lcd display how it works quotation

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

About: I"ve been a president at two colleges and currently provide consulting services for small businesses, non-profits, and educational organizations. In a previous life, I was a human factors engineer and human pe…

If you like collecting quotations like I do, then this instructable is for you. This instructable will show you how to put together a way to display your quotes for all to see, using things you probably already have around the house.

Any kind of quote will do, but because the picture frame scrolls through the images that will contain the quotes it works best if you keep the quotes short. Longer quotes, although interesting, may not remain on screen long enough to be read. If you have a number of longer quotations, see "Some Final Notes" at the end of this instructable for tips that you can consider for longer display times.

Look at the sample images stored on your LCD picture frame. For my frame, all of the sample images were 856x480 pixels. To determine this, right click on the image file, and select Properties. You should see a number of tabs, one of which should be called “Details.” Click on the details tab; under Image you should see a width and height. Write this down or keep the window open, because we will use it to set up PowerPoint.

Take the smaller of the two numbers (usually the height), and divide that by the larger number. In my case, 480/856=0.5607. Checking the table below (which shows common screen image ratios), I can see that the native images on my LCD picture frame are just about in 16:9 format.

Open PowerPoint, and start a new presentation. On the ribbon, click Design, Page Setup. In the setup dialog box, select the image format that matches the native format of your LCD picture frame. We do this because it helps prevent the software driving the frame from cropping or stretching the images unnecessarily. Click Home on the ribbon.

At this point, your presentation should have two slides: The initial default title slide, and your newly inserted blank slide. Click on the first slide (the title slide), click your right mouse button, and select delete. You should be left with a single blank slide in your presentation, sized to the native image size of your LCD picture frame.

In many cases, the picture won’t fill the slide because it’s in a different format than the native format for the LCD picture frame. Thus, we’ll need to resize the image to fit. At the same time, we don’t want to distort the image either. Here’s the most straightforward approach:

Move the image all the way to the right edge of the PowerPoint slide, then up until the top of the image aligns with the top of the slide. The image should “snap” to the edges of the slide.

Grab the lower-left corner of the image and drag it to the left-center edge of the slide. By grabbing the lower-left corner (or any corner, for that matter), you maintain the aspect ratio of the image and you can resize it without distortion. Again, the image should snap to the edge of the slide.

With the picture still selected, click on the “Crop” button. The circle-shaped resize handles at the image’s corners should change to crop handles. Grab the bottom-center crop handle with your mouse, and push up until it snaps onto the bottom of the slide.

A word about cropping the images: When you crop images, you may lose parts of the image that make it a pleasing composition. Feel free to drag any of the crop handles and move the photo around until you get the image looking the way you want. Just make sure when you’re finished, the image is aligned with the edges of the PowerPoint slide.

Click Insert on the ribbon, and click on the text box button. Select a font, font color, and size that make the quote readable. Move to your word processing file with your quotes, highlight and copy the quotation you want to use, and then use "Paste Special, Unformatted Text" to paste the quotation into the text box.

Resize the text box as necessary, and place it in a good location on the image. For the quote here I used 24-point Arial Black in white (I have seen the quote attributed to Will Rodgers, Fred Rogers, and Wynn Catlin; I think Will is most likely but I’m amused by the incongruity of attributing it to Mr. Rogers!).

1. PowerPoint 2007 has an option under the Insert ribbon called “Photo Album.” This will bring in many photos at once, into different slides. However, it brings in all the images in 4:3 format. I haven"t found a way to change this. If you change the slide layout of the Photo Album to something else (like 16:9) PowerPoint stretches the images to fit.

2. If you insert all of your images, resize them, and crop, you can run the “Compress Pictures” process (explained in Step 3, Bringing In Images) once; it will fix all of the images on all of the slides at once.

3. Once you add your first quote, select the text box and copy it. Then, move to each slide and select “Paste.” This will place a formatted text box on each slide, in the same location from which it was copied. This is a great place to start. One caveat: When pasting your quotes from your word processing program, use “Paste Special” and choose unformatted text. That preserves your text box formatting.

4. My LCD picture frame doesn’t let you change the display time for pictures, and some of the transitions happen too quickly to allow you to read the entire quote. You can do what I did, which was to make two copies of every slide. PowerPoint is creative in its naming; the slides are called Slide1.jpg, Slide2.jpg, et cetera. I named my copies Slide1a.jpg, Slide2a.jpg. The file system sorts the original and the copy together when the files are named this way, so every quote is displayed twice with an intervening transition.

5. If you don’t have a lot slides suitable for quotes, consider visiting a site like Interface Lift, which has a wide range of images in a variety of formats for desktop wallpapers. Chances are, you’ll be able to find images in a format suitable for the native format of your LCD picture frame.

6. Finally, experiment with fonts and type colors. You can even use transparent fills in the text box to make the text stand out a bit more if your slide has a complex background.

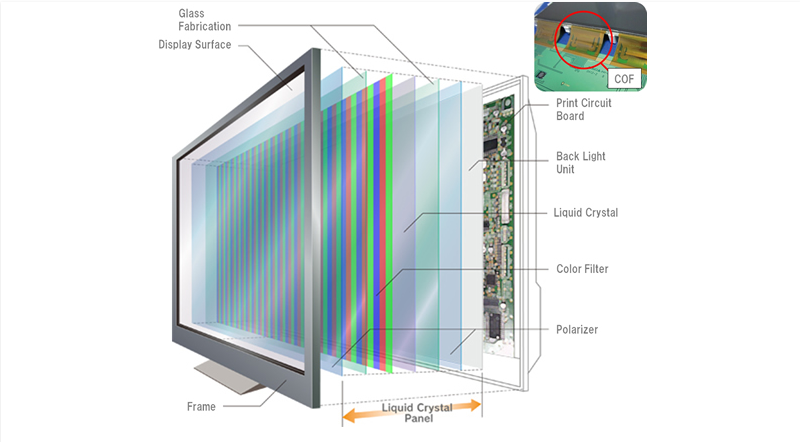

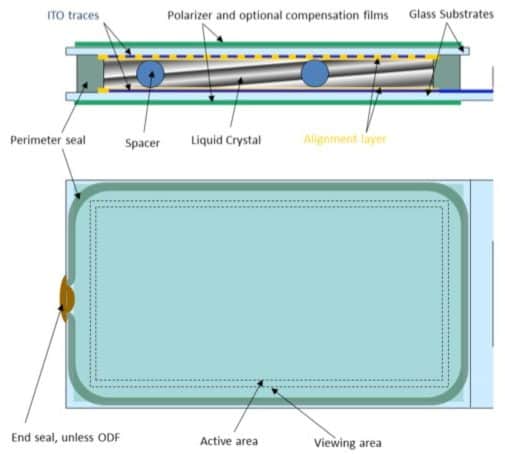

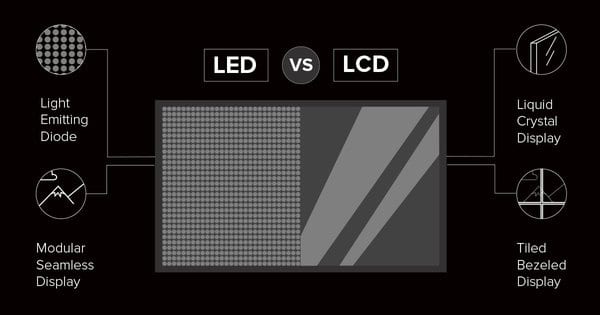

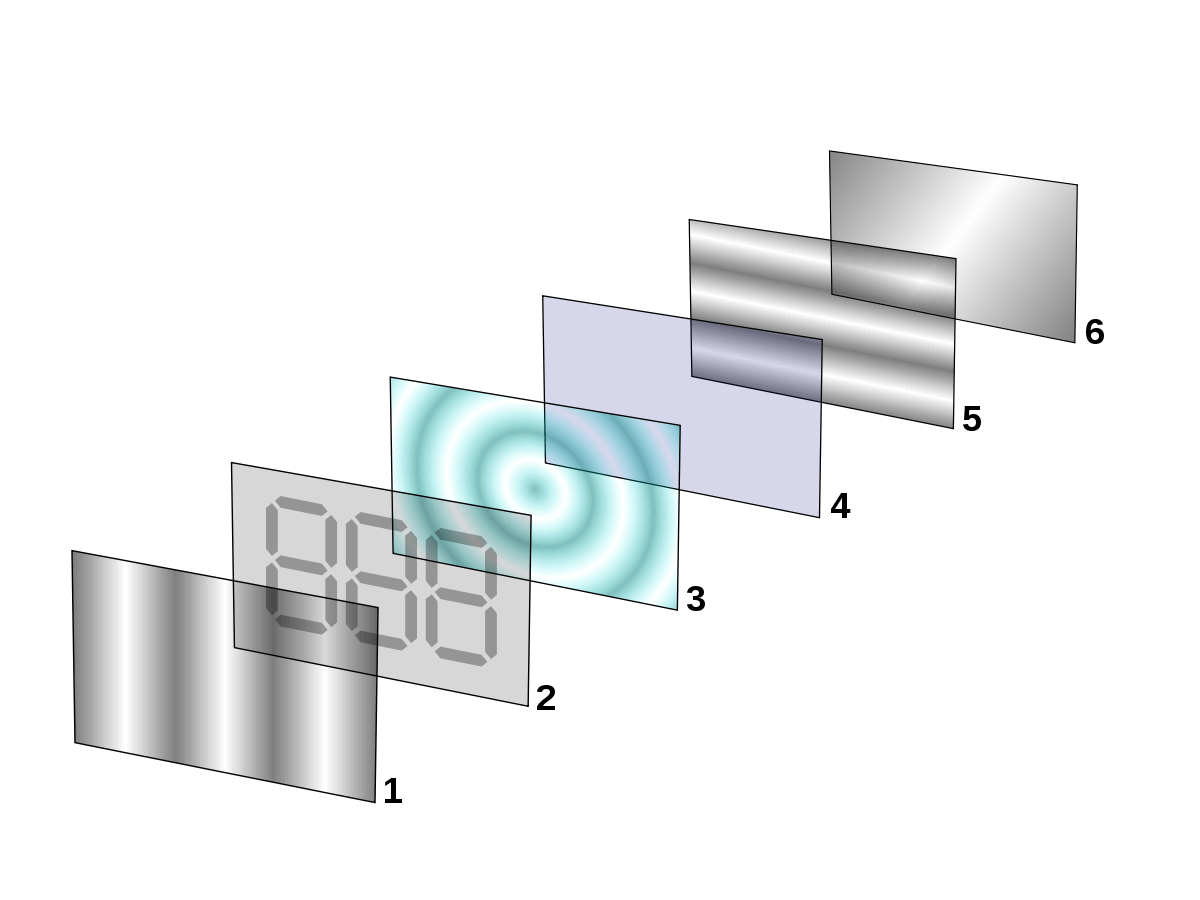

Industrial LCD monitors usually work in front of an industrial sized computer. However, any video source, such as a digital camera, could be used to power the display. “LCD” is an acronym for “liquid crystal display,” which refers to the technology these monitors utilize. In the past, industrial monitors used cathode ray tube (CRT) technology. This was before LCD became popular. Today, LCD technology is used throughout most industrial displays which is what gives these massive scoreboards and billboard advertisements a digital picture that is so clear. An LCD is composed of several layers: the mirror, polarizing film, glass filter, negative electrode, liquid crystal layer, positive electrode, cover glass, and displayed image. Electric currents charge the liquid crystals, which causes the latter to change structure. The altered crystals, in turn, polarize light, and after the light passes through all those layers, they change into the display that you see.

Anindustrial monitor exists in four common types: budget displays, business/professional displays, multimedia displays and gaming displays. They differ in terms of price, panel size and features. For example, budget displays are the most basic and are similar to a desktop PC or laptop. Professional displays on the other hand are a larger, more expensive, and offer additional display options. Multimedia displays are best for your home photo and video projects, while gaming displays need to have the specs to accommodate moving images.

First of all, LCD monitors are more energy-efficient than CRT monitors which most likely explains the decline in use of CRT monitors. LCD monitors have also become more affordable because of their widespread availability and massive industry production. Besides being more affordable, LCD monitors offer reduced radiation emission, require less space, and weigh less. No matter what your application may be, we would highly recommend you consider an industrial LCD monitor before any other type of digital monitor.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

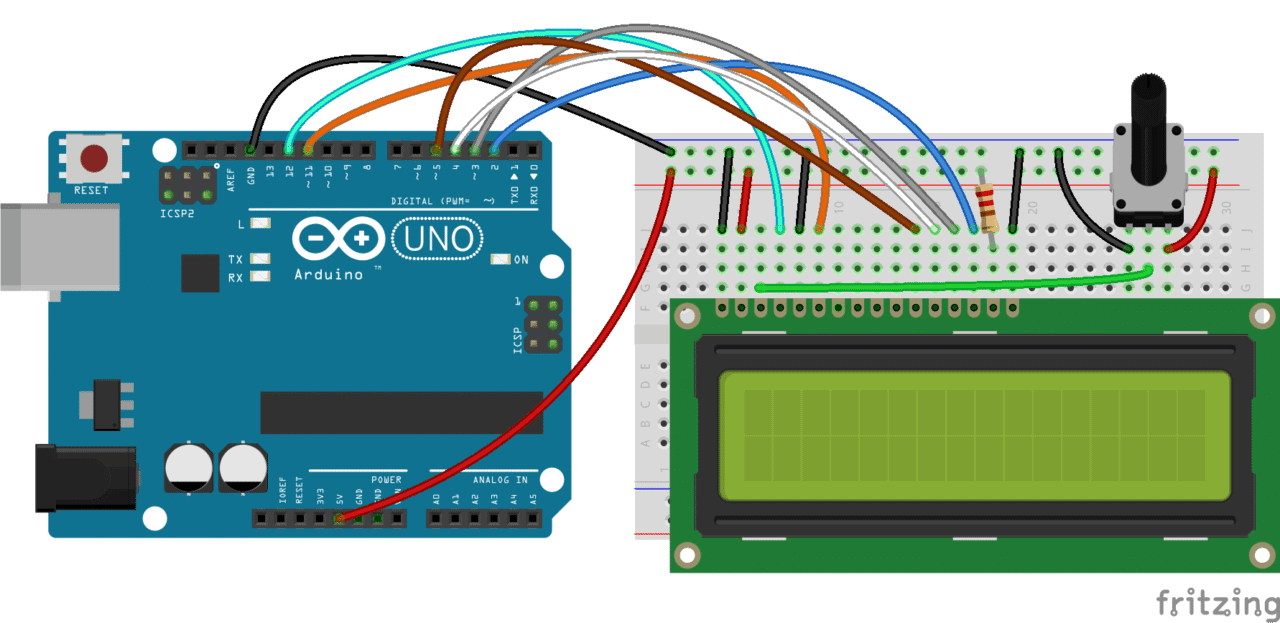

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

The 3-in-1 Smart Car and IOT Learning Kit from SunFounder has everything you need to learn how to master the Arduino. It includes all of the parts, wiring diagrams, code, and step-by-step instructions for 58 different robotics and internet of things projects that are super fun to build!

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

All of the code below uses the LiquidCrystal library that comes pre-installed with the Arduino IDE. A library is a set of functions that can be easily added to a program in an abbreviated format.

In order to use a library, it needs be included in the program. Line 1 in the code below does this with the command #include

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now lets just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

This function takes a string of text and scrolls it from right to left in increments of the character count of the string. For example, if you have a string of text that is 3 characters long, it will shift the text 3 spaces to the left with each step:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

If you found this article useful, subscribe via email to get notified when we publish of new posts! And as always, if you are having trouble with anything, just leave a comment and I’ll try to help you out.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

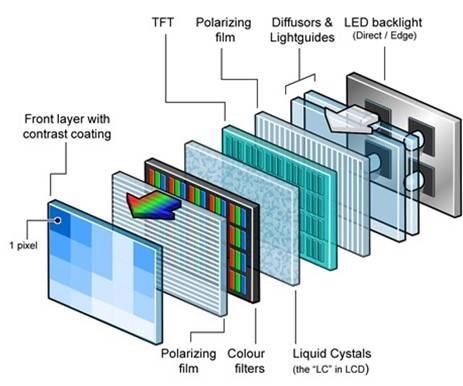

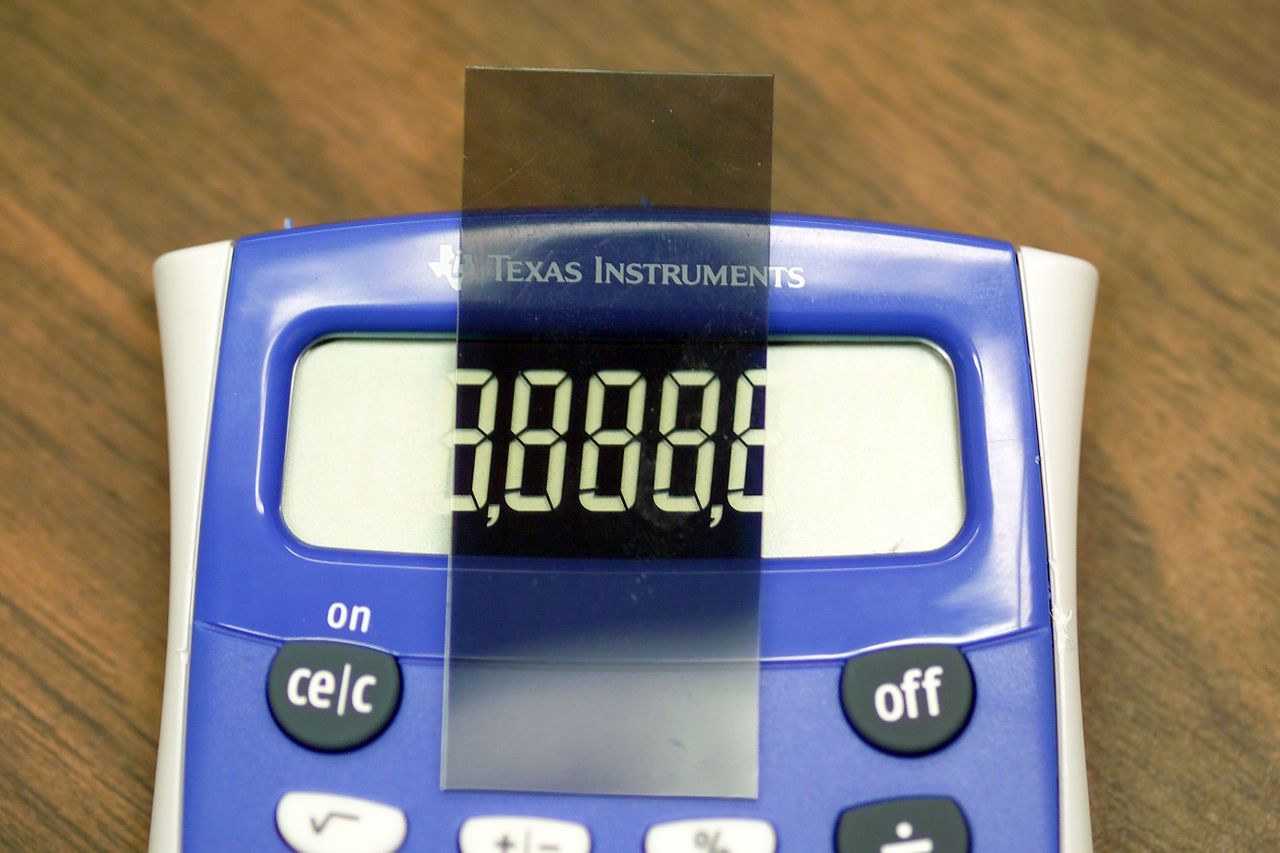

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

In Layman’s language, when an electric current is applied to the electrodes, i.e. to the segment line and common line, it twists the Liquid Crystals w.r.t to the polarizing filter, obstructing the light in that particular area as shown in the figure below. Hence, that area becomes darker and prominent.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your products need to be used with a switchable backlight, then trans-reflective reflectors are best to be used for front reflectors. If the device has to be used without backlight, then we can select a reflective polarizer for the back-panel as it gives the best contrast ratio.

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

Anti-glare filters are bonded with the top polarising filters using adhesive. It improves the viewability by re-directing light waves so they don’t reflect back towards the viewer thus reducing glare. Newer materials are capable of reducing the front glare by up to less than 0.3%.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

COG can be used as it is cheaper and makes the assembly process simpler, but if the dimensions are a constraint, then the COB is also a viable option.

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

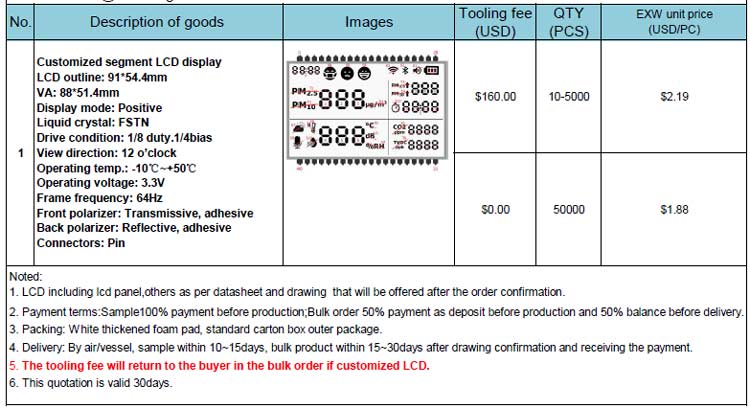

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

The tooling time and cost depend on how detailed and accurate designs you sent to the manufacturer. They then send the exact dimensions and technical details of the product they will be manufacturing. Once you confirm the design, they manufacture and ship the product which might take 4-8 weeks to arrive depending on the size of the order and mode of transportation selected.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Liquid Crystal Displays (LCDs) are widely used in electronic devices for all kinds of industries. They are typically divided into three display types based on their light transmission modes. The three main types of LCD modes are transmissive, reflective, and transflective. The main difference is how they use light to illuminate the pixels in the display:Transmissive LCDs require a backlight for clear visibility.

Transmissive displays rely on a backlight to be visible. For this kind of display, light emitting from the back of the display glass must pass through the LCD towards the front to light the pixels. Transmissive LCDs are suitable in low-light environments since they rely on a backlight to be visible. These displays are also used in applications where high-resolution images, videos, and high quality are important, which is why you will commonly find

The most common devices using transmissive LCDs are smartphones, tablets, computer monitors, and televisions. They are also used in digital cameras, camcorders, automotive displays, navigation systems, in-flight entertainment systems, medical equipment, kiosks, and point-of-sale (POS) terminals.

Advantages of transmissive LCDsHigh image quality: Transmissive LCDs can produce high-quality, bright, vivid images with a wide color gamut and high contrast ratio.

Good visibility in low-light environments: Transmissive LCDs rely on a backlight to be visible, which makes them suitable for darker lighting conditions.

Disadvantages of transmissive LCDsHigh power consumption: Transmissive LCDs require a backlight to be visible, which increases power consumption and reduces the end product"s battery life.

Reflective displays rely on bright ambient light to be visible. There is no backlight source inside this kind of display; instead, light is reflected from the surrounding environment for the pixels to be visible.

Reflective LCDs are great for outdoor or sunlight-readable applications where the device is exposed to direct sunlight. These displays are also used in small handheld devices where power consumption is a concern.

graphic COG LCDs and character LCDs with positive display types. The most common devices using reflective LCDs are outdoor applications such as GPS devices and portable devices such as e-readers, camera viewfinders, and digital watches.

Advantages of reflective LCDsLow power consumption: Reflective LCDs do not require a backlight, which reduces their power consumption and extends the device"s battery life.

Thin and lightweight: Reflective LCDs are thinner and lighter than transmissive LCDs since they don"t have a backlight, making them well-suited for portable devices.

Disadvantages of reflective LCDsLimited viewing angles: Reflective LCDs have a limited viewing angle, making it difficult to read the display from certain angles.

Transflective displays combine backlighting and ambient light reflection to illuminate the pixels, resulting in a display with both transmissive and reflective properties.

Transflective LCDs are commonly used in industrial and medical equipment, where it"s essential to have high visibility in any lighting conditions. They are also widely used in marine, military, and aviation applications where the operator needs to see the display in bright and low light conditions.

Advantages of transflective LCDsHigh visibility and contrast: Transflective LCDs combine the benefits of reflective and transmissive displays, providing good visibility in both bright sunlight and low-light environments.

Low power consumption: Transflective LCDs do not require a backlight always on, which reduces power consumption and extends battery life when the backlight is off.

Disadvantages of transflective LCDsLimited color depth: Transflective LCDs typically have a reduced color depth compared to transmissive LCDs, which can affect overall image quality.

The future of transmissive, reflective, and transflective LCD displays is likely to be influenced by technological advances and changes in consumer preferences. LCDs may eventually be replaced by newer technologies such as

OLEDs, Micro-LEDs, and QD-LCDs. For now, LCDs are still a widely used display technology, with display types and modes equipped for every kind of industry and environment.

Updated: Oct 28, 2019:Despite all the advances in LCD display technology viewing angle is still an important topic, panel viewing angles are still poor, good, better and best, but none are 100% perfect.

The viewing angle of an LCD panel is typical given based on the normal aspect ratio which is generally landscape for the types of LCD panels we work with. It is quoted for both horizontal and vertical in degrees from perpendicular to the display or as a total of left & right and up & down. So for example the newer IPS panels now claim up to 89 degree viewing angle from perpendicular for both horizontal and vertical.

Specifications are no replacement for actually seeing and evaluating an LCD panel, the reason is that there can be characteristics that the specifications don’t mention. For example I have seen an LCD panel with excellent viewing angle specifications but when testing it I could see a color shift at around 45 degrees from perpendicular.

Further to the previous point, even though LCD panel specification may quote H (horizontal) & V (vertical) viewing angles the performance in portrait model may be quite different to landscape mode.

I realize not every application needs or even suits having a wide viewing angle. Digital signage displays clearly benefit from a wide viewing angle if used in a poster or menu board but some overhead information displays need a good 6 o’clock viewing angle, ie when viewed from below, but the 12 o’clock viewing angle may not be critical.

IPS panels have had quite a few years of being a leading technology for excellent viewing angle with not only impressive specifications but genuinely excellent results. More recently companies like AUO have been showing panels with a new technology that appears to provide not only equivalent viewing angles but also excellent color fidelity over the range of viewing angles.

At this time the viewing angle of a LCD panel is not a tunable setting, it is a fixed part of the LCD panel design. Filters can be added by reworking the panel or adding to the front but these will typically limit rather than extend the viewing angle.

If you"re looking for ~500-1000 display panels with the intent to buy, I would strongly suggest speaking with an account manager, sales rep, and/or applications engineer at a distributor. Such an order will likely generate enough revenue for them to give you a whole lot more than the time of day. I know the local account managers and FAE"s for a few large component distributors in my area (Future Electronics and Allied Electronics), and they are usually helpful, though not always prompt.

Looking at Future, they do seem to have a few LCDs quoted on their site, however it is certainly not a comprehensive list. If you contact a sales rep (there or anywhere) and provide them your requirements, they may come back with additional parts that their manufacturers produce that better fit your need.

Unless your volumes are going to be in the millions, let me dispel any thoughts you have of "Why not just talk to (LCD mfc) directly?". Said manufacturers will not care about you, and the premium they will charge to deal with you (if they bother at all) will be higher than what a typical distributor would, because, frankly, they do not want your direct business. Use the middlemen. They will make specifying, finding, and sourcing LCD panels vastly easier and cheaper.

Dr Pan: Hello, Greg. Segment LCD screen can only be used for simple display content of numbers and characters at a specified position. For example, the display on clock, landline, calculator, etc.

It is supposed to be a replacement for LED segment display. If we compare it with LED segment display, it is more stylish and high class, but more expensive. If we compare it with dot matrix LCD, the display content is very simple and absence of variation, but much cheaper. It is widely used in monochrome LCD screen: TN, HTN, STN, FSTN and VA because of relatively low cost.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

The first step is to select temperature sensors that can be affixed to the display while being small enough to fit within a restricted envelope. Thermistors, thermocouples, or RTDs are all options to consider since they represent relatively low-cost and high-reliability ways to measure the display’s surface temperature. These types of sensors also provide an electrical output that can be calibrated for the desired temperature range.

The next step is to determine the number of temperature sensors and their approximate location on the display. It’s recommended that a minimum of two temperature sensors be used to control the heater. By using multiple sensors, this provides the circuit redundancy and allows for a weighted average of the temperature measurement to mitigate non-uniform heating. Depending on the temperature sensors location, and the thermal mass of the materials involved, the control loop can be optimized to properly control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Insulating materials, air gaps, or other means can be incorporated in the design to manage the way heat travels throughout your system on the way toward an eventual “steady state” condition. During development, prototypes can be built with numerous temperature sensors to map the heat transfer, allowing for the optimal placement of temperature sensors, an adequately sized heater, and a properly controlled feedback loop.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

At TeleTraders, we want to buy your used LCD Displays from you in bulk. If you’re older LCD Displays are still usable, consider selling them to TeleTraders to help offset your equipment upgrade costs. Give TeleTraders a call at

We are based in Georgia, but we work with companies all over the U.S. and are committed to offering the most competitive rates on logistics and used equipment.

When it comes time to update your office, offset your expenses and sell used LCD Displays. We will make you a competitive offer for your old monitors, LCDs, computers, modems, and laptops.

Our company is happy to purchase your old used, outdated LCD displays and monitors to free your business from the sometimes complicated electronics disposal processes. Please give us a call at 770-864-9179 or get a Free Online Quote to get started.

Even if you do not see your office equipment brand listed here, we will likely accept the items as a part of your offload package. Contact our team anytime to inquire about the brands we purchase from our clients.

We work hard to repurpose or recycle the working items to save all companies money on their equipment costs and reduce the consumption of Earth’s natural resources. Equipment with minor problems may go through our refurbishment process to restore its functionality and improve its appearance to be resold again.

Since we recycle and dispose of the equipment, in addition to repurposing and reselling the items, your items do not need to be in perfect shape to qualify for our many purchase programs.

If you do not have instant access to this information, do not worry – Our team will help walk you through the assessment process for each item in your inventory.

Our team utilizes industry experience to provide you with a fair and competitive price quote for your old used LCD displays and computer devices. We continue to upgrade our knowledge base as office equipment quickly becomes outdated in the constantly changing world of electronics. We team up with many companies around the world to quickly resell, repurpose, or recycle the LCD displays sent our way. Our efforts ensure the electronics remain in operation well beyond their initial run with your company.

When you sell your LCD displays and other office equipment to TeleTraders, we can also handle all of the packing, removal and transporting for the equipment, helping free up both your space and your time.

We understand that office technology needs change over time. The LCD displays and monitors that worked for your office a year or two ago may not be keeping pace anymore with your needs. We can help by offering you the best rates possible for your bulk LCD displays. Contact TeleTraders to get started right now.

When it’s time to upgrade your computer and LCD displays, you shouldn’t have to spend lots of time trying to figure out how to dispose of, sell or recycle your used LCD displays and office equipment – that’s where TeleTraders will be able to help you.

We handle all nationwide projects and provide some of the best logistics rates to help compensate, giving you the some of the most competitive returns on your original IT tech investments.

We can also provide a certificate of disposal for situations involving equipment that needs to be disposed of either because it’s no longer a valuable asset, or contains secure information that needs to be destroyed.

We request a detailed list of your used office LCD displays, including make, model, and quantity of units. Please, also include a photo of your equipment so we can gauge the current quality of the hardware.

TeleTraders is happy to accept most major and minor brands of common IT office LCD displays, office LCD display systems, and also other IT office equipment. If there is any question about whether we will accept your brand of equipment, feel free to contact us by phone or email at any time and we will respond to your inquiry as quickly as possible.

We are always looking to help businesses, small and large, offset the costs of upgrading their IT office LCD displays and IT office LCD display systems. In order to make an inquiry about a possible trade-in valuation, please Contact Us so we can work with you to evaluate used IT office LCD display gear. You may also Call Us directly for immediate assistance.

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function.

If driving the backlight of the C version display with 12 Volts and a series resistor, substituting a D version display will not work since the four LEDs need more than 12 Volts to get the same current flowing.

The provided display driver example code is designed to work with Microchip, however it is generic enough to work with other micro-controllers. The code includes display reset sequence, initialization and example PutPixel() function.

Please see the DT028CTFT for reference designs. The schematics between the A and the C are the same with the exception that the A does not have the IPS interface.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey