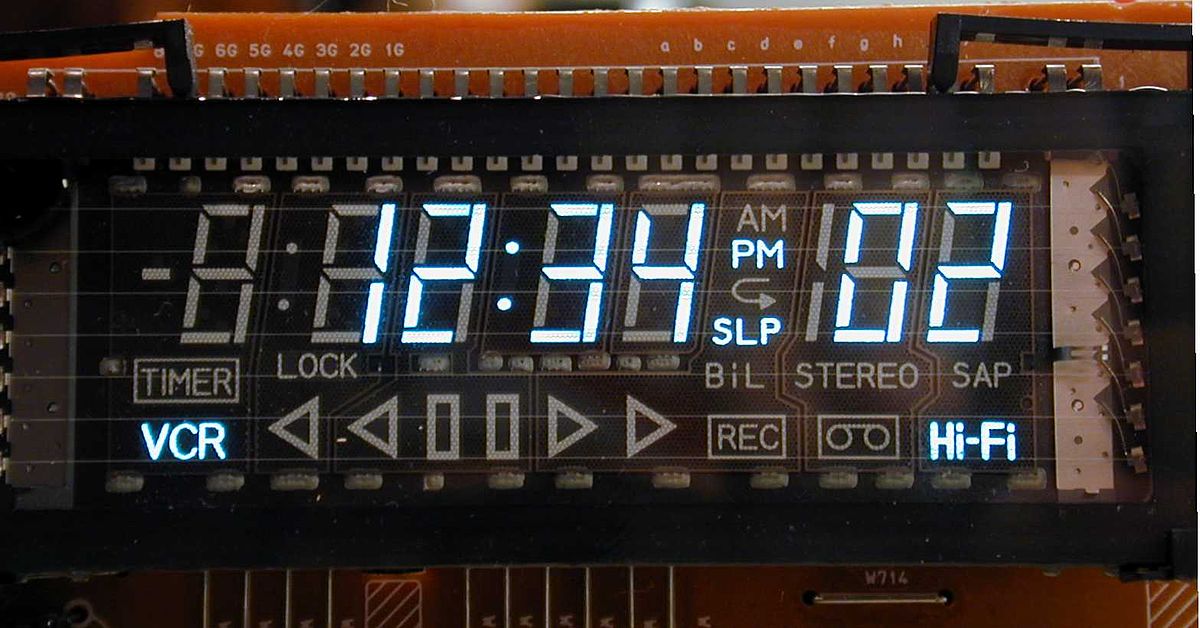

A vacuum fluorescent display (VFD) is a display device once commonly used on consumer electronics equipment such as video cassette recorders, car radios, and microwave ovens.

A VFD operates on the principle of cathodoluminescence, roughly similar to a cathode ray tube, but operating at much lower voltages. Each tube in a VFD has a phosphor-coated carbon anode that is bombarded by electrons emitted from the cathode filament.triode vacuum tube because it also has a mesh control grid.

Unlike liquid crystal displays, a VFD emits very bright light with high contrast and can support display elements of various colors. Standard illumination figures for VFDs are around 640 cd/m2 with high-brightness VFDs operating at 4,000 cd/m2, and experimental units as high as 35,000 cd/m2 depending on the drive voltage and its timing.Cadmium was commonly used in the phosphors of VFDs in the past, but the current RoHS-compliant VFDs have eliminated this metal from their construction, using instead phosphors consisting of a matrix of alkaline earth and very small amounts of group III metals, doped with very small amounts of rare earth metals.

VFDs can display seven-segment numerals, multi-segment alpha-numeric characters or can be made in a dot-matrix to display different alphanumeric characters and symbols. In practice, there is little limit to the shape of the image that can be displayed: it depends solely on the shape of phosphor on the anode(s).

The device consists of a hot cathode (filaments), grids and anodes (phosphor) encased in a glass envelope under a high vacuum condition. The cathode is made up of fine tungsten wires, coated by alkaline earth metal oxides (barium,electrons when heated to 650 °Cdiffused by the grids (made using Photochemical machining), which are made up of thin (50 micron thick) stainless steel.fluoresce, emitting light. Unlike the orange-glowing cathodes of traditional vacuum tubes, VFD cathodes are efficient emitters at much lower temperatures, and are therefore essentially invisible.graphite, which in turn is coated with phosphor. This transfers energy from the trace to the segment. The shape of the phosphor will determine the shape of the VFD"s segments. The most widely used phosphor is Zinc-doped copper-activated Zinc oxide,

The cathode wire to which the oxides are applied is made of tungsten or ruthenium-tungsten alloy. The oxides in the cathodes are not stable in air, so they are applied to the cathode as carbonates, the cathodes are assembled into the VFD, and the cathodes are heated by passing a current through them while inside the vacuum of the VFD to convert the carbonates into oxides.

The principle of operation is identical to that of a vacuum tube triode. Electrons can only reach (and "illuminate") a given plate element if both the grid and the plate are at a positive potential with respect to the cathode.multiplexed displays where the multiple grids and plates form a matrix, minimizing the number of signal pins required. In the example of the VCR display shown to the right, the grids are arranged so that only one digit is illuminated at a time. All of the similar plates in all of the digits (for example, all of the lower-left plates in all of the digits) are connected in parallel. One by one, the microprocessor driving the display enables a digit by placing a positive voltage on that digit"s grid and then placing a positive voltage on the appropriate plates. Electrons flow through that digit"s grid and strike those plates that are at a positive potential. The microprocessor cycles through illuminating the digits in this way at a rate high enough to create the illusion of all digits glowing at once via persistence of vision.

The extra indicators (in our example, "VCR", "Hi-Fi", "STEREO", "SAP", etc.) are arranged as if they were segments of an additional digit or two or extra segments of existing digits and are scanned using the same multiplexed strategy as the real digits. Some of these extra indicators may use a phosphor that emits a different color of light, for example, orange.

The light emitted by most VFDs contains many colors and can often be filtered to enhance the color saturation providing a deep green or deep blue, depending on the whims of the product"s designers. Phosphors used in VFDs are different from those in cathode-ray displays since they must emit acceptable brightness with only around 50 volts of electron energy, compared to several thousand volts in a CRT.

Besides brightness, VFDs have the advantages of being rugged, inexpensive, and easily configured to display a wide variety of customized messages, and unlike LCDs, VFDs are not limited by the response time of rearranging liquid crystals and are thus able to function normally in cold, even sub-zero, temperatures, making them ideal for outdoor devices in cold climates. Early on, the main disadvantage of such displays was their use of significantly more power (0.2 watts) than a simple LCD. This was considered a significant drawback for battery-operated equipment like calculators, so VFDs ended up being used mainly in equipment powered by an AC supply or heavy-duty rechargeable batteries.

During the 1980s, this display began to be used in automobiles, especially where car makers were experimenting with digital displays for vehicle instruments such as speedometers and odometers. A good example of these were the high-end Subaru cars made in the early 1980s (referred to by Subaru enthusiasts as a digi-dash, or digital dashboard). The brightness of VFDs makes them well suited for use in cars. The Renault Espace and older models of Scenic used VFD panels to show all functions on the dashboard including the radio and multi message panel. They are bright enough to read in full sunlight as well as dimmable for use at night. This panel uses four colors; the usual blue/green as well as deep blue, red and yellow/orange.

This technology was also used from 1979 to the mid-1980s in portable electronic game units. These games featured bright, clear displays but the size of the largest vacuum tubes that could be manufactured inexpensively kept the size of the displays quite small, often requiring the use of magnifying Fresnel lenses.LCD games could be manufactured for a fraction of the price, did not require frequent changes of batteries (or AC adapters) and were much more portable. Since the late 1990s, backlit color active-matrix LCD displays have been able to cheaply reproduce arbitrary images in any color, a marked advantage over fixed-color, fixed-character VFDs. This is one of the main reasons for the decline in popularity of VFDs, although they continue to be made. Many low-cost DVD players still feature VFDs.

From the mid-1980s onwards, VFDs were used for applications requiring smaller displays with high brightness specifications, though now the adoption of high-brightness organic light-emitting diodes (OLEDs) is pushing VFDs out of these markets.

Vacuum fluorescent displays were once commonly used as floor indicators for elevators by Otis Elevator Company worldwide and Montgomery Elevator Company in North America (the former from the early 1980s to the mid-2000s in the form of (usually two) 16-segment displays, and the latter from the mid 1980s to the mid 1990s in the form of (usually 3) 10x14 dot-matrix displays).

In addition to the widely used fixed character VFD, a graphic type made of an array of individually addressable pixels is also available. These more sophisticated displays offer the flexibility of displaying arbitrary images, and may still be a useful choice for some types of consumer equipment.

Several radio amateurs have experimented with the possibilities of using VFDs as triode amplifiers.Korg released the Nutube, an analogue audio amplifier component based on VFD technology. The Nutube is used in applications such as guitar amplifiers from Vox

Fading is sometimes a problem with VFDs. Light output drops over time due to falling emission and reduction of phosphor efficiency. How quickly and how far this falls depends on the construction and operation of the VFD. In some equipment, loss of VFD output can render the equipment inoperable. Fading can be slowed by using a display driver chip to lower the voltages necessary to drive a VFD. Fading can also occur due to evaporation and contamination of the cathode. Phosphors that contain sulfur are more susceptible to fading.

Emission may usually be restored by raising filament voltage. Thirty-three percent voltage boost can rectify moderate fade, and 66% boost severe fade.

Of the three prevalent display technologies – VFD, LCD, and LED – the VFD was the first to be developed. It was used in early handheld calculators. LED displays displaced VFDs in this use as the very small LEDs used required less power, thereby extending battery life, though early LED displays had problems achieving uniform brightness levels across all display segments. Later, LCDs displaced LEDs, offering even lower power requirements.

The first VFD was the single indication DM160 by Philips in 1959. It could easily be driven by transistors, so was aimed at computer applications as it was easier to drive than a neon and had longer life than a light bulb. The 1967 Japanese single digit seven segment display in terms of anode was more like the Philips DM70 / DM71 Magic Eye as the DM160 has a spiral wire anode. The Japanese seven segment VFD meant that no patent royalties needed to be paid on desk calculator displays as would have been the case using Nixies or Panaplex neon digits. In the UK the Philips designs were made and marketed by Mullard (almost wholly owned by Philips even before WWII).

The Russian IV-15 VFD tube is very similar to the DM160. The DM160, DM70/DM71 and Russian IV-15 can (like a VFD panel) be used as triodes. The DM160 is thus the smallest VFD and smallest triode valve. The IV-15 is slightly different shape (see photo of DM160 and IV-15 for comparison).

Joseph A. Castellano (ed), Handbook of display technology, Gulf Professional Publishing, 1992 ISBN 0-12-163420-5 Chapter 7 Vacuum Fluorescent Displays pp. 163 and following

N9WOS (29 July 2005). "VFD as an audio/RF amplifier?". Electronics Point forums. Archived from the original on 11 March 2018. Retrieved 11 March 2018.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

Unlike OLED and microLED displays, LCDs cannot achieve true blacks for pixels which are illuminated by the backlight. Some LED-backlit LCDs use local dimming zones to increase contrast between bright and dim areas of the display, but this can result in a "blooming" or "halo" effect on dark pixels in or adjacent to an illuminated zone.

The local dimming method of backlighting allows to dynamically control the level of light intensity of specific areas of darkness on the screen, resulting in much higher dynamic-contrast ratios, though at the cost of less detail in small, bright objects on a dark background, such as star fields or shadow details.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

The evolution of energy standards and the increasing public expectations regarding power consumption made it necessary for backlight systems to manage their power. As for other consumer electronics products (e.g., fridges or light bulbs), energy consumption categories are enforced for television sets.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. The quantum dors may be in a separate layer as a quantum dot enhacement film, or replace pigment-based green and red resists normally used in LCD color filters. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is too low or the user is sensitive to flicker, this may cause discomfort and eyestrain similar to the flicker of CRT displays at lower refresh rates.

Competing display technologies for the best image performance; A.J.S.M. de Vaan; Journal of the society of information displays, Volume 15, Issue 9 September 2007 Pages 657–666; http://onlinelibrary.wiley.com/doi/10.1889/1.2785199/abstract?

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

Scott Wilkinson. "Ultimate Vizio Archived 26 August 2009 at the Wayback Machine". UltimateAVmag.com. Posted Fri 29 May 2009. Retrieved 16 December 2009.

LED TVs: 10 things you need to know; David Carnoy, David Katzmaier; CNET.com/news; 3 June 2010; https://www.cnet.com/news/led-tvs-10-things-you-need-to-know/

Method of and device for generating an image having a desired brightness; D.A. Stanton; M.V.C. Stroomer; A.J.S.M. de Vaan; US patent USRE42428E; 7 June 2011; https://worldwide.espacenet.com/publicationDetails/biblio?CC=US&NR=RE42428E

Chen, Haiwei; Zhu, Ruidong; Li, Ming-Chun; Lee, Seok-Lyul; Wu, Shin-Tson (24 January 2017). "Pixel-by-pixel local dimming for high-dynamic-range liquid crystal displays". Optics Express. 25 (3): 1973–1984. doi:ISSN 1094-4087. PMID 29519046.

"Implementing directive 2005/32/EC of the European Parliament and of the Council with regard to ecodesign requirements for televisions", 2009; http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32009R0642

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; https://ieeexplore.ieee.org/document/6520956

Energy Efficiency Success Story: TV Energy Consumption Shrinks as Screen Size and Performance Grow, Finds New CTA Study; Consumer Technology Association; press release 12 July 2017; https://cta.tech/News/Press-Releases/2017/July/Energy-Efficiency-Success-Story-TV-Energy-Consump.aspx Archived 4 November 2017 at the Wayback Machine

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

Broadband reflective polarizers based on form birefringence for ultra-thin liquid crystal displays; S.U. Pan; L. Tan and H.S. Kwok; Vol. 25, No. 15; 24 July 2017; Optics Express 17499; https://www.osapublishing.org/oe/viewmedia.cfm?uri=oe-25-15-17499&seq=0

Polarisation-sensitive beam splitter; D.J. Broer; A.J.S.M. de Vaan; J. Brambring; European patent EP0428213B1; 27 July 1994; https://worldwide.espacenet.com/publicationDetails/biblio?CC=EP&NR=0428213B1&KC=B1&FT=D#

www.electronicdesign.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 72f34325e42ecb179a2ad5981afc8831 63.210.148.230 03/08/2023 09:18 PM UTC

These convenient syringe style testers are charged with a special concentrated dye that holds together underwater. 6" plastic "needle" allows for precise dye placement without creating unwanted currents.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The World"s Most Widely Used Weathering Tester™.Test plastics, coatings, and other materials for durability when exposed to outdoor sunlight, heat, and water.

UV light is responsible for almost all photodegradation of durable materials exposed outdoors. The QUV tester’s fluorescent lamps simulate the critical short-wave UV and realistically reproduce the physical property damage caused by sunlight. Types of damage include color change, gloss loss, chalking, cracking, crazing, hazing, blistering, embrittlement, strength loss and oxidation.

Dew, not rain, is responsible for most of the wetness that occurs in outdoor exposure. The QUV UV test chamber"s condensation system realistically simulates dew and accelerates its effect using elevated temperature.

The condensation process automatically purifies the ordinary tap water used in the system. This is because the process of evaporating and condensing the water onto the specimens is actually a distillation process, which removes all impurities. See LU-0801 - QUV Brochure.

The QUV tester conveniently accommodates up to 48 specimens (75mm × 150mm) and complies with a wide range of international, national, and industry specifications, ensuring the reliability and reproducibility of your test program. Visit our standards page for more information.

The QUV UV tester’s simple, proven design makes it easy to install, easy to use, and almost maintenance-free. It operates completely automatically, 24 hours a day, 7 days a week. Features include:Dual touchscreen user interface for easy operation and programming in 17 user-selectable languages: English, Spanish, French, German, Italian, Japanese, Chinese, Korean, Czech, Dutch, Polish, Portuguese, Russian, Swedish, Thai, Turkish, Vietnamese

This is a simplified version of the QUV tester for the lab where economy is critical. The model QUV/basic uses fluorescent UV lamps and a condensation system for moisture simulation. The model, however, does not include the SOLAR EYE irradiance control. Consequently, the light intensity cannot be adjusted or calibrated. This means the QUV/basic tester cannot be used for high irradiance testing. In addition, periodic lamp replacement and repositioning is required.

Q-Lab recommends the QUV/basic tester for comparative exposures where the test specimens and the control specimens are exposed at the same time, in the same tester.

The most popular QUV model features the SOLAR EYE Irradiance Control, for precise maintenance of UV light intensity. The QUV/se tester uses a proven condensation mechanism to simulate outdoor moisture attack.

The SOLAR EYE system is a precision control system that automatically maintains light intensity through a feedback loop. The controller monitors UV intensity and compensates for lamp aging and variability by adjusting power to the lamps. The SOLAR EYE system provides: Controlled irradiance

The QUV/spray tester has the same functions as a standard QUV/se, but also includes a water spray system. Short periods of spray can be used to create a thermal shock. Longer periods can be used to achieve mechanical erosion. The QUV/spray tester can be set to produce: UV alone, spray alone, or condensation. Deionized water is recommended for all spray applications.

UVC light is used widely in ultraviolet germicidal irradiation (UVGI), a technique used to eliminate harmful viruses and bacteria. This short-wavelength, high-energy UVC light can also degrade the materials and surfaces it disinfects. The QUV/uvc model uses UVC lamps to deliver light concentrated at 254 nm to test for material durability against photodegradation effects resulting from exposure to UVC light. The QUV/uvc tester has multiple safety features to prevent stray UVC light from escaping; it is also not equipped with condensation or water spray.

Model QUV/cwSome industry test methods specify the use of cool white fluorescent lamps for indoor photostability testing. To reproduce these indoor light conditions, the QUV/cw uses ordinary cool white fluorescent lamps. It has a SOLAR EYE irradiance control system that monitors and controls visible light output, rather than UV. See LU-0823 - QUV/cw Summary for more information.Temperature Control

All QUV UV testers precisely control temperature to enhance accuracy and accelerate test results. Although temperature does not normally affect the primary photochemical reaction, it does affect the rate of any subsequent reactions. Therefore, the QUV tester’s ability to control temperature is essential during UV exposure.

Standard specimen holders easily adjust for any thickness up to 20mm (3/4") and allow fast, snap-action specimen mounting. Retaining rings provide positive hold-down and do not require that test specimens be cut to close tolerance. In addition, custom holders are available for mounting various products, such as lenses, larger specimens, and 3-D components. See the accessories tab or our specimen mounting page for more information.

Controls & Optional SoftwareThe Dual Touchscreen Display is designed to be both functional and easy-to-use. The QUV main controller features dual, full-color touchscreen displays and can be programmed in eight user-selectable languages (English, French, Spanish, Italian, German, Chinese, Korean, and Japanese). This system includes complete self-diagnostic error checking, constantly monitoring the status and performance of all systems. It also displays tester error messages and routine service reminders as needed. The multicolor LED status indicator light updates users on the tester’s operational state at a glance.

An external USB port on every QUV tester allows users to perform software upgrades quickly to address key performance issues. For quality systems that require documented proof of test conditions, this USB port can also be used to download tester performance history. Additionally, every QUV tester is equipped with an Ethernet connection. Optional VIRTUAL STRIPCHART PC software allows the user to automatically record and monitor exposure conditions and directly transfer data from the QUV UV test chamber to a Windows-based computer. Data from either the USB export or PC application can be emailed directly to Q-Lab"s technical support desk for expert troubleshooting and diagnostics.

Fluorescent UV lamps are inherently more stable than other types of lamps, including xenon arc lamps. The spectral power distribution (SPD) does not change with lamp aging, even up to 8,000 hours. This gives more reproducible test results, fewer lamp changes, and lower operational costs.

Q-Lab produces more UV lamps than the rest of the weathering industry combined. Q-Lab"s lamps are specially engineered to our own proprietary specifications, based on our 50 years of experience with fluorescent UV technology. We have the most stringent quality control testing in the industry. The result is that the QUV tester provides the most consistent, stable spectrum, year after year.

Several different types of UV lamps are available for different applications, which are listed below. See LU-8160 - A Choice of Lamps for QUV and LU-0823 - QUV/cw Summary for more specific application guidelines

The QUV tester’s UVA-340 lamps give the best simulation of sunlight in the critical short wavelength region from 365 nm down to the solar cut-off of 295 nm. See LU-8052 - SPD for QUV UVA-340.

UVA-340+ LampsUVA-340+ lamps offer the same spectrum as UVA-340 lamps but provide longer lifetime at high irradiance, up to 1500 hours at 1.55 W/m2/nm and 750 hours at the maximum irradiance (1.70 W/m2/nm).

The QUV UV tester’s UVA-351 lamps simulate the UV portion of sunlight filtered through window glass. It is most useful for interior applications, for testing of some inks and for polymer damage that can occur in an environment near a window. See LU-8053 - SPD for QUV UVA-351.

The QUV tester’s UVB-313EL lamps maximize acceleration utilizing short-wave UV that is more severe than the UV normally found at the earth’s surface. Consequently, these lamps may produce unrealistically severe results for some materials. UVB-313EL lamps are most useful for QC and R&D applications, or for testing very durable materials. See LU-8051 - SPD for QUV UVB-313EL.

UVB-313EL+ lamps offer nearly the same spectrum as UVB-313EL lamps but provide longer lifetime at high irradiance, up to 1500 hours at 1.55 W/m2/nm and 750 hours at the maximum irradiance (1.70 W/m2/nm)

UVC lamps deliver high-intensity, monchromatic, short-wave UV light at 254 nm, which is well below the solar cut-on. This wavelength represents the most common type of UVC emission used for disinfection of surfaces exposed to harmful bacteria and viruses. While it can kill these pathogens effectively, UVC light can also cause photodegradation of plastics, coatings, and fabrics. UVC lamps reproduce this damaging irradiance, in order to evaluate durability of materials exposed to UVC light

Also known as FS-40 or F40 UVB, this is the original QUV lamp. FS-40 lamps are still specified in a few legacy automotive test methods. QFS-40 lamps should only be used in the QUV/basic tester. See LU-8050 - SPD for QUV QFS-40.

The QUV UV test chamber’s cool white lamps (used only in model QUV/cw) effectively reproduce and accelerate indoor lighting conditions encountered in office and commercial environments as well as retail display lighting. See LU-8049 - SPD for QUV/cw.

The QUV black panel temperature sensor needs to be calibrated periodically by the user to assure accurate and consistent results. Calibrating the QUV black panel temperature sensor is quick and simple, and is performed with any standard reference thermometer.

Easy Calibration Assures AccuracyFor all models except QUV/basic, the QUV SOLAR EYE irradiance sensor needs to be calibrated periodically by the user to assure accurate and consistent results. Calibrating the QUV tester using the AUTOCAL system is extremely simple. It takes only a few minutes and virtually eliminates human error.

Q-Lab has two classes of devices used for irradiance calibration. The Universal Calibrator system is standard with all new QUV testers and is fully compatible with all previous model, as well as Q-SUN testers. The CR10 is Q-Lab"s legacy QUV irradiance calibration system but remains forward-compatible with all new QUV testers. For more information, see LU-0801 - QUV Brochure.

UC10 smart sensors need to be replaced yearly for a newly-calibrated device. This is the most cost-effective option for most users. UC10 smart sensors can, alternatively, be returned to Q-Lab once per year for an inexpensive recalibration. See Recalibration Return Procedure.

Our calibration labs are accredited to ISO 17025 by the American Association of Laboratory Accreditation (A2LA - Ohio Certificate Number 2382-01, China Certificate Number 2383-02, and England Certificate Number 2383-03). Calibrations are traceable to the U.S. National Institute of Standards and Technology (NIST).

Standard specimen holders adjust for any thickness up to 20mm (3/4") and allow fast, snap-action specimen mounting. Retaining rings provide positive hold-down and do not require that test specimens be cut to close tolerance.

In addition, custom holders are available for mounting various products, such as lenses, larger specimens, and 3-D components. Bottle holders, textile holders and special mountings are also available. See LU-8001 - QUV Sample Mounting or the specimen mounting pagefor more detailed information.

To significantly reduce the cost of running the QUV tester’s optional water spray system, Q-Lab offers an optional water repurification systemthat reuses the water that normally would go down the drain.

In labs where space is a premium, QUV UV testers can be stacked two-high with space saver frames. See LU-0820 - QUV Space Saver Specifications for more detailed information.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey