iphone display screens for car made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

As Apple mainly relies on Samsung and LG to manufacture its OLED panels for the iPhone, another Chinese factory wants a piece of Cupertino’s company money. As reported by

CSOT, together with Apple, first review the OLED panel produced from its T4 factory at Wuhan, China, sources said. The factory is designed to house three phases for a total capacity of 45,000 substrates per month. Two phases are currently live.

As of now, the Chinese company had supplied OLED panels for Samsung’s Galaxy M models in 2021. CSOT will also supply OLED panels for Galaxy A73 this year, The Elecreports.

The publication notes that it won’t be an easy path for CSOT, as China’s largest display panel maker BOE had failed “multiple times in Cupertino’s evaluation processes before finally being able to supply OLED panels to the iPhone maker.”

As 9to5Mac reported earlier this week, BOE, which currently manufactures OLED panels for iPhone 12 and iPhone 13 – and will do the same for this year’s iPhone 14 – will try to supply displays for iPhone 15 Pro as well.

Although Apple has a very high standard on its supply chains, having more options is good. As The Elec notes, “Cupertino can also already use BOE to pressure Samsung Display and LG Display into lowering their unit prices. BOE’s OLED production capacity will also expand to 144,000 substrates per month by the end of this year or early next year, triple that of the maximum capacity at CSOT’s T4 factory.”

You’re reading 9to5Mac — experts who break news about Apple and its surrounding ecosystem, day after day. Be sure to check out our homepage for all the latest news, and follow 9to5Mac on Twitter, Facebook, and LinkedIn to stay in the loop. Don’t know where to start? Check out our exclusive stories, reviews, how-tos, and subscribe to our YouTube channel

The company changed the specs of the displays it was making for the iPhone 13, but this was detected by the Cupertino company – which ordered BOE to cease production. Apple’s reason for the change of heart may be a cynical one …

Apple has always liked to have multiple suppliers for as many components as possible. This is partly for risk management: If one supplier has a problem, Apple can ask others to ramp up production to fill the gap. But it’s also to give the company even more power when it comes to price negotiations – it can threaten to transfer orders to a rival if a supplier won’t come down to the desired price.

Samsung Display has the most sophisticated OLED manufacturing capabilities, which is why it has sometimes been the sole supplier for certain iPhone screens. Fellow Korean company LG has long been Apple’s secondary supplier.

BOE has for years been a third supplier of displays for Apple’s older LCD iPhones, but only started making OLED panels for Apple as of the iPhone 12. It was on track to pick up orders for 30-40M iPhones this year.

All that looked like it might be lost when the company quietly changed the specs of the OLED panels it was supplying to Apple for the 6.1-inch model of the iPhone 13. It looked for a time like this might cost the company its iPhone 14 orders.

However, it seems Apple forgave the company, as it was last month allowed to resume production of screens for the iPhone 13, and seemed to be back in the running for iPhone 14 orders.

After the controversy with the iPhone 13 OLED panels, “executives of the Chinese company visited Cupertino to explain the situation to Apple and receive approval for OLED panels aimed at iPhone 14.” The publication sources say BOE will supply around 5 million units at most given its recent debacle with the panels for the iPhone 13.

According to the upstream and downstream information of the industrial chain, the AMOLED panel of BOE, a large Chinese panel manufacturer, has passed Apple’s iPhone 14 certification […]

BOE received a notice from Apple about the passing of the iPhone 14 AMOLED panel certification. BOE will put into mass production in advance in July, and start bulk shipments in September. This certification was passed earlier in the year than those for the iPhone 12 and 13 series […]

According to the report, according to industry estimates, in 2022, Apple will purchase more than 90 million flexible AMOLED panels for iPhone 14, of which Samsung Display (SDC) will supply 60 million pieces and LGD will supply 25 million pieces. BOE supplies more than 5 million pieces.

The company is not known for a forgiving attitude when it comes to suppliers that don’t play by the rules, and secretly loosening the specs was a major offense. So it was somewhat surprising to see BOE so quickly forgiven.

From the production volume estimates seen, BOE is being given a far smaller number of orders than was expected – almost a token amount. That suggests Apple is punishing the company while still using it as a bargaining chip for its primary orders.

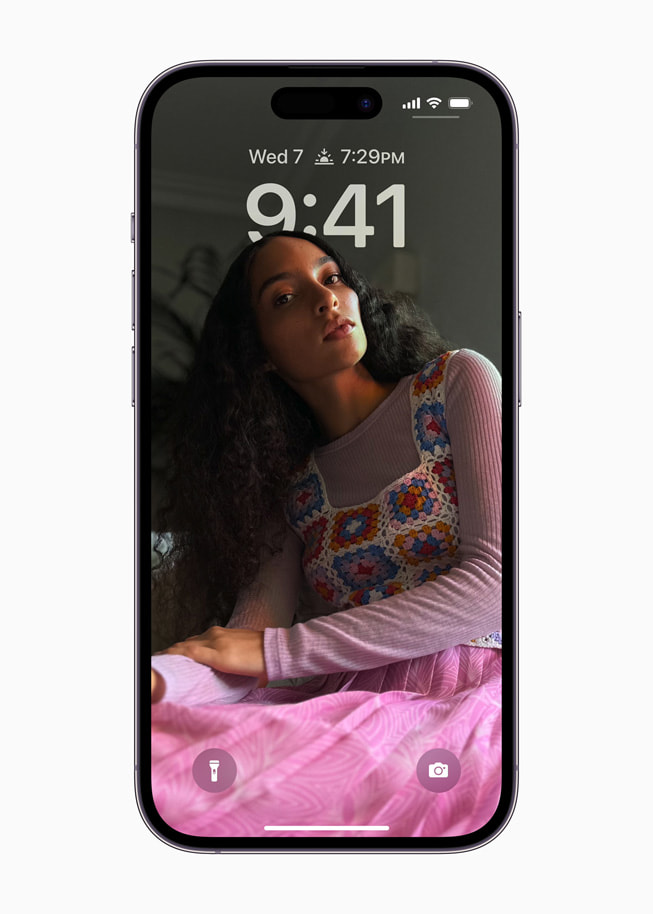

This year, we’re expecting very visible differences in the displays, between the standard and Pro models. The former are expected to stick to the existing notch design, while the two Pro models are likely to have “hole-punch and pill” cutouts for the camera and Face ID array.

You’re reading 9to5Mac — experts who break news about Apple and its surrounding ecosystem, day after day. Be sure to check out our homepage for all the latest news, and follow 9to5Mac on Twitter, Facebook, and LinkedIn to stay in the loop. Don’t know where to start? Check out our exclusive stories, reviews, how-tos, and subscribe to our YouTube channel

Ever since Apple made the switch to OLED panels with the iPhone X series in 2017, it has relied on Samsung to source a majority of these panels. Samsung was an obvious choice for Apple for the sole reason that it was (and continues to be) the world’s largest manufacturer of OLED panels, with LG coming in a distant second.

This changed in 2020 when Apple signed up a little-known Chinese company called BOE to make displays for its lower-tier iPhone 12. While Samsung and LG continue to supply Apple with OLED panels, 2023 may finally see BOE increase the number of displays it makes for Apple. It is also likely to meet the stringent quality standards set by Apple so its screens can end up on the future top-tier iPhone 15 Pro model.

Even though BOE has been an Apple supplier for a long time, having supplied LCD panels in the past, its entry into the exclusive club of OLED manufacturers was a significant milestone in the company’s history. To reduce its dependence on a single supplier for something as crucial as the display, Apple inked a deal with LG Display to supply it with OLED panels. LG’s production capacity, however, hasn’t been able to scale up or even come close to Samsung’s levels — and Apple’s expectations. Unsurprisingly, until 2020, 80% of Apple products with an OLED panel used Samsung panels, with the other 20% using LG-made displays.

Things did not start too well for BOE, though, after Apple was reportedly unhappy with the quality of the initial batch of BOE-made panels intended for some iPhone 12 models. Nevertheless, following initial hiccups, BOE eventually managed to supply a sizable number of 6.06-inch OLED panels to Apple — most of which found their way onto Apple’s lower-priced iPhone 12 series and the current iPhone 13 series.

Apple’s decision not to use BOE-made panels for the top-tier iPhone 13 models also had a lot to do with the fact that the iPhone 13 series also marked Apple’s transition to using LTPO (Low-Temperature Polycrystalline Oxide) display technology on the more expensive iPhone 13 models.

With BOE still perfecting its LTPO capabilities, it is unlikely that we’ll see BOE-made panels on the top-tier iPhone 14 models in 2022. In fact, reports already indicate that panels for the top-tier iPhone 14 models will primarily come from Samsung — with a tiny percentage supplied by LG.

According to the South Korean publication The Elec, BOE’s moment of glory is likely to come in 2023. The company is reportedly working steadfastly to ensure that its OLED panels will match the quality standards set by Apple. It aims to chip away a sizable share from LG and Samsung that year and supply LTPO OLED panels for future iPhone 15 Pro models.

Apart from taking measures to improve its quality, BOE has also been aggressively expanding and modernizing its production facilities. This includes an entirely new assembly line for making flexible OLEDs, which is expected to open in multiple phases across 2023.

Things are looking great for BOE even in 2022, with Apple expected to use close to 50 million BOE-made panels for the iPhone 14 series. This will account for a healthy 20% of Apple’s OLED requirement. At current growth rates, BOE is likely to beat LG Display and become Apple’s second-biggest OLED panel supplier in 2022. And given its breakneck growth, even Samsung’s coveted status as the largest iPhone display supplier may well be within reach in a few years.

Foxconn, one of the electronics manufacturers that makes Apple"s iPhones, revealed plans today to build a factory in Wisconsin to produce flat-screen displays. Foxconn"s total investment in the Wisconsin factory amounts to $10 billion, more than the original $7 billion that Foxconn had been talking about investing in US manufacturing since Donald Trump took office as President. The factory will create at least 3,000 jobs and upwards of 13,000 jobs, as well as up to 22,000 induced jobs in other parts of Wisconsin. President Trump praised the deal at the press event, claiming it was a win for anyone who "believes in the label "Made in the USA.""

The factory will be located in southeastern Wisconsin in House Speaker Paul Ryan"s congressional district. However, it will not come for free. Wisconsin Governor Scott Walker said at the event that Foxconn will receive an incentive package $3 billion over the next few years, including state, local, and federal incentives. Advertisement

Foxconn will build flat-screen LCD display panels at the new factory under the Sharp brand, which the company bought in 2016 for $1.5 billion. At the press event, Gou and Governor Walker emphasized LCD display manufacturing for the automotive, healthcare, and other industries, rather than OLED display manufacturing.

Currently iPhones still use LCD displays, which means the Wisconsin factory could potentially provide LCD panels for those handsets. However, Sharp President Tai Jeng-wu has suggested in the past that Apple could use OLED displays in the future. There have also been rumors of OLED displays being used in forthcoming iPhone 8 models, but nothing has been confirmed. Currently there"s no official word that any panels made in the new Wisconsin factory will be used in Apple products going forward.

Don"t expect Apple to fully produce iPhones in the US anytime soon either. President Trump announced this week that Apple plans to build three "big" manufacturing plants in the US, but Apple did not announce that with him, nor did the company comment publicly on that notion. There are a number of incentives keeping iPhone production in China, including tax breaks and subsidies. Even if the incentives provided to Foxconn in Wisconsin are a step in a new direction, much more negotiation and work would need to be done before iPhones or any Apple products are completely "made in the USA."

Detection Mode requires devices with the LiDAR Scanner. The LiDAR Scanner is available only on iPhone 12 Pro, iPhone 12 Pro Max, iPhone 13 Pro, iPhone 13 Pro Max, iPhone 14 Pro, iPhone 14 Pro Max, iPad Pro 12.9‑inch (4th generation or later), and iPad Pro 11‑inch (2nd generation or later).

Sound Recognition should not be relied on in circumstances where you may be harmed or injured, in high-risk or emergency situations, or for navigation.

Live Captions are available on iPhone 11 and later, iPad models with A12 Bionic and later, and Mac computers with Apple silicon. Live Captions are available for calls and media when users have their system language set to English (Canada, U.S.). Accuracy of Live Captions may vary and should not be relied on in high-risk or emergency situations.

VoiceOver Image Recognition works with iPad Pro with iPadOS 14 or later and iPhone XR or later with iOS 14 or later. For macOS, Image Recognition requires macOS Big Sur or later.

Live Listen requires compatible Made for iPhone hearing devices and supports iPhone 4s or later, iPad Pro, iPad (4th generation or later), iPad Air or later, and iPad mini or later. To use Live Listen with AirPods, AirPods Pro, AirPods Max, or Powerbeats Pro, the iOS or iPadOS device requires iOS 14.3 or later or iPadOS 14.3 or later.

Voice Control is not available in all areas and on all Apple software. Voice Control utilizes the Siri speech recognition engine for Cantonese (Hong Kong), Chinese (China mainland), English (Australia, Canada, India, UK, U.S.), French (France), German (Germany), Japanese (Japan), and Spanish (Mexico, Spain, U.S.).

A very small portion of Apple’s latest iPhones will be made in India, and part of Google’s newest Pixel phone production will be done in Vietnam, people familiar with their plans said.

The shift is a response to growing concerns about the geopolitical tensions and pandemic-induced supply chain disruptions that have involved China in the last few years. China has long been the world’s factory floor for high-tech electronics, unrivaled in its ability to secure legions of high-skilled workers and the production capacity to handle demand for the next hot device.

But American companies are seeing more risk there — a perspective forged during the Trump-era trade war, with its tit-for-tat tariffs, and cemented by China’s saber-rattling after Speaker Nancy Pelosi’s visit to Taiwan last month. They fear that basing a supply chain largely in China may thrust them into the middle of its escalating conflict with the United States over Taiwan.

On Wednesday, China announced that factory activity contracted for a second straight month in August, according to the country’s closely watched survey of purchasing managers.

The fracturing supply chain is rippling across Asia, causing a spike in industrial land prices in Vietnam, a revival of manufacturing in Malaysia and a surge in demand for low-wage workers in India. For China, it is siphoning away manufacturing activity when the country is reeling from its slowest economic growth in decades.

“Everyone is thinking about moving, even if they’re not acting yet,” said Anna-Katrina Shedletsky, founder of Instrumental, a Bay Area company that remotely monitors assembly lines for electronics companies.

When the first outbreak of Covid-19 shut down factories in China in early 2020, the closures roiled sales plans for many companies, including Apple, which had to cut its quarterly sales forecast because it couldn’t make iPhones.

The company’s operations team started to look at alternative manufacturing locations to hedge against future shutdowns in China, said three former employees, who asked not to be identified because they are not permitted to speak about their work at the company.

Vietnam, which Apple had already earmarked for AirPods production in 2020, became a much-discussed option, one of the people said. Since then, Apple has started producing its watch in the country and moved some iPad manufacturing there. In Apple’s most recent list of its top 200 suppliers, 20 use factories in Vietnam. By comparison, 155 of the companies operate factories in China.

Apple plans to assemble and package a small fraction of this year’s iPhone 14, the company’s flagship device, in India for the first time. While most of the initial and most critical production for that device is happening in China, Apple will move some of its overall iPhone production to India later — mainly as a way to assess the ability for future manufacturing there, two people familiar with the plans said.

Even as Apple pushed ahead with plans, the company was careful not to antagonize China’s ruling Communist Party since the vast majority of its products are still made there. As China carried out military drills around Taiwan during Ms. Pelosi’s visit, Apple reminded its Taiwanese suppliers to label components destined for China as made in “Chinese Taipei” or “Taiwan, China,” according to a report in Japan’s Nikkei newspaper.

A billboard outside a Foxconn factory in Bac Ninh advertised that the company is looking to hire 5,000 workers “urgently” with an offer of roughly $300 in monthly pay for an entry-level position. It is less than half the monthly pay — 4,500 yuan, or about $650 — that Foxconn is offering new hires at its assembly lines in Shenzhen in southeastern China.

The pay disparity underscores another reason that companies are looking for new manufacturing options. Over the past decade, manufacturing workers in China have tripled their annual income to more than $9,300, according to the country’s Bureau of Statistics.

But Google’s planning for next year’s phones demonstrates how hard it will be for companies to move from China completely. Google is exploring a foldable phone for 2023, but making a device like that, using newer screen and hinge technology, would probably require production to be close to key suppliers in China, these people said.

So for alternatives to China, proximity matters. Interest from Foxconn and others has caused industrial real estate prices in Vietnam to spike by nearly a third since 2019 to $105 per square meter (about $9.75 per square foot), while the cost of warehouses has risen 20 percent, according to Cushman & Wakefield, a global commercial real estate firm.

Five years ago, said Trang Bui, Cushman’s general manager for Vietnam, she showed industrial land to clients once every other month. Now, she travels daily with clients from the United States, Taiwan, South Korea, Japan, Europe and China to see real estate for factories.

ImageA factory worker shopping for phone accessories in a newly built neighborhood near the Van Trung Industrial Park.Credit...Linh Pham for The New York Times

Analysts don"t expect the new iPhone, which has been dubbed the iPhone 11 by industry watchers, to include significant updates to previous models. The expectation is that the company will not release phones with any major changes, including 5G, until 2020.

Selecting a Chinese company would be a surprising move, given the company has warned of the impact of the U.S.-China trade war on its business. Many of Apple"s major products, including the iPhone, are produced in China.

Anyone who has bought an iPhone or another Apple product has seen the note on the company’s packaging that its products are designed in California, but that doesn"t mean they"re manufactured there. Answering the question of where the iPhone is made isn"t simple.

Manufacturing is the process of making the components that go into the iPhone. While Apple designs and sells the iPhone, it doesn"t manufacture its components. Instead, Apple uses manufacturers from around the world to deliver individual parts. The manufacturers specialize in particular items—camera specialists manufacture the lens and camera assembly, screen specialists build the display, and so on.

Assembling, on the other hand, is the process of taking all the individual components built by specialist manufacturers and combining them into a finished, working iPhone.

Because there are hundreds of individual components in every iPhone, it"s not possible to list every manufacturer whose products are found on the phone. It"s also difficult to discern exactly where those components are made because sometimes one company builds the same component at multiple factories.

The components manufactured by those companies all around the world are ultimately sent to just two companies to assemble into iPods, iPhones, and iPads. Those companies are Foxconn and Pegatron, both of which are based in Taiwan.

Technically, Foxconn is the company’s trade name; the firm’s official name is Hon Hai Precision Industry Co. Ltd. Foxconn is Apple"s longest-running partner in building these devices. It currently assembles the majority of Apple"s iPhones in its Shenzen, China, location, although Foxconn maintains factories in countries across the world, including Thailand, Malaysia, the Czech Republic, South Korea, Singapore, and the Philippines.

Apple confirmed BOE"s panels for the forthcoming iPhones on Thursday, and BOE intends to start mass producing them before the end of this month. The panels will be delivered in large quantities to Apple in September, the month when the Cupertino corporation typically introduces new iPhone models, as per GSM Arena.

After Apple learned that BOE had unilaterally changed some of the design elements of its iPhone 13 panels, BOE"s place in the supply chain for the iPhone 14 was questioned for a few weeks.

The Chinese display manufacturer was in trouble for a while, but it appears that the situation has changed today, and BOE will now supply Apple with its next goods.

As per insiders in the industry, Apple is expected to order 90 million display panels this year for the iPhone 14 family, of which 60 million will come from Samsung Display, 25 million from LG Display, and 5 million from BOE, as reported by GSM Arena.

Hon Hai Precision Industry Co., Ltd., trading as Hon Hai Technology Group in China and Taiwan and Foxconn internationally, is a Taiwanese multinational electronics contract manufacturer established in 1974 with headquarters in Tucheng, New Taipei City, Taiwan. In 2021, the company"s annual revenue reached 5.99 trillion New Taiwan dollars (US$175 billion) and was ranked 20th in the 2022 Fortune Global 500. It is the world"s largest technology manufacturer and service provider. While headquartered in Taiwan, the company earns the majority of its revenue from assets in mainland China and is one of the largest employers worldwide.Terry Gou is the company founder and former chairman.

Foxconn manufactures electronic products for major American, Canadian, Chinese, Finnish, and Japanese companies. Notable products manufactured by Foxconn include the BlackBerry,iPad,iPhone, iPod,Kindle,Nintendo gaming systems since the GameCube (except subsequent Nintendo DS models), Nokia devices, Sony devices (including the PlayStation 3 and PlayStation 4 gaming consoles), Google Pixel devices, Xiaomi devices, every successor to Microsoft"s first Xbox console,TR4 CPU socket on some motherboards. As of 2012, Foxconn factories manufactured an estimated 40% of all consumer electronics sold worldwide.

Foxconn named Young Liu its new chairman after the retirement of founder Terry Gou, effective on 1 July 2019. Young Liu was the special assistant to former chairman Terry Gou and the head of business group S (semiconductor). Analysts said the handover signals the company"s future direction, underscoring the importance of semiconductors, together with technologies like artificial intelligence, robotics, and autonomous driving, after Foxconn"s traditional major business of smartphone assembly has matured.

One of the important milestones for Foxconn occurred in 2001 when Intel selected the company to manufacture its Intel-branded motherboards instead of Asus.Huizhou, Southern China.

Expansion was further pursued after a March 2012 acquisition of a 10-percent stake in the Japanese electronics company Sharp Corporation for US$806 million and to purchase up to 50 percent of the LCDs produced at Sharp"s plant in Sakai, Japan.Itu, Brazil, creating 10,000 jobs.

In 2016, Foxconn, together with Tencent and luxury-car dealer Harmony New Energy Auto, founded Future Mobility, a car start up that aimed to sell all-electric fully autonomous premium cars by 2020.Belkin International for $866m on 26 March 2018.

In July 2019, Foxconn appointed Liu, Young-Way as the new chairman of the Group, which was then ranked 25th among Forbes Top 100 Digital Companies. Soon afterward, Foxconn, led by Young Liu, introduced its “3+3 Model for Transformation, prioritizing the three key industries: electric vehicles, digital health, and robotics industries. The Group is also committed to developing artificial intelligence, semiconductors, and next-generation communication technologies, building blocks in the Group"s technology strategy.

In 2020, Foxconn established “Hon Hai Research Institute,” with five research centers, each having an average of 40 high technology R&D professionals, all of whom are focused on the research and development of new technologies, the strengthening of Foxconn’s technology, and product innovation pipeline, efforts to support the Group’s transformation from “brawn” to “brains,” and the enhancement of the competitiveness of Foxconn’s “3+3” strategy.

Foxconn’s 2020 revenue was NT$5.36 trillion (US$193 billion).Circuits Assembly magazine named Foxconn the largest electronics manufacturing services company in the world for the 14th straight year.

On 5 February 2020, Foxconn started producing medical masks and clothing at its Shenzhen factory in China during the Chinese New Year and the height of the COVID-19 pandemic. The company initially said the masks it makes would be for internal employee use. The outbreak of coronavirus disease 2019 led to a worldwide spike in demand for masks, resulting in global shortages.Longhua Park produced our first mask at 4:41am on 5 February. It was the simplest yet most important product Foxconn has ever made. It not only supplied the group"s need for epidemic prevention it also contributed to the general public and boosted the morale of the group. All that resulted from our colleagues" hard work."

Following almost a year of public controversy regarding its COVID-19 vaccine shortage;TSMC, and negotiate purchasing COVID-19 vaccines on its behalf.BioNTech"s Chinese sales agent Fosun Pharma announced that Foxconn and TSMC had reached an agreement to purchase 10 million BioNTech COVID-19 vaccines from Germany for Taiwan.

In 2020, Foxconn initiated MIH Alliance to create an open EV ecosystem that promotes collaboration in the mobility industry, with more than 2,200 companies joining the open standard since its launch. The company announced plans to become more involved as a contract assembler of EVs. In the same year, Foxconn partnered with Fiat Chrysler Automobiles N.V. and Yulon Group for a move into EVs. Foxconn has been holding the Hon Hai Tech Day (HHTD) event since 2020 to showcase its latest achievements. In HHTD21, Foxconn introduced for the first time three self-developed EV models: the Model C recreational vehicle, the Model E sedan, and the Model T electric bus.

In January 2021, Foxconn and Geely Holding Group signed a strategic cooperative agreement and will establish a joint venture company to provide OEM and customized consulting services relating to whole vehicles, parts, intelligent drive systems, and automotive ecosystem platforms to global automotive enterprises and ridesharing companies. In February 2021, it announced an agreement with EV startup Fisker Inc. to jointly produce more than 250,000 vehicles a year. In March 2021, Foxtron, the JV company of Foxconn and Yulon, announced cooperation with Nidec to strengthen the power on EV key component development.

In July 2021, Foxconn teamed up with CTBC Financial Holding Co., Ltd to create a new fund targeting EV investments. In June 2021, Foxconn invested T$995.2 million ($36 million) in Gigasolar Materials Corp to develop EV battery materials. In September 2021, Foxconn collaborated with Thailand’s state-owned oil supplier PTT Public Co. to invest US$1–2 billion in launching an EV joint venture in Thailand. In the same month, Foxconn and Gogoro formed a strategic technology and manufacturing partnership to introduce new levels of manufacturing capabilities and scale for Gogoro battery swapping technologies and Smart Scooters. In October 2021, it agreed to purchase a former GM auto plant from Lordstown Motors and to purchase $50 million of the company"s common stock. Under the agreement, Foxconn would use the plant to produce Lordstown"s Endurance pickup truck. Fisker vehicles would also be made at the same plant.

In January 2022, Foxconn signed an MoU with the Indonesian Ministry of Investment/BKPM, IBC, Indika, and Gogoro to jointly develop a sustainable new energy ecosystem in Indonesia that focuses on electric batteries, electric mobility, and associated industries. In May 2022, Foxconn announced the completion of the Lordstown Motors facility purchase and further signed a contract manufacturing agreement and a joint venture agreement with LMC for product development.

In mid-2021, Foxconn announced that the company will enter into more semiconductor production and will be expanding into supplying chips for electric vehicles (EVs) and electronics equipment used for healthcare.Vedanta Limited, one of India’s leading multinational groups, to manufacture semiconductors in India. In April 2022, it was announced Foxconn had acquired the wireless telecommunications company, arQana Technologies - with the new organization being rebranded as “iCana".AchernarTek for an undisclosed amount. The acquisition and consolidation will help Foxconn develop semiconductors for the automotive sector and 5G infrastructure.

Another Foxconn factory "city" is located at Zhengzhou Technology Park in Zhengzhou, Henan province, where a reported 120,000 workers were employed as of 2012,iPhone line and is sometimes referred to as "iPhone City".

On 21 October 2022, and in response to a Covid outbreak at Zhengzhou Technology Park, "Foxconn imposes restrictions," including travel restrictions "on iPhone assembly plant, with dine-in meal facilities closed."Zhengzhou Airport Economy Zone, where the Foxconn factory is situated.

As of mid-2015, Foxconn was in talks to manufacture Apple"s iPhone in India.Adani Group for expansion in the country. In August 2015, Foxconn invested in Snapdeal. In September 2016 Foxconn started manufacturing products with Gionee.Chennai.

Foxconn has a facility in San Jerónimo, Chihuahua that assembles computers,Juárez – a former Motorola production base that manufactures mobile phones,set-top box factory acquired from Cisco Systems.

On June 2, 2022, Foxconn announced that their Mexico-based production plant had been hit by a ransomware attack in late May, disrupting production. The facility affected was located in Tijuana, Baja California and specializes in the production of consumer electronics, medical devices, and industrial products.

In January 2019, Foxconn said it was reconsidering its initial plans to manufacture LCD screens at the Wisconsin plant, citing high labour costs in the United States.

In October 2021, Lordstown Motors announced a $250 million deal to sell a former GM plant to Foxconn, which would become a contract assembler for the company"s Endurance pickup truck. The deal was completed in May 2022 for a final price of $230 million.

Foxtron (鴻華先進科技) is a joint venture of Foxconn and Yulon Group founded in 2020 for vehicular manufacturing and research and development of electric vehicles.

Allegations of poor working conditions have been made on several occasions. News reports highlight the long working hours,Taiwanese co-workers,Apple Inc. audited the maker of its iPods and iPhones in 2007,

Concerns increased in early 2012 by an article published in The New York Times in October 2011.Apple Inc. and performed by the Fair Labor Association found that workers were routinely subjected to inhumane bouts of overtime of up to 34 hours without a pay increase and suggested that debilitating workplace accidents and suicides may be common.Students and Scholars Against Corporate Misbehaviour, has written numerous negative reports on Foxconn"s treatment of its employees, such as in 2010 and 2011.

In October 2012, the company admitted that 14-year-old children had worked for a short time at a facility in Yantai, Shandong Province, as part of an internship programme,

Also in October 2012, there was a crisis concerning an injured worker in which 26-year-old Zhang TingzhenReuters reported that Foxconn told the family to transport and submit him for a disability assessment in Huizhou 70 km away, or it would cut off funding for his treatment.brain haemorrhage en route,

In February 2015, Beijing News reported that an official with the All China Federation of Trade Union (ACFTU), Guo Jun, said that Foxconn allegedly forced employees to work overtime, resulting in occasional death by karōshi or suicide. Jun also said that the illegal overtime resulted from a lack of investigation and light punishments. Foxconn, in return, issued a statement questioning Guo"s allegations, arguing workers wanted to work overtime to earn more money.

In November 2017, the Financial Times reported that it had found several students working 11-hour days at the iPhone X plant in Henan province, violating the 40-hour-per-week mandate for children. In response, Foxconn announced that it has stopped the interns" illegal overtime work at the factory in which 3,000 students had been hired that September.

Since 2016, Foxconn has been replacing its workforce with robots, which have replaced 50% of Foxconn"s labor force in 2016, and there are plans for completely automated factories.

In January 2012, there was a protest by workers about conditions in Wuhan, with 150 workers threatening to commit mass suicide if factory conditions were not improved.Zhengzhou, where the iPhone X was being manufactured.

It"s no secret that Apple iPhones are made in China. This fact is written on the packaging, or directly on smartphones. However, in the territory of China, only the individual parts are assembled into the final equipment. It is much more interesting to watch where the iPhone camera, battery or processor is made.

Namely, if you start researching where spare parts and components for iPhone devices are made, you will find that they areoften produced by competitors. For example, Samsung. Parts for Apple smartphones come from various countries around the world and their development is in charge of well-known companies. Which specifically? We will tell you this in the following lines:

For many users, an amazing camera is a significant factor in which they prefer the iPhone over competing smartphones. Apple relies on several camera suppliers, but the largest is the Japanese company Sony. It makes rear cameras. The American company OmniVisiontakes care of the delivery of FaceTime cameras to Apple smartphones. Older iPhone models can still be equipped with cameras from the manufacturer Qualcomm.

The display is one of the most frequently ordered Apple spare parts. iPhone smartphone screens are characterized by their fantastic graphics and color. They are manufactured by several companies, the largest of which is the South Korean company LG.Some displays are supplied by Sharp.

The touch screen driver, manufactured by Broadcom for Apple, is also worth noting with the iPhone LCD. Last but not least, the surface of any iPhone screen must not lack durable Gorilla Glass. This is supplied by the American company Corning.

You might not expect it, but it really is. The Korean manufacturer Samsung has been supplying batteries for iPhones for more than 10 years. The paradox is that he is considered to be Apple"s biggest competitor.

Like cameras, processors are one of Apple"s largest smartphone domains. Thanks to their excellent performance parameters,the devices can operate extremely smoothly in all circumstances. And who is the supplier of these exceptional chips? The answer may surprise you again. There are two manufacturers, one of which is Samsung again. The second is the Taiwanese company TSMC.

Fortunately, if you"re looking for replacement parts for Apple smartphones, you don"t have to order them directly from individual manufacturers. You will find them all in our wide offer!

Charles W. L. Hill is the Hughes M. and Katherine Blake Professor of Strategy and International Business at the Foster School of Business, University of Washington. The Foster School has a Center for International Business Education and Research (CIBER), one of only 17 funded by the U.S. Department of Education, and is consistently ranked as a Top-25 business school. Learn more about Professor Hill at foster.uw.edu/faculty-research/directory/charles-hill A native of the United Kingdom, Professor Hill received his PhD from the University of Manchester, UK. In addition to the University of Washington, he has served on the faculties of the University of Manchester, Texas A&M University, and Michigan State University.Professor Hill has published over 50 articles in top academic journals, including the Academy of Management Journal, Academy of Management Review, Strategic Management Journal, and Organization Science. Professor Hill has also published several textbooks including International Business (McGraw-Hill) and Global Business Today (McGraw-Hill). His work is among the most widely cited in the world in international business and strategic management. Beginning in 2014, Dr. Hill partnered with Dr. Tomas Hult in a formidable co-authorship of the IB franchise of textbooks (International Business, Global Business Today). This brought together two of the most cited international business scholars in history.Professor Hill has taught in the MBA, Executive MBA, Technology Management MBA, Management, and PhD programs at the University of Washington. During his time at the University of Washington he has received over 25 awards for teaching excellence, including the Charles E. Summer Outstanding Teaching Award.Professor Hill works on a private basis with a number of organizations. His clients have included Microsoft, where he has been teaching in-house executive education courses for two decades. He has also consulted for a variety of other large companies (e.g., AT&T Wireless, Boeing, BF Goodrich, Group Health, Hexcel, Microsoft, Philips Healthcare, Philips Medical Systems, Seattle City Light, Swedish Health Services, Tacoma City Light, Thompson Financial Services, WRQ, and Wizards of the Coast). Professor Hill has also served on the advisory board of several start-up companies.For recreation, Professor Hill enjoys skiing, and competitive sailing!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey