tft display layers price

A wide variety of tft screen prices options are available to you, You can also choose from original manufacturer, odm and agency tft screen prices,As well as from tft, ips, and standard.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

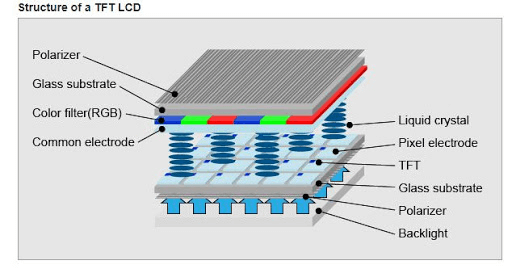

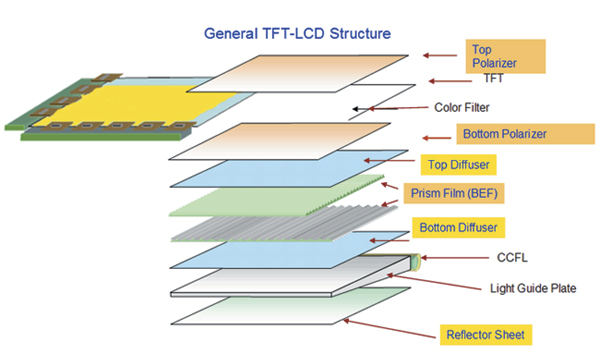

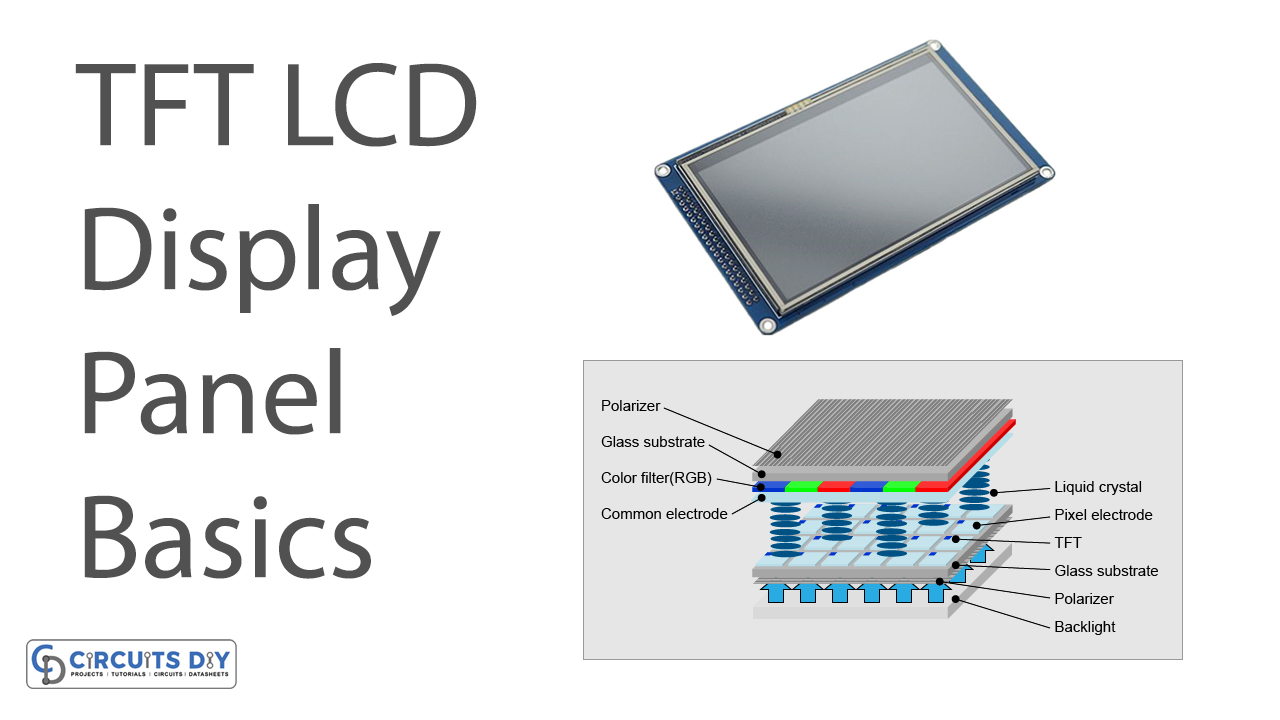

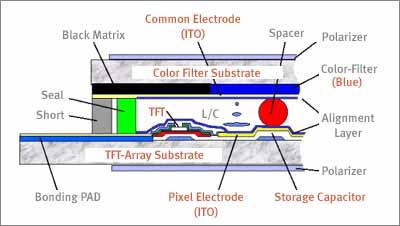

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

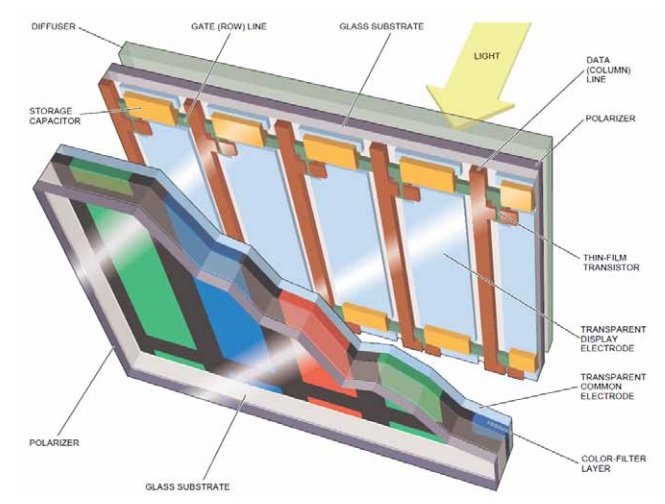

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

On the surface level is the other glass substrate. Just beneath this glass substrate is where the actual pixels and sub-pixels reside, forming the RGB color filter. In order to counteract the electrodes of the previously mentioned layer, this surface layer has counter (or common) electrodes on the side closer to the liquid crystals that close off the circuit that travels between the two layers. In both these substrate layers, the electrodes are most frequently made of indium tin oxide (ITO) because they allow for transparency and have good conductive properties.

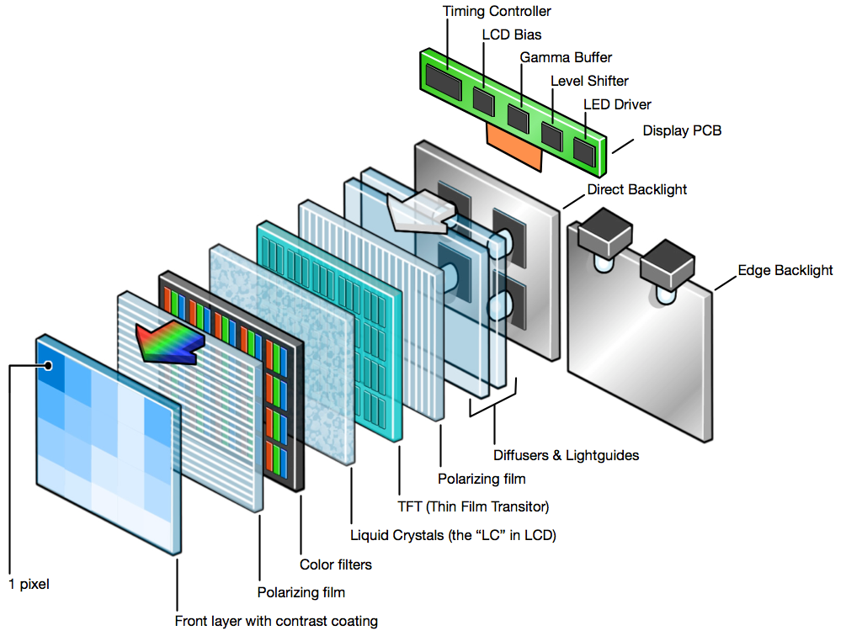

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

According to IMARC Group’s latest report, titled “TFT LCD Panel Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022-2027”, the global TFT LCD panel market size reached US$ 157 Billion in 2021. Looking forward, IMARC Group expects the market to reach US$ 207.6 Billion by 2027, exhibiting a growth rate (CAGR) of 4.7% during 2022-2027.

A thin-film-transistor liquid-crystal display (TFT LCD) panel is a liquid crystal display that is generally attached to a thin film transistor. It is an energy-efficient product variant that offers a superior quality viewing experience without straining the eye. Additionally, it is lightweight, less prone to reflection and provides a wider viewing angle and sharp images. Consequently, it is generally utilized in the manufacturing of numerous electronic and handheld devices. Some of the commonly available TFT LCD panels in the market include twisted nematic, in-plane switching, advanced fringe field switching, patterned vertical alignment and an advanced super view.

The global market is primarily driven by continual technological advancements in the display technology. This is supported by the introduction of plasma enhanced chemical vapor deposition (PECVD) technology to manufacture TFT panels that offers uniform thickness and cracking resistance to the product. Along with this, the widespread adoption of the TFT LCD panels in the production of automobiles dashboards that provide high resolution and reliability to the driver is gaining prominence across the globe. Furthermore, the increasing demand for compact-sized display panels and 4K television variants are contributing to the market growth. Moreover, the rising penetration of electronic devices, such as smartphones, tablets and laptops among the masses, is creating a positive outlook for the market. Other factors, including inflating disposable incomes of the masses, changing lifestyle patterns, and increasing investments in research and development (R&D) activities, are further projected to drive the market growth.

The competitive landscape of the TFT LCD panel market has been studied in the report with the detailed profiles of the key players operating in the market.

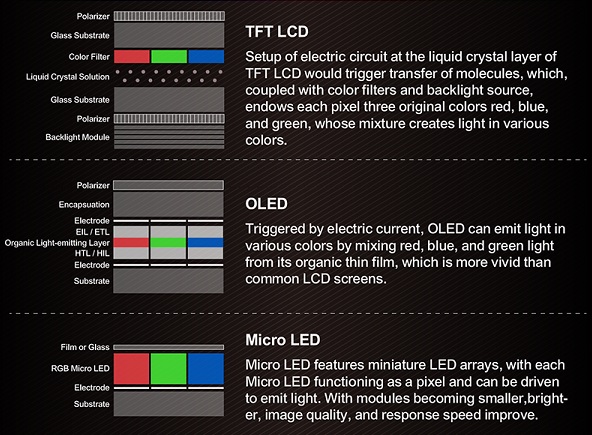

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

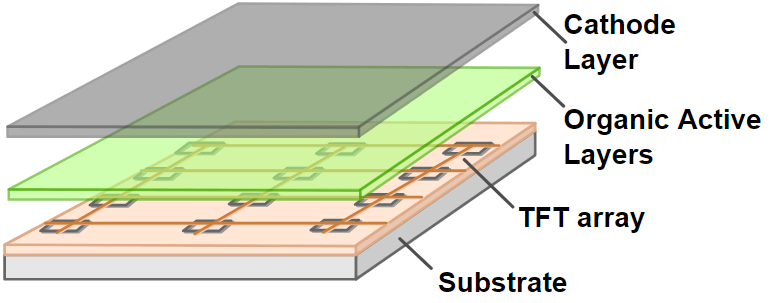

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

TFT or thin film transistor is a variant of the LCD technology. TFTs are active matrix LCDs, which help improve contrast, color, and picture quality. Thin film transistors are used along with capacitors to improve image quality in many electronic devices. Owing to their several advantages, these TFT displays are available in various specifications. The 4.3 inch TFT display is one of the most popular among them. The 4.3-inch TFT LCD display module touch screen has a resolution of 480X272 with an RGB interface. This display finds applications in mobile phones, cars, embedded systems, and certain industrial equipment among others. There are many 4.3-inch TFT LCD module manufacturers making this display; however, certain features may slightly differ based on the manufacturer. However, it is essential that you source it from a reliable manufacturer. Microtips Technology, one of the leading 4.3-inch TFT LCD module manufacturers, offers the new low-cost 4.3-inch TFT display. This post discusses the common features, working, and benefits of using this new low cost 4.3-inch TFT LCD display module touch screen provided by Microtips.

As mentioned, TFT is a subset of the LCD technology. TFT is an active matrix display. There are active matrix displays and passive matrix displays used in LCD flat panels of computers, phones, and so on. The images produced by active matrix are responsive and enable a wider angle of view compared to passive matrix display. Passive matrix displays, on the other hand, use a grid of horizontal and vertical wires to display an image. In this case, the charge of two wires is altered to change a pixel at intersection. The response time of producing an image with the passive matrix technology is much slower than active matrix. Also, at times, the image quality produced by passive matrix is blurred and pixelated. Active matrix, in comparison, offers many more advantages and a fine image quality, and hence is widely used in making 4.3-inch TFT LCD display module touch screens. The pixels on the TFT screen are arranged in a row-column configuration. The glass panel has an amorphous silicon transistor on which the pixels are attached. This enables each pixel to get a new charge and keep it consistent even after the screen is refreshed to load a new image. So, each pixel continues to be in its maintained state when other pixels are being used. This is one reason why this technology is called active matrix.

Display Mode: This indicates the image resolution and maximum number of colors available. Here, the display mode is usually white with some transmissivity.

Interface: The display interface helps humans exchange information with software. For instance, you need to control color, brightness, and other parameters as there are many interface options. This display has RGB interface and a TFT-LCD display type.

Response Time: This indicates the time in which you receive a response on your command, with tough screens it is much faster than typing a command. Once you touch the screen, most 4.3-inch TFT LCD display module touch screens respond in 15ms.

Active Area: Most 4.3-inch TFT LCD module manufacturers make this display with an active area of 95.04X53.86 mm and pixel pitch of 0.198(W) x0.198(H)mm.

Operating Temperature Range: Most displays are designed to function accurately in harsh environments and weather. These displays usually have an operating temperature ranging from -20 to +70 degrees Celsius.

Suited for Advanced Applications: These displays are suitable for car system scree, industrial systems and equipment, and mobile phones among others

In the era of touchscreen smartphones, TFT LCD display technology has become one of the unique features and primary selling points. Consumers’ device needs and requirements have evolved along with the continuous innovations in technology. Aside from unique features (i.e., touchscreens, crisp text, blur-free video, vibrant images), more and more people now demand mobile devices at low cost. Now, how is this possible?

There are several options available in the market. Here, we’ve rounded up all the things you need to know about TFT LCD module so you’ll know what to look out for on your mobile hunt.

TFT module is suitable for a variety of applications, such as smartphones, game consoles, and navigation systems, among others. It has a low power draw when showing colors, making it easier to see displayed images outdoors.

TFT Display is the most common display technology for mobile phones. TFT LCD enhances image quality, offering better image quality and higher image resolutions compared to earlier LCD display generation.

TFT module is offered in a standard display, resistive touch, and capacitive touch versions. It also comes in a variety of sizes. Mobile devices with TFT LCD display have a full-color RGB mode that showcases rich colors, detailed images, and bright graphics.

This type of touchscreen LCD display module contains two layers of conductive material with a small gap that acts as resistance. Here’s what happens when an object touches the resistive touch screen:

It is undeniable that LCD display technology has significantly made its way in our daily lives. Aside from mobile devices, TFT LCD screens are now also being used with computer monitors, television screens, game devices, and more.

A thin-film transistor liquid crystal display, TFT LCD display for short, is a type of LCD display that uses thin-film transistor technology to improve image quality.

TFT LCD displays have many advantages over traditional LCD displays. While traditional LCDs use a single layer of transistors, TFT LCDs use a thin film of transistors. This allows for better image quality, as well as improved response time and lower power consumption. TFT LCDs are also thinner and lighter than traditional LCDs, making them ideal for use in portable devices.

When choosing a TFT LCD, it is important to consider the viewing angle and colour reproduction. While TFT IPS displays offer better image quality, they are also more expensive.

TFT LCDs are used in a wide variety of industries, including consumer electronics, computing, telecommunications, automotive, and medical to name a few. Specifically, they are used in:Computers and laptop computers

TFT LCDs use two types of cover glass. Rigid cover glass is made of either soda-lime glass or Gorilla Glass. Flexible cover glass is used in some TFT LCDs, such as those used in mobile phones. The flexible cover glass is more resistant to breakage than rigid cover glass, making it ideal for use in portable devices.

The touchscreen is an optional part of the display module that allows the user to interact with the display. A touchscreen is a layer of glass that is coated with a material that is sensitive to pressure. When the user presses on the touchscreen, the pressure is registered and converted into an electrical signal.

Nauticomp Inc. is a leading provider of industrial LCD displays. Our products are designed for use in a variety of industries, including maritime, aerospace, and military. We offer a wide range of LCDs, including TFT LCDs, OLEDs, and LEDs. Contact us today to learn more about our products and services.

Custom Segment Liquid Crystal Displays are seen in products that measure the PH level of swimming pools, monitors used to measure specific gases in a mine, or in thermometers used to see if a child is running a fever. They are one of the oldest display technologies, but still one of the most popular.

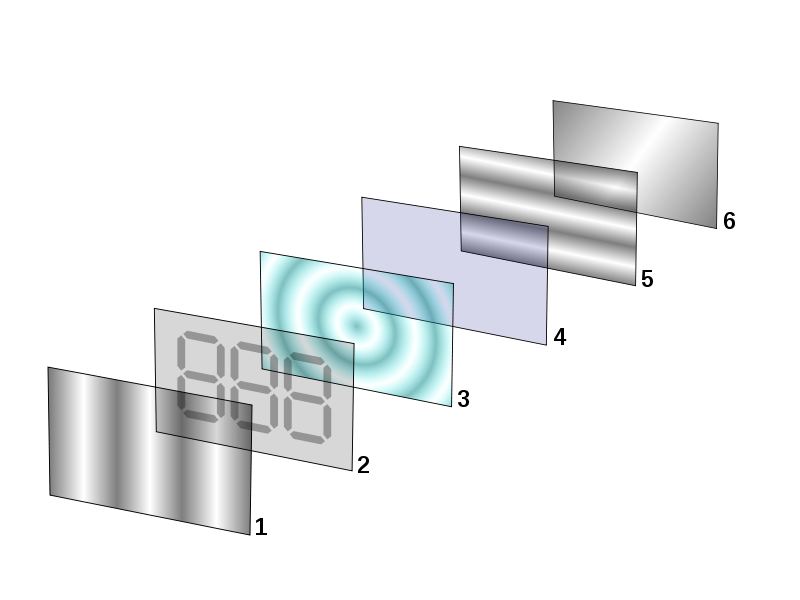

Segment LCDs, also called static displays or glass-only displays, are constructed of two pieces of ITO (Indium tin oxide) glass with a twisted nematic fluid sandwiched in between. A static display is a segment display with one pin for every one segment.

These displays are still one of the most popular technologies in use and the majority of them are custom. Many people think the process of designing a custom segment liquid crystal display is complicated and too complex to be understood except for a few experienced people. But after designing custom LCDs for over 14 years, it can be said that just about anyone can select the best options for their product.

Although Segment displays are an older technology, it is still one of the most popular. After all, they cannot display all the colors of a TFT or OLED like what can be seen on a cell phone and tablet.

The tooling fee for a custom display is the lowest of all the technologies and allows the customer to receive a LCD that is manufactured to the exact dimensions requested, including custom icons and segments.

Segment displays require less power than other display technology such as TFT, OLED, and UWVD. This makes these LCDs ideal for applications that are battery powered or solar powered. They require the lowest power to drive, an estimated 2uA per centimeter squared. Glass only displays (no backlight and no controller) require an estimated 10% of the power that is required for a LED backlight. In other words, a static display without a backlight will draw around 1mA; the same display with a LED backlight will demand from 10mA up to 25mA. Most displays can be driven at 3.3V or 5V since microprocessors can operate at both voltages. 3.3V is becoming more popular since two double ‘AA’ batteries can produce between 3.0V and 3.3V.

There are four numbers in the above LCD (0 8 4 7) all are seven segments. In other words the ‘0’ has seven segments, the ‘8’ has seven segments and so on. Each number has seven independent segments. Each segment can be turned on and off independently to create other numbers and some letters such as E, F C and others. This is an example of a ‘seven’ segment. But there are some letters that a seven segment cannot display such as the letter ‘M’ or ‘V’. In this case a fourteen segment configuration can be used.

Hence the display is called a segment display because each segment can be turned “on” and “off” individually. You choose the number of seven or fourteen segments and which icons you want on your custom display.

Segment displays earn the name ‘glass only display’ because the majority of them are glass with small metal leads attached to both sides of the display. However, it is possible to add a PCB (Printed Circuit Board) or a controller driver chip (IC). The construction of the display is similar to that of a sandwich. You take two pieces of glass, glue one piece on top of the other, than inject a fluid between the two pieces of glass. In the drawing below you see a side view of a segment display. The glass on top is smaller than the glass on the bottom. This is to allow room for the pins.

Segment LCDs, like all LCD display technologies, operate best between specific temperature ranges. You choose the temperature ranges that it will operate in. There are two standard configurations: normal temperature and wide temperature. The wider the temperature range, the more expensive the display.

The standard operating temperature range for a segment LCD is 0C to 50C. It is possible to build the display with a different fluid that will allow it to operate from -30C to 80C (F). With the addition of a heater, the display can operate down to -50C.

When the display becomes too cold, the fluid between the two layers of glass starts to freeze; when the display does freeze, the segments that were “on” when it froze will stay on. The display will not change until the temperature increases. When the display becomes too hot, a black spot will develop in the center of the glass. Basically the fluid is boiling. When the temperate comes down, the display will operate normally.

VATN (BTN) – Vertically Aligned Twisted Nematic is only available in negative mode (light colored letters on a dark/black background). VATN displays produce very bright segments and can be easily read.

Sunlight readable tft lcd display included color transflective tft lcd and high brightness tft lcd,both high brightness tft LCD (transmissive display) and transflective lcd are viewable under sunlight conditions, butwhich one would be the most suitable sunlight redable lcd display for your application? let"s see the comparison in the following article.

Compare to transmissive display, transflective TFT has a reflector layer inside tft lcd cell that is in front of the backlight. The incoming light is reflected and used to illuminate the TFT display. Transflective TFT have both "transmissive" and "reflective" modes.

Both display modes work together for enhanced performance, as a result, the performance of the display content in very bright light is perfect even without any backlight on the transmissive tft lcd. Customers using a transflective TFT LCD module can save power by reducing or turning the display"s backlight off during bright environments.

Transflective TFT become more popular since the demand of requiring good performance in bright environments and direct sunlight.so that the transflective TFT displays are perfectly readable under almost any ambient light conditions. In addition, they arevery energy efficient, making them ideal for battery powered devices and mobile applications.

In the following, we make a full comparison about the high brightness tft lcd vs transflective tft lcd display in the technical parameters, display performance, and cost evaluation. After read this article, you would get a deep comprehension about sunlight readable display tft, and how to select sunlight readable tft lcd display, to choose a most suitable transflective tft lcd or high brightness tft lcd (transmisive display) for your outdoor display.

them ideal for battery powered devices and mobile applications.Customers using a transflective screen can save power by reducing or turning off the display’s backlight during bright

ratio only about 2%, they are not a significant transflective tft lcd, it is the alternative transflective lcd solution that the reflective layer is located on the back polarizer, not in the color filter, the 2% reflective ratio is too low to say it is transflective

its cost around 18 USD,So transflective tft lcd is good, but are you ready to pay more cost about your sunlight readable tft lcd display, I hope you had a answer after read this article.

When transflective LCD technology used in regular TFT LCD with a reflective function. via the imposed reflective function, the modified tft LCD can reflect the ambient light passing the LCD cell and utilize the reflected light beams as its illumination. The stronger the ambient light is, the brighter the LCD will be needed.Transflective LCD modules are with both transmissive and reflective properties, and the image display effect depends on the conditions of the ambient environment. for transflective tft lcd, the tft lcd display uses a backlight with a transmissive property in dark environments, and uses external light with a reflective property in bright environments. so the transflective lcd method allows for better color performance than transmissive tft lcd with same backlight brightness, then the transflective lcd provides similar color characteristics similar to the transmissive mode that indoor. The net Reflectance rate of regular Transflective LCD solution is from 0.9% to 8% varied from panels selected. For example, with 1.3% net reflectance rate and under 10,000 ambient sunlight conditions, the brightness gain is around 130 nits added to original backlight brightness.

You could also find more information about "what makes best sunlight readable lcd display" here :https://www.szmaclight.com/new/Sunlight-readable-display.html

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

IPS TFT is a deviation of a traditional TN TFT Display. The most fundamental difference is that light is not rotated in plane and passing through polarizer films, but instead perpendicular to shutter the light. This approach to the technology improves contrast and enables symmetrical viewing angles from all directions.

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

For its transparency, flat and smooth surface, and excellent heat resistance, this product is used as a substrate for various types of displays such as televisions, personal computers, smart phones, tablet devices, and in-vehicle infotainment. It is an alkali-free aluminosilicate glass that was developed by using the float process.

It is necessary for TFT-LCD glass to meet many strict quality requirements. Unlike window pane glass, glass for TFT-LCDs is not allowed to contain alkalis. This is because alkali-ions contaminate liquid crystal materials and even adversely affect the characteristics of the TFT. Additionally, the glass should not exhibit large sagging even though its thickness is just 0.3 to 0.7 mm and should have excellent heat resistance while assuring dimensional stability even after being heated at high temperature. The glass also should have properties that its composition does not dissolve during the fabrication process using chemicals. "AN100", non-alkali glass developed by us, is the one that has fulfilled those various requirements. Furthermore, since "AN100" does not contain hazardous materials such as arsenic or antimony, it has high reputation for being an environment-friendly glass. Our technologies are supporting the design of thin, large, and environmentally friendly LCD TVs.

Majority of LCDs in wide use now are TFT-LCDs. In a TFT-LCD, a layer of thin film that forms transistors is used as a device that applies voltage to the liquid crystal layer, and those transistors control the voltage supplied to each pixel. The advantages of a TFT-LCD are high resolution and quick response time that enables motion image to be fine and clear.

Recently, displays with higher resolution such as 4K and 8K are being developed one after another and have made it possible for viewers to enjoy vivid and fine picture even in very large screen sizes.

It is AGC’s display glass substrates, developed using its distinctive precision glass processing technologies, that support these higher resolution TVs.

Smartphones and tablets can now be considered life necessities, and the LCD screen is the most frequently used interface whenever such devices are used. Without the LCD display, it is not possible to send email or view pictures taken by the camera function.

Furthermore, LCDs play an important role in a variety of applications such as in-vehicle displays, e.g. navigation systems and center information displays, and digital signage.

Mobile display technology is firmly split into two camps, the AMOLED and LCD crowds. There are also phones sporting OLED technology, which is closely associated with the AMOLED panel type. AMOLED and LCD are based on quite different underlying technologies, leading manufacturers to tout a number of different benefits depending on which display type they’ve opted for. Smartphone manufacturers are increasingly opting for AMOLED displays, with LCD mostly reserved for less expensive phones.

Let’s find out if really there’s a noticeable difference between these two display technologies, what sort of differences we can expect, and if the company marketing hype is to be believed.

It’s hidden in the name, but the key component in these display types is a Light Emitting Diode (LED). Electronics hobbyists will no doubt have played around with these little lights before. In a display panel, these are shrunk down dramatically and arranged in red, green, and blue clusters to create an individual pixel that can reproduce white light and various colors, including red, green, and blue.

The arrangement of these sub-pixels alters the performance of the displays slightly. Pentile vs striped pixel layouts, for example, results in superior image sharpness, but lower pixel life spans due to the smaller pixel sizes.

Finally, the AM part in AMOLED stands in for Active Matrix, rather than a passive matrix technology. This tells us how each little OLED is controlled. In a passive matrix, a complex grid system is used to control individual pixels, where integrated circuits control a charge sent down each column or row. But this is rather slow and can be imprecise. Active Matrix systems attach a thin film transistor (TFT) and capacitor to each LED. This way, when a row and column are activated to access a pixel, the capacitor at the correct pixel can retain its charge in between refresh cycles, allowing for faster and more precise control.

One other term you will encounter is Super AMOLED, which is Samsung’s marketing term for a display that incorporates the capacitive touchscreen right into the display, instead of it being a separate layer on top of the display. This makes the display thinner.

The major benefits from OLED type displays come from the high level of control that can be exerted over each pixel. Pixels can be switched completely off, allowing for deep blacks and a high contrast ratio. Great if you want a display capable of playing back HDR content. Being able to dim and turn off individual pixels also saves on power ever so slightly. The lack of other layers on top of the LEDs means that the maximum amount of light reaches the display surface, resulting in brighter images with better viewing angles.

The use of LEDs and minimal substrates means that these displays can be very thin. Furthermore, the lack of a rigid backlight and innovations in flexible plastic substrates enables flexible OLED-based displays. Complex LCD displays cannot be built in this way because of the backlight requirement. Flexy displays were originally very promising for wearables. Today, premium-tier smartphones make use of flexible OLED displays. Although, there are some concerns over how many times a display can flex and bend before breaking.

LCD stands for Liquid Crystal Display and reproduces colors quite differently from AMOLED. Rather than using individual light-emitting components, LCD displays rely on a backlight as the sole light source. Although multiple backlights can be used across a display for local dimming and to help save on power consumption, this is more of a requirement in larger TVs.

The really complicated part comes next, as light is then polarized and passed through a crystal element. The crystal can be twisted to varying degrees depending on the voltage applied to it, which adjusts the angle of the polarized light. The light then passes through a second polarized filter that is offset by 90 degrees compared with the first, which will attenuate the light based on its angle. Finally, a red, green, or blue color filter is applied to this light, and these sub-pixels are grouped into pixels to adjust colors across the display.

All combined, this allows an LCD display to control the amount of RGB light reaching the surface by culling a backlight, rather than producing colored light in each pixel. Just like AMOLED, LCD displays can either be active or passive matrix devices, but most smartphones are active these days.

This wide variation in the way that light is produced has quite a profound difference to the user experience. Color gamut is often the most talked-about difference between the two display types, with AMOLED providing a greater range of color options than LCD, resulting in more vibrant-looking images.

OLED displays have been known for additional green and blue saturation, as these tend to be the most powerful colors in the sub-pixel arrangement, and very little green is required for white light. Some observers find that this extra saturation produces results that they find slightly unnatural looking. Although color accuracy has improved substantially in the past few years and tends to offer better accuracy for wider color gamuts like DCI-P3 and BT-2020. Despite not possessing quite such a broad gamut, LCD displays typically offer 100% sRGB gamut used by most content and can cover a wide gamut and most of the DCI-P3 color space too.

As we mentioned before, the lack of a backlight and filtering layers weighs in favor of OLED over LCD. LCD displays often suffer from light bleed and a lower contrast ratio as the backlight doesn’t switch off even when pixels are supposed to be black, while OLED can simply switch off its pixels. LCD’s filtering layer also inherently blocks some light and the additional depth means that viewing angles are also reduced compared to OLED.

One downside of AMOLED is that different LEDs have different life spans, meaning that the individual RBG light components eventually degrade at slightly different rates. As well as the dreaded but relatively rare burn-in phenomenon, OLED display color balance can drift very slightly over time, while LED’s single backlight means that color balance remains more consistent across the display. OLED pixels also often turn off and on slower, meaning that the highest refresh rate displays are often LCD. Particularly in the monitor market where refresh rates exceed 120Hz. That said, plenty of OLED smartphones offer 90, 120, and even 144Hz support.

There are some pros and cons to both technologies and some reasonable user preferences between the different color and contrast profiles. Although the prevalence of multiple display modes available in modern smartphones makes this somewhat less of an issue these days. However, the falling production costs and additional benefits of OLED displays have made them a more popular choice than ever across a wide range of price segments. OLED dominates the high-end smartphone and TV spaces owing to its wider color gamut, superior contrast ratio, while still supporting decent refresh rates. Not to mention its flexible characteristics for brand new mobile form factors.

Major display manufacturers, such as LG Display and Samsung Display, are betting big on OLED technology for the future, making major investments into additional production facilities. Particularly when it comes to its use in flexible display technology. The AMOLED panel market is expected to be worth close to $30 billion in 2022, more than double its value in 2017 when this article was first published.

That said, developments in Quantum Dot and mini LED displays are closing the already small performance gap between LCD and OLED, so certainly don’t count LCD out of the race just yet.

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

If some elements of the picture i.e., your company logo is in the same place of the screen for a long period of time, for couple of weeks, months or a year, the crystals will memorize the state and later, when we change the image, we may see some ghosting of those elements. It really depends on many conditions like temperature and even the screen image that we display on the screen for longer periods of time. When you build your application, you can use some techniques to avoid it, like very rapid contrast change and of course to avoid the positioning the same image in the same position for a longer time.

You may have seen this phenomenon already as it is common in every display technology, and even companies like Apple put information on their websites, that users may encounter this phenomenon and how to fix it. It is called image ghosting or image persistence, and even Retina displays are not free of it.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

On the picture above, you can see further explanation of the grayscale inversion from Wikipedia. It says that some early panels and also nowadays TN displays, have grayscale inversion not necessary up-down, but it can be any angle, you need to check in the datasheet. The reason technologies like IPS (In-Plane Switching), used in the latest Riverdi displays, or VA, were developed, was to avoid this phenomenon. Also, we do not want to brag, but the Wikipedia definition references our website.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

To summarize, when you buy older technology like TN and displays, which are still very popular, and Riverdi is selling them as well, you need to be careful where you put your display. If it is a handheld device, you will see the display from the bottom, but if you put it on a wall, you will see the display from the top, so you need to define it during the design phase, because later it is usually impossible or expensive to change the direction.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

If we wanted to talk about disadvantages, there is a question mark over it, as some of them may be true, some of them do not rely on real cases, what kind of display, what kind of technology is it. Sometimes the IPS displays can have higher power consumption than others, in many cases however, not. They can be more expensive, but not necessarily. The new IPS panels can cost like TN panels, but IPS panels definitely have a longer response time. Again, it is not a rule, you can make IPS panels that are very fast, faster than TN panels, but if you want the fastest possible display, probably the TN panel will be the fastest. That is why the TN technology is still popular on the gaming market. Of course, you can find a lot of discussions on the internet, which technology is better, but it really depends on what you want to achieve.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey