tft display layers pricelist

A wide variety of tft screen prices options are available to you, You can also choose from original manufacturer, odm and agency tft screen prices,As well as from tft, ips, and standard.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

For its transparency, flat and smooth surface, and excellent heat resistance, this product is used as a substrate for various types of displays such as televisions, personal computers, smart phones, tablet devices, and in-vehicle infotainment. It is an alkali-free aluminosilicate glass that was developed by using the float process.

It is necessary for TFT-LCD glass to meet many strict quality requirements. Unlike window pane glass, glass for TFT-LCDs is not allowed to contain alkalis. This is because alkali-ions contaminate liquid crystal materials and even adversely affect the characteristics of the TFT. Additionally, the glass should not exhibit large sagging even though its thickness is just 0.3 to 0.7 mm and should have excellent heat resistance while assuring dimensional stability even after being heated at high temperature. The glass also should have properties that its composition does not dissolve during the fabrication process using chemicals. "AN100", non-alkali glass developed by us, is the one that has fulfilled those various requirements. Furthermore, since "AN100" does not contain hazardous materials such as arsenic or antimony, it has high reputation for being an environment-friendly glass. Our technologies are supporting the design of thin, large, and environmentally friendly LCD TVs.

Majority of LCDs in wide use now are TFT-LCDs. In a TFT-LCD, a layer of thin film that forms transistors is used as a device that applies voltage to the liquid crystal layer, and those transistors control the voltage supplied to each pixel. The advantages of a TFT-LCD are high resolution and quick response time that enables motion image to be fine and clear.

Recently, displays with higher resolution such as 4K and 8K are being developed one after another and have made it possible for viewers to enjoy vivid and fine picture even in very large screen sizes.

It is AGC’s display glass substrates, developed using its distinctive precision glass processing technologies, that support these higher resolution TVs.

Smartphones and tablets can now be considered life necessities, and the LCD screen is the most frequently used interface whenever such devices are used. Without the LCD display, it is not possible to send email or view pictures taken by the camera function.

Furthermore, LCDs play an important role in a variety of applications such as in-vehicle displays, e.g. navigation systems and center information displays, and digital signage.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

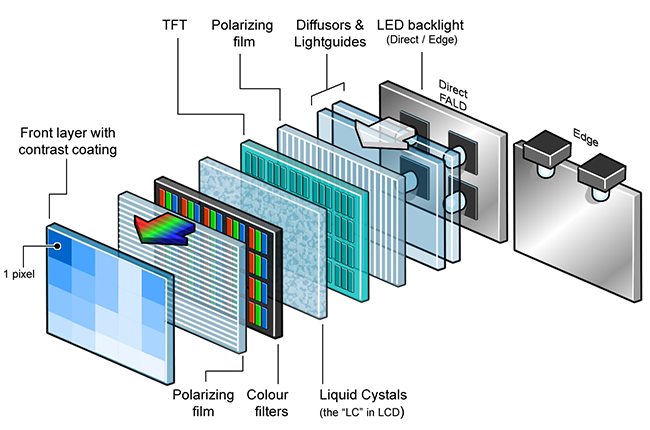

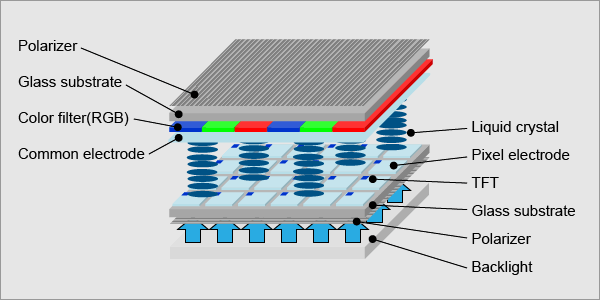

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

TFT (Thin-Film Transistor) Displays are active-matrix LCDs with full RGB color screens. These screens feature bright, vivid colors and have the ability to show fast animations, complex graphics and crisp custom fonts. TFTs are perfect displays for providing a rich user interface for all types of products. While typically used in consumer devices like personal DVD players and handheld devices, TFTs are also well suited for industrial application.

TFTs are Active-Matrix LCDs that have tiny switching transistors and capacitors. These tiny transistors control each pixel on the display and require very little energy to actively change the orientation of the liquid crystal in the display. This allows for faster control of each Red, Green and Blue sub-pixel cell thus producing clear fast-moving color graphics.

The transistors in the TFT are arranged in a matrix on the glass substrate. Each pixel on the display remains off until addressed by applying a charge to the transistor. Unlike conventional Passive-Matrix displays, in order to activate a specific pixel, the corresponding row is turned on and a charge is sent down the proper column. This is where only the capacitor at the designated pixel receives a charge and is held until the next refresh cycle. Essentially, each transistor acts as an active switch. By incorporating an active switch, this limits the number of scan lines and eliminates cross-talk issues.

MVA (Multi-domain Vertical Alignment) displays can offer wide viewing angles, good black depth, fast response times, and good color reproduction and depth. Each pixel within a MVA type TFT consists of three sub-pixels (Red, Green and Blue). Each of these sub-pixels is divided further into two or more sub-pixels, where the liquid crystals are randomly lined up due to the ridged polarized glass. When a charge is applied to the transistor, the crystals twist. With these crystals being randomly placed, it allows the backlight to shine through in all different directions keeping the intended color saturation retained while giving the display a 150deg. viewing angle.

In-Plane Switching (IPS) TFTs were developed to improve on the poor viewing angle and the poor color reproduction of TN TFT panels at that time. The crystal molecules move parallel to the panel plane instead of perpendicular to it. This change reduces the amount of light scattering in the matrix, which gives IPS its characteristic wide viewing angles and good color reproduction. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists.

IPS (In-Plane Switching) displays provide consistent, accurate color from all viewing angles without blur or grayscale inversion. IPS displays show clear images with fast response time, and no halo effect is produced when touched. Each pixel within an IPS type TFT consists of three sub-pixels (Red, Green and Blue). Each sub-pixel has a pair of electrodes to control the twisting of the Liquid Crystals. Unlike TN type TFTs where the electrodes are on opposing plates, the electrodes in an IPS TFT are on only one of the glass plates (i.e. in the same plane). When voltage is applied to the electrodes, all the Liquid Crystal molecules align in parallel with that plane and allow light to pass through to the polarizers and RGB color filters. In effect, TN displays force the Liquid Crystal molecules perpendicular to the glass which blocks some light from coming out at wide angles, while IPS displays keep the Liquid Crystal molecules in line to allow light through at all angles.

Low-temperature polycrystalline silicon (LTPS) is polycrystalline silicon that has been synthesized at relatively low temperatures (~650 °C and lower) compared to in traditional methods (above 900 °C). LTPS is important for display industries, since the use of large glass panels prohibits exposure to deformative high temperatures. More specifically, the use of polycrystalline silicon in thin-film transistors (LTPS-TFT) has high potential for large-scale production of electronic devices like flat panel LCD displays or image sensors.

Polycrystalline silicon (p-Si) is a pure and conductive form of the element composed of many crystallites, or grains of highly ordered crystal lattice. In 1984, studies showed that amorphous silicon (a-Si) is an excellent precursor for forming p-Si films with stable structures and low surface roughness. Silicon film is synthesized by low-pressure chemical vapor deposition (LPCVD) to minimize surface roughness. First, amorphous silicon is deposited at 560–640 °C. Then it is thermally annealed (recrystallized) at 950–1000 °C. Starting with the amorphous film, rather than directly depositing crystals, produces a product with a superior structure and a desired smoothness. In 1988, researchers discovered that further lowering temperature during annealing, together with advanced plasma-enhanced chemical vapor deposition (PECVD),could facilitate even higher degrees of conductivity. These techniques have profoundly impacted the microelectronics, photovoltaic, and display enhancement industries.

A simple transflective display is shown as below, in which there are two regions, T and R respectively. The cell gap in two regions are different, dT = 2*dR. This is to maintain the reflection and transmission from two regions are the same intensity, and give same color reproduction, because in the T region, light only goes through the LC layer once, while in the R region, light passes through twice.

Lieff Cabraser served as Court-appointed Co-Lead Counsel for direct purchasers in litigation against the world’s leading manufacturers of Thin Film Transistor Liquid Crystal Displays.

TFT-LCDs are used in flat-panel televisions as well as computer monitors, laptop computers, mobile phones, personal digital assistants, and other devices. Plaintiffs charged that defendants conspired to raise and fix the prices of TFT-LCD panels and certain products containing those panels for over a decade, resulting in overcharges to purchasers of those panels and products.

In March 2010, the Court certified two nationwide classes of persons and entities that directly purchased TFT-LCDs from January 1, 1999 through December 31, 2006, one class of panel purchasers, and one class of buyers of laptop computers, computer monitors, and televisions that contained TFT-LCDs.

TFT stands for Thin-Film Transistor. TFT technology is a new standard these days for manufacturing displays, monitors, laptop screens, and other devices. TFT LCD displays can show crisp text, vivid colors, fast animations, and complex graphics.

TFT LCD monitors, also called flat panel displays, are replacing the old style cathode ray tubes (CRTs) as the displays of choice. Almost all LCD monitors today take advantage of the TFT technology.

Each pixel on a TFT display is backed by a tiny transistor. Transistors are so small these days, they need only a very minimal charge to control what they do. TFT displays are much more energy efficient than regular CRT screens that need a powerful light source.

TFT displays also allow for very fast re-drawing of the display, so the image has very little chance to flicker. This was not always the case with flat-panel monitors. Original passive matrix LCD displays were not able to refresh at very high rates and therefore could not keep up with fast moving images. A TFT monitor refresh rate is very high resulting in a display that can be used for video, gaming, and all forms of multimedia.

A TFT monitor delivers crisp text, vibrant colors, and an improved response time for multimedia applications. Today"s standard for response rate in TFT monitors is 16 ms or less.

In general, a LCD display comprises of a layer of LCD material and one or more polarizing layers made of plastic, glass, or some other material. A LCD display has a sandwich-like structure with liquid crystals filled between two glass (or plastic or polycarbonate) plates.

These liquid crystals when stimulated by an external electrical charge can change the properties of light passing through them. When you align two polarizing materials with each other, light passes through. When you align one polarizing agent at a 90° angle to the other, light is blocked. Change the voltage, and the amount of light passing through the display is changed.

A TFT display is an advanced LCD display. A TFT monitor uses so-called thin-film transistor technology to project a picture on the screen. Transistors in a TFT display are used to change the orientation of the polarizing agent.A typical 17-inch TFT monitor has about 1.3 million pixels and 1.3 million transistors. The following text explains TFT in a greater detail...

Passive LCD panels cannot quickly change the orientation of the crystal. Well, it is quick, but not quick enough to display fast-moving graphics. To overcome this slowness, engineers came up with active-LCD technology. Active-LCD displays use transistors to actively change the orientation of crystals. That is where TFT comes from. T in TFT for transistor. This method allows for faster control of the LCD cell but is also more complex.

While passive-LCD displays start to blur with images moving faster than 8 to 15 frames/sec, TFT displays can display full-motion video and graphics because they use fast switching transistors.

Now that we know how a LCD works and what it behind TFT, we can start talking about color. Each pixel in a color TFT LCD is subdivided into three subpixels. One of the subpixels is capable of producing red, the other one green, and the last one blue color. Red, green, and blue are the basic colors. Any other color can be produced by mixing up these three. One set of RGB subpixels is equal to one pixel.

Old TFT displays and the small ones in simple applications such as calculators are reflective TFT. A reflective TFT display has no backlight. The polarizing agent at the rear of the TFT display is simply a mirror layer behind the TFT panel. The agent merely reflects incoming light from the front of the display. You need to be in a well-lit room to be able to read this type of display.

The next step in a TFT LCD design was to add a light source to it. More advanced TFT displays have added sidelights or front lights to these displays. Sidelights and front lights are virtually the same as backlights. The difference is just the position of the light. Front lights sit on the side or slightly in front of the TFT layers. They are designed so that the light they produce shines through the TFT panel and bounces off the reflective polarizing agent back through the display.

A transmissive TFT uses a backlight. Most TFT LCD panels today are designed with a backlight. The source of the light is mounted at the rear side of the LCD panel and shines light towards your eyes through the TFT panel"s polarizing medium (liquid crystal). Small displays, such as cell phones or calculators, use light source that is placed along the sides of the display.

The common TFT-display backlight is the CCFL (cold-cathode fluorescent lamp). CCFLs are similar to fluorescent light tubes that you commonly find in offices and homes. Their advantage is that they are small, inexpensive, replaceable, and cheap.

The polarizing medium in a TFT that transmits or blocks the backlight is clear, so any light shining on the display from the front competes with the backlight. If the light source shining on the front of the TFT display is strong enough, such as sun on a sunny day, it simply overpowers your laptop TFT display"s backlight and the display image is washed out. A reflective TFT display is usually a better choice for applications with high ambient light.

LED technology has only recently achieved the white light necessary to illuminate these panels. LEDs are the choice these days because they are stable over temperature ranges, durable, and very energy efficient. That is why if you buy a laptop with a TFT LED back-lighted display, it is possible that it will go for as much as 8 hours with your battery.

With the continuous innovation of display technology, the types of lcd monitor module screens have become more and more, and different types of display products have also been applied to different industry terminals. What are the most fundamental differences between TFT color screen and monochrome screen?

The working reasons of the TFT color display screen and the monochrome screen are completely different. The monochrome screen is composed of 7 pen segments, and there are many points in a range, called pixels. The monochrome screens are all made of fixed size. These points are arranged in an array; for example, 12864 is composed of 64 points in the horizontal direction 128X and the vertical direction. There are many names for monochrome screens, such as pen-segment LCD screens, pattern LCD screens, dot matrix screens, digital screens, and so on.

The TFT color screen is filled with liquid crystal material between two parallel plates, and the arrangement of molecules inside the liquid crystal material is changed by voltage so as to achieve the purpose of shading and transmitting light to display images with different shades and staggered patterns. Adding a filter layer of three primary colors between the plates can realize the display of color images. Therefore, the working principle of TFT color screen and monochrome screen is completely different.

Monochrome TFT display screens are generally used in calculators, watches, remote controls, telephones and so on. But, TFT color screens are widely used, such as handheld terminals, high-end mobile phones, smart homes, Internet of Things equipment, health care, artificial intelligence, video phones, walkie-talkies. More and more terminal products will be more inclined to choose TFT color screen as the display device of the terminal products.

TFT color screens are more expensive than monochrome TFT display screens, because the raw materials and production processes are different, and TFT color screens require higher raw materials, and the processing technology is also very complicated, the cost is higher, and the product performance And it is more popular among people. Monochrome TFT display screens generally have the problem of high MOQ. Because of their low price, monochrome TFT display screen manufacturers generally increase the quantity of order.

TFT color screen and monochrome screen are currently the two most common types of display screens on the market. There is no certainty who is better, only what kind of display screen is more suitable. Both TFT color screens and monochrome screens have their own advantages and disadvantages. It is better for everyone to be rational in the selection.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey