lcd display c code manufacturer

In electronics world today, Arduino is an open-source hardware and software company, project and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards (‘shields’) or breadboards (for prototyping) and other circuits.

The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the “Arduino language”. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go. It aims to provide a low-cost and easy way for hobbyist and professionals to create devices that interact with their environment using sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats and motion detectors.

In order to follow the market tread, Orient Display engineers have developed several Arduino TFT LCD displays and Arduino OLED displays which are favored by hobbyists and professionals.

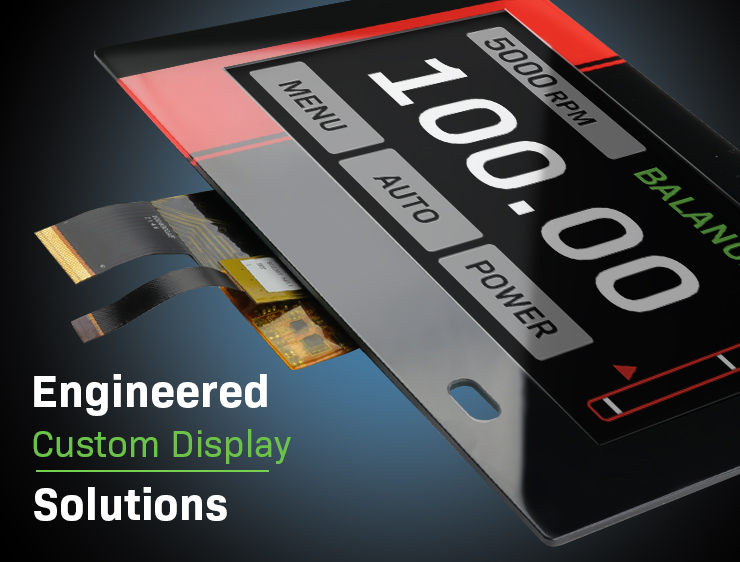

Although Orient Display provides many standard small size OLED, TN and IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

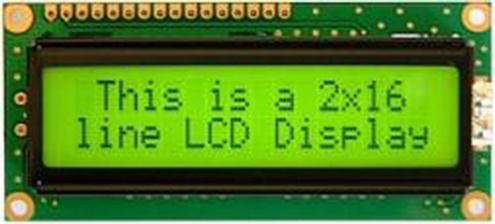

Newhaven 16x2 character Liquid Crystal Display shows characters with dark pixels on a bright yellow/green background when powered on. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0216HZ-FL-YBW-C display has an optimal view of 6:00 and comes with a temperature compensation circuit. This display operates at 5V supply voltage and is RoHS compliant.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

Before you get involved with LCD display programming, its critical you first choose the correct LCD display for your product. All LCD modules can be classified into one of two categories: those requiring a controller/driver chip and those that don"t.

Displays requiring a controller/driver chip to interface with your product require a programmer to write software code, sometimes referred to as firmware, to connect the LCD to the end product. Those that have a controller/driver are much easier and faster to program. Specifically, this article will address programming the character or alphanumeric displays with a parallel bus (a parallel bus LCD sends and receives 4 bits, 8 bits or 16 bits of data at a time).

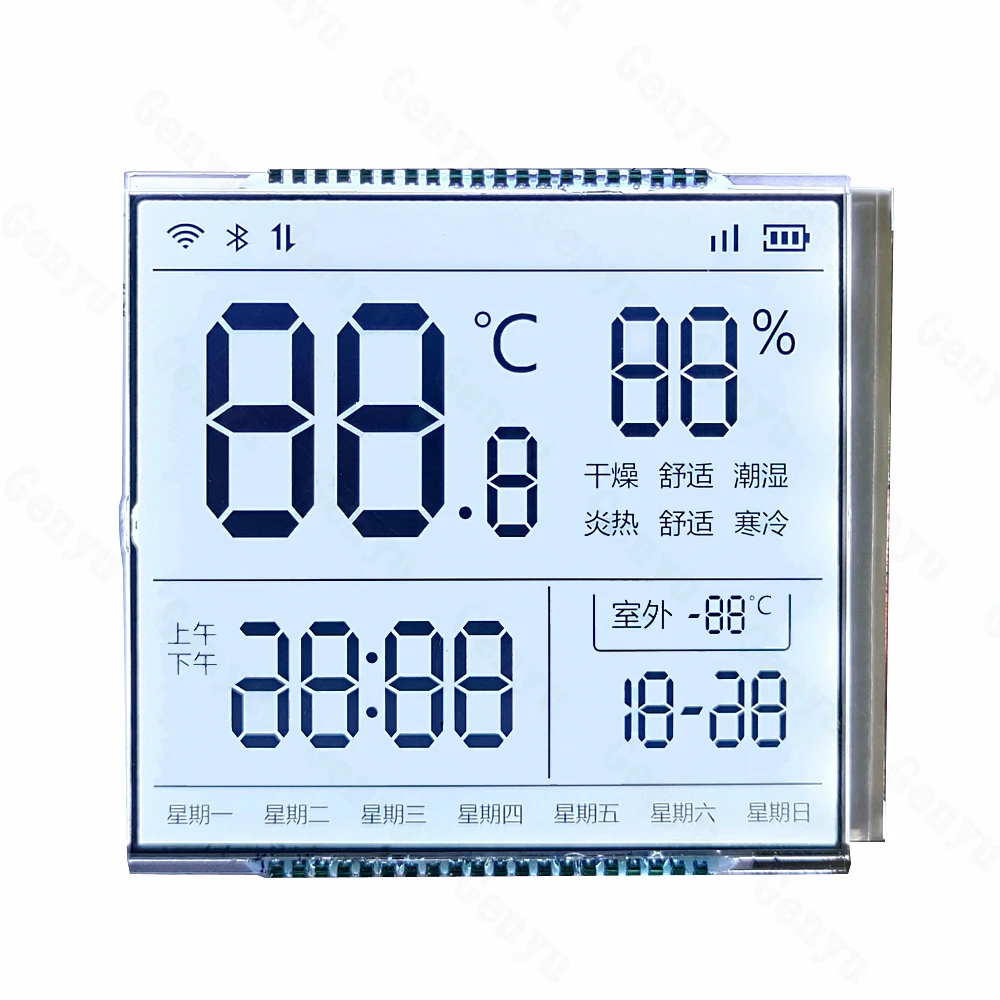

The second category, those that don"t require a controller/driver chip, are called static or segment displays. This means that there is one connection on the LCD for each segment. Although this eliminates the controller chip, it requires a great deal of connections between the display and the customers product.

So what exactly is this all important piece of technology—the controller/driver (C/D)—that will make your life easier through quick and simple programming? It is a small microprocessor whose function is to convert the designers’ firmware/software into characters, numbers, and punctuation marks. The C/D makes it easy for the product designer to quickly program the character display. Inside each C/D is a character table, sometimes referred to as a character map or font table, which contains pre-loaded letters, numbers, and punctuation. The table allows the designer to call out the requested character by addressing the number of that character. In other words, the letter ‘T’ may be the number 27 and the n-dash (i.e. “-”) could be number 122. This eliminates the need to create each character from scratch and reduces the amount of time necessary to program the LCD module. In the font table shown below, the letter ‘P’ would be displayed when the designer calls the number sequence below.

D0=0, D1=0, D2=0, D3=0, D4 =0, D5=0, D6=1, D7=1. The letter Do, D1 and so on above means data bit 0, data bit 1 etc. Most character displays use eight data bits.

The character table contains 255 possible characters. This number of characters is sufficient for one language, but would be impossible to display every character in every language when limited to only 255 options. This challenge is solved by making use of a different C/D for each language. You can order a C/D for French, German and many other languages.

There are several manufactures of C/D’s including Seiko, Epson, Toshiba, and Sunplus. There are distinct advantages of having multiple makers in multiple places in the world. Specifically, you won’t have to worry about a delay in the supply chain that is the result from the constraint of the C/D being made by only one or two manufacturers. You don’t want anything to delay the launch of your product.

Character LCD displays contain 14 pins if no backlight is attached and 16 pins when an EL or LED backlight is included with the module. Below is a breakdown of each pin and the function of that pin. The function of these pins directly relates to your success at programming character LCD displays, so pay attention!

The Ground is necessary for the voltage and the contrast adjust to reference. Ground, also referred to as zero volts, is required on all electronic devices. Electrical ground is similar to the ground floor of a tall building. All the floors above the ground floor are positive and all the floors below the ground floor, the basement, are negative. The ground pin on the LCD is connected to the ground on the customer’s product

This is the Logic voltage necessary to drive the LCD. There are two common voltages for a character LCD, 3.3V (this is equal to two "aa" batteries in series) and 5V.

It is possible to order a character LCD with both a positive and negative voltage. This option is not very common and is seen in replacing older discontinued displays.

We do not recommend using the same Ground and VDD connections to supply both your LCD logic and your LED backlight. It is better to use a separate power for your backlight which is what pins 15 and 16 or the A and K tab on the side of the LCD are designed for.

This is the connection for the contrast adjust. This function is to modify the voltage between VDD and Ground and then to adjust the contrast. If you are not able to achieve the desired contrast, it may be necessary to add a resistor to the back of the printed circuit board. The addition of the resistor alleviates the low contrast issue.

Register Select has two positions: 1 (on or high) or 0 (off or low). When RS is low (0), the data is to be treated as an instruction such as ‘move the position of the cursor’ or ‘clear the screen’. When RS is high (1), the data being sent to the display is a letter, number or punctuation mark that is to be displayed on the screen.

The RW line is the "Read/Write" control line. When RW is low (0), the information on the data bus is being written to the LCD. When RW is high (1), the program is effectively querying (or reading) the LCD. Only one instruction ‘check LCD status’ is a read command. All others are write commands--so RW will almost always be set to low.

The data bits on a parallel LCD display can accept up to 8 bits of data at a time. It is possible to use just four of the eight data bits if your microcontroller lacks enough connections to drive all 8 bits; however, this is a slow transfer of information. The data bit lines are numbered DB and begin at number DB0, DB1 etc. up to DB7.

These two lines are called A for Anode and K for Cathode. Yes, it is strange to use the letter K for a word that starts with a C, but that is an entirely different subject!

The anode is the positive voltage for the backlight, while the K is the ground for the backlight. You have options when it comes to ordering your backlights; you can order an LCD display with either a 3.3V LED backlight or a 4.2V LED backlight.

One key component in LCD display programming is to make sure the controller driver you have designed will continue in production. Over time C/D suppliers will discontinue various models. So, the issue you solved with maintaining a steady supply chain does crop up again when models become obsolete. To mitigate the inconvenience, when the IC is discontinued, the LCD supplier will recommend a replacement or compatible controller. This is where the word ‘compatible’ does not mean ‘exact drop in equivalent’; however, we find that a compatible controller is an exact match 95% of the time. If you find yourself in that unlucky 5%, then you will either need to make a last-time buy of the controller that is being discontinued or change the software on your product to match the new controller.

If you just need a few samples, it`s better to directly on ourAliexpress store, we are 5 stars feedback supplier with 100% Honesty. (The buy link is on the right of the product image)

Different displays have different characteristics, just tell Panox Display your application, and operating environment, Panox Display will suggest a suitable display for you.

But Panox Display is not a school, if customers don`t know the basic knowledge to design circuit boards, we suggest using our controller board to drive the display.

First, you need to check whether this display has On-cell or In-cell touch panel, if has, it only needs to add a cover glass on it. If not, it needs an external touch panel.

Because the shape of the cover glass depends on the design of the clients, to avoid infringement of appearance, most of the developers need different customized touch panels.

If you don`t know or don`t want to write a display program on Raspberry Pi, it`s better to get an HDMI controller board from us, and Panox Display will send a config.txt file for reference.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

If you’ve ever attempted to connect an LCD display to an Arduino, you’ve probably noticed that it uses a lot of Arduino pins. Even in 4-bit mode, the Arduino requires seven connections – half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It only uses two I/O pins that are not even part of the digital I/O pin set and can be shared with other I2C devices.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

If you look closely, you can see tiny rectangles for each character on the screen as well as the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

There is a jumper on the board that provides power to the backlight. To control the intensity of the backlight, you can remove the jumper and apply external voltage to the header pin labeled ‘LED’.

If you have multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter to avoid conflicting with another I2C device.

For this purpose, the adapter comes with three solder jumpers/pads (A0, A1, and A2). The address is set when a jumper is shorted with a blob of solder.

An important point to note here is that several companies, including Texas Instruments and NXP Semiconductors, manufacture the same PCF8574 chip. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1, and A2) are located at the end of the 7-bit I2C address register.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1, and A2) are located at the end of the 7-bit I2C address register. However, the remaining bits in the address register are different.

So the I2C address of your LCD is most likely 0x27 or 0x3F. If you’re not sure what your LCD’s I2C address is, there’s an easy way to figure it out. You’ll learn about that later in this tutorial.

Now we are left with the pins that are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected correctly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also referred to as A5 (SCL) and A4 (SDA).

After wiring the LCD, you will need to adjust the contrast of the LCD. On the I2C module, there is a potentiometer that can be rotated with a small screwdriver.

Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, the first row of rectangles will appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

Before you can proceed, you must install the LiquidCrystal_I2C library. This library allows you to control I2C displays using functions that are very similar to the LiquidCrystal library.

To install the library, navigate to Sketch > Include Library > Manage Libraries… Wait for the Library Manager to download the library index and update the list of installed libraries.

Filter your search by entering ‘liquidcrystal‘. Look for the LiquidCrystal I2C library by Frank de Brabander. Click on that entry and then choose Install.

As previously stated, the I2C address of your LCD depends on the manufacturer. If your LCD has a PCF8574 chip from Texas Instruments, its I2C address is 0x27; if it has a PCF8574 chip from NXP Semiconductors, its I2C address is 0x3F.

If you’re not sure what your LCD’s I2C address is, you can run a simple I2C scanner sketch that scans your I2C bus and returns the address of each I2C device it finds.

However, before you upload the sketch, you must make a minor change to make it work for you. You must pass the I2C address of your LCD as well as the display dimensions to the LiquidCrystal_I2C constructor. If you’re using a 16×2 character LCD, pass 16 and 2; if you’re using a 20×4 character LCD, pass 20 and 4.

The next step is to create an object of LiquidCrystal_I2C class. The LiquidCrystal_I2C constructor accepts three inputs: I2C address, number of columns, and number of rows of the display.

In the setup, three functions are called. The first function is init(). It initializes the interface to the LCD. The second function is clear(). This function clears the LCD screen and positions the cursor in the upper-left corner. The third function, backlight(), turns on the LCD backlight.

The function setCursor(2, 0) is then called to move the cursor to the third column of the first row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal_I2C Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

If you find the default font uninteresting, you can create your own custom characters (glyphs) and symbols. They come in handy when you need to display a character that isn’t in the standard ASCII character set.

As previously discussed in this tutorial, a character is made up of a 5×8 pixel matrix; therefore, you must define your custom character within this matrix. You can define a character by using the createChar() function.

To use createChar(), you must first create an 8-byte array. Each byte in the array corresponds to a row in a 5×8 matrix. In a byte, the digits 0 and 1 indicate which pixels in a row should be OFF and which should be ON.

CGROM is non-volatile memory that retains data even when the power is removed, whereas CGRAM is volatile memory that loses data when the power is removed.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which pixels to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

Creating custom characters has never been easier! We’ve developed a small application called Custom Character Generator. Can you see the blue grid below? You can click on any pixel to set or clear that pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

There’s no limit to what you can create. The only limitation is that the LiquidCrystal_I2C library only supports eight custom characters. But don’t be sad, look at the bright side; at least we have eight characters.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

This sketch contains eight custom-characters. Take, for example, the Heart[8] array. You can see that the bits (0s and 1s) are forming the shape of a heart. 0 turns the pixel off, and 1 turns it on.

In the setup, we use the createChar() function to create a custom character. This function accepts two parameters: a number between 0 and 7 to reserve one of the eight supported custom characters, and the name of the array.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

Now you must have guessed it, Yes 8-bit mode is faster and flawless than 4-bit mode. But the major drawback is that it needs 8 data lines connected to the microcontroller. This will make us run out of I/O pins on our MCU, so 4-bit mode is widely used. No control pins are used to set these modes. It"s just the way of programming that change.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

The Dot Factory is a small open source tool (MIT licensed) intended to generate the required C language information to store many fonts and images, as efficiently as possible, on a microcontroller. These fonts are then uploaded via the LCD driver (see the Drivers and Modules page for a few) to the actual dot matrix LCD. It is written in C# for Visual Studio 2008 and has been tested on Windows XP, 2003, Vista, 7 and Linux via Mono.

Working with dot matrix LCDs with microcontrollers, while not difficult, is tedious. The actual LCD controller allows us to upload simple visual data (dot on or dot off) into the LCD’s dot matrix, but not much else. It is up to our software to decide what to upload when we want to draw lines, circles and more importantly – text.

While there are software graphic libraries that allow us to generate a character “on the fly” using vector graphics (the character is described as a series of drawing commands that allow scaling and decoration) – these are much too complex and large to integrate in a microcontroller environment. Consequently, we must store the exact appearance of a character as a series of 1s and 0s, equivalent to a “dot on” “dot off” on the LCD, and upload this as a bitmap when we want to display text. While it is possible to generate this manually, it is desired to have a tool to do our grunt work by converting windows fonts (given a size and decoration) into a series of bitmaps.

TDF is comprised of two panes – the input pane on the left (what you want to generate) and the output pane on the right (the generated output, in C code). The input pane can accept either a font of your choice (for writing text to the LCD) or an image. When generating a font, you have the option of either generating all the available letters (by selecting “All” in the Insert Text box and clicking the plus button) or by typing in which letters, numbers or symbols you are actually using in your application (for example: 0123abcd). If you are writing a simple application that has only a few sentences, you can type them wholly in this box without fear of duplicating letters – TDF takes care of that by discarding any duplicates. This way only the letters you use will take up space.

Once you have completed setting up what it is you’d like to generate (be it an image or font), select the output method in the output pane. If you are using the LCD drivers on this website, you want it to generate an MSb first output, otherwise images will come out wrong. If you have a compiler that supports the “0b” binary specifier, you can select “binary” rather than “hex”. This will allow you to visually see the pixels you will set and allow for manual touch up by the user without having to calculate hex and experimentation. Click generate and your C code will be outputted to the text box below. Copy paste this into your application (it is recommended to put this in a separate module, not your LCD driver module, for organizational reasons).

Note that 5×7 and 5×8 fonts cannot be generated using this tool. While some TTF fonts can render characters this small they are usually distorted to the point of uselessness. You can download a ready made five by seven font here. I ripped this font from text file a while ago, so apologies to the uncredited author.

The character bitmap array: This holds the actual characters as a bitmap (only the characters selected in the input pane). Each byte represents a single vertical page sent to the LCD. All vertical padding is removed from the characters

The character descriptor array: Allows O(1) mapping between a character’s ASCII value and required meta information about the character – namely its width in bits and its offset into the character bitmap array. When the LCD driver needs to find where character X is located in the bitmap array, it will jump to index [X - font.startCharacter] in the descriptor array. The startCharacter is the first character (that is, the character with the lowest ASCII value) used for this font. By defining a startCharacter we can reduce the number of elements in the descriptor array.

The font information: This element is essentially the font descriptor for this font. It holds information regarding this font like the name of the character bitmap and descriptor arrays, the font start character and how many pixels wide a space character is for this font. The LCD driver will replace the space character with empty pixels (this saves both processing time, space in the character bitmap array and space in the character descriptor array – since the space is the first ASCII character and is commonly used).

The generated structures are generated with documentation, but you may want to see a sample bitmapDb header file for detailed info on the character descriptor array and font information structures. For image generation, only the image’s bitmap array and size descriptors are generated. Note that the height value is pixels (bits) and width values are in pages.

I usually release versions according to user demand. If you think TDF can use whatever feature, drop me a line. When enough users request something I invest the time to add it.

Version 0.1.2 (29may11): Fixed width/height being swapped. Added support for configuring image descriptor format (bits/bytes). Thanks geo for the heads up and suggestion

Version 0.1.1 (25may11): Added support for multiple descriptor arrays with a double lookup. Before this version TheDotFactory could generate Unicode characters but the lookup tables were usually too huge to be of any use. Using this feature, a double lookup is employed, allowing for fast lookups for characters residing at disparate ranges. See the video for an explanation (will be posted in the next few days). In addition to this, added support for specifying character ranges instead of inputing the actual characters. For example, <<100-120>> will generate characters for ASCII characters 100 to 120. Thanks a bunch to Archis Bhave for inputs and testing. Source is now distributed via github.

Version 0.1.0 (15dec10): Added support to format the generated variable names (thanks SpiralBrain), added end character indication to font information (thanks Nick Jensen), added the ability to save to clipboard from File menu and added the ability to save the source/header to file via file menu (don’t remember who, but someone wondered why this wasn’t in. I personally think all fonts should be in a single module and so I opted for copy/paste, but to each his own)

Version 0.0.8 (29may10): Fixed two unreported crashes (clicking generate without entering any text and when a newline existed in generated text), added the ability to copy the outputted text by using a context menu

Version 0.0.7 (28may10): Added ability to select whether character descriptor array is to be created and which character will be used to visualize the font (thanks Christian Treczoks), syntax coloring automatically disabled when generating large amounts of text (will be fixed properly next version), properly handled bitmaps with no black pixels in them (displays error instead of a crash), some minor cosmetics

Version 0.0.6 (03mar10): Bug fix for image generation (tried to save a temporary file for debugging in a custom directory) – thanks to Nir Shemeshfor pointhing this out!

Version 0.0.5 (23dec09): Added support for rotation (90 degree increments), space character generation, width (bit/byte) selection of character width and font height, optional generation of character height/width and font height, structures are now generated with documention, input text and font is persisted throughout invokations of the application, persistent preset management – add, edit, delete output configuration presets

Version 0.0.3 (30jul09): Added output configuration: hex/binary, MSb First/LSb first, configurable padding removal, comment control, flip X/Y and more

To run this executable, you must have the .NET framework installed. The stable binary has been in the wild for a month at least with no major bugs reported. Non stable binary contains new features and bug fixes (see revision history).

On the MSP-EXP430FR6989 LaunchPad User"s Guide (http://www.ti.com/lit/ug/slau627a/slau627a.pdf) Table 3 on Page 12 there is a list of the LCD segments for each Digit. On there, each Digit has an ending character to it that designates which segment will light up. Those are what are used to map out the two columns.

The following example is my first attempt at printing to an LCD display using the dsPIC30F4011 microcontroller. The display I’m using is a 16×1 character screen with what I think is a standard Hitachi interface. It’s my first time using one of these, so the code is a bit long-winded at the moment, but the good news is that it’s working!

This LCD module uses the Hitachi interface, which has 4-bit and 8-bit operating modes. Here, the 4-bit mode is used, which means that each byte transmitted from the dsPIC to the LCD module is split into two 4-bit nibbles which are transmitted one after the other. The advantage of 4-bit mode is that less microcontroller pins are required – 7 digital outputs in total: 3 control lines and 4 data lines. (Actually, strictly speaking, you could get away with only 6 lines.)

The circuit diagram is shown below. Note that the 5 connections to the PICkit 2 USB programmer are not shown. (Link to editable SVG version of this image, created using Inkscape.)

The LCD module I’m using is shown below (front and back views of the same device). The 6-pin header at one end of the breadboard is the connector for the PICkit 2 USB programmer.

I was surprised to discover that 16×1 LCD modules of this type (1 line with 16 characters of text) are typically structured as if they had 2 lines of 8 characters. The first 8 characters are “line 1” and the second 8 characters are “line 2”. As a result, in the program below, half of the single line of text to be displayed is written to “line 1” and half is written to “line 2”.

From Figure 3 above we can see that the DDRAM controller should have a memory map of 104 bytes (00H to 67H = 68H = 104D), but the location that can be used is only 80 bytes 00H-27H (40 bytes) and 40H-67H (40 bytes); Note that the 28H-3FH address (24 location) is not visible.

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

The voltage source of this display is +5 V connected to Pin 2 (VCC) and GND power supply connected to Pin 1 (VSS) and Pin 16 (GND); Pin 1 (VSS) and Pin 16 (GND) are combined together and connected to the GND of the power supply.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey