photocentric lcd panel free sample

Photocentric has been working with Ukrainian aligner experts, Usmih, to help them develop an innovative aligner manufacturing process that pushes the boundaries of what 3D can offer the dental industry in both throughput and cost.

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

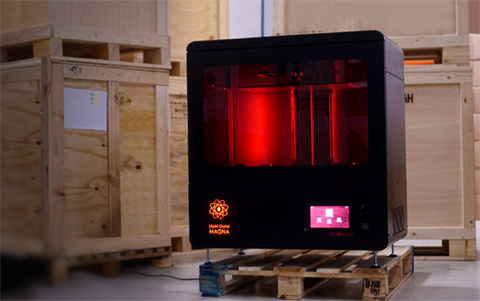

SouSmile is Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, they invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce their dental aligners in scale.

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser.

As an homage to this classic game, 3D w praktyce were tasked with creating a short stop-frame animation. For this animation, a 3D print-ready file of the character Rockford was created using Photocentric Studio which was then printed on the LC Magna.

Discover how military collectable manufacturer Staples & Vine overcame production challenges with the adoption of Photocentric’s 3D printing processes.

The powerful alliance of Xkelet and Photocentric has created a new solution to traditional orthotics; a digital 3D printed splint that provides significant benefits over traditional methods and is revolutionising the treatment of damaged bones.

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

The only 3D printer that can deliver significant speed, volume and cost savings to your business today. The evolution of LC Magna continues with a host of new features added. We invented 3D LCD printing and the LC Magna 3D printer continues to represent the pinnacle of our product development. With 1,000’s successfully deployed around the world get in touch today to see how Magna can transform your business.

By working together with Photocentric and their LC Magna 3D printer we want to continue to push the boundaries in investment casting to make the impossible, possible for our customers, and their customers’.

We now have a solid and reliable way of turning our products into reality thanks to our collaboration with Photocentric and their unique LC Magna 3D printer technology. Our business is built on helping people and that’s exactly what our partnership enables us to do. We can now provide an advanced 3D printed solution to traditional orthotics globally, at a cost and speed unknown before.

We have recently tested 3D prints produced by the Photocentric Magna and were thoroughly impressed with their accuracy and quality, when measured against our standard calibration models. The Magna models ranked very high amongst all printed 3D arches we have ever experimented with.

Photocentric have spent 1000’s of hours developing proprietary technologies that enable consistent, high-quality prints to be produced at scale. Blow-Peel is a patented technology that features in our LC Magna.

Jointly developed by Photocentric and CoreTechnologie, the innovative Photocentric Additive software suite has been specifically created for the LC Magna.

Photocentric has launched its Liquid Crystal Magna v.2, with a completely re-engineered LCD screen, designed to take its capabilities for additive manufacturing to the next level.

Photocentric says that the Magna v.2 delivers significantly faster print speeds, boosts productivity rates and reduces waste, making it more appealing for producing end-use parts at scale at a low cost per unit.

“Magna is the jewel in the crown of Photocentric, and we’re thrilled to launch this new model which builds on the solid foundations of its predecessor,” said Photocentric sales director Sally Tipping.

Featuring a 700 x 395 x 1200 mm build volume and an 8K 7660 x 4320 pixel display, the LC Titan is the largest, most powerful Photocentric unit to date. These beefed-up specifications enable the firm’s latest system to 3D print polymer parts at a speed of up to 16 mm per hour, with automotive, transport, creative arts and merchandising applications.

Established in 2002, Photocentric has spent the last two decades progressively developing and wielding its photopolymer expertise to advance the manufacture of plastic parts. The firm’s 3D printer R&D really took off in 2014, when it received Innovate UK funding to develop a new LCD system. Since then, Photocentric has patented its technology and moved into a new 35,000 sq. ft facility.

In 2015, the company went on to launch its debut system, the Liquid Crystal, before introducing the larger-format LC Maximus. Up until the release of the LC Titan, the latter, which shipped with a 40” 4K LCD screen and enabled the mass-production of parts, was Photocentric’s largest machine to date. That said, the photopolymer specialist’s offering hasn’t always prioritized capacity.

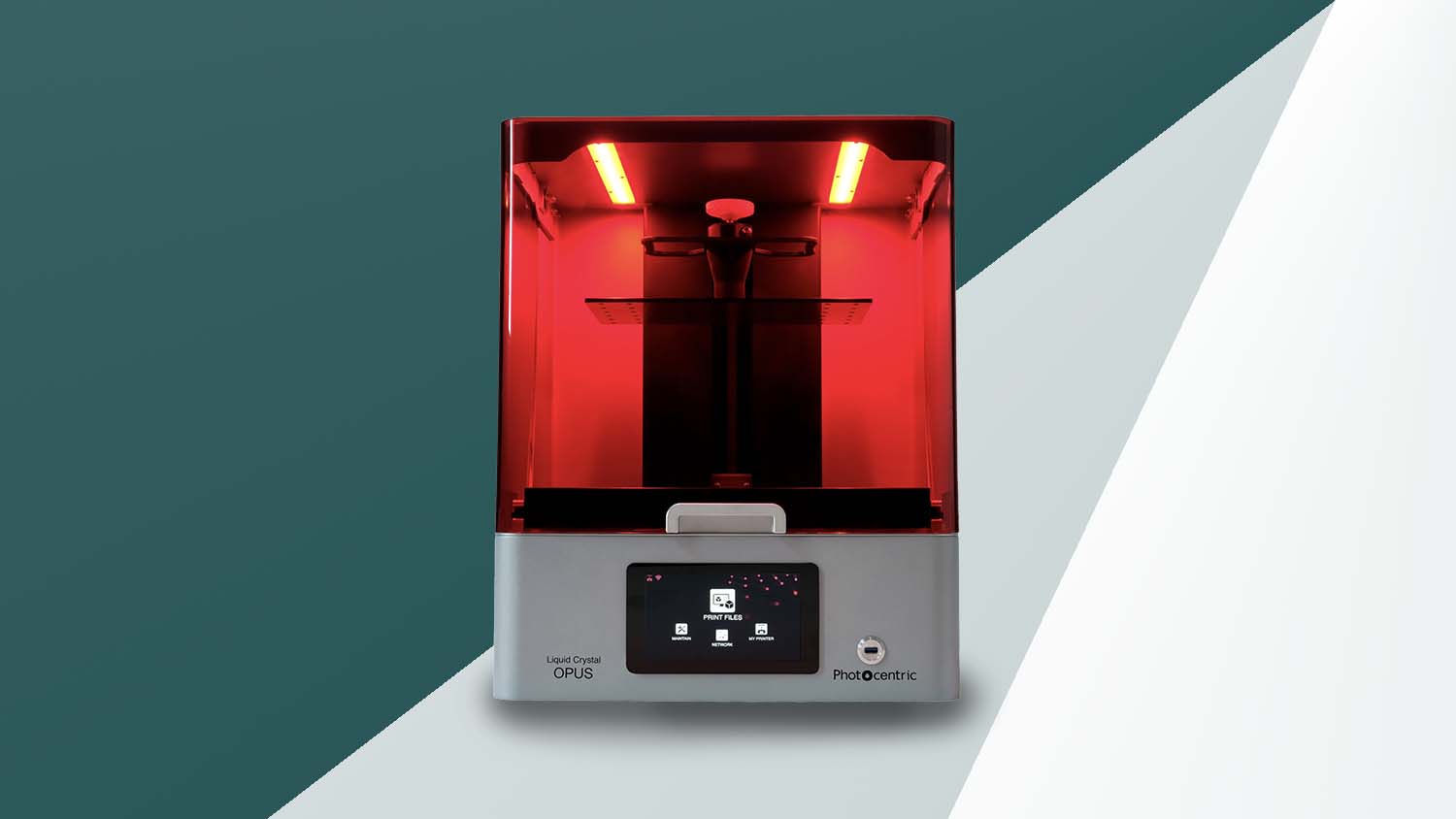

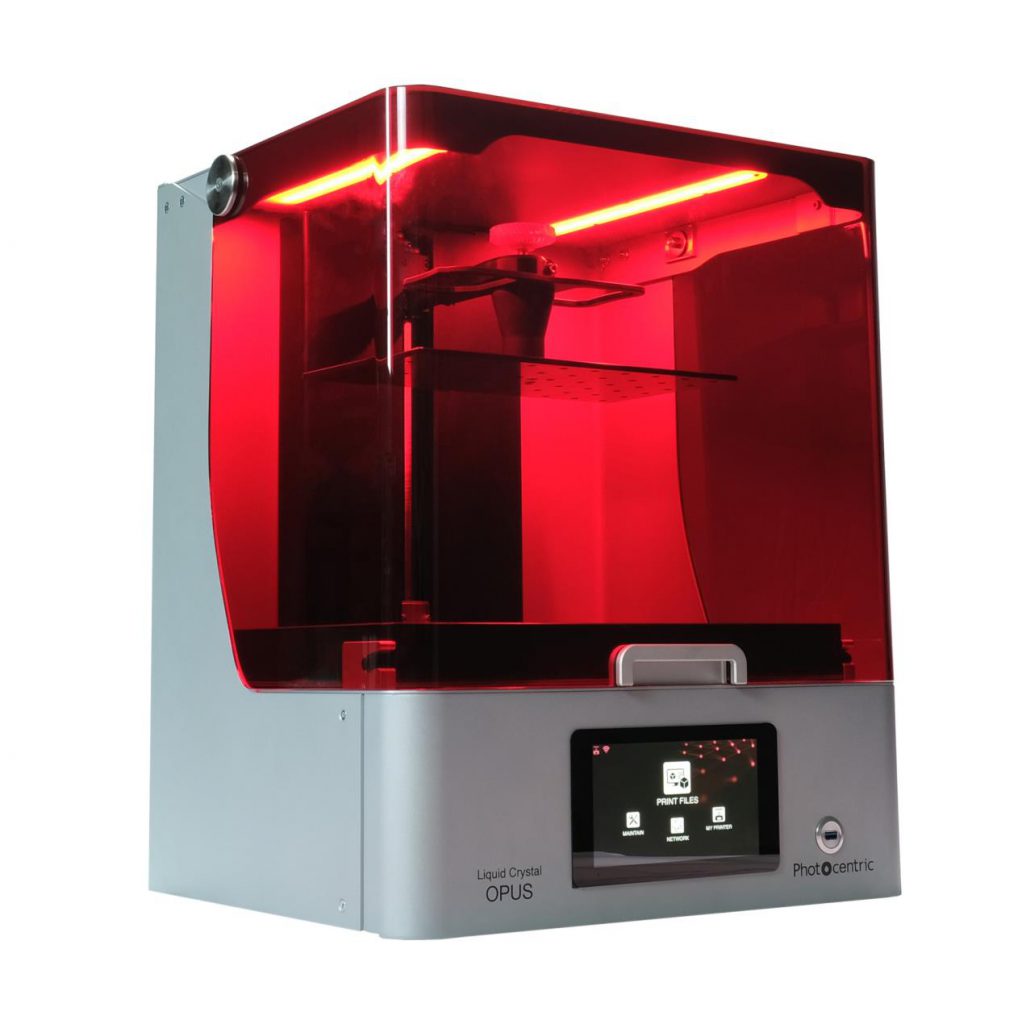

The LC Opus, for instance, has a print speed of 18 mm per hour, meaning that despite its smaller 310 x 174 x 220 mm build volume, it remains Photocentric’s fastest machine. As such, the system is said to be ideal for those operating in dental labs or engineering workshops seeking a rapid, reliable and compact production tool.

Debuted in prototype form at this year’s Formnext, the LC Titan represents a significant upgrade on Photocentric’s recently-upgraded LC Magna system. Although the machines feature the same light output of 2MW per cm2 at 460nm and resulting print speed, the LC Titan packs a larger build volume and more powerful LCD display.

While other details about Photocentric’s latest offering remain thin on the ground, the firm has revealed that it is set to ship with a high-performance integrated control software. The system also comes fitted with a resin autofill system, designed to help users automate and accelerate their 3D printing workflow, and a peel release technology that makes it easier for users to remove parts once processed.

Alongside the LC Titan, Photocentric showcased a range of exhibits 3D printed at its purpose-built print farm in Peterborough. These included parts manufactured from alumina, a versatile ceramic with the ductility, as well as the chemical and thermal properties, needed to lend it aerospace, medical, automotive, chemical and electronics applications.

Working with the Centre of AM Excellence or ‘AM-COE,’ the firm has also started offering to mass produce 3D printed silica cores with improved performance compared to their injection molded counterparts, for high-value customers. Turbine blades produced through this partnership were displayed at Photocentric’s booth, as were aligners 3D printed by S4S Dental and casts created by Xkelet.

“We are thrilled to be back at Formnext bringing our latest advancements on materials, hardware and control software to scale up additive manufacturing processes through automation and enable customers to run production parts in our 66,000 sqft digital factory,” Photocentric CEO Paul Holt said ahead of the show. “On display there will be an array of parts with textures and finishes that we manufacture using [our] combined technologies.”

Below are the technical specifications for Photocentric’s new LC Titan 3D printer, which will be available for purchase from 2023. Prospective customers can request a quote from Photocentric directly.

Britain-based 3D printer and materials producer Photocentric has just unveiled their plans to release the largest LCD 3D printer on the planet. Aside from its size, it is also capable of mass production volumes and large-scale prototyping. Photocentric have been producing light curing LCD screen technology and resins but the LC Maximus is their largest project yet. The company is looking to release it in the second quarter of 2019.

“LCD screen-based 3D printers have been the fastest growing area in 3D resin printing; this machine cements our position as the leading innovator in this exciting sector.” Explained Sally Tipping, Sales Director at Photocentric.

The printer will boast a 700 x 893 x 510 mm build size and 4K 40” LCD screen. It will cure each individual layer at intervals of 15 seconds with XY resolution of 230 microns. For contrast, their previous largest printer was 82 x 49 x 74 cm with 23.8” LCD. Unlike SLA and DLP, the company uses LCDs derived from phones, tablets and televisions. While the LCDs are quite ordinary, it’s the resin that has the high reactivity to photo-stimuli. It also allows them to make the printers on a far cheaper scale.

LCD-based printing works with the same basic principles as DLP and SLA, just with different hardware setups. The process is actually called Daylight Polymer Printing. It uses a low energy light source to polymerize liquid resins and form objects. In contrast, DLP and SLA high-intensity UV laser or a light projectors. The use of LCD screens also means that DPP uses very specific “daylight” resins that harden in contact with LCD light.

The company has also announced a partnership with BASF, one of the largest chemical producers in the world. The collaboration may just give the company an edge over its competitors in terms of producing mass production polymers for 3D printing. Since Photocentric also distribute resins, this could also be a great way to expand their own portfolio of items.

For Photocentric, 2019 is shaping up to be a momentous year in which it introduces a number of disruptive, game changing LCD 3D printers, resins and chemicals to various markets

The last 18 months have been a particularly productive period of time for international 3D printer manufacturers Photocentric. “We have been incredibly busy in recent times, during which we have developed a number of new printers,” begins Managing Director,

For Paul and the rest of the Photocentric team, the first half of 2019 has been very much about laying the groundwork for the launch of its new printers, starting with the LC Magna, for

“Its combination of large build volume and accurate printing make it the right tool for mass manufacture. The build volume is 510mm x 280mm x 350mm and it operates with a 4K Ultra HD screen, giving it unparalleled precision and detail when creating high resolution mass manufactured parts. LC Magna’s large build volume capabilities and maximised build plate capacity allows users to increase throughput, speed up assembly production and reduce lead times. Therefore, a glasses manufacturer – for instance – can now produce 36 optical frames within 12 hours, while a dental technician can print 46 flat arches in just over two hours. Magna is our first release of our next generation of LCD printers, we will be releasing our next additions later in 2019.”

Another recent highlight for the company was its success at the 3D Printing Industry Awards in early June 2019, when it was presented with the ‘Best Desktop Printer of the Year’ prize as a mark of recognition for its previous LCD printer innovation – the Liquid Crystal (LC) Precision 1.5. “This was a credible sign of the hard work and dedication that everyone at Photocentric pours into our unique method of LCD printing,” Paul states. “It is exciting as it gives a glimpse into what the future may hold for us as we start to release our next generation of LCD 3D printers that will revolutionise the additive manufacturing industry.”

As Paul goes on to detail, there is a vast array of wonderful examples of LCD technology being used in proactive industries today. “An example of this would be Quimbaya Orfebreria, an Argentinian goldsmith,” he says. “In the face of some difficulties arising from product demand outweighing supply, it made the decision to replace traditional methods with 3D printing by making use of the LC Precision 1.5. As a result of this, the company’s manufacturing time was reduced by 80 per cent, production was increased by 400 per cent, and it is now able to produce more intricate and complex designs for its clients.”

As a chemical manufacturer, as well as an LCD printer manufacturer, Photocentric has a host of exciting new products in the pipeline for release later in 2019. These include, a high temperature resin, which has been tested to 300 degrees centigrade, as well as a new grade of stronger, more flexible resin. Furthermore, having witnessed first-hand the demand for LCD 3D printing at the 2019 International Dental Show, the company will be releasing its first targeted dental printer – Liquid Crystal Dental – this year.

“Quarter four of 2019, meanwhile, will see the release of something huge, that being the Liquid Crystal (LC) Max,” Paul reveals. “This will be the largest LCD printer to ever become available! It uses a 4K 40” LCD screen and offers a massive build volume of 700mm x 893mm x 510mm, and for prints like large automotive parts, furniture, sporting goods or even full scale body mannequins, LC Max is the printer of choice for extra-large requirements.”

Earlier, Paul made mention of Photocentric working closely with BASF, and partnerships such as this will form a key part of the future growth aims of the company. “In the case of BASF, our partnership focuses on establishing and expanding the 3D printing business with materials, system solutions, components and services,” he adds. “This cooperation offers solutions to industries that enable processes to be made using additive manufacturing to replace traditional tooling methods, and creates flexibility of geometry, absence of tooling costs and custom design.

“At the same time, we are developing our partner network to springboard into the US and Asian markets, and are working ever-more closely with large industrial OEMs and with our distribution partners around the world to offer solutions to real applications. The key to growth will be proving that we have the printers and materials that the market needs. There are many additive manufacturing technologies available now, but few that offer affordable, large scale printing, and the opportunity to work closely with the manufacturer to develop the right materials for specific applications, which Photocentric can do!”

Photocentric, inventor of LCD 3D printing, will showcase its latest additive manufacturing technologies at RAPID+TCT, 17-19 May at Huntington Place, Michigan.

On show at Booth 3035 will be Photocentric Additive software developed with CoreTechnologie, LC Magna and LC Opus printers, as well as a host of printed parts on display showcasing the array of textures and finishes that can be produced using the technologies.

The combined benefits of software and hardware exhibited will illustrate how Photocentric is focusing on creating the digital factories of the future.

“We’re delighted to be at RAPID+TCT to demonstrate how our solutions can deliver speed, volume, and cost savings to help manufacturers to beat their competitors,” says Paul Anfinson, CEO, Photocentric Inc. “We’re going to be joined at this year’s show by our partners from CoreTechnologie who helped us develop the Photocentric Additive software solution. Our customers that have been using this software have been really impressed by its functionality and processing speed. In addition to the thousands of textures immediately available, users can add their own customised finishes, or even rid layer lines to save on additional finishing costs. This technology is unrivalled in large format LCD printing and makes for an unbeatable package. We continue to deliver innovation to our partners thanks to our sustained investment in research and development and we’re excited at the prospect of meeting old and new customers in Detroit.”

Photocentric Additive software is designed for use in a large array of applications including automotive, wearables, consumer electronics, and more. Additive supports lattice structures and creates new possibilities for the design community with a host of customisation options. Visitors will also be able to see Photocentric LC Magna, which delivers an effective large-scale additive manufacturing solution with an impressive build volume.

Also on show, the Photocentric LC Opus is a UV open-source 3D Printer which allows freedom of material choice whilst delivering fast and accurate prints.

Photocentric is the inventor of LCD-based 3D printing, and an award-winning specialist resin and LCD printer manufacturer based in Cambridgeshire, UK and Arizona, USA.

Building on its vision of enabling custom mass manufacture with its innovative 3D printing technologies using LCD screens, Photocentric’s large format LCD printer range includes Liquid Crystal Magna, which delivers significant speed, volume and cost savings to business around the world in a range of industries.

Photocentric is a patent holder in visible light curing technologies and specialises in photopolymerisation, manufacturing an innovative range of photopolymer resins compatible with any printer operating from 355nm to 460nm.

Photocentric, the inventor of LCD 3D printing, has launched Liquid Crystal Magna v.2, a completely re-engineered LCD screen-based printer designed to take additive manufacturing to the next level. The LC Magna v.2 delivers significantly faster print speeds, boosts productivity rates, and reduces waste. Versatile and rugged, this brand-new Magna is well suited to small batch, on-demand, or full production applications, and consistently delivers accurate end-use parts at scale at a very low cost per unit.

“Magna is the jewel in the crown of Photocentric, and we’re thrilled to launch this new model which builds on the solid foundations of its predecessor,” says Sally Tipping, sales director, Photocentric. “The product development team has maintained everything that has made the LC Magna so popular with our customers – including its impressive build volume – whilst adding a range of features that have boosted print speeds, further improved reliability and substantially increased processing power. We are tremendously excited about the possibilities of the new Magna and can’t wait to see what our customers do with it.”

Photocentric is the inventor of LCD-based 3D printing, and an award-winning specialist resin and LCD printer manufacturer based in Cambridgeshire, UK and Arizona, USA.

Building on its vision of enabling custom mass manufacture with its innovative 3D printing technologies using LCD screens, Photocentric’s large format LCD printer range includes Liquid Crystal Magna, which delivers significant speed, volume, and cost savings to business around the world in a range of industries.

Photocentric is a patent holder in visible light curing technologies and specializes in photopolymerisation, manufacturing an innovative range of photopolymer resins compatible with any printer operating from 355nm to 460nm.

Some of the parts on display on Photocentric’s booth at Formnext have been produced in the largest Photocentric 3D printer to date, Titan; a prototype with a 700 x 395 x 1,200 mm build volume, a 8K 32” LCD screen, a fast 16 mm/h and a 91 µm pixel pitch resolution. This combination of size, high resolution, print speed and accuracy makes large scale production a reality for additive manufacturing applications in automotive, transport, creative arts and merchandising.

Paul Holt, Founder of Photocentric said: “This year, we are co-exhibiting with software partner Core Technologie; jointly, we have developed Photocentric Additive software for our Liquid Crystal 3D printers. On display there will be an array of parts with textures and finishes that we manufacture using the combined technologies.”

Photocentric is delivering ceramic production parts in Alumina and Silica benefiting from extensive years of experience in photopolymer and LCD-based large-scale manufacturing to mass manufacture Alumina parts. Alumina is a great versatile ceramic showing superior electronic, chemical and thermal properties and customers use it in advanced applications such as aerospace, medical, automotive, chemical and electronic industries.

Dental labs have adopted Photocentric’s latest plant-based resins and processes to use more sustainable materials and less energy. The results are cost-effective production runs and affordable patient care. At Formnext, Photocentric will be displaying dental models made in several materials and optimised for various 3D printers.

Photocentric has partnered with Loctite and BASF Forward AM to develop and validate high-performance engineering-grade resins for industrial applications. On show there will be parts with remarkable properties such as high elongation, high rebound and high impact absorption.

Aerospace turbine blade ceramic cores printed by AM-COE, Automotive vents printed by 3D Next Level, aligners and mouthguards printed by S4S Dental, immobiliser casts printed by Xkelet are some of the 3D prints to be exhibited at Photocentric stand.

Integral to the printer is the visible light illuminating ultra high resolution LCD panel used to create the parts. The 5.5″ display offers a 2K resolution to building faithful representations of your 3D models.

An upgraded, maintenance free drive unit features in the Photocentric Liquid Crystal Precision 1.5. The unit enables increased accuracy over the height of the printer offering increased reliability to print both large solid parts and small intricate details.

The printer is controlled with a full set of top of the range electronics, ensuring full quality control and long lasting reliability. With continuous development Photocentric offer the best control for all aspects of the printing process.

This invention relates to three-dimensional (3D) printers used to make a 3D object and in particular 3D printers where the method of forming the 3D printed object is by selectively hardening liquid photopolymer by electromagnetic radiation emitted through liquid crystal display (LCD) screens.

Traditionally photopolymer was selectively hardened by light emitted from a laser or by focusing the light from a digital light processing (DLP) projector emitted through its digital mirror device onto either the upper or lower layer of resin in a vat. This invention, however, relates to the field of 3D printing where the image source is a visual display screen, specifically an LCD screen.

LCD screen based 3D printers have recently become widely manufactured typically incorporating the LCD screen from mobile phones as the digital mask to deliver custom polymerisation. LCD screens are particularly attractive for digital image creation in 3D printers because they are mass manufactured consumer items and are therefore available at very low cost. Furthermore, they generate very high-resolution images driven by the demand for higher and higher quality images for human viewing. They expose an entire layer of the vat simultaneously with relatively even light distribution without any requirement to refocus the light through a lens. They are available in a wide variety of formats from the very small screens used in near-eye headsets, mobiles, tablets, monitors and large format TV screens. Furthermore, the LCD screens, and the printers that contain them, are simpler to manufacture than competitive technologies. In the case of a laser based 3D printer, complex electronics and galvanometers are required and in the case of a DLP printer, a lens is required to refocus the widening light beam back onto a smaller area. In contrast, visual display screen device based 3D printers are effectively composed of an electronic driver board, a linear drive, a resin containment vat, a visual display screen and optionally a modified light generation source.

The image in LCD based 3D printers is created by pixels with the colour of light usually being created by combining the separate light emitted from the screen"s sub-pixels, typically, but not exclusively, by simultaneously opening the blue, green and red sub-pixels to create polymerisation. As polymerization in 3D printers is a binary process, in that you can either create light polymerization or not, LCD screen based printers are usually arranged to deliver a monochromatic image, most commonly white or blue light to create polymerization and no light to prevent it.

As most photopolymers used in these types of LCD based printers incorporate photoinitiators that are active in the near-UV region or blue light visible, it is the blue sub-pixel that creates nearly all or all of the polymerization, with the green (if illuminated) providing a smaller usable amount and the red sub-pixel providing almost no useful energy. Thus, the light emitted through the LCD screen that can create polymerization is effectively emitted through only one third of the available area of a pixel. Therefore to achieve polymerization that hardens and joins the resin above two neighbouring pixels the exposure time must be extended to allow the blue light to widen laterally to harden the liquid above the green and red sub-pixels.

There have been numerous different approaches to improving the image in LCD or digital micro-mirror device based 3D printers with the intention of delivering resolutions at greater than pixel size.

US 2017/0102679 to Greene et al, herein incorporated by reference in its entirety, describes methods for improving image in LCD or DLP based printers by delivering a greyscale image to voxels via the sub-pixels.

US 2017/0031207 to Li, herein incorporated by reference in its entirety, describes methods for improving the image in LCD based 3D printers by using monochrome light through the sub-pixels.

CN106903877A, herein incorporated by reference in its entirety, describes methods for delivering a greyscale image via the red, green and blue sub-pixels in LCD screen based 3D printera.

In an aspect, a stereolithographic 3D printer comprises a liquid crystal display (LCD) screen comprising a plurality of pixels, each pixel comprising a plurality of sub-pixels; a 3D printing apparatus; a memory configured to store data representing a 3D object; and a processor configured to: divide the 3D object represented by the data into a plurality of slices, map each slice of the 3D object to a pixel layout of the LCD screen, determine a proportion of each pixel that is contained within each slice of the 3D object, assign illumination values to the sub-pixels of each pixel based on the determined proportion for the respective pixel for each slice, and control both the LCD screen in accordance with the assigned illumination values, and the 3D printing apparatus to print the 3D object.

In some embodiments, the 3D printing apparatus comprises a liquid photopolymer vat; a build platform having a build surface; and an actuator that varies a separation distance between the build surface and the LCD screen.

In another aspect, a method of controlling a stereolithographic 3D printer having a liquid crystal display (LCD) screen comprises dividing a 3D object represented by a data file into a plurality of slices; mapping each slice of the 3D object to a pixel layout of the LCD screen, the LCD screen comprising a plurality of pixels, with each pixel comprising a plurality of sub-pixels; determining a proportion of each pixel that is contained within each slice of the 3D object; assigning illumination values to the sub-pixels of each pixel based on the determined proportion for the respective pixel for each slice; and controlling illumination of the LCD screen in accordance with the assigned illumination values.

In some cases, the method further comprises printing the 3D object. In some cases, the method further comprises plotting the 3D object into a 3D space associated with the LCD screen in the 3D printer; and increasing the effective resolution of one or more axis of the 3D space by assigning new data points to separate the pixels into the plurality of sub-pixels.

In some instances, increasing the effective resolution of the 3D space comprises determining a sub-pixel layout within the LCD screen used in 3D printer; determining a factor by which the amount of data points will be increased; and increasing the effective resolution of the 3D space by generating the sub-pixels.

In some embodiments, merging new data points into the mapped pixel layout comprises: a. determining a point of origin from where the process will begin; b. determining the sub-pixel layout within the LCD panel used in the 3D; c. determining a factor by which the amount of data points will be reduced; and d. merging the new data points into the mapped pixel layout used by the LCD screen.

In some cases, the method comprises adjusting the one or more of the sub-pixel hex values based on a reactivity of a photopolymer resin. Furthermore, in some instances, the method comprises adjusting the one or more sub-pixel hex values based on an unevenness of light transmitted through the LCD screen.

mapping each two-dimensional slice onto a two-dimensional grid of pixels associated with an LCD screen of a 3D printer, each pixel comprising three sub-pixels; identifying perimeter pixels corresponding to a perimeter of each two-dimensional slice; assigning a first value to sub-pixels of each perimeter pixel that are within the perimeter and a second value to sub-pixels of each perimeter pixel outside the perimeter; and selectively illuminating sub-pixels having the first value at a higher intensity than sub-pixels having the second value. In some cases the method further comprising printing the 3D object.

In some embodiments, the method further comprises adjusting the first value based on the reactivity of the photopolymer resin. Furthermore, in some cases the method comprises adjusting the first value based on an unevenness of light transmitted from the LCD screen.

This invention describes novel methods relating to the separate control of the sub-pixels in an LCD based 3D printer to deliver enhanced resolution by more accurate control of the illumination. More specifically it relates to the independent control of the sub-pixels in monochrome LCD screens. The method of making an object in an LCD based 3D printer includes obtaining an object that describes a 3D structure; creating more than one slice, typically of the same thickness, and creating a file to transfer to the sliced image to the screen. The resolution of the image is defined principally by the accuracy of the representation of the perimeter of each layer, or practically how accurately the pixels or sub-pixels are illuminated to conform to the desired curve of the perimeter with the emitted light being capable of hardening the polymer just above or below it.

It is an object of this invention to assign different intensity levels to the sub-pixels in monochrome LCD screens, utilizing an algorithm to do the calculations that will allow separate control of the three sub-pixels. This will in effect extend the two-dimensional effective resolution in one or more axis by a factor of up to three times.

The implementation of the algorithm can be incorporated into a software system, 3D printing apparatus or associated computer programs. The implementation can include sending the one or more graphic files directly to the LCD screen in the printer or sending one or more graphic files to the 3D printer"s computer where the methods claimed can be performed. The implementation involves determining whether the pixels at the perimeter should be extended, ie an additional part of the adjoining pixel is given a high hex value or if the pixels at the perimeter should be constrained, i.e. an existing part of the pixel should be given a low hex value. The implementation involves determining whether the extended pixel should have high or low hex value depending on the desired amount of it is within the contained area.

Mapping the 3D object into the three-dimensional space can include slicing the 3D object into two-dimensional slices and mapping each slice onto a two-dimensional grid of pixels. In this implementation the individual pixels are sliced to form one or more pixels. Determining the one or more containment degrees can include determining a number of data points within a pixel of the one or more pixels that are at least partially contained by the 3D object and determining a number of second points within the pixel that are not contained by the 3D object. Some implementations can include adjusting the one or more low hex value intensity levels based on the rate of cure for given light intensities of the photopolymer. Implementations can include scaling the 3D object based on a scaling factor to account for shrinkage. Implementations can include extending the resolution in one or more axis based on a factor that is dependent on the LCD panel technology. Mapping the 3D object can include slicing the scaled 3D object.

The system can include a computer processor configured to perform operations together with a memory that can store a 3D object that describes a 3D structure. The operations can include mapping the 3D object into a 3D space that conforms to the LCD screen size; calculating and extending the effective resolution of this 2D image in one or more axes by a factor dependent on the number of sub-pixels in the LCD panel used in 3D printer. It can include determining one or more extended pixels that are fully contained within the object and assigning a high hex value (max: 255) to them and assigning a low hex value (min: 0) to constrained pixels which are outside 3D object or aren"t fully contained. The low hex value must be sufficient to prevent polymerization and the high hex vale must be large enough to enable polymerisation after a predetermined curing time which is specific to the 3D printer. It can include grouping or merging the extended or constrained pixels into the original resolution starting from any point on one or more of the extended axes. By this process each extended pixel or constrained is the equivalent of one subpixel value in the original resolution.

The 3D printer can include a vat capable of holding photopolymer resin, wherein the vat includes a transparent film; a build plate configured and arranged to move within the vat during three-dimensional printing of a structure on the build plate; a backlight unit to project light through the LCD panel; and an electronic controller to manage the printing process. The controller can be configured to perform operations that include mapping a 3D object into a three-dimensional space; generating one or more graphic files based on assigned intensity levels, utilizing an algorithm to do the essential calculations, extending the effective 2D image resolution in one or more axes by a factor dependent on the number of sub-pixels in the the LCD panel used in 3D printer, determining one or more extended pixels that are fully contained within the object and assigning a high hex value (max: 255) them while assigning a low hex value (min: 0) to constrained pixels which are outside 3D object or aren"t fully contained and grouping and merging extended pixels into the original resolution on one or more extended axes.

FIG. 1 shows an example of a 3D printing system connected to a computer which provides information about a 3D structure to the 3D printing system for printing. The computer communicates with a controller of the printing system, the controller having an integrated circuit board with firmware to control the various system components such as the linear drive and backlight unit (104) for the LCD panel (102). The system includes a vat to hold the photopolymer (105) a light transmitting membrane to protect the screen (106) to build the 3D object (103) on the build platform (101). This process shown is known as bottom-up, the reverse procedure known as top-down can also be used. The base of the vat is typically made of a low surface energy high light transmission film, such as fluorinated ethylene propylene (FEP), perfluoroalkoxy copolymer (PFA) or polymethylpentene (PMP), but also can be made of a silicone such as polydimethylsiloxane (PDMS). The light emitted from the backlight will have a wavelength which can initiate the photoinitator incorporated in the photopolymer to create free-radicals or cations from photons and enable polymerisation. The build plate can start at a position near the bottom or top of the vat and selective images of the light are displayed through the LCD panel to create solid layers of the desired structure as the build plate is sequentially moved away from the LCD screen. This system may also include specific adaptions to enable peel and easy removal at the build interface. The light transmitting panel can be configured to allow selective light to pass through the LCD array of pixels, each one comprising of sub-pixels. In some implementations the backlight can unmodified from that supplied with the visual display device, or alternatively it can be a single light emitting diode (LED) positioned a distance away from the LCD panel, or alternatively it can be an array of LEDs with individual lenses or can be a set of lasers with lenses or alternatively any method of illumination that delivers collimated or near-collimated light.

The 3D printing program, the controller, or both can apply sub-pixel color rendering techniques to smooth out the perimeter of each layer of the structure. The sub-pixel color rendering technique can assign light intensity levels based on a sub-pixel containment. The light intensity levels can include a high level for 100% containment (hex value of 255), a black level for 0% containment (hex value of 0), and multiple colors there between 0 and 255 for partial containment within a 3D object. The partial containment values can be computed based on the geometry of the 3D object and the resolution of the screen. Based on the output of the sub-pixel color rendering technique, the 3D printing program, the controller, or both can output the graphic files that represent the desired selective display of light to be passed through the LCD panel to create each layer of the 3D object.

FIG. 4 shows an example of a cross section of a digital object which contains a pixel grid ready to be displayed on the LCD panel. The 3D object is plotted onto an expanded grid of pixels and has all of its addressable elements with assigned values. Starting from any point on one or more extended axis, the resolution is then divided by the same factor by which it was previously expanded. In FIG. 4 the resolution on the x-axis has been merged, generating one pixel containing three sub-pixels, each containing different hex values. This sub-pixel color rendering technique generates 2D graphics files which include a grid of pixels rendered to a specific resolution and pixel pitch to match that of the LCD panel used in the 3D printer. Pixels that are partially contained within a 3D object have different color hex code applied to each individual sub-pixel. One or more sub-pixels within a partially contained pixel which are outside the digital object can have their hex value set to a low number (minimum hex value is 0), therefore blocking the light passing through the LCD panel. One or more sub-pixels, within a partially contained pixel, which are fully contained within a digital object can have their hex value set to high number (maximum hex value is 255).

FIG. 6 shows a flowchart of an example of this sub-pixel rendering technique that can transform a digital object into a graphic data suitable for displaying on a 3D printer and enhance its resolution in the process. A device such as a printer controller or a computer can perform this process. The process obtains a digital object that describes a 3D structure, which can include accessing a file that defines the meshes that cover the surface of the structure. The file can be in a format such as Stereolithography (stl) file format or Polygon File Format (ply), other types of file formats are also possible. The process maps each slice of the 3D object onto an area that is associated with the LCD screen of the 3D printer. Mapping the 3D object can include identifying pixels that are fully contained within the 3D object, pixels that are partially contained within the 3D object and pixels that are outside the 3D object. In some implementations, the process can receive one or more parameters that describe the capabilities of the 3D printer such as the LCD resolution in the x, y and z dimensions and the maximum sizes for each dimension. The process can use these parameters to determine the number and shape of the revised pixels in the grid.

The process will increase the effective resolution of the 2D space in one or more axes. The process generates new data points to separate the sub-pixels into new addressable elements. The 3D object size is then extended by a factor that is the number of sub-pixels in a pixel. The process determines one or more increased resolution pixels that are fully contained within the 3D object and assigns a high hex value (max: 255); determines one or more pixels which are outside 3D object or aren"t fully contained and assigns a low hex value (min: 0). The process then divides the pixels into groups starting from any point of origin using the same factor value used to increase the number of addressable elements. In each group the pixels will have their own value assigned. Each group will then be merged back to the original resolution where with each pixel containing multiple sub-pixels. The sub-pixels have their own values assigned and each merged pixel will contain multiple hex values which represent color codes. Typically, LCD panel pixels consist of three sub-pixels, commonly red, green and blue. Monochrome screens can be created by not applying or removing the colour filters, commonly red, green and blue light-transmitting filters. These sub-pixel light intensity levels can be represented as 8-bit values that range from 0 (black) to 255 (white).

The process in this invention sends one or more graphic files to the 3D printer. In some implementations, sending the one or more graphic files can include transmitting data via a network connection or a Universal Serial Bus (USB). The 3D printer can receive the 3D object, perform the process outlined in FIG. 6 and send the contents of the one or more graphic files to the LCD panel within the 3D printer. Sending the contents can include transmitting a sequence of bits over a serial bus between a controller and the LCD screen or alternatively sending the contents of the one or more graphic files to the 3D printer via a wireless connection or USB interface.

The 3D printer can include a vat capable of holding photopolymer, wherein the vat includes a transparent film base, a build plate configured to move within the vat during printing constructing the solid structure on the build plate, a light source to project light through the LCD panel and a controller to control the printing of the solid structure and to control the light between the light source and the film through individual pixels. The LCD panel can be configured to project the image of each layer for the length of time to enable polymerising of that layer, the light having a predetermined wavelength and an intensity that is sufficient to cure the photopolymer.

2. A 3D printer comprising a vat capable of holding a liquid comprising a photopolymer, wherein the vat includes a transparent film, a build plate configured and arranged to move within the vat during three-dimensional printing of a structure on the build plate, a backlight device to project light through a monochrome LCD panel and a controller to control the printing of the structure, movement of the build plate and timing of the light projection device, wherein the controller is configured to perform operations comprising: mapping a 3D object into a three-dimensional space; increasing the effective resolution of one or more axes of the three-dimensional space by assigning new data points to separate pixels into more addressable elements, specifically sub-pixels.

3. A method of paragraph 1 comprising obtaining by a data processing apparatus a 3D object that describes a three-dimensional structure; plotting by data processing apparatus that 3D object into a three-dimensional space associated with the LCD screen in the 3D printer;

7. A method of paragraph 3, wherein increasing the effective resolution of the three-dimensional space comprises: determining a sub-pixel layout within the LCD screen used in 3D printer;

11. A method of paragraph 3, comprising adjusting the one or more sub-pixel hex values based on the unevenness of the light transmitted through the LCD panel in the 3D printer.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey