lcd display how it works pricelist

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

The 43 inches and 55 inches rose more than double digits in August, reaching 13.7% each, and rose another $7 and $13, respectively, to $91 and $149, respectively, in September.

For larger sizes, overseas stocks remained strong, with prices for 65 inches and 75 inches rising $10 on average to $200 and $305 respectively in September.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

This kind of price correction is in line with the law of industrial development. Only with reasonable profit space can the whole industry be stimulated to move forward.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

A lot of consumers wonder how manufacturers determine the LCD display panel prices. After all, display solutions such as TFT LCDs and HMI touch screens do not always come cheap. And sometimes, a few products that can indeed be purchased for lower prices may come with several quality issues.

Hence, we’ve rounded up a list of factors that influence how to display modules such as TFTs, LCD, and touch screens are priced. You can also use these factors to evaluate to whom you should place your next orders for your display solutions.

LCD fluids are used in altering the light orientation passing through glass substrates. Hence, this causes the panel’s active pixels to darken. Different kinds of LCD panel fluids provide unique characteristics and change a panel’s viewing angle, temperature range, and display clarity.

TN fluid contains liquid crystal substances that allow light to pass through by twisting and untwisting at a 90-degree angle. This display technology is available in monochrome; that is, black characters against a gray background.

The viewing angle is limited in a panel containing TN fluid. This means that the text or image display becomes harder to read if you rotate the device away from its center. The display is also not that sharp compared to displays using other technologies.

Another characteristic of this fluid is that it works well even in colder temperatures. It’s because TN fluid has the quickest response time among the other LCD fluid types.

TN fluid is considered the cheapest LCD fluid type. However, this doesn’t mean that TN isn’t widely used. The display technology is greatly utilized in digital clocks, pagers, and gas pumps.

LCD modules with STN fluid enjoy a wider display angle, greater multiplexing, higher image contrast, and sharper response than devices using TN fluids. However, modules with STN fluids may have slower response times when used in lower temperatures due to the fluid freezing inside the device.

STN fluid falls under the moderately cheap LCD module price. Furthermore, STN fluid is widely utilized in several monochrome LCD devices such as POS machines, inexpensive feature phones, and informational screens of some devices.

The CSTN fluid technology takes away the monochrome finish of the typical STN fluid devices. Red, green, and blue filters are added to the fluid module to allow a colored display. New versions of CSTN often feature a viewing angle of 140 degrees and 100ms response times.

CSTN is a bit pricier than TN and STN fluids. But it’s a good choice if you need to display color images on your LCD device. In fact, a lot of color feature phones use CSTN as an alternative to the TFT displays, saving almost half the manufacturing costs.

A device using FSTN fluid has better viewing angles and can produce a sharp black-and-white coloration. It is a good choice for devices that need to display small yet easy-to-read images.

In terms of cost, the LCD display module price of a unit with FSTN is higher compared to TN and STN. But this is concerning the better visual quality that FSTN offers.

To cap off this part, the fluids used in a screen is a big factor in determining the overall LCD screen display panel price. As you can see, the four fluid types often used in LCD screens rise in costs with respect to the visual quality produced by each technology.

The temperature range in which LCD screen displays may work varies intensely. Some displays continue to work at optimal performance even when used in cold or hot outdoor temperatures. Lower-quality LCD panels may start having glitches at the slightest change of temperature and humidity. Hence, the temperature range may have a huge impact on the LCD display panel price as well.

In hot environments– The liquid crystals may begin to deteriorate, while the electrical components will start overheating and cause damage to the display screen performance.

Now, most LCD screen panels don’t experience such temperature extremes. In fact, a typical LCD TV can operate properly between approximately o°C and 32°C (32° – 90° F). Meanwhile, other screen modules (usually the industrial-grade ones) have unique capabilities to work in even more extreme ends of the temperature scale.

If you want to look for the most cost-effective type of LCD panel for your device, then you must consider the following standard LCD unit temperature types:

Normal temperature units work well in environments that have indoor temperatures at approximately 20-35°C (68-95°F). Some LCD modules may work well above up to 50°C (122°F). Such LCD modules can be used in daily settings by the typical consumer public.

LCD units under this type are made to withstand lower and higher temperature ranges. Extreme operating temperatures may range anywhere from -30°C to 85°C (-22-185°F). Most LCD modules with wide/extreme temperature capabilities are used in extremely cold areas such as Artic places and ski resorts, as well as humid and moisture-rich hot outdoor areas.

Generally, the LCD module price goes up if the entire display unit can withstand higher temperature ranges. Those who can operate under normal temperature ranges only are usually cheaper.

Hence, you must consider the places where you’ll be installing your LCD display devices. You can’t just use cheaper LCD modules for an industrial-grade display machine. Treat your LCD panel as an investment and select a panel that will yield better screen performance that’ll last several years for you and your business.

It’s an unspoken rule, but monochrome modules are generally cheaper than color-capable ones. However, color-capable display modules may also have cost variations depending on their display capabilities.

Color LCDs have three subpixels that hold red, blue, and green color filters. Each subpixel can have as much as 256 color shades, depending on the variation and control of the voltage applied to it.

Now, when you combine 256 shades of both red, blue, and green subpixels, color LCDs can display a color palette of up to 16.8 million colors. And all these are made possible by millions of transistors etched onto the glass modules.

Display size also plays a large role in an LCD device’s color capability. Smaller screens need fewer pixels and transistors since they have smaller display sizes. These screens are also less costly to make. Now, larger screens with high color resolution and huge display sizes require more transistors and pixels, justifying the higher prices of such monitors.

A touch screen display module is more costly than a non-touch monitor module. Touch capability is integrated into Human Machine Interface (HMI) modules and is generally used in kiosks, bank ATMs, hospital equipment, and similar devices in other industries.

HMI touch screen price is also dependent on what kind of touch screen technology it uses. Here are some of the common touch technologies integrated to HMI touch screen devices:

Capacitive touch screens are the most common in the display industry today. This technology uses transparent conductors, insulators, and glass to create the panel. An electrostatic field change in the screen’s module happens when a human finger touches the screen surface. This ultimately creates signals that are sent to the touch screen controller for processing.

In general, capacitive touch screens are the most cost-effective choice for HMI machines. Since they are considered the gold standard of commercial touch screen technologies, they do come with a high price tag.

Infrared grid technology uses photodetector pairs and X-Y infrared LED components to allow sensors to pick up the touch and its exact location. Infrared grids have been used in several touch screen modules before the capacitive touch screen technology took over.

We’ve explained the following factors at length for both public consumers and business clients to understand the variations in TFT, LCD, and HMI touch screen prices.

Cheap doesn’t necessarily mean low-quality. Also, expensive options aren’t always a wise choice, either. You can maximize your buying or manufacturing options if you know how to compare LCD modules and panels depending on the specifications you truly need for your display machines and devices.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

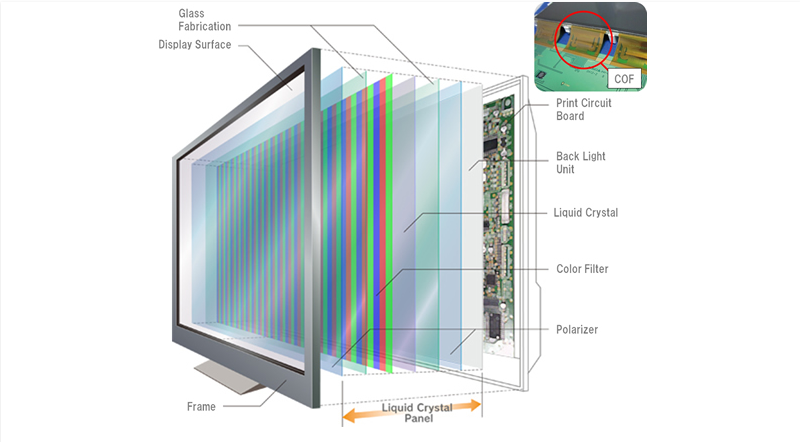

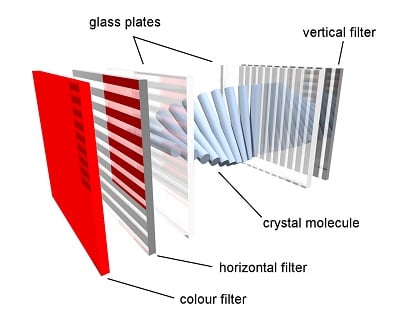

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

As light strikes the first filter, it is polarized. The molecules in each layer then guide the light they receive to the next layer. As the light passes through the liquid crystal layers, the molecules also change the light"s plane of vibration to match their own angle. When the light reaches the far side of the liquid crystal substance, it vibrates at the same angle as the final layer of molecules. If the final layer is matched up with the second polarized glass filter, then the light will pass through.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

Photo: A less well known trick of polarized light: it makes crystals gleam with amazing spectral colors due to a phenomenon called pleochroism. Photo of protein and virus crystals, many of which were grown in space. Credit: Dr. Alex McPherson, University of California, Irvine. Photo courtesy of NASA Marshall Space Flight Center (NASA-MSFC).

Photo: Prove to yourself that an LCD display uses polarized light. Simply put on a pair of polarizing sunglasses and rotate your head (or the display). You"ll see the display at its brightest at one angle and at its darkest at exactly 90 degrees to that angle.

Photo: How liquid crystals switch light on and off. In one orientation, polarized light cannot pass through the crystals so they appear dark (left side photo). In a different orientation, polarized light passes through okay so the crystals appear bright (right side photo). We can make the crystals change orientation—and switch their pixels on and off—simply by applying an electric field. Photo from liquid crystal research by David Weitz courtesy of NASA Marshall Space Flight Center (NASA-MSFC).

LCD displays use a relatively new technology, but all of the early teething problems have long been worked out and the prices of LCD displays have fallen to the point that they are now mainstream products. A good LCD display, such as the ViewSonic VP191 19" model shown in Figure 11-2, provides top-notch image quality in a compact package. Although traditional CRTs have advantages of their own, most people who experience the bright, contrasty image of a good LCD display will never return to using a CRT monitor.

If you convert from a standard CRT display to a flat-screen CRT display or (particularly) an LCD display, you may notice an odd effect. Your eye and brain become used to seeing the curved surface of the old display as flat. The new display, which truly is flat, looks concave! Straight lines appear to bow inward, particularly if you work close to the display. The effect is so convincing that Robert actually held a straight-edge up to his new LCD display. Sure enough, the "bent" lines were straight. Don"t worry, though. The optical illusion disappears after only a couple hours" use.

CRT monitors were the dominant PC display technology until recently, but that has changed. For displays bundled with new PCs, LCDs exceeded CRTs in popularity by late 2002. By 2005, LCDs had also begun to outsell CRTs in retail channels. Lower cost and other advantages of CRTs ensure that they"ll remain available for years to come, but the emphasis has definitely shifted to LCDs.

Unlike CRT monitors, which have a maximum resolution but can easily be run at lower resolutions, LCDs are designed to operate at one resolution, called the native resolution. You can run an LCD at lower than native resolution, but that results in either the image occupying only part of the screen at full image quality or, via pixel extrapolation, the image occupying the full screen area but with greatly reduced image quality.

LCDs are available in analog-only, digital/analog hybrid, and digital-only interfaces. Using an analog interface requires converting the video signal from digital to analog inside the PC and then from analog to digital inside the monitor, which reduces image quality, particularly at higher resolutions. Synchronization problems occur frequently with analog interfaces, and can cause various undesirable display problems. Finally, analog interfaces are inherently noisier than digital interfaces, which causes subtle variations in display quality that can be quite disconcerting.

Whereas CRT monitors require high vertical refresh rates to ensure stable images, LCDs, because of their differing display technology, can use much lower refresh rates. For example, at 1280x1024 resolution on a CRT monitor, you"ll probably want to use an 85 Hz or higher refresh rate for good image quality. At the same resolution on an LCD, 60 Hz is a perfectly adequate refresh rate. In fact, on LCDs, a lower refresh rate often provides a better image than a higher refresh rate.

Unlike CRT monitors, whose phosphor-based pixels respond essentially instantaneously to the electron beam, LCD panels use transistors, which require time to turn on or turn off. That means there is a measurable lag between when a transistor is switched on or off and when the associated pixel changes to the proper state. That lag, called rise time for when the transistor is switched on and fall time for when it is switched off, results in a corresponding lag in image display.

Fast LCD response time is a Good Thing. Fast response means smoother scrolling and no ghosting or smearing, even when you view fast-motion video. Unfortunately, there"s no standard way to measure or specify response time, so different LCD makers use different methods. That means you can"t necessarily compare the response time specified by one LCD maker directly with that specified by another. (Actually, it"s worse than that; you can"t necessarily compare response times for two different models made by the same company.)

When LCDs first appeared, most makers specified rise-and-fall response in milliseconds (ms), the time required for a pixel to change from black to white (rise time) and then from white to black (fall time), also called the black-white-black (bwb) response. Nowadays, in addition to or instead of bwb, many LCD makers specify white-black-white (wbw) response and/or gray-to-gray (gtg) response, the time required to go from one level of gray to another.

And gtg times are not necessarily comparable between different brands, or even between different models from the same company, because gtg time depends on which particular levels of gray are tested. Do we specify gtg response for going from an almost-black gray to an almost-white gray, or for going from one almost-middle gray to another almost-middle gray? It makes a difference.

Some makers also specify the rise time separately. For example, we found one display that was advertised as having a 4 ms response time, but the product data sheet on the maker"s web site listed that display as having an 8 ms response time. Both numbers were accurate, as far as they went. The 4 ms time quoted in the ad referred to rise time (black to white). The 8 ms time quoted in the technical documents referred to bwb response.

It is not safe to make assumptions about one type of response time based on another type. For example, one LCD may have response times of 20 ms bwb and 8 ms gtg, while another model from the same manufacturer may have response times of 16 ms bwb and 12 ms gtg. So, is the second LCD slower or faster than the first? It depends on which numbers you decide to use. Advertisers use the fastest numbers available. Count on it.

All of these response-time numbers can be different, and there"s no direct relationship among them. If you look only at ads (as opposed to technical documentation), it"s often not clear what type of response time is being specified. If a response time is quoted without qualification, such as "16 ms," that ordinarily (but not always) refers to bwb response.

A fast bwb (or wbw) response time is more important for general use, while a fast gtg response time is more important for gamers and graphic artists. For general use, bwb response of 25 ms to 30 ms is acceptable to most people, and 16 ms to 20 ms preferable. For gaming and other demanding applications, bwb response of 12 ms is generally acceptable and 8 ms preferable, with gtg response no slower than 8 ms and 4 ms or less desirable.

LCDs are brighter than CRTs. A typical CRT has brightness of about 100 candelas/square meter, a unit of measurement called a nit. (Some displays are rated in foot Lamberts (fL); one fL equals about 3.43 nits). A typical LCD is rated at 250 to 350 nits, roughly three times as bright as a typical CRT. CRTs dim as they age, although a brightness control with enough range at the upper end can often be used to set an old CRT to near original brightness. The CCRTs used to backlight LCDs also dim as they age, but generally fail completely before reduced brightness becomes a major issue.

Contrast measures the difference in luminance between the brightest and dimmest portions of an image, and is expressed as a ratio. The ability to display a high-contrast image is an important aspect of image quality, particularly for text. An average CRT may have a contrast ratio of 200:1, and a superb CRT 250:1. An inexpensive LCD may have a contrast ratio of 400:1, and a superb LCD 1,000:1. In other words, even an inexpensive LCD may have higher contrast than an excellent CRT.

Even good flat-screen CRTs are subject to objectionable reflections when used in bright environments, such as having the screen facing a window. Good LCDs are much superior in this respect. Short of direct sunlight impinging on the screen, a good LCD provides excellent images under any lighting conditions.

A typical CRT is about as deep as its nominal screen size. For example, a 19" CRT may be 19" from front to back. Large CRTs may be difficult to fit physically in the available space. Conversely, LCDs are quite shallow. The panel itself typically ranges from 1.5" to 3" deep, and even with the base most LCDs are no more than 7" to 8" deep. Also, where a large CRT may weigh 50 to 100 pounds or more, even large LCDs are quite light. A typical 17" LCD might weigh 10 pounds, and even a 23" unit may weigh less than 20 pounds. That small size and weight means that it"s possible to desk- or wall-mount an LCD with relatively inexpensive mounting hardware, compared to the large, heavy, expensive mounting hardware needed for CRTs.

Stated LCD display sizes are accurate. For example, a 19" LCD has a display area that actually measures 19" diagonally. CRT sizes, on the other hand, are nominal because they specify the diagonal measurement of the entire CRT, part of which is covered by the bezel. For example, a nominal 19" CRT might have a display area that actually measures 18.1" diagonally. A couple of lawsuits several years ago convinced CRT makers to begin stating the usable size of their CRTs. This is stated as VIS (viewable image size or visible image size), and is invariably an inch or so smaller than the nominal size.

This VIS issue has given rise to the belief that a 15" LCD is equivalent to a 17" CRT, a 17" LCD to a 19" CRT, and so on. In fact, that"s not true. The image size of a typical 17" CRT is an inch or so larger than that of a 15" LCD, as is the image size of a 19" CRT relative to a 17" LCD.

Depending on size and other factors, a typical CRT consumes 100 to 160 watts while operating, while an LCD consumes only a quarter to a half as much power. Using an LCD reduces your electricity bill directly by consuming less power and indirectly by reducing the heating load on your air conditioning during hot weather.

Current LCDs are available in analog-only, digital-only, and models with both analog and digital inputs. Analog input is acceptable for 15" (1024x768) models, but for 17" (1280x1024) models analog video noise becomes an issue. At that screen size and resolution, analog noise isn"t immediately obvious to most people, but if you use the display for long periods the difference between using a display with a clean digital signal and one with a noisy analog signal will affect you on almost a subconscious level. For a 19" (1280x1024) LCD, we regard a digital signal as extremely desirable but not absolutely essential. For a larger display or above 1280x1024, we wouldn"t consider using analog signaling.

Insist on true 24-bit color support, which may be described as support for 16.7 million colors. Most current LCDs support 24-bit color, allocating one full byte to each of the three primary colors, which allows 256 shades of each color and a total of 16.7 million colors to be displayed. Many early LCDs and some inexpensive current models support only six bits per color, for a total of 18-bit color. These models use extrapolation to simulate full 24-bit color support, which results in poor color quality. If an LCD is advertised as "24-bit compatible," that"s good reason to look elsewhere. Oddly, many LCDs that do support true 24-bit color don"t bother to mention it in their spec sheets, while many that support only 18-bit color trumpet the fact that they are "24-bit compatible."

Most LCD makers produce three or more series of LCDs. Entry-level models are often analog-only, even in 19" and 21" sizes, and have slow response times. Midrange models usually accept analog or digital inputs, and generally have response times fast enough for anything except 3D gaming and similarly demanding uses. The best models may be analog/digital hybrids or digital-only, and have very fast response times. Choose an entry-level model only if you are certain that you will never use the display for anything more than word processing, web browsing, and similarly undemanding tasks. If you need a true CRT-replacement display, choose a midrange or higher model with a digital interface and the fastest response time you are willing to pay for.

Decide what panel size and resolution is right for you. Keep in mind that when you choose a specific LCD model, you are also effectively choosing the resolution that you will always use on that display.

Buy the LCD locally if possible. Whether or not you buy locally, insist on a no-questions-asked return policy. LCDs are more variable than CRT monitors, both in terms of unit-to-unit variation and in terms of usability with a particular graphics adapter. This is particularly important if you are using an analog interface. Some analog LCDs simply don"t play nice with some analog graphics adapters. Also, LCDs vary from unit to unit in how many defective pixels they have and where those are located. You might prefer a unit with five defective pixels near the edges and corners rather than a unit with only one or two defective pixels located near the center of the screen.

If you buy locally, ask the store to endorse the manufacturer"s warranty that is, to agree that if the LCD fails you can bring it back to the store for a replacement rather than dealing with the hassles of returning the LCD to the maker.

If possible, test the exact LCD you plan to buy (not a floor sample) before you buy it. Ideally, and particularly if you will use the analog interface, you should test the LCD with your own system, or at least with a system that has a graphics adapter identical to the one you plan to use. We"d go to some extremes to do this, including carrying our desktop system down to the local store. But if that isn"t possible for some reason, still insist on seeing the actual LCD you plan to buy running. That way, you can at least determine if there are defective pixels in locations that bother you. Also, use a neutral gray screen with no image to verify that the backlight evenly illuminates the entire screen. Some variation is unavoidable, but one or more corners should not be especially darker than the rest of the display, nor should there be any obvious "hot" spots.

Recommended Brands: Our opinion, confirmed by our readers and colleagues, is that NEC-Mitsubishi, Samsung, Sony, and ViewSonic make the best LCDs available. Their LCDs particularly their midrange and better models provide excellent image quality and are quite reliable. You"re likely to be happy with an LCD from any of these manufacturers.

Stick with good name brands and buy a midrange or higher model from within that name brand. That doesn"t guarantee that you"ll get a good LCD, but it does greatly increase your chances. The LCD market is extremely competitive. If two similar models differ greatly in price, the cheaper one likely has significantly worse specs. If the specs appear similar, the maker of the cheaper model has cut corners somewhere, whether in component quality, construction quality, or warranty policies.

Large LCD panel prices have been continuously increasing for last 10 months due to an increase in demand and tight supply. This has helped the LCD industry to recover from drastic panel price reductions, revenue and profit loss in 2019. It has also contributed to the growth of Quantum Dot and MiniLED LCD TV.

Strong LCD TV panel demand is expected to continue in 2021, but component shortages, supply constraints and very high panel price increase can still create uncertainties.

LCD TV panel capacity increased substantially in 2019 due to the expansion in the number of Gen 10.5 fabs. After growth in 2018, LCD TV demand weakened in 2019 caused by slower economic growth, trade war and tariff rate increases. Capacity expansion and higher production combined with weaker demand resulted in considerable oversupply of LCD TV panels in 2019 leading to drastic panel price reductions. Some panel prices went below cash cost, forcing suppliers to cut production and delay expansion plans to reduce losses.

?Panel over-supply also brought down panel prices to way lower level than what was possible through cost improvement. Massive 10.5 Gen capacity that can produce 8-up 65″ and 6-up 75″ panels from a single mother glass substrate helped to reduce larger size LCD TV panel costs. Also extremely low panel price in 2019 helped TV brands to offer larger size LCD TV (>60-inch size) with better specs and technology (Quantum Dot & MiniLED) at more competitive prices, driving higher shipments and adoption rates in 2019 and 2020.

While WOLED TV had higher shipment share in 2018, Quantum Dot and MiniLED based LCD TV gained higher unit shares both in 2019 and 2020 according to Omdia published data. This trend is expected to continue in 2021 and in the next few years with more proliferation of Quantum Dot and MiniLED TVs.

Panel suppliers’ financial results suffered in 2019 as they lost money. Suppliers from China, Korea and Taiwan all lowered their utilization rates in the second half of 2019 to reduce over-supply. Very low prices combined with lower utilization rates made the revenue and profitability situation for panel suppliers difficult in 2019. BOE and China Star cut the utilization rates of their Gen 10.5 fabs. Sharp delayed the start of production at its 10.5 Gen fab in China. LGD and Samsung display decided to shift away from LCD more towards OLED and QDOLED respectively. Both companies cut utilization rates in their 7, 7.5 and 8.5 Gen fabs. Taiwanese suppliers also cut their 8.5 Gen fab utilization rates.

Some suppliers also shifted capacity away from TV to other applications. In summary, drastic price reduction resulted in a cut in utilization rates, delays in fab construction and ramp-ups and the closing down of older fabs, or conversion to OLED or QDOLED fabs. This helped to reduce oversupply.

An increase in demand for larger size TVs in the second half of 2020 combined with component shortages has pushed the market to supply constraint and caused continuous panel price increases from June 2020 to March 2021. Market demand for tablets, notebooks, monitors and TVs increased in 2020 especially in the second half of the year due to the impact of “stay at home” regulations, when work from home, education from home and more focus on home entertainment pushed the demand to higher level.

With stay at home continuing in the firts half of 2021 and expected UEFA Europe football tournaments and the Olympic in Japan (July 23), TV brands are expecting stronger demand in 2021. The panel price increase resulting in higher costs for TV brands. It has also made it difficult for lower priced brands (Tier2/3) to acquire enough panels to offer lower priced TVs. Further, panel suppliers are giving priority to top brands with larger orders during supply constraint. In recent quarters, the top five TV brands including Samsung, LG, and TCL have been gaining higher market share.

In last few months top glass suppliers Corning, NEG and AGC have all experienced production problems. A tank failure at Corning, a power outage at NEG and an accident at an AGC glass plant all resulted in glass supply constraints when demand and production has been increasing. In March this year Corning announced its plan to increase glass prices in Q2 2021. Corning has also increased supply by starting glass tank in Korea to supply China’s 10.5 Gen fabs that are ramping up. Most of the growth in capacity is coming from Gen 8.6 and Gen 10.5 fabs in China.

Major increases in panel prices from June 2020, have increased costs and reduced profits for TV brand manufacturers. TV brands are starting to increase TV set prices slowly in certain segments. Notebook brands are also planning to raise prices for new products to reflect increasing costs. Monitor prices are starting to increase in some segments. Despite this, buyers are still unable to fullfill orders due to supply issues.

TV panel prices increased in Q4 2020 and are also expected to increase in the first half of 2021. This can create challenges for brand manufacturers as it reduces their ability to offer more attractive prices in coming months to drive demand. Still, set-price increases up to March have been very mild and only in certain segments. Some brands are still offering price incentives to consumers in spite of the cost increases. For example, in the US market retailers cut prices of big screen LCD and OLED TV to entice basketball fans in March.

Higher LCD price and tight supply helped LCD suppliers to improve their financial performance in the second half of 2020. This caused a number of LCD suppliers especially in China to decide to expand production and increase their investment in 2021.

New opportunities for MiniLED based products that reduce the performance gap with OLED, enabling higher specs and higher prices are also driving higher investment in LCD production. Suppliers from China already have achieved a majority share of TFT-LCD capacity.

BOE has acquired Gen 8.5/8.6 fabs from CEC Panda. ChinaStar has acquired a Gen 8.5 fab in Suzhou from Samsung Display. Recent panel price increases have also resulted in Samsung and LGD delaying their plans to shut down LCD production. These developments can all help to improve supply in the second half of 2021. Fab utilization rates in Taiwan and China stayed high in the second half of 2020 and are expected to stay high in the first half of 2021.

Price increases for TV sets are still not widespread yet and increases do not reflect the full cost increase. However, if set prices continue to increase to even higher levels, there is the potential for an impact on demand.

QLED and MiniLED gained share in the premium TV market in 2019, impacting OLED shares and aided by low panel prices. With the LCD panel price increases in 2020 the cost gap between OLED TV and LCD has gone down in recent quarters.

OLED TV also gained higher market share in the premium TV market especially sets from LG and Sony in the last quarter of 2020, according to industry data. LG Display is implimenting major capacity expansion of its OLED TV panels with its Gen 8.5 fab in China.Strong sales in Q4 2020 and new product sizes such as 48-inch and 88-inch have helped LG Display’s OLED TV fabs to have higher utilization rates.

Samsung is also planning to start production of QDOLED in 2021. Higher production and cost reductions for OLED TV may help OLED to gain shares in the premium TV market if the price gap continues to reduce with LCD.

Lower tier brands are not able to offer aggressive prices due to the supply constraint and panel price increases. If these conditions continue for too long, TV demand could be impacted.

Strong LCD TV demand especially for Quantum Dot and MiniLED TV is expected to continue in 2021. The economic recovery and sports events (UEFA Europe footbal and the Olympics in Japan) are expected to drive demand for TV, but component shortages, supply constraints and too big a price increase could create uncertainties. Panel suppliers have to navigate a delicate balance of capacity management and panel prices to capture the opportunity for higher TV demand. (SD)

Sweta Dash, President, Dash-InsightsSweta Dash is the founding president of Dash-Insights, a market research and consulting company specializing in the display industry. For more information, contact [email protected] or visitwww.dash-insights.com

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved March 07, 2023, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed March 07, 2023. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: March 07, 2023. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited March 07, 2023)

LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph], DSCC, January 10, 2022. [Online]. Available: https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

I’m hearing from some industry friends that LCD display panel prices are rising – which on the surface likely seems incongruous, given the economic slowdown and widespread indications that a lot of 2020 and 2021 display projects went on hold because of COVID-19.

On the other hand, people are watching a lot more TV, and I saw a guy at Costco the other day with two big-ass LCD TVs on his trolley. And a whole bunch of desktop monitors were in demand in 2020 to facilitate Work From Home. So demand for LCD displays is up outside of commercial purposes.

Continuing strong demand and concerns about a glass shortage resulting from NEG’s power outage have led to a continuing increase in LCD TV panel prices in Q1. Announcements by the Korean panel makers that they will maintain production of LCDs and delay their planned shutdown of LCD lines has not prevented prices from continuing to rise.

Panel prices increased more than 20% for selected TV sizes in Q3 2020 compared to Q2, and by 27% in Q4 2020 compared to Q3, and we now expect that average LCD TV panel prices in Q1 2021 will increase by another 9%.

Prices increased in Q4 for all sizes of TV panels, with massive % increases in sizes from 32” to 55” ranging from 28% to 38%. Prices for 65” and 75” increased at a slower rate, by 19% and 8% respectively, as capacity has continued to increase on those sizes with Gen 10.5 expansions.

Prices for every size of TV panel will increase in Q1 at a slower rate, ranging from 4% for 75” to 13% for 43”. Although we continue to expect that the long-term downward trend will resume in the second quarter of 2021, we no longer expect that panel prices will come close to the all-time lows seen earlier this year. The situation remains dynamic, and the pandemic may continue to affect both supply and demand.

TV panel prices however, continued to rise at an ‘unprecedented’ rate again, far ahead of our expectations, and panel producers do not seem to be hesitant about continuing to push prices further.

Given that TV set demand continues to outstrip production capacity, panel producers are already expecting to raise prices again in 1Q, typically a sequentially weaker quarter. There is a breaking point at which TV set brands will forego requested panel price increases in order to preserve what is left of margins, and with the increasing cost of TV set panel inventory, we expect TV set producers to become unprofitable relatively quickly.

Does that mean they will stop buying and face losing market share to those that are willing to pay higher prices to see unit volume growth? Eventually, but heading into the holidays it doesn’t seem likely this year, so we expect TV panel prices to rise again in December.

With a lot of the buyer market for digital signage technology financial wheezing its way into 2021, rising hardware prices are likely even less welcomed than in more normal times. But the prices for display hardware, in particular, are dramatically lower they were five years ago, and even more so looking back 10-15 years.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

DCI is a focused team of experienced professionals who engineer and provide communications solutions for industrial automation systems. We specialize in partnering with companies to select the best wireless solution for a wide variety of industrial and business-critical applications in the Oil, Gas, Railroad, Water, Wastewater, Mining, and Electrical Utility Industries as well as film production, marine applications, emergency services and wherever high-reliability connectivity is needed. 2022 is our 25th year in business. We only sell business to business (B2B) but may sell to a consumer on an exception basis.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

LCDs don’t emit light on their own and must instead have a backlight that shines through the LCD material to display an image. Today’s LCD-based displays use a number of LEDs for the backlighting. To achieve a greater contrast ratio than a standard dynamic range display, the LEDs in the backlight change their brightness level, allowing the display to dim the backlight for darker blacks and brighten it for brighter whites, which creates a wider contrast ratio. There are several different dimming designs that can be used in the backlight to accomplish this.

Global Dimming: The backlight, which consists of a string of LEDs on one edge of the LCD panel, is treated as a single “zone” and is dimmed for dark scenes and brightened for bright scenes. This is the least expensive type of dimming and can be accomplished with a standard LCD panel. This approach works well for scenes with a limited dynamic range. This type of dimming is typically found on notebooks as it has the lowest power consumption of any dimming technique and generates the least amount of heat. The disadvantage of this design is that the simultaneous contrast ratio is never greater than the contrast ratio of the LCD panel, usually around 1000:1.

Local Dimming: This represents a wide variety of different sub-designs, each detailed below. What differentiates all of the local-dimming designs from global-dimming is that global dimming has a single backlight zone, the entire screen’s backlight is adjusted as one control, in local dimming the screen’s backlight is split into segments which can be independently adjusted.

1D Local Dimming: This design also uses an “edge-lit” string of LEDs, but in this case groups of LEDs on the string can be independently controlled. For most displays, the string of LEDs is located at the bottom of the panel, resulting in a number of vertical zones, equally spaced across the horizontal edge of the display. An edge-lit LED string typically contains between eight and sixteen LED groups, resulting in eight to sixteen dimming zones. This design allows for simultaneous contrast ratios of 6,000:1 to 100,000:1. 1D local dimming is currently the most common design found in HDR televisions and displays.

1.5D Local Dimming: Similar to the 1D local dimming, using edge lighting. However in this design an LED lighting string exists on two sides of the panel, typically top and bottom although left and right designs also exists. The advantage of this design is that it typically has 2×16 zones, so twice as many zones as 1D, but more importantly the top and the bottom of the screen are independently controlled, versus the 1D design where each zone is typically the full vertical height of the screen.

2D or Full array local dimming (FALD): In this design the backlight LEDs are moved from the edge of the panel to the rear of the panel and are arranged in a two-dimensional matrix of LEDs. Each LED is independently controlled and adjusts the brightness of just one “square of a checkerboard” on the display, although typically they are rectangles rather than perfect squares. Today’s HDR displays and televisions typically have between 384 and 1152 zones. These designs are the most expensive, due to the complexity of the circuitry and the processing demands required. The design can also generate a large amount of heat, and often requires cooling fans and/or heat sinks to be placed behind the LCD panel to draw heat away from the display electronics. Full array local dimming produces the best image quality of all of these designs and can achieve simultaneous contrast ratios of 20,000:1 to 500,000:1. Due to the high cost of this design, these displays command the highest prices and typically cost thousands of dollars.

Active-dimming: is the term VESA adopted for one of the new tests in our Certification Test Spec v1.1 (CTS v1.1) where we added a new kind of validation procedure to ensure that displays were actually dimming the backlight based on real-time analysis of the video content, rather than merely only dimming when metadata changes occurred in the video stream. It would be typical that during a movie or game that the metadata for HDR10 would not change, however each frame may have a different peak luminance than the prior frame, and thus could adjust the backlight accordingly. This yields better power saving, and better HDR blacks. The new tests in CTS v1.1 ensure that we test, without changing the metadata of the signal, a dramatic reduction in peak luminance from a full-white checkerboard, to a checkerboard where the white boxes are only 5 cd/m2, this provides ample opportunity for the dimming algorithm to reduce the backlight power. When reducing the backlight power the black level of the black segments of the checkerboard will also reduce, and this is what is measured and used in our calculation of active-dimming stops, (for the more technical, “stops” originally used in photography are a power-of-2 logarithmic function).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey