fluorescent lamp in lcd panel testing factory

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Maurice Broomfield (1916-2010) worked to photograph the changing face of British manufacturing industries during the 1950s and 1960s. His photographs are recognized for their uniquely modern design elements, humanist strain, and their contribution to the documentation of the rebirth of British industry in the post war era.

Broomfield was often commissioned by manufacturers to produce photographs of a company"s product, facilities and workers. One approach that lent a special force to his photographs of industry was his attitude towards workers; instead of emphasizing the mechanical or repetitive qualities of modern work, he chose to illuminate the strength and sensitivity of individuals. In his images, monumental machines and bizarre equipment are examined or operated by crisply attired men and women.

Heavily influenced by the New Objectivity aesthetic that emerged in Germany in the 1920s, Broomfield employed the use of dramatic lighting and unconventional camera angles, but brought the aesthetic to new levels in his use of colour film. He worked closely with Imperial Chemical Industries (ICI) and llford, the manufacturer of photographic paper, to test new colour processes. His, and the industry"s shift, from black and white to colour, is represented in these 12 photographs.

Broomfield"s photographs were the focus of an exhibition at the Science Museum entitled "Maurice Broomfield"s "New Look" at Industry" (February-May, 2007). The exhibition highlighted Broomfield"s photographs as important records of the post war era British manufacturing culture, but also pointed to their distinctly contemporary value: as the manufacturing sector has increasingly turned to cheaper markets in Asia and elsewhere, these photographs serve as reminders of a recent stage in Britain"s manufacturing history.

Broomfield described Philips electronics’ headquarters as ‘an industrial photographer’s paradise’. This picture illustrates a section of the company’s publication, Seeing the Light: Vision and Realisation (1958), discussing the Lighting Advisory Bureau and Demonstration Laboratories. Instead of his usual floodlamps, Broomfield used the light from the testing rig itself to illuminate the man in his lab coat who seems to glow with the same inner light as the tube he holds.

SummaryMaurice Broomfield (1916-2010) worked to photograph the changing face of British manufacturing industries during the 1950s and 1960s. His photographs are recognized for their uniquely modern design elements, humanist strain, and their contribution to the documentation of the rebirth of British industry in the post war era.

Broomfield was often commissioned by manufacturers to produce photographs of a company"s product, facilities and workers. One approach that lent a special force to his photographs of industry was his attitude towards workers; instead of emphasizing the mechanical or repetitive qualities of modern work, he chose to illuminate the strength and sensitivity of individuals. In his images, monumental machines and bizarre equipment are examined or operated by crisply attired men and women.

Heavily influenced by the New Objectivity aesthetic that emerged in Germany in the 1920s, Broomfield employed the use of dramatic lighting and unconventional camera angles, but brought the aesthetic to new levels in his use of colour film. He worked closely with Imperial Chemical Industries (ICI) and llford, the manufacturer of photographic paper, to test new colour processes. His, and the industry"s shift, from black and white to colour, is represented in these 12 photographs.

Broomfield"s photographs were the focus of an exhibition at the Science Museum entitled "Maurice Broomfield"s "New Look" at Industry" (February-May, 2007). The exhibition highlighted Broomfield"s photographs as important records of the post war era British manufacturing culture, but also pointed to their distinctly contemporary value: as the manufacturing sector has increasingly turned to cheaper markets in Asia and elsewhere, these photographs serve as reminders of a recent stage in Britain"s manufacturing history.

Explore the Collections contains over a million catalogue records, and over half a million images. It is a working database that includes information compiled over the life of the museum. Some of our records may contain offensive and discriminatory language, or reflect outdated ideas, practice and analysis. We are committed to addressing these issues, and to review and update our records accordingly.

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

A vacuum fluorescent display (VFD) is a display device once commonly used on consumer electronics equipment such as video cassette recorders, car radios, and microwave ovens.

A VFD operates on the principle of cathodoluminescence, roughly similar to a cathode ray tube, but operating at much lower voltages. Each tube in a VFD has a phosphor-coated carbon anode that is bombarded by electrons emitted from the cathode filament.triode vacuum tube because it also has a mesh control grid.

Unlike liquid crystal displays, a VFD emits very bright light with high contrast and can support display elements of various colors. Standard illumination figures for VFDs are around 640 cd/m2 with high-brightness VFDs operating at 4,000 cd/m2, and experimental units as high as 35,000 cd/m2 depending on the drive voltage and its timing.Cadmium was commonly used in the phosphors of VFDs in the past, but the current RoHS-compliant VFDs have eliminated this metal from their construction, using instead phosphors consisting of a matrix of alkaline earth and very small amounts of group III metals, doped with very small amounts of rare earth metals.

VFDs can display seven-segment numerals, multi-segment alpha-numeric characters or can be made in a dot-matrix to display different alphanumeric characters and symbols. In practice, there is little limit to the shape of the image that can be displayed: it depends solely on the shape of phosphor on the anode(s).

The device consists of a hot cathode (filaments), grids and anodes (phosphor) encased in a glass envelope under a high vacuum condition. The cathode is made up of fine tungsten wires, coated by alkaline earth metal oxides (barium,electrons when heated to 650 °Cdiffused by the grids (made using Photochemical machining), which are made up of thin (50 micron thick) stainless steel.fluoresce, emitting light. Unlike the orange-glowing cathodes of traditional vacuum tubes, VFD cathodes are efficient emitters at much lower temperatures, and are therefore essentially invisible.graphite, which in turn is coated with phosphor. This transfers energy from the trace to the segment. The shape of the phosphor will determine the shape of the VFD"s segments. The most widely used phosphor is Zinc-doped copper-activated Zinc oxide,

The cathode wire to which the oxides are applied is made of tungsten or ruthenium-tungsten alloy. The oxides in the cathodes are not stable in air, so they are applied to the cathode as carbonates, the cathodes are assembled into the VFD, and the cathodes are heated by passing a current through them while inside the vacuum of the VFD to convert the carbonates into oxides.

The principle of operation is identical to that of a vacuum tube triode. Electrons can only reach (and "illuminate") a given plate element if both the grid and the plate are at a positive potential with respect to the cathode.multiplexed displays where the multiple grids and plates form a matrix, minimizing the number of signal pins required. In the example of the VCR display shown to the right, the grids are arranged so that only one digit is illuminated at a time. All of the similar plates in all of the digits (for example, all of the lower-left plates in all of the digits) are connected in parallel. One by one, the microprocessor driving the display enables a digit by placing a positive voltage on that digit"s grid and then placing a positive voltage on the appropriate plates. Electrons flow through that digit"s grid and strike those plates that are at a positive potential. The microprocessor cycles through illuminating the digits in this way at a rate high enough to create the illusion of all digits glowing at once via persistence of vision.

The extra indicators (in our example, "VCR", "Hi-Fi", "STEREO", "SAP", etc.) are arranged as if they were segments of an additional digit or two or extra segments of existing digits and are scanned using the same multiplexed strategy as the real digits. Some of these extra indicators may use a phosphor that emits a different color of light, for example, orange.

The light emitted by most VFDs contains many colors and can often be filtered to enhance the color saturation providing a deep green or deep blue, depending on the whims of the product"s designers. Phosphors used in VFDs are different from those in cathode-ray displays since they must emit acceptable brightness with only around 50 volts of electron energy, compared to several thousand volts in a CRT.

Besides brightness, VFDs have the advantages of being rugged, inexpensive, and easily configured to display a wide variety of customized messages, and unlike LCDs, VFDs are not limited by the response time of rearranging liquid crystals and are thus able to function normally in cold, even sub-zero, temperatures, making them ideal for outdoor devices in cold climates. Early on, the main disadvantage of such displays was their use of significantly more power (0.2 watts) than a simple LCD. This was considered a significant drawback for battery-operated equipment like calculators, so VFDs ended up being used mainly in equipment powered by an AC supply or heavy-duty rechargeable batteries.

During the 1980s, this display began to be used in automobiles, especially where car makers were experimenting with digital displays for vehicle instruments such as speedometers and odometers. A good example of these were the high-end Subaru cars made in the early 1980s (referred to by Subaru enthusiasts as a digi-dash, or digital dashboard). The brightness of VFDs makes them well suited for use in cars. The Renault Espace and older models of Scenic used VFD panels to show all functions on the dashboard including the radio and multi message panel. They are bright enough to read in full sunlight as well as dimmable for use at night. This panel uses four colors; the usual blue/green as well as deep blue, red and yellow/orange.

This technology was also used from 1979 to the mid-1980s in portable electronic game units. These games featured bright, clear displays but the size of the largest vacuum tubes that could be manufactured inexpensively kept the size of the displays quite small, often requiring the use of magnifying Fresnel lenses.LCD games could be manufactured for a fraction of the price, did not require frequent changes of batteries (or AC adapters) and were much more portable. Since the late 1990s, backlit color active-matrix LCD displays have been able to cheaply reproduce arbitrary images in any color, a marked advantage over fixed-color, fixed-character VFDs. This is one of the main reasons for the decline in popularity of VFDs, although they continue to be made. Many low-cost DVD players still feature VFDs.

From the mid-1980s onwards, VFDs were used for applications requiring smaller displays with high brightness specifications, though now the adoption of high-brightness organic light-emitting diodes (OLEDs) is pushing VFDs out of these markets.

Vacuum fluorescent displays were once commonly used as floor indicators for elevators by Otis Elevator Company worldwide and Montgomery Elevator Company in North America (the former from the early 1980s to the mid-2000s in the form of (usually two) 16-segment displays, and the latter from the mid 1980s to the mid 1990s in the form of (usually 3) 10x14 dot-matrix displays).

In addition to the widely used fixed character VFD, a graphic type made of an array of individually addressable pixels is also available. These more sophisticated displays offer the flexibility of displaying arbitrary images, and may still be a useful choice for some types of consumer equipment.

Several radio amateurs have experimented with the possibilities of using VFDs as triode amplifiers.Korg released the Nutube, an analogue audio amplifier component based on VFD technology. The Nutube is used in applications such as guitar amplifiers from Vox

Fading is sometimes a problem with VFDs. Light output drops over time due to falling emission and reduction of phosphor efficiency. How quickly and how far this falls depends on the construction and operation of the VFD. In some equipment, loss of VFD output can render the equipment inoperable. Fading can be slowed by using a display driver chip to lower the voltages necessary to drive a VFD. Fading can also occur due to evaporation and contamination of the cathode. Phosphors that contain sulfur are more susceptible to fading.

Emission may usually be restored by raising filament voltage. Thirty-three percent voltage boost can rectify moderate fade, and 66% boost severe fade.

Of the three prevalent display technologies – VFD, LCD, and LED – the VFD was the first to be developed. It was used in early handheld calculators. LED displays displaced VFDs in this use as the very small LEDs used required less power, thereby extending battery life, though early LED displays had problems achieving uniform brightness levels across all display segments. Later, LCDs displaced LEDs, offering even lower power requirements.

The first VFD was the single indication DM160 by Philips in 1959. It could easily be driven by transistors, so was aimed at computer applications as it was easier to drive than a neon and had longer life than a light bulb. The 1967 Japanese single digit seven segment display in terms of anode was more like the Philips DM70 / DM71 Magic Eye as the DM160 has a spiral wire anode. The Japanese seven segment VFD meant that no patent royalties needed to be paid on desk calculator displays as would have been the case using Nixies or Panaplex neon digits. In the UK the Philips designs were made and marketed by Mullard (almost wholly owned by Philips even before WWII).

The Russian IV-15 VFD tube is very similar to the DM160. The DM160, DM70/DM71 and Russian IV-15 can (like a VFD panel) be used as triodes. The DM160 is thus the smallest VFD and smallest triode valve. The IV-15 is slightly different shape (see photo of DM160 and IV-15 for comparison).

Joseph A. Castellano (ed), Handbook of display technology, Gulf Professional Publishing, 1992 ISBN 0-12-163420-5 Chapter 7 Vacuum Fluorescent Displays pp. 163 and following

N9WOS (29 July 2005). "VFD as an audio/RF amplifier?". Electronics Point forums. Archived from the original on 11 March 2018. Retrieved 11 March 2018.

Top: two non-integrated compact fluorescent lamps. Bottom: two fluorescent tube lamps. Both types require a ballast in the light fixture. A matchstick, left, is shown for scale.

Typical F71T12 100 W G13 bi-pin lamp used in tanning beds. The (Hg) symbol indicates that this lamp contains mercury. In the US, this symbol is now required on all mercury-containing fluorescent lamps.

Inside the lamp end of a preheat G13 lamp. In this lamp, the filament is surrounded by an oblong metal cathode shield, which helps reduce lamp end darkening.

A fluorescent lamp, or fluorescent tube, is a low-pressure mercury-vapor gas-discharge lamp that uses fluorescence to produce visible light. An electric current in the gas excites mercury vapor, which produces short-wave ultraviolet light that then causes a phosphor coating on the inside of the lamp to glow. A fluorescent lamp converts electrical energy into useful light much more efficiently than an incandescent lamp. The typical luminous efficacy of fluorescent lighting systems is 50–100 lumens per watt, several times the efficacy of incandescent bulbs with comparable light output. For comparison, the luminous efficacy of an incandescent bulb may only be 16 lumens per watt.

Fluorescent lamp fixtures are more costly than incandescent lamps because, among other things, they require a ballast to regulate current through the lamp, but the initial cost is offset by a much lower running cost. Compact fluorescent lamps are now available in the same popular sizes as incandescents and are used as an energy-saving alternative in homes.

Because they contain mercury, many fluorescent lamps are classified as hazardous waste. The United States Environmental Protection Agency recommends that fluorescent lamps be segregated from general waste for recycling or safe disposal, and some jurisdictions require recycling of them.

The fluorescence of certain rocks and other substances had been observed for hundreds of years before its nature was understood. By the middle of the 19th century, experimenters had observed a radiant glow emanating from partially evacuated glass vessels through which an electric current passed. One of the first to explain it was the Irish scientist Sir George Stokes from the University of Cambridge in 1852, who named the phenomenon "fluorescence" after fluorite, a mineral many of whose samples glow strongly because of impurities. The explanation relied on the nature of electricity and light phenomena as developed by the British scientists Michael Faraday in the 1840s and James Clerk Maxwell in the 1860s.

Little more was done with this phenomenon until 1856 when German glassblower Heinrich Geissler created a mercury vacuum pump that evacuated a glass tube to an extent not previously possible. Geissler invented the first gas-discharge lamp, the Geissler tube, consisting of a partially evacuated glass tube with a metal electrode at either end. When a high voltage was applied between the electrodes, the inside of the tube lit up with a glow discharge. By putting different chemicals inside, the tubes could be made to produce a variety of colors, and elaborate Geissler tubes were sold for entertainment. More important, however, was its contribution to scientific research. One of the first scientists to experiment with a Geissler tube was Julius Plücker, who systematically described in 1858 the luminescent effects that occurred in a Geissler tube. He also made the important observation that the glow in the tube shifted position when in proximity to an electromagnetic field. Alexandre Edmond Becquerel observed in 1859 that certain substances gave off light when they were placed in a Geissler tube. He went on to apply thin coatings of luminescent materials to the surfaces of these tubes. Fluorescence occurred, but the tubes were very inefficient and had a short operating life.

Inquiries that began with the Geissler tube continued as even better vacuums were produced. The most famous was the evacuated tube used for scientific research by William Crookes. That tube was evacuated by the highly effective mercury vacuum pump created by Hermann Sprengel. Research conducted by Crookes and others ultimately led to the discovery of the electron in 1897 by J. J. Thomson and X-rays in 1895 by Wilhelm Röntgen. But the Crookes tube, as it came to be known, produced little light because the vacuum in it was too good and thus lacked the trace amounts of gas that are needed for electrically stimulated luminescence.

One of the first mercury vapor lamps invented by Peter Cooper Hewitt, 1903. It was similar to a fluorescent lamp without the fluorescent coating on the tube and produced greenish light. The round device under the lamp is the ballast.

Thomas Edison briefly pursued fluorescent lighting for its commercial potential. He invented a fluorescent lamp in 1896 that used a coating of calcium tungstate as the fluorescing substance, excited by X-rays, but although it received a patent in 1907,Nikola Tesla made similar experiments in the 1890s, devising high-frequency powered fluorescent bulbs that gave a bright greenish light, but as with Edison"s devices, no commercial success was achieved.

One of Edison"s former employees created a gas-discharge lamp that achieved a measure of commercial success. In 1895 Daniel McFarlan Moore demonstrated lamps 2 to 3 meters (6.6 to 9.8 ft) in length that used carbon dioxide or nitrogen to emit white or pink light, respectively. They were considerably more complicated than an incandescent bulb, requiring both a high-voltage power supply and a pressure-regulating system for the fill gas.

Moore invented an electromagnetically controlled valve that maintained a constant gas pressure within the tube, to extend the working life.General Electric’s motivation to improve the incandescent lamp, especially its filament. GE"s efforts came to fruition with the invention of a tungsten-based filament. The extended lifespan and improved efficacy of incandescent bulbs negated one of the key advantages of Moore"s lamp, but GE purchased the relevant patents in 1912. These patents and the inventive efforts that supported them were to be of considerable value when the firm took up fluorescent lighting more than two decades later.

At about the same time that Moore was developing his lighting system, Peter Cooper Hewitt invented the mercury-vapor lamp, patented in 1901 (). Hewitt"s lamp glowed when an electric current was passed through mercury vapor at a low pressure. Unlike Moore"s lamps, Hewitt"s were manufactured in standardized sizes and operated at low voltages. The mercury-vapor lamp was superior to the incandescent lamps of the time in terms of energy efficiency, but the blue-green light it produced limited its applications. It was, however, used for photography and some industrial processes.

Mercury vapor lamps continued to be developed at a slow pace, especially in Europe, and by the early 1930s, they received limited use for large-scale illumination. Some of them employed fluorescent coatings, but these were used primarily for color correction and not for enhanced light output. Mercury vapor lamps also anticipated the fluorescent lamp in their incorporation of a ballast to maintain a constant current.

Cooper-Hewitt had not been the first to use mercury vapor for illumination, as earlier efforts had been mounted by Way, Rapieff, Arons, and Bastian and Salisbury. Of particular importance was the mercury-vapor lamp invented by Küch and Retschinsky in Germany. The lamp used a smaller bore bulb and higher current operating at higher pressures. As a consequence of the current, the bulb operated at a higher temperature which necessitated the use of a quartz bulb. Although its light output relative to electrical consumption was better than that of other sources of light, the light it produced was similar to that of the Cooper-Hewitt lamp in that it lacked the red portion of the spectrum, making it unsuitable for ordinary lighting. Due to difficulties in sealing the electrodes to the quartz, the lamp had a very short life.

The next step in gas-based lighting took advantage of the luminescent qualities of neon, an inert gas that had been discovered in 1898 by isolation from the atmosphere. Neon glowed a brilliant red when used in Geissler tubes.Georges Claude, a Frenchman who had developed a technology and a successful business for air liquefaction, was obtaining enough neon as a byproduct to support a neon lighting industry.electrodes with a lot of surface area, it showed that a major impediment to gas-based lighting could be overcome.

The development of the neon light also was significant for the last key element of the fluorescent lamp, its fluorescent coating.Edmund Germer, who were employees of a German firm in Berlin. A German patent was granted but the lamp never went into commercial production.

All the major features of fluorescent lighting were in place at the end of the 1920s. Decades of invention and development had provided the key components of fluorescent lamps: economically manufactured glass tubing, inert gases for filling the tubes, electrical ballasts, long-lasting electrodes, mercury vapor as a source of luminescence, effective means of producing a reliable electrical discharge, and fluorescent coatings that could be energized by ultraviolet light. At this point, intensive development was more important than basic research.

In 1934, Arthur Compton, a renowned physicist and GE consultant, reported to the GE lamp department on successful experiments with fluorescent lighting at General Electric Co., Ltd. in Great Britain (unrelated to General Electric in the United States). Stimulated by this report, and with all of the key elements available, a team led by George E. Inman built a prototype fluorescent lamp in 1934 at General Electric’s Nela Park (Ohio) engineering laboratory. This was not a trivial exercise; as noted by Arthur A. Bright, "A great deal of experimentation had to be done on lamp sizes and shapes, cathode construction, gas pressures of both argon and mercury vapor, colors of fluorescent powders, methods of attaching them to the inside of the tube, and other details of the lamp and its auxiliaries before the new device was ready for the public."

In addition to having engineers and technicians along with facilities for R&D work on fluorescent lamps, General Electric controlled what it regarded as the key patents covering fluorescent lighting, including the patents originally issued to Hewitt, Moore, and Küch. More important than these was a patent covering an electrode that did not disintegrate at the gas pressures that ultimately were employed in fluorescent lamps. Albert W. Hull of GE"s Schenectady Research Laboratory filed for a patent on this invention in 1927, which was issued in 1931.

While the Hull patent gave GE a basis for claiming legal rights over the fluorescent lamp, a few months after the lamp went into production the firm learned of a U.S. patent application that had been filed in 1927 for the aforementioned "metal vapor lamp" invented in Germany by Meyer, Spanner, and Germer. The patent application indicated that the lamp had been created as a superior means of producing ultraviolet light, but the application also contained a few statements referring to fluorescent illumination. Efforts to obtain a U.S. patent had met with numerous delays, but were it to be granted, the patent might have caused serious difficulties for GE. At first, GE sought to block the issuance of a patent by claiming that priority should go to one of their employees, Leroy J. Buttolph, who according to their claim had invented a fluorescent lamp in 1919 and whose patent application was still pending. GE also had filed a patent application in 1936 in Inman"s name to cover the “improvements” wrought by his group. In 1939 GE decided that the claim of Meyer, Spanner, and Germer had some merit, and that in any event a long interference procedure was not in their best interest. They therefore dropped the Buttolph claim and paid $180,000 to acquire the Meyer, et al. application, which at that point was owned by a firm known as Electrons, Inc. The patent was duly awarded in December 1939.Sylvania Electric Products, Inc., which claimed infringement on patents that it held.

Even though the patent issue was not completely resolved for many years, General Electric"s strength in manufacturing and marketing gave it a pre-eminent position in the emerging fluorescent light market. Sales of "fluorescent lumiline lamps" commenced in 1938 when four different sizes of tubes were put on the market. They were used in fixtures manufactured by three leading corporations, Lightolier, Artcraft Fluorescent Lighting Corporation, and Globe Lighting. The Slimline fluorescent ballast"s public

introduction in 1946 was by Westinghouse and General Electric and Showcase/Display Case fixtures were introduced by Articraft Fluorescent Lighting Corporation in 1946.Westinghouse publicized the new lights through exhibitions at the New York World"s Fair and the Golden Gate International Exposition in San Francisco. Fluorescent lighting systems spread rapidly during World War II as wartime manufacturing intensified lighting demand. By 1951 more light was produced in the United States by fluorescent lamps than by incandescent lamps.

In the first years zinc orthosilicate with varying content of beryllium was used as greenish phosphor. Small additions of magnesium tungstate improved the blue part of the spectrum yielding acceptable white. After it was discovered that beryllium was toxic, halophosphate-based phosphors took over.

The fundamental mechanism for the conversion of electrical energy to light is the emission of a photon when an electron in a mercury atom falls from an excited state into a lower energy level. Electrons flowing in the arc collide with the mercury atoms. If the incident electron has enough kinetic energy, it transfers energy to the atom"s outer electron, causing that electron to temporarily jump up to a higher energy level that is not stable. The atom will emit an ultraviolet photon as the atom"s electron reverts to a lower, more stable, energy level. Most of the photons that are released from the mercury atoms have wavelengths in the ultraviolet (UV) region of the spectrum, predominantly at wavelengths of 253.7 and 185 nanometers (nm). These are not visible to the human eye, so ultraviolet energy is converted to visible light by the fluorescence of the inner phosphor coating. The difference in energy between the absorbed ultra-violet photon and the emitted visible light photon goes toward heating up the phosphor coating.

Electric current flows through the tube in a low-pressure arc discharge. Electrons collide with and ionize noble gas atoms inside the bulb surrounding the filament to form a plasma by the process of impact ionization. As a result of avalanche ionization, the conductivity of the ionized gas rapidly rises, allowing higher currents to flow through the lamp.

The fill gas helps determine the electrical characteristics of the lamp but does not give off light itself. The fill gas effectively increases the distance that electrons travel through the tube, which allows an electron a greater chance of interacting with a mercury atom. Additionally, argon atoms, excited to a metastable state by the impact of an electron, can impart energy to a mercury atom and ionize it, described as the Penning effect. This lowers the breakdown and operating voltage of the lamp, compared to other possible fill gases such as krypton.

A fluorescent lamp tube is filled with a mix of argon, xenon, neon, or krypton, and mercury vapor. The pressure inside the lamp is around 0.3% of atmospheric pressure.fluorescent coating made of varying blends of metallic and rare-earth phosphor salts. The lamp"s electrodes are typically made of coiled tungsten and are coated with a mixture of barium, strontium and calcium oxides to improve thermionic emission.

A germicidal lamp uses a low-pressure mercury-vapor glow discharge identical to that in a fluorescent lamp, but the uncoated fused quartz envelope allows ultraviolet radiation to transmit.

Fluorescent lamp tubes are often straight and range in length from about 100 millimeters (3.9 in) for miniature lamps, to 2.43 meters (8.0 ft) for high-output lamps. Some lamps have the tube bent into a circle, used for table lamps or other places where a more compact light source is desired. Larger U-shaped lamps are used to provide the same amount of light in a more compact area, and are used for special architectural purposes. Compact fluorescent lamps have several small-diameter tubes joined in a bundle of two, four, or six, or a small diameter tube coiled into a helix, to provide a high amount of light output in little volume.

Light-emitting phosphors are applied as a paint-like coating to the inside of the tube. The organic solvents are allowed to evaporate, then the tube is heated to nearly the melting point of glass to drive off remaining organic compounds and fuse the coating to the lamp tube. Careful control of the grain size of the suspended phosphors is necessary; large grains lead to weak coatings, and small particles leads to poor light maintenance and efficiency. Most phosphors perform best with a particle size around 10 micrometers. The coating must be thick enough to capture all the ultraviolet light produced by the mercury arc, but not so thick that the phosphor coating absorbs too much visible light. The first phosphors were synthetic versions of naturally occurring fluorescent minerals, with small amounts of metals added as activators. Later other compounds were discovered, allowing differing colors of lamps to be made.

Fluorescent lamps are negative differential resistance devices, so as more current flows through them, the electrical resistance of the fluorescent lamp drops, allowing for even more current to flow. Connected directly to a constant-voltage power supply, a fluorescent lamp would rapidly self-destruct because of the uncontrolled current flow. To prevent this, fluorescent lamps must use a ballast to regulate the current flow through the lamp.

The terminal voltage across an operating lamp varies depending on the arc current, tube diameter, temperature, and fill gas. A general lighting service 48-inch (1,219 mm) T12

The simplest ballast for alternating current (AC) use is an inductor placed in series, consisting of a winding on a laminated magnetic core. The inductance of this winding limits the flow of AC current. This type of ballast is common in 220–240V countries (And in North America, up to 30W lamps). Ballasts are rated for the size of lamp and power frequency. In North America, the AC voltage is insufficient to start long fluorescent lamps, so the ballast is often a step-up autotransformer with substantial leakage inductance (so as to limit the current flow). Either form of inductive ballast may also include a capacitor for power factor correction.

Fluorescent lamps can run directly from a direct current (DC) supply of sufficient voltage to strike an arc. The ballast must be resistive, and would consume about as much power as the lamp. When operated from DC, the starting switch is often arranged to reverse the polarity of the supply to the lamp each time it is started; otherwise, the mercury accumulates at one end of the tube. Fluorescent lamps are (almost) never operated directly from DC for those reasons. Instead, an inverter converts the DC into AC and provides the current-limiting function as described below for electronic ballasts.

The performance of fluorescent lamps is critically affected by the temperature of the bulb wall and its effect on the partial pressure of mercury vapor within the lamp.

Using an amalgam with some other metal reduces the vapor pressure and extends the optimum temperature range upward; however, the bulb wall "cold spot" temperature must still be controlled to prevent condensing. High-output fluorescent lamps have features such as a deformed tube or internal heat-sinks to control cold spot temperature and mercury distribution. Heavily loaded small lamps, such as compact fluorescent lamps, also include heat-sink areas in the tube to maintain mercury vapor pressure at the optimum value.

A Sankey diagram of energy losses in a fluorescent lamp. In modern designs, the biggest loss is the quantum efficiency of converting high-energy UV photons to lower-energy visible light photons.

Only a fraction of the electrical energy input into a lamp is converted to useful light. The ballast dissipates some heat; electronic ballasts may be around 90% efficient. A fixed voltage drop occurs at the electrodes, which also produces heat. Some of the energy in the mercury vapor column is also dissipated, but about 85% is turned into visible and ultraviolet light.

Not all the UV radiation striking the phosphor coating is converted to visible light; some energy is lost. The largest single loss in modern lamps is due to the lower energy of each photon of visible light, compared to the energy of the UV photons that generated them (a phenomenon called Stokes shift). Incident photons have an energy of 5.5 electron volts but produce visible light photons with energy around 2.5 electron volts, so only 45% of the UV energy is used; the rest is dissipated as heat.

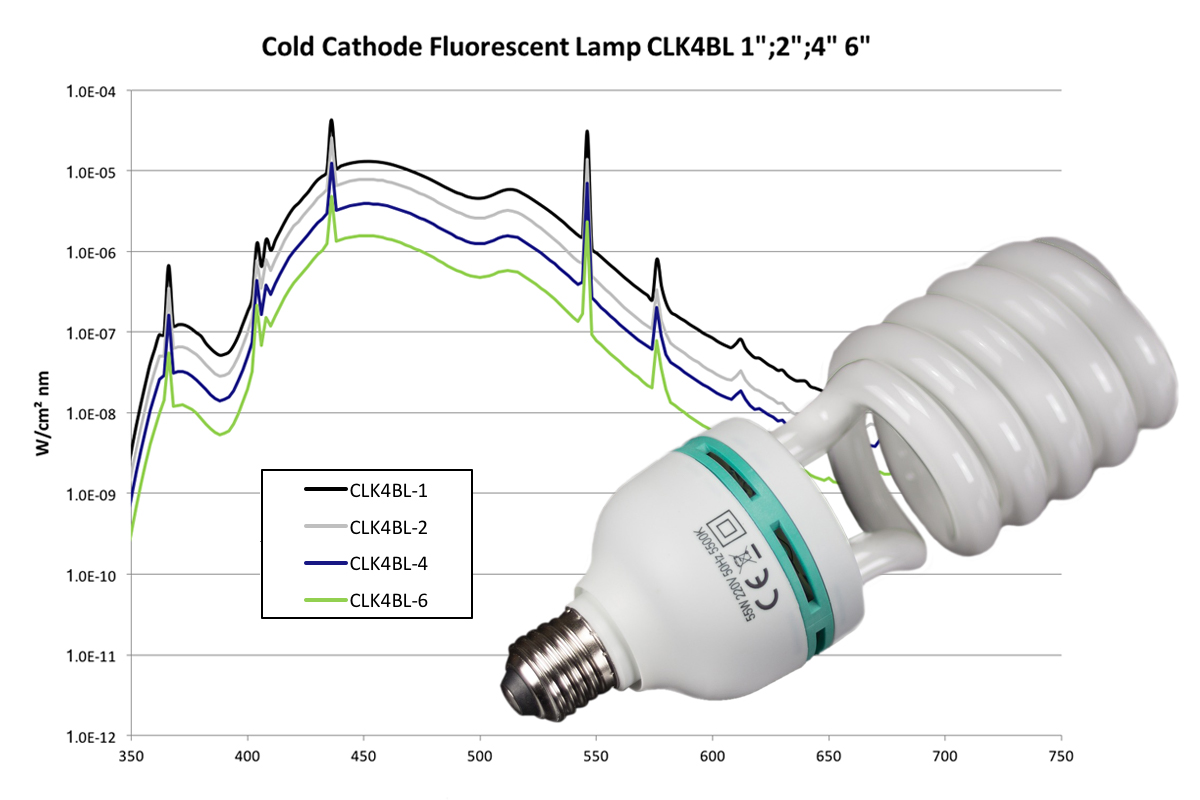

A cold-cathode fluorescent lamp from an emergency-exit sign. Operating at a much higher voltage than other fluorescents, the lamp produces a low-amperage glow discharge rather than an arc, similar to a neon light. Without direct connection to line voltage, current is limited by the transformer alone, negating the need for a ballast.

Most fluorescent lamps use electrodes that emit electrons into the tube by heat, known as hot cathodes. However, cold cathode tubes have cathodes that emit electrons only due to the large voltage between the electrodes. The cathodes will be warmed by current flowing through them, but are not hot enough for significant thermionic emission. Because cold cathode lamps have no thermionic emission coating to wear out, they can have much longer lives than hot cathode tubes. This makes them desirable for long-life applications (such as backlights in liquid crystal displays). Sputtering of the electrode may still occur, but electrodes can be shaped (e.g. into an internal cylinder) to capture most of the sputtered material so it is not lost from the electrode.

Cold cathode lamps are generally less efficient than thermionic emission lamps because the cathode fall voltage is much higher. Power dissipated due to cathode fall voltage does not contribute to light output. However, this is less significant with longer tubes. The increased power dissipation at tube ends also usually means cold cathode tubes have to be run at a lower loading than their thermionic emission equivalents. Given the higher tube voltage required anyway, these tubes can easily be made long, and even run as series strings. They are better suited for bending into special shapes for lettering and signage, and can also be instantly switched on or off.

The gas used in the fluorescent tube must be ionized before the arc can "strike" . For small lamps, it does not take much voltage to strike the arc and starting the lamp presents no problem, but larger tubes require a substantial voltage (in the range of a thousand volts). Many different starting circuits have been used. The choice of circuit is based on cost, AC voltage, tube length, instant versus non-instant starting, temperature ranges and parts availability.

A preheat fluorescent lamp circuit using an automatic starting switch. A: Fluorescent tube, B: Power (+220 volts), C: Starter, D: Switch (bi-metallic thermostat), E: Capacitor, F: Filaments, G: Ballast

Preheating, also called switchstart, uses a combination filament–cathode at each end of the lamp in conjunction with a mechanical or automatic (bi-metallic) switch (see circuit diagram to the right) that initially connect the filaments in series with the ballast to preheat them; after a short preheating time the starting switch opens. If timed correctly relative to the phase of the supply AC, this causes the ballast to induce a voltage over the tube high enough to initiate the starting arc.

Before the 1960s, four-pin thermal starters and manual switches were used.glow switch starter automatically preheats the lamp cathodes. It consists of a normally open bi-metallic switch in a small sealed gas-discharge lamp containing inert gas (neon or argon). The glow switch will cyclically warm the filaments and initiate a pulse voltage to strike the arc; the process repeats until the lamp is lit. Once the tube strikes, the impinging main discharge keeps the cathodes hot, permitting continued electron emission. The starter switch does not close again because the voltage across the lit tube is insufficient to start a glow discharge in the starter.

With glow switch starters a failing tube will cycle repeatedly. Some starter systems used a thermal over-current trip to detect repeated starting attempts and disable the circuit until manually reset.

Electronic starters use a different method to preheat the cathodes.integrated circuit chip. Electronic starters may be optimized for fast starting (typical start time of 0.3 seconds),

Electronic starters only attempt to start a lamp for a short time when power is initially applied, and do not repeatedly attempt to restrike a lamp that is dead and unable to sustain an arc; some automatically stop trying to start a failed lamp.

T12 fluorescent tubes. The first two are rapid start, (for "tombstone" and socket holders respectively) while the third is an instant-start lamp. The instant-start has a characteristic, rounded, single pin, for plugging into the spring-loaded socket holders.

Instant start fluorescent tubes were invented in 1944. Instant start simply uses a high enough voltage to break down the gas column and thereby start arc conduction. Once the high-voltage spark "strikes" the arc, the current is boosted until a glow discharge forms. As the lamp warms and pressure increases, the current continues to rise and both resistance and voltage falls, until mains or line-voltage takes over and the discharge becomes an arc. These tubes have no filaments and can be identified by a single pin at each end of the tube (for common lamps; compact cold-cathode lamps may also have a single pin, but operate from a transformer rather than a ballast). The lamp holders have a "disconnect" socket at the low-voltage end which disconnects the ballast when the tube is removed, to prevent electric shock. Instant-start lamps are slightly more energy efficient than rapid start, because they do not constantly send a heating current to the cathodes during operation, but the cold cathodes starting increases sputter, and they take much longer to transition from a glow discharge to an arc during warm up, thus the lifespan is typically about half of those seen in comparable rapid-start lamps.

Because the formation of an arc requires the thermionic emission of large quantities of electrons from the cathode, rapid start ballast designs provide windings within the ballast that continuously warm the cathode filaments. Usually operating at a lower arc voltage than the instant start design; no inductive voltage spike is produced for starting, so the lamps must be mounted near a grounded (earthed) reflector to allow the glow discharge to propagate through the tube and initiate the arc discharge via capacitive coupling. In some lamps a grounded "starting aid" strip is attached to the outside of the lamp glass. This ballast type is incompatible with the European energy saver T8 fluorescent lamps because these lamps requires a higher starting voltage than that of the open circuit voltage of rapid start ballasts.

Quick-start ballasts use a small auto-transformer to heat the filaments when power is first applied. When an arc strikes, the filament heating power is reduced and the tube will start within half a second. The auto-transformer is either combined with the ballast or may be a separate unit. Tubes need to be mounted near an earthed metal reflector in order for them to strike. Quick-start ballasts are more common in commercial installations because of lower maintenance costs. A quick-start ballast eliminates the need for a starter switch, a common source of lamp failures. Nonetheless, Quick-start ballasts are also used in domestic (residential) installations because of the desirable feature that a Quick-start ballast light turns on nearly immediately after power is applied (when a switch is turned on). Quick-start ballasts are used only on 240 V circuits and are designed for use with the older, less efficient T12 tubes.

The semi-resonant start circuit was invented by Thorn Lighting for use with T12 fluorescent tubes. This method uses a double wound transformer and a capacitor. With no arc current, the transformer and capacitor resonate at line frequency and generate about twice the supply voltage across the tube, and a small electrode heating current.

Semi-resonant start circuits are mainly restricted to use in commercial installations because of the higher initial cost of circuit components. However, there are no starter switches to be replaced and cathode damage is reduced during starting making lamps last longer, reducing maintenance costs. Because of the high open circuit tube voltage, this starting method is particularly good for starting tubes in cold locations. Additionally, the circuit power factor is almost 1.0, and no additional power factor correction is needed in the lighting installation. As the design requires that twice the supply voltage must be lower than the cold-cathode striking voltage (or the tubes would erroneously instant-start), this design cannot be used with 240 volt AC power unless the tubes are at least 1.2 m (3 ft 11 in) length. Semi-resonant start fixtures are generally incompatible with energy saving T8 retrofit tubes, because such tubes have a higher starting voltage than T12 lamps and may not start reliably, especially in low temperatures. Recent proposals in some countries to phase out T12 tubes will reduce the application of this starting method.

Electronic ballasts employ transistors to change the supply frequency into high-frequency AC while regulating the current flow in the lamp. These ballasts take advantage of the higher efficacy of lamps, which rises by almost 10% at 10 kHz, compared to efficacy at normal power frequency. When the AC period is shorter than the relaxation time to de-ionize mercury atoms in the discharge column, the discharge stays closer to optimum operating condition.

Low cost ballasts contain only a simple oscillator and series resonant LC circuit. This principle is called the current resonant inverter circuit. After a short time the voltage across the lamp reaches about 1 kV and the lamp instant-starts in cold cathode mode. The cathode filaments are still used for protection of the ballast from overheating if the lamp does not ignite. A few manufacturers use positive temperature coefficient (PTC) thermistors to disable instant starting and give some time to preheat the filaments.

More complex electronic ballasts use programmed start. The output frequency is started above the resonance frequency of the output circuit of the ballast; and after the filaments are heated, the frequency is rapidly decreased. If the frequency approaches the resonant frequency of the ballast, the output voltage will increase so much that the lamp will ignite. If the lamp does not ignite, an electronic circuit stops the operation of the ballast.

Many electronic ballasts are controlled by a microcontroller, and these are sometimes called digital ballasts. Digital ballasts can apply quite complex logic to lamp starting and operation. This enables functions such as testing for broken electrodes and missing tubes before attempting to start, detection of tube replacement, and detection of tube type, such that a single ballast can be used with several different tubes. Features such as dimming can be included in the embedded microcontroller software, and can be found in various manufacturers" products.

Since introduction in the 1990s, high-frequency ballasts have been used in general lighting fixtures with either rapid start or pre-heat lamps. These ballasts convert the incoming power to an output frequency in excess of 20 kHz. This increases lamp efficiency.

The life expectancy of a fluorescent lamp is primarily limited by the life of the cathode electrodes. To sustain an adequate current level, the electrodes are coated with an emission mixture of metal oxides. Every time the lamp is started, and during operation, some small amount of the cathode coating is sputtered off the electrodes by the impact of electrons and heavy ions within the tube. The sputtered material collects on the walls of the tube, darkening it. The starting method and frequency affect cathode sputtering. A filament may also break, disabling the lamp.

This tube failed after it had been turned on many times. Too much of the thermionic emission mix had sputtered off the cathodes, instead sticking to and blackening the glass.

The filament of a low-pressure mercury gas-discharge lamp, with white thermionic emission coating acting as hot cathode. A little of the coating is sputtered away at every start; the lamp ultimately fails.

Low-mercury designs of lamps may fail when mercury is absorbed by the glass tube, phosphor, and internal components, and is no longer available to vaporize in the fill gas. Loss of mercury initially causes an extended warm-up time to full light output, and finally causes the lamp to glow a dim pink when the argon gas takes over as the primary discharge.

Subjecting the tube to asymmetric current flow, effectively operates it under a DC bias, and causes asymmetric distribution of mercury ions along the tube. The localized depletion of mercury vapor pressure manifests itself as pink luminescence of the base gas in the vicinity of one of the electrodes, and the operating lifetime of the lamp may be dramatically shortened. This can be an issue with some poorly designed inverters.

The spectrum of light emitted from a fluorescent lamp is the combination of light directly emitted by the mercury vapor, and light emitted by the phosphorescent coating. The spectral lines from the mercury emission and the phosphorescence effect give a combined spectral distribution of light that is different from those produced by incandescent sources. The relative intensity of light emitted in each narrow band of wavelengths over the visible spectrum is in different proportions compared to that of an incandescent source. Colored objects are perceived differently under light sources with differing spectral distributions. For example, some people find the color rendition produced by some fluorescent lamps to be harsh and displeasing. A healthy person can sometimes appear to have an unhealthy skin tone under fluorescent lighting. The extent to which this phenomenon occurs is related to the light"s spectral composition, and may be gauged by its color rendering index (CRI).

Correlated color temperature (CCT) is a measure of the "shade" of whiteness of a light source compared with a blackbody. Typical incandescent lighting is 2700 K, which is yellowish-white.

Fluorescent spectra in comparison with other forms of lighting. Clockwise from upper left: Fluorescent lamp, incandescent bulb, candle flame and LED lighting.

Color rendering index (CRI) is a measure of how well colors can be perceived using light from a source, relative to light from a reference source such as daylight or a blackbody of the same color temperature. By definition, an incandescent lamp has a CRI of 100. Real-life fluorescent tubes achieve CRIs of anywhere from 50 to 98. Fluorescent lamps with low CRI have phosphors that emit too little red light. Skin appears less pink, and hence "unhealthy" compared with incandescent lighting. Colored objects appear muted. For example, a low CRI 6800 K halophosphate tube (an extreme example) will make reds appear dull red or even brown. Since the eye is relatively less efficient at detecting red light, an improvement in color rendering index, with increased energy in the red part of the spectrum, may reduce the overall luminous efficacy.: 8

Lighting arrangements use fluorescent tubes in an assortment of tints of white. Mixing tube types within fittings can improve the color reproduction of lower quality tubes.

Some of the least pleasant light comes from tubes containing the older, halophosphate-type phosphors (chemical formula Ca5(PO4)3(F, Cl):Sb3+, Mn2+). This phosphor mainly emits yellow and blue light, and relatively little green and red. In the absence of a reference, this mixture appears white to the eye, but the light has an incomplete spectrum. The color rendering index (CRI) of such lamps is around 60.

Since the 1990s, higher-quality fluorescent lamps use triphosphor mixture, based on europium and terbium ions, which have emission bands more evenly distributed over the spectrum of visible light. Triphosphor tubes gives a more natural color reproduction to the human eye. The CRI of such lamps is typically 85.

A typical "cool white" fluorescent lamp utilizing two rare-earth-doped phosphors, Tb3+, Ce3+:LaPO4 for green and blue emission and Eu:Y2O3 for red. For an explanation of the origin of the individual peaks click on the image. Several of the spectral peaks are directly generated from the mercury arc. This is likely the most common type of fluorescent lamp in use today.

Halophosphate phosphors in these lamps usually consist of trivalent antimony- and divalent manganese-doped calcium halophosphate (Ca5(PO4)3(Cl, F):Sb3+, Mn2+). The color of the light output can be adjusted by altering the ratio of the blue-emitting antimony dopant and orange-emitting manganese dopant. The color rendering ability of these older-style lamps is quite poor. Halophosphate phosphors were invented by A. H. McKeag et al. in 1942.

The spectrum is nearly identical to a normal fluorescent lamp except for a near total lack of light shorter than 500 nanometers. This effect can be achieved through either specialized phosphor use or more commonly by the use of a simple yellow light filter. These lamps are commonly used as lighting for photolithography work in cleanrooms and as "bug repellent" outdoor lighting (the efficacy of which is questionable).

There is typically only one phosphor present in a blacklight lamp, usually consisting of europium-doped strontium fluoroborate, which is contained in an envelope of Wood"s glass.

Fluorescent lamps come in many shapes and sizes.compact fluorescent lamp (CFL) is becoming more popular. Many compact fluorescent lamps integrate the auxiliary electronics into the base of the lamp, allowing them to fit into a regular light bulb socket.

In US residences, fluorescent lamps are mostly found in kitchens, basements, or garages, but schools and businesses find the cost savings of fluorescent lamps to be significant and rarely use incandescent lights. Electricity costs, tax incentives and building codes result in higher use in places such as California. Fluorescent use is declining as LED lighting, which is more energy efficient and doesn"t contain mercury, is replacing fluorescents.

In other countries, residential use of fluorescent lighting varies depending on the price of energy, financial and environmental concerns of the local population, and acceptability of the light output. In East and Southeast Asia it is very rare to see incandescent bulbs in buildings anywhere.

Many countries are encouraging the phase-out of incandescent light bulbs and substitution of incandescent lamps with fluorescent lamps or LED and other types of energy-efficient lamps.

In addition to general lighting, special fluorescent lights are often used in stage lighting for film and video production. They are cooler than traditional halogen light sources, and use high-frequency ballasts to prevent video flickering and high color-rendition index lamps to approximate daylight color temperatures.

Fluorescent lamps convert more of the input power to visible light than incandescent lamps. A typical 100 watt tungsten filament incandescent lamp may convert only 5% of its power input to visible white light (400–700 nm wavelength), whereas typical fluorescent lamps convert about 22% of the power input to visible white light.: 20

Fluorescent lamp efficacy is dependent on lamp temperature at the coldest part of the lamp. In T8 lamps this is in the center of the tube. In T5 lamps this is at the end of the tube with the text stamped on it. The ideal temperature for a T8 lamp is 25 °C (77 °F) while the T5 lamp is ideally at 35 °C (95 °F).

Typically a fluorescent lamp will last 10 to 20 times as long as an equivalent incandescent lamp when operated several hours at a time. Under standard test conditions fluorescent lamps last 6,000 to 80,000 hours (2 to 27 years at 8 hours per day).

The higher initial cost of a fluorescent lamp compared with an incandescent lamp is usually compensated for by lower energy consumption over its life.

Compared with an incandescent lamp, a fluorescent tube is a more diffuse and physically larger light source. In suitably designed lamps, light can be more evenly distributed without point source of glare such as seen from an undiffused incandescent filament; the lamp is large compared to the typical distance between lamp and illuminated surfaces.

Fluorescent lamps give off about one-fifth the heat of equivalent incandescent lamps. This greatly reduces the size, cost, and energy consumption devoted to air conditioning for office buildings that would typically have many lights and few windows.

The extra energy used to start a fluorescent lamp is equivalent to a few seconds of normal operation; it is more energy-efficient to switch off lamps when not required for several minutes.

If a fluorescent lamp is broken, a very small amount of mercury can contaminate the surrounding environment. About 99% of the mercury is typically contained in the phosphor, especially on lamps that are near the end of their life.

Due to the mercury content, discarded fluorescent lamps must be treated as hazardous waste. For large users of fluorescent lamps, recycling services are available in some areas, and may be required by regulation.

Fluorescent lamps emit a small amount of ultraviolet (UV) light. A 1993 study in the US found that ultraviolet exposure from sitting under fluorescent lights for eight hours is equivalent to one minute of sun exposure.

Fluorescent lamps require a ballast to stabilize the current through the lamp, and to provide the initial striking voltage required to start the arc discharge. Often one ballast is shared between two or more lamps. Electromagnetic ballasts can produce an audible humming or buzzing noise. In North America, magnetic ballasts are usually filled with a tar-like potting compound to reduce emitted noise. Hum is eliminated in lamps with a high-frequency electronic ballast. Energy lost in magnetic ballasts is around 10% of lamp input power according to GE literature from 1978.

Simple inductive fluorescent lamp ballasts have a power factor of less than unity. Inductive ballasts include power factor correction capacitors. Simple electronic ballasts may also have low power factor due to their rectifier input stage.

Fluorescent lamps are a non-linear load and generate harmonic currents in the electrical power supply. The arc within the lamp may generate radio frequency noise, which can be conducted through power wiring. Suppression of radio interference is possible. Very good suppression is possible, but adds to the cost of the fluorescent fixtures.

Fluorescent lamps near end of life can present a serious radio frequency interference hazard. Oscillations are generated from the negative differential resistance of the arc, and the current flow through the tube can form a tuned circuit whose frequency depends on path length.

Fluorescent lamps operate best around room temperature. At lower or higher temperatures, efficacy decreases. At below-freezing temperatures standard lamps may not start. Special lamps may be used for reliable service outdoors in cold weather.

Fluorescent tubes are long, low-luminance sources compared with high pressure arc lamps, incandescent lamps and LEDs. However, low luminous intensity of the emitting surface is useful because it reduces glare. Lamp fixture design must control light from a long tube instead of a compact globe. The compact fluorescent lamp (CFL) replaces regular incandescent bulbs in many light fixtures where space permits.

Fluorescent lamps with magnetic ballasts flicker at a normally unnoticeable frequency of 100 or 120 Hz and this flickering can cause problems for some individuals with light sensitivity;autism, epilepsy,lupus,chronic fatigue syndrome, Lyme disease,vertigo.

A stroboscopic effect can be noticed, where something spinning at just the right speed may appear stationary if illuminated solely by a single fluorescent lamp. This effect is eliminated by paired lamps operating on a lead-lag ballast. Unlike a true strobe lamp, the light level drops in appreciable time and so substantial "blurring" of the moving part would be evident.

Fluorescent lamps may produce flicker at the power supply frequency (50 or 60 Hz), which is noticeable by more people. This happens if a damaged or failed cathode results in slight rectification and uneven light output in positive and negative going AC cycles. Power frequency flicker can be emitted from the ends of the tubes, if each tube electrode produces a slightly different light output pattern on each half-cycle. Flicker at power frequency is more noticeable in the peripheral vision than it is when viewed directly.

Near the end of life, fluorescent lamps can start flickering at a frequency lower than the power frequency. This is due to instability in the negative resistance of arc discharge,

New fluorescent lamps may show a twisting spiral pattern of light in a part of the lamp. This effect is due to loose cathode material and usually disappears after a few hours of operation.: 22

Electromagnetic ballasts may also cause problems for video recording as there can be a so-called beat effect between the video frame rate and the fluctuations in intensity of the fluorescent lamp.

Fluorescent light fixtures cannot be connected to dimmer switches intended for incandescent lamps. Two effects are responsible for this: the waveform of the voltage emitted by a standard phase-control dimmer interacts badly with many ballasts, and it becomes difficult to sustain an arc in the fluorescent tube at low power levels. Dimming installations require a compatible dimming ballast. Some models of compact fluorescent lamps can be dimmed; in the United States, such lamps are identified as complying with UL standard 1993.

Systematic nomenclature identifies mass-market lamps as to general shape, power rating, length, color, and other electrical and illuminating characteristics.

In the United States and Canada, lamps are typically identified by a code such as FxxTy, where F is for fluorescent, the first number (xx) indicates either the power in watts or length in inches, the T indicates that the shape of the bulb is tubular, and the last number (y) is the diameter in eighths of an inch (sometimes in millimeters, rounded-up to the nearest millimeter). Typical diameters are T12 or T38 (1+1⁄2 inch or 38 mm) for residential lamps, T8 or T26 (1 inch or 25 mm) for commercial energy-saving lamps.

Overdriving a fluorescent lamp is a method of getting more light from each tube than is obtained under rated conditions. ODNO (Overdriven Normal Output) fluorescent tubes are generally used when there is

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey