photocentric lcd panel made in china

Photocentric has been working with Ukrainian aligner experts, Usmih, to help them develop an innovative aligner manufacturing process that pushes the boundaries of what 3D can offer the dental industry in both throughput and cost.

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

SouSmile is Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, they invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce their dental aligners in scale.

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser.

As an homage to this classic game, 3D w praktyce were tasked with creating a short stop-frame animation. For this animation, a 3D print-ready file of the character Rockford was created using Photocentric Studio which was then printed on the LC Magna.

Discover how military collectable manufacturer Staples & Vine overcame production challenges with the adoption of Photocentric’s 3D printing processes.

The powerful alliance of Xkelet and Photocentric has created a new solution to traditional orthotics; a digital 3D printed splint that provides significant benefits over traditional methods and is revolutionising the treatment of damaged bones.

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

LCD driven 3D printers have been the most significant invention in Additive Manufacturing in the last 7 years and have become the go to choice for high resolution, low price printing.

To appreciate the benefits of our patented LCD print technology we have summarised the differences between it and other stereolithographic (SLA) or vat polymerisation 3D printing methods

DLP projectors became a widely used alternative to lasers being able to cure a much larger area the size of a mobile phone screen at 2k and 4K resolutions. The bulb and Digital Mirror Device need replacing and calibrating. Even though it can cure an area larger than a laser beam, it cant match an LCD for resolution, reliability or cost.

The concept we invented. Using an LCD screen as a light source, an entire layer is encoded simultaneously, rather than small area by area. LCD printing benefits from one of the greatest technological advances of the last 50 years the use of visual display screens. It can produce much larger volumes than alternative methods, creating new products at rates previously unimaginable. The simplicity of the process is its strength, if using daylight as opposed to UV, the exposure is even and the machine stable for many years of use.

LCD driven 3D printers have been the most significant invention in Additive Manufacturing in the last 7 years and have become the go to choice for high resolution, low price printing.

To appreciate the benefits of our patented LCD print technology we have summarised the differences between it and other stereolithographic (SLA) or vat polymerisation 3D printing methods

DLP projectors became a widely used alternative to lasers being able to cure a much larger area the size of a mobile phone screen at 2k and 4K resolutions. The bulb and Digital Mirror Device need replacing and calibrating. Even though it can cure an area larger than a laser beam, it cant match an LCD for resolution, reliability or cost.

The concept we invented. Using an LCD screen as a light source, an entire layer is encoded simultaneously, rather than small area by area. LCD printing benefits from one of the greatest technological advances of the last 50 years the use of visual display screens. It can produce much larger volumes than alternative methods, creating new products at rates previously unimaginable. The simplicity of the process is its strength, if using daylight as opposed to UV, the exposure is even and the machine stable for many years of use.

With our earliest granted visible light patent using LCD screens stretching back to Jan 2005 and 22 granted patents and a further 20 pending all concerned in innovations in 3D printing using LCD screens, we are the undisputed innovators in both LCD 3D printing and visible light polymerisation.

We use both daylight and UV in our LCD screen printers, but we prefer using visible light as the rate of cure through depth is more even and the screen suffers no light degradation, so in practice the printer can last a lifetime.

With our earliest granted visible light patent using LCD screens stretching back to Jan 2005 and 22 granted patents and a further 20 pending all concerned in innovations in 3D printing using LCD screens, we are the undisputed innovators in both LCD 3D printing and visible light polymerisation.

We use both daylight and UV in our LCD screen printers, but we prefer using visible light as the rate of cure through depth is more even and the screen suffers no light degradation, so in practice the printer can last a lifetime.

Our printers use an array of LEDs as a light source, shining near parallel highly collimated light through the LCD panel and onto the resin layer. As an entire layer is exposed simultaneously it is highly efficient.

Photocentric printers create product using a “bottom-up” process, where the object being printed is pulled up layer by layer attached to the print platform, rising out of the resin bath. The process is repeated until the object is built.

Our printers use an array of LEDs as a light source, shining near parallel highly collimated light through the LCD panel and onto the resin layer. As an entire layer is exposed simultaneously it is highly efficient.

Photocentric printers create product using a “bottom-up” process, where the object being printed is pulled up layer by layer attached to the print platform, rising out of the resin bath. The process is repeated until the object is built.

LCD screens are the most cost effective and reliable visual display device on the planet which is constantly improving in resolution and lowering in price.

Featuring a 700 x 395 x 1200 mm build volume and an 8K 7660 x 4320 pixel display, the LC Titan is the largest, most powerful Photocentric unit to date. These beefed-up specifications enable the firm’s latest system to 3D print polymer parts at a speed of up to 16 mm per hour, with automotive, transport, creative arts and merchandising applications.

Established in 2002, Photocentric has spent the last two decades progressively developing and wielding its photopolymer expertise to advance the manufacture of plastic parts. The firm’s 3D printer R&D really took off in 2014, when it received Innovate UK funding to develop a new LCD system. Since then, Photocentric has patented its technology and moved into a new 35,000 sq. ft facility.

In 2015, the company went on to launch its debut system, the Liquid Crystal, before introducing the larger-format LC Maximus. Up until the release of the LC Titan, the latter, which shipped with a 40” 4K LCD screen and enabled the mass-production of parts, was Photocentric’s largest machine to date. That said, the photopolymer specialist’s offering hasn’t always prioritized capacity.

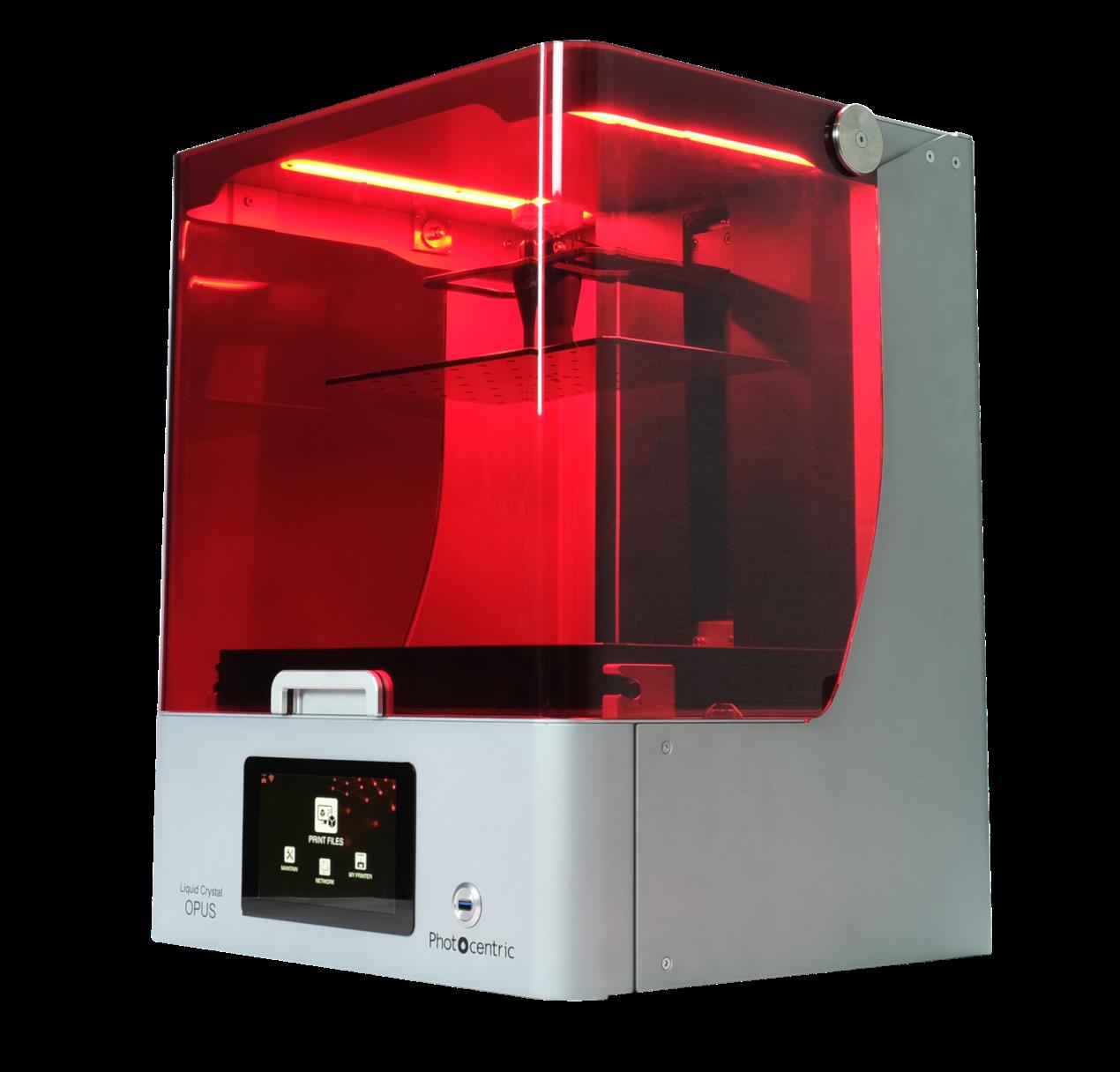

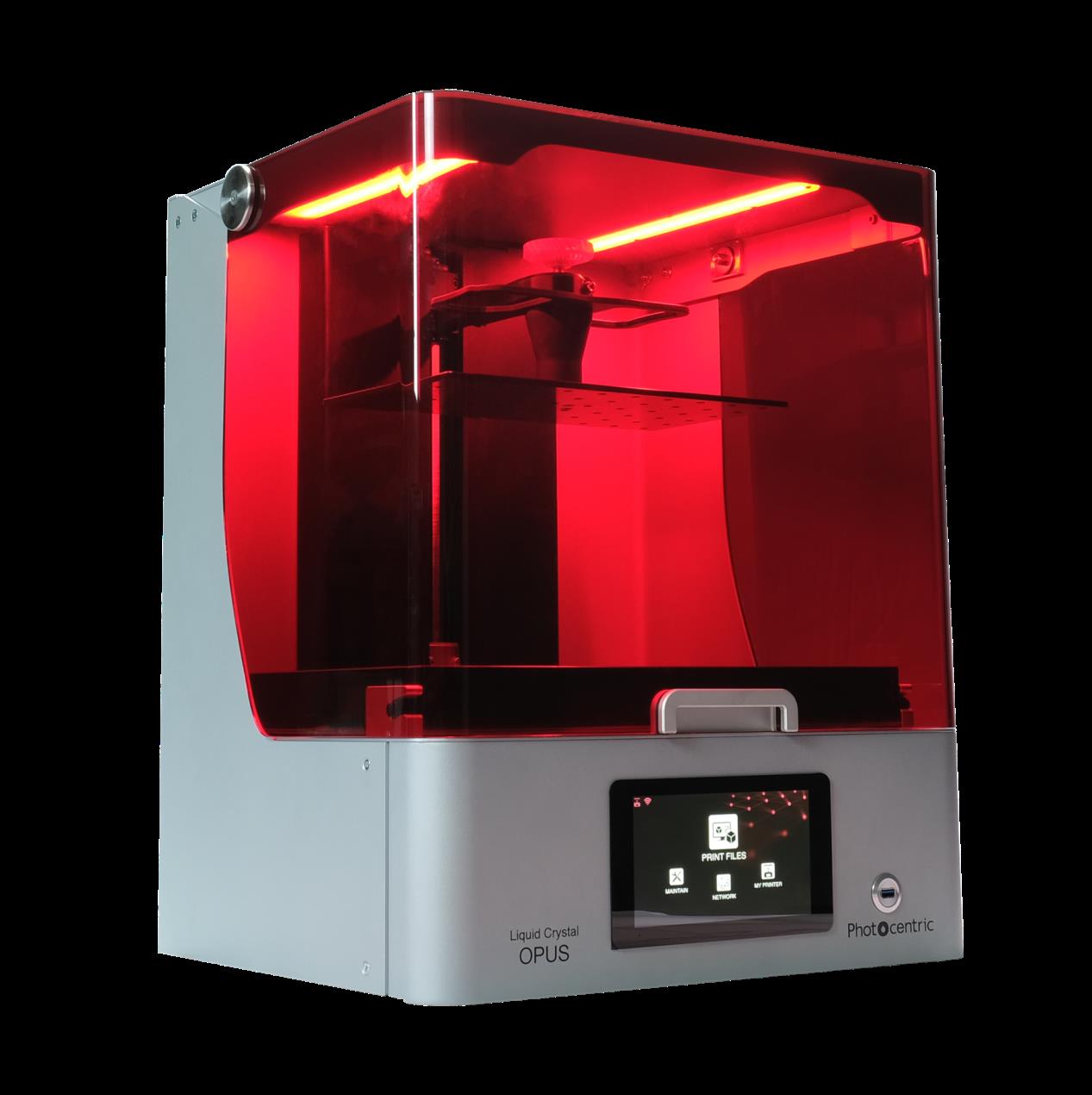

The LC Opus, for instance, has a print speed of 18 mm per hour, meaning that despite its smaller 310 x 174 x 220 mm build volume, it remains Photocentric’s fastest machine. As such, the system is said to be ideal for those operating in dental labs or engineering workshops seeking a rapid, reliable and compact production tool.

Debuted in prototype form at this year’s Formnext, the LC Titan represents a significant upgrade on Photocentric’s recently-upgraded LC Magna system. Although the machines feature the same light output of 2MW per cm2 at 460nm and resulting print speed, the LC Titan packs a larger build volume and more powerful LCD display.

While other details about Photocentric’s latest offering remain thin on the ground, the firm has revealed that it is set to ship with a high-performance integrated control software. The system also comes fitted with a resin autofill system, designed to help users automate and accelerate their 3D printing workflow, and a peel release technology that makes it easier for users to remove parts once processed.

Alongside the LC Titan, Photocentric showcased a range of exhibits 3D printed at its purpose-built print farm in Peterborough. These included parts manufactured from alumina, a versatile ceramic with the ductility, as well as the chemical and thermal properties, needed to lend it aerospace, medical, automotive, chemical and electronics applications.

Working with the Centre of AM Excellence or ‘AM-COE,’ the firm has also started offering to mass produce 3D printed silica cores with improved performance compared to their injection molded counterparts, for high-value customers. Turbine blades produced through this partnership were displayed at Photocentric’s booth, as were aligners 3D printed by S4S Dental and casts created by Xkelet.

“We are thrilled to be back at Formnext bringing our latest advancements on materials, hardware and control software to scale up additive manufacturing processes through automation and enable customers to run production parts in our 66,000 sqft digital factory,” Photocentric CEO Paul Holt said ahead of the show. “On display there will be an array of parts with textures and finishes that we manufacture using [our] combined technologies.”

Below are the technical specifications for Photocentric’s new LC Titan 3D printer, which will be available for purchase from 2023. Prospective customers can request a quote from Photocentric directly.

Photocentric, a Peterborough-based 3D printer and materials manufacturer, has introduced the largest LCD 3D printer. The Liquid Crystal (LC) Maximus is designed to be used for mass production and large-scale prototyping.

Sally Tipping, Sales Director at Photocentric said, “LCD screen-based 3D printers have been the fastest growing area in 3D resin printing; this machine cements our position as the leading innovator in this exciting sector.”

Photocentric’s technology is referred to as Daylight Polymer Printing (DPP). DPP uses a low energy light source to polymerize liquid resins, in contrast to a high-intensity UV laser or a light projector used in SLA/DLP methods.

The light source in SLA/DLP is purpose-built, whereas Photocentric’s 3D printers use mass-produced LCD screens from mobiles, tablets, and large screen televisions. For this reason, LCD 3D printers tend to be cheaper than SLA/DLP printers but offer the same print quality.

As the DPP uses LCD screens to harden the resin, the chemistry of the liquid material needs to be different from the one used in UV printing. Photocentric manufactures and sells specific daylight resins which harden with exposure to LCD screen light.

Photocentric printers offer high quality and affordable alternative to SLA/DLP 3D printers. This year, the company’s Liquid Crystal Precision was also shortlisted for the 3D Printing Industry Award in the category of

The latest 3D printer from Photocentric, the LC Maximus, uses a 4K 40” LCD screen to cure each individual layer at an interval of 15 seconds with XY resolution of 230 microns.

The massive 700 x 893 x 510mm build size of the printer makes it ideal for mass producing parts, such as dental models and manufacturing large-scale prototypes. To demonstrate these capabilities, Photocentric is currently running a Facebook campaign.

Photocentric is prototyping a life-size model of a motorbike. Every Sunday at 6 p.m (GMT) leading up to formnext 2018 Photocentric’s team 3D prints and assembles a motorbike prototype part.

With the rear wheel, exhaust system and the engine 3D printed, and assembled, the project is now 45% complete. The finished bike will be exhibited at formnext 2018, where Photocentric will be in Hall 3.1, Stand A10.

To gain speed over its competitors, Photocentric has also announced a partnership with Germany’s BASF, the largest chemical producer in the world. The collaboration will see the development of photopolymers and 3D printers for mass production.

To provide alternatives to conventional methods of manufacturing, Photocentric is developing 3D printers that operate using patented technology to create a 3D object from a 2D image on a screen. Using the light emitted from an LCD screen that was originally intended for use in a smartphone, tablet or TV to harden a photopolymer made to react in light. The company is a pioneer in using LCD screens for 3D printing. Now it is focusing on creating an array of different LCD 3D printers and partnering with 16 universities to enhance research in different fields that are benefiting from 3D printing technology. Based in Peterborough, UK, the 3D printer and resin manufacturer has just launched the first model of their next generation large format LCD printers, the Liquid Crystal (LC) Magna. At 510 mm x 280 mm x 350 mm, Magna will be the largest build volume LCD screen-based printer currently available on the market.

The “disruptive industry-changing machine,” as Sales Director of Photocentric, Sally Tipping, refers to it, “sets new standards making it best in class in almost every respect.” According to Photocentric, LCD screen-based 3D printers have been the fastest growing area in 3D resin printing, and the company holds patents in visible light curing technologies, building on theirvision of enabling bespoke mass manufacturing.

One of the most popular applications for 3D printing is in digital dentistry, and the firm hopes that Liquid Crystal Magna will be used in the mass production of dental models. Dental technicians need a high volume of patient-specific models, and now Photocentric claims that they can print 46 flat dental arches in just over 1 hour, which cost less than £1.60 per arch when used with Photocentric’s in-house dental model resin. And in under five hours, they can vertically print up to 80 arches. In the last few years, 3D printing has gained traction in the dental market, both in labs and multiple high volume applications, expected to reach 5 billion dollars by 2023.

Photocentric commercialized the first 3D printer based on an LCD screen in 2016. That year they won the Queen’s Award for Innovation and in 2018 the Queen’s Award for International Trade. It’s hard to believe that the company began with a main focus on making simple and cheap business stamps in 2002. Which they still market and they are now the largest clear stamp manufacturer outside of China.Since then, the company has evolved into manufacturing 3D printers using LCD screens, patented photopolymer packs for making stamps, anda range of photopolymer resins compatible with any printer operating from 355 mm to 460 mm.

The use of LCD screens from smartphones, tablets, and large format TV screens is at the core of Photocentric’s 3D printers. The retail price of the LC is 10,995 pounds, which includes the printer, two kilograms of Daylight Black Hard resin, another two kilograms of Daylight Dental Model White resin, and a perpetual license for Photocentric Studio Software for two computers. With a global distribution network in over 50 countries and with industry demands heavily increasing, Photocentric is trying to get their product in as many markets as possible, including America and many European countries. Their global chain of distributors is making their way into major cities and towns where jewelry designers, inventors, engineers, and dental technicians are looking to turn their design concepts into tangible prototypes or end-use functional parts.

Towards the end of 2019, Photocentric plans to release other LCD printers andresins. Their photopolymer resin, which is manufactured in theUK by an in-house team of chemists, will soon be followed by new resins for large component investment casting, a high-temperature resin for direct printing molds (over 300°C) and a tough formulation for impact resistance. Just last year, they partnered with BASF 3D Printing Solutions to create the photopolymers and printers necessary to enable the custom mass manufacture of parts.This cooperation offers solutions to industries that enable processes to be made using additive manufacturing to replace traditional tooling methods and creating flexibility in geometry and custom design. BASF provides functional resins that are needed for specific industrial uses and Photocentric manufactures the printers.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey