lcd panel layer thcikenss price

One of the advantages of designing a custom display is the ability to reduce your LCD display’s thickness by selecting a thin ITO glass; which is key to a thin LCD module.

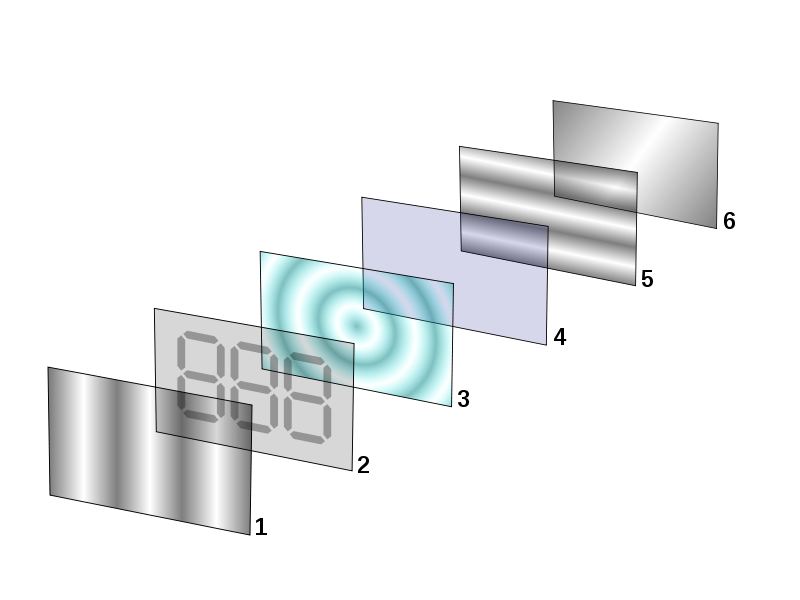

The structure of the LCD is very basic, but a special glass called ITO glass is used in constructing the display. Three sides of the ITO glass are glued together with an adhesive or epoxy. Both the ITO glass and the nematic fluid used are transparent. There is a small gap of one or two millimeters between the top and bottom layer of glass. A nematic fluid is then injected between the layers. Finally, a cap is placed on the fourth side to keep the fluid from leaking out.

A polarizer is applied on both the top and bottom layer of glass. The polarizer on the top layer is always Transmissive, whereas the bottom layer can be Reflective, Transflective or Transmissive. For more details on the different types of polarizers, please read our article: LCD Polarizers.

ITO glass can be cut to custom dimensions, but smaller sized glass can add a significant cost increase to the overall cost of the LCD. The reason for the increased cost is the amount of labor and time required to add a polarizer to the small piece of glass.

Many times customers require the display to be as thin as possible; one method to achieve a thin LCD module is to select a thinner ITO glass. Keep in mind that the thinner the glass, the more expensive and the higher the fallout rate.

Note:Fallout rate does not mean failures of the LCD’s in the field; fallout is when the display fails on the manufacturing line. If the display fails in production, it is discarded before it is shipped to the customer.Once the display passes QA (Quality Assurance) it will operate normally for the life of the product.

It is possible to add a backlight to the monochrome display to make the display readable in low or no light conditions. The challenge of adding a LED backlight is that it increases the thickness of the LCD by as much as 5mm to 9mm.

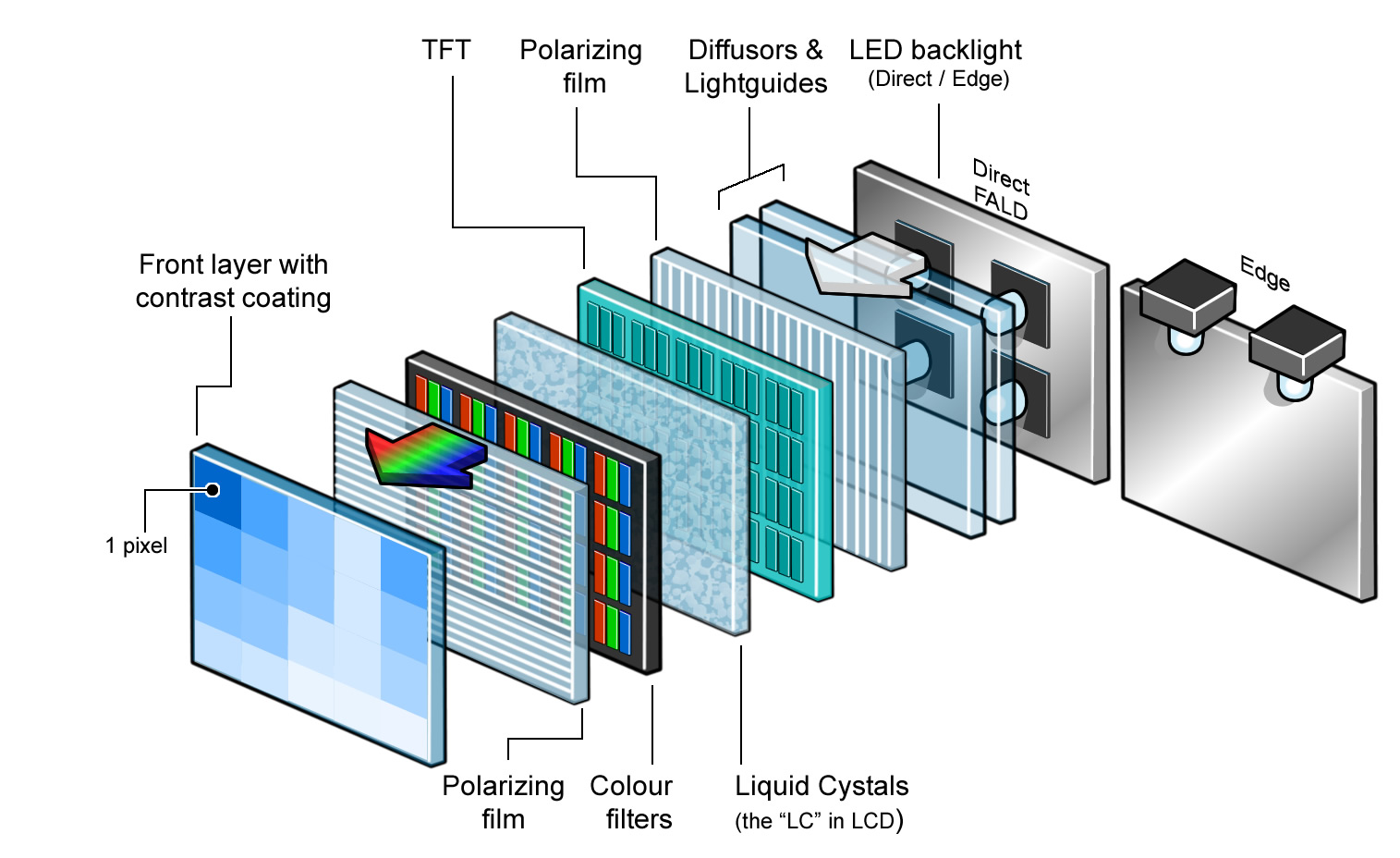

In the photo above, a segmented LCD is combined with a LED backlight and backlight diffuser. A printed circuit board (PCB) is used to hold the assembly together. As the backlights name suggests, a light is placed behind the bottom layer of ITO glass.

Note: A backlight diffuser’s job function is similar to the lamp shade used on a table lamp. It disperses the light from each led to provide a more uniform appearance. Without the diffuser, there would be hot and cold spots on the display. A hot spot is where the backlight is too close to the LCD glass and it is overly bright; the area around the hot spot is dimmer and is referred to as a ‘cold spot’.

There are four methods to reduce the thickness of the LCD display/backlight combination; thereby creating a thin LCD module. However, these solutions do not apply to TFTs, VFDs, LEDs or OLEDs (Organic Light Emitting Diodes).

In the integration the backlight is sandwiched between the LCD and PCB. The LCD’s leads (pins) are then soldered to the PCB securely holding the backlight in place. This helps to create a thin LCD module.

Advantages of a PCB mounted LED backlight:The PCB combines the backlight and the LCD; this is great in applications that operating in environments of heavy vibration.

It is possible to build the PCB with only one or two layers to reduce the thickness, but current design practices call for a separate plane for power and ground. Also, a thinner board may not be as strong.

Another way to combine the LCD and the LED backlight is to use either a plastic clip to bind them together, or to use an epoxy or adhesive. There are advantages and disadvantages to both, but we suggest the plastic clip solution.

This method requires a one-time tooling fee to design and prototype a small, flexible plastic clip that holds the backlight and display together. The clip only adds a few pennies to the overall cost of the LCD combination.

This method is accomplished without any tooling cost and only adds a penny or two to the overall cost of the LCD assembly, but we do not recommend this approach.

An edge-lit display means that the LEDs are not placed behind the bottom layer of glass, but along the edge between the two layers of glass. This alone helps to create a thin LCD module.

Disadvantages to an Edge-lit display:One of the Challenges of this solution is that it increases the size of the overall display in the X and Y directions (Length and Width). Which means the sides of backlight will stick out beyond the LCD.

Side-lit displays work well for smaller size LCDs, but create hot spots around the edges if the display is too large. This is more evident with a white LED edge-lit; since white LEDs are much brighter than other colors and sometimes need to be dimmed to reduce their starkness.

EL backlights are AC (Alternating Current) driven, this requires an inverter either on the LCD or on the customers’ board. Inverters add extra cost and labor.

LEDs are DC (Direct Current) driven and do not require an inverter. Many times the voltage for the LED backlight is the same as for the LCD which means one less power supply is required.

Seoul, Korea (July 11, 2013) – LG Display [NYSE: LPL, KRX: 034220], a leading innovator of display technology, today announced that it will unveil the world"s slimmest Full HD LCD panel for smartphones. The state-of-the-art 5.2-inch panel is an exciting advancement for the premium mobile device market enabling sleeker Full HD smartphones featuring better "grip-ability" and a superior viewing experience.

Only 2.2mm thin with a 2.3mm bezel, LG Display"s new panel is both slimmest and narrowest among existing Full HD LCD panels designed for mobile devices. This world"s slimmest Full HD LCD panel will provide larger visible display space on smartphones, critical as mobile devices are used for multimedia viewing more than ever before. Additionally, the panel will make devices easier to grip as well as lighter in weight.

Key to realizing the world"s slimmest panel is LG Display"s Advanced One-Glass-Solution (OGS), the latest touch technology enabling an enhanced touch screen experience, developed and applied to the new panel for the first time ever. Dual Flexible Printed Circuits, superior to a single circuit, have been inserted between the panel and touch film, reducing the number of lines on the panel by more than 30 percent. Utilization of a direct bonding system has also resulted in Optical Clear Resin between the panel and touch film for greater brightness.

The new panel"s superiority in displaying resolution, brightness, and contrast ratio results in enhanced outdoor readability. By utilizing 1,080X1,920 pixels consisting of Red, Green, Blue (RGB) sub-pixels, the panel is a true Full HD display. And with a brightness of 535 nits at maximum, LG Display"s panel outperforms all current mobile Full HD LCD panels. Finally, measuring contrast in real-life surroundings with Ambient Contrast Ratio results in a reading of 3.74:1 based on 10,000 lux, confirming the perfect performance of the panel even in strong outdoor sunlight conditions. Renowned testing firm Intertek has officially certified these results.

"Today"s introduction of the world"s slimmest Full HD LCD panel represents an exciting advancement for the high-end smartphone segment, and is possible due to our world-class expertise in IPS and touch technologies," said Dr. Byeong-Koo Kim, Vice President and Head of LG Display"s IT and Mobile Development Group. "LG Display will continue its commitment to developing products that maximize consumer value as well as opening new doors for the mobile and tablet PC industry."

One of these choices is deciding between an LCD display or an LED video wall. Continue reading to find out more about the basics, as well as the advantages and disadvantages of each solution.

Most people are familiar with LCD technology, which stands for Liquid Crystal Display. These types of displays have a massive presence in this world, used in living rooms to watch movies, fast-food restaurants to showcase menus, airports to show flight schedules, and everything in between. LCD technology was developed in the 1960s and has been used worldwide as a standard for roughly 20 years. It is a tried-and-true technology that has stood the test of time and will be around for the foreseeable future.

On an LCD screen, the panel is illuminated by a light source and works through reflection or transmission of light. Overall, LCD displays have better viewing angles and less glare than LED screens. This technology was designed to be energy efficient and tends to be lighter in weight.

An LCD video wall is made up of multiple LCD panel monitors mounted on a surface to create a digital canvas, which then work together to create a unified experience. They operate 24/7 at a high brightness and have thin bezels that help create a seamless look when the displays are placed next to one another.

Bezel thickness and the brightness rating are among key attributes to consider for an LCD video wall display. Here is what each of these means and why.

Nits:Brightness is measured in Nits. A higher Nit value means the display will be brighter. A brighter display is necessary in a room that sees plenty of direct sunlight, or if the intent is to draw in visitors from far away. With LCD video walls, the price of the hardware goes up as the display size and brightness increase, and the bezel width decreases.

The next item to consider is the type of content that will be displayed on your video wall. LCD displays have high resolution screens — modern 4K displays have over 8 million pixels! This means that the content being displayed is highly detailed and crystal-clear. A viewer could stand less than 1 foot away from the screen and be able to see exactly what is being shown on the screen.

Like previously mentioned with LCD video walls, an important consideration in the decision-making process is the type of content that will be displayed on the video wall. LED video walls suffer from image degradation and pixilation from up close, so fine details will be lost, and text will be illegible. If detail from up close is important, LCD displays are much better suited for that situation.Content examples that are well-suited for an LCD video wall:

Video walls are relatively new. But LCD technology has had decades of mainstream adoption, and with that comes both familiarity and lower costs. If those are important to you, then an LCD video wall is likely the right choice.

LED video walls are similar to LCD video walls, but the digital canvas is built using LED panels. Individual LED panels can be anywhere from 12”x12” to 36”x18”, which is much smaller than LCD displays. LED panels have a larger presence in this world than most might think—they are found indoors and outdoors at stadiums, arenas, concert venues, airports, and in use as large digital advertisements in iconic places such as Times Square.

The module is a small rectangular board that contains all the individual LEDs (light-emitting diodes).Unlike LCD, there is no glass or color filter on the LED video wall panels. The individual diodes that are placed on the modules produce both color and light.

One of the most impressive features of LED panels is that they can be combined to create almost any shape, without a bezel interrupting the digital canvas. LED video wall panels can be placed on curved surfaces, 90-degree edges, and other non-standard surfaces. The smaller size of the panels in relation to LCD video wall displays means they can fill more space on a surface—they aren’t limited to standard 46” and 55” sizes as are LCD video wall displays.

The most important factor to consider when scoping LED panels for a video wall is what is referred to as “pixel pitch.” The pixel pitch is effectively the distance between each pixel on the LED panel—a pixel pitch of 6mm means each pixel is spaced 6 millimeters away from the adjacent pixel. The smaller the pixel pitch, the smaller the distance is between each pixel, which means there are more pixels per square inch on the digital canvas.

As is the case with an LCD video wall, an LED video wall will add exciting drama and premium value to showcase spaces. LED panel displays don’t enjoy the benefit of decades of mainstream adoption as do their LCD counterparts. However, the technology curve is increasing their availability and lowering their costs. At this time, an LED video wall will have higher upfront costs compared to an LCD video wall. If cost is the main concern, then an LED video wall system will not likely fit into your budget

Limitless shapes and sizes:the smaller size of LED panels allows them to be combined to create unique canvases, including curved, 90-degree edge, and other combinations not possible with LCD displays

Easy maintenance and service; high reliability:LED module replacement takes seconds with little effort; LED panels are rated with a lifetime of 80,000-100,000 hours, depending on the product

The QuintSonic-T is a Multi-Layer Ultrasonic Coating Thickness Gauge, specially designed for non-destructive coating thickness measurements of up to 8 layers of paint, primer, and other coatings applied on plastic, composites, metal, and other materials. Total thickness, as well as individual layer thickness, can be measured in one simple process.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

As the thickness monitoring requires high-resolution, low noise cameras and high performance LED illumination units operating at selective wavelengths this measurement option is best planned to be integrated into the inspection system at an early stage. The costs for a second hardware set can, thus, be saved and the solar panel inspection system becomes a true all-around solution.

For layer thickness measurement, as for e.g. in-line spot test or in off-line laboratory situations, Dr. Schenk alternatively offers a technology using a white light spectrometer.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

Even though some say the picture quality of an LED TV is better, there is no straight answer for which has better picture quality since both TVs use the same kind of screen. For instance, a higher-end LCD TV can have a better quality than a low-end LED TV, but if you look at high-end models of either TV, the picture quality will be comparable.

LED TVs use energy-efficient light emitting diodes (LED) for backlighting. These consume less power than cold cathode fluorescent lamps (CCFL) used in traditional LCD televisions. Power savings are typically 20-30%.

Edge-LEDs (the most common) are positioned around the rim of the screen and use a special diffusion panel to spread the light evenly behind the screen.

Flat Screen LCDs, about an inch or two thick are more expensive, but also more popular because of their sleek look and the flexible options of standing on a surface or mounting on a wall.

Front projection LCDs or projectors, which project an image onto the front of the screen. The TV itself is just a box installed anywhere in a room, which projects the image onto a flat screen hung on the wall as large as 300 inches.

Rear projection LCDs, where the image is sent from the rear of the TV to the screen in front. Rear projection LCDs are wide, heavy and only available in large sizes (60" and up).

Optimization of electronic circuitry is as important as that of LCD, in some cases, it is difficult for engineer with little LCD background to fully comprehend what is needed for good looking display

Very long, in most cases, providing the operating condition is stable, the LCD may operate for years. Just for reference, below is typical life time for displays:

TFT-LCD, which stands for thin-film-transistor liquid crystal display, consists of glass substrates on the bottom, a color filter substrate on the top and liquid crystal in between. The special properties of the liquid crystal are manipulated to create images. These technology intensive products represent the next generation in displays. They are flat and thin, easy to carry around and consume less power. Refer to the Technology section for details.

TFT-LCDs solve the problems of portability, bulkiness and electro-magnetic emissions that CRT displays present. The current brightness and response time problems with TFT-LCDs are being addressed with technology advancements. The main applications for TFT-LCD was notebook PCs and desktop monitors, where they replace CRT`s thick tubes. Importantly, industrial applications and value-added niche markets such as medical equipment and instrument panels are growing fast. In the future, TFT-LCDs will be found in most every facet of life.

There are two types of LCDs commonly used in the market. One is TN (twisted nematic); this type of LCD has a narrow viewing angle. The other is STN (super-twisted Nematic); this has a wider viewing angle.

Yes, since the LCDs are widely used, some of the applications will be in extreme weather conditions where a wide temperature range is required. Normally the wide temperature range for a TN type LCD is -30 ~ 75C (operation Temp.) and -30 ~ 70C (storage temp.)

A. There are two types of driving modes. One is "Static" and the other is Multiplexed". "Static" is a method of activating an LCD where each segment has an independent connection, whereas the "Multiplexed" method is a method where the LCD is driven by different channels. This method requires additional information such as "Duty" and "Bias". For example, 1/2 duty, 1/4 Bias defines an 8 x 1 LCD display.

We use four different viewing directions for LCDs: 3 o"clock, 6 o"clock, 9 o"clock and 12 o"clock viewing means you look at the LCD from its left side, 6 o"clock means you look at the LCD from the bottom...and so on. 6"clock is the most common viewing direction. Examples of 6 o"clock viewing are calculators and notebooks.

LCD is driven by AC (alternating current), it is best to use standard LCD driver IC to generate as this will simplified your development time. Alternatively, for simple TN segment drive, most MCU may emulate the AC current but would need a lot of background know how. For example, simple TN segment drive would require as low as 40Hz to as high as 120 Hz. Depending on the operating environment such as temperature and would affect the contrast of the display. Some experiment may be need to find the optimum operating condition.

ESD stands for electro-static discharge, it is arc or discharge of electrons between two surface when potential difference is great enough for discharge to take place. Because LCD is made mainly by non-conductive material such as glass and plastic, ESD can happens in LCD. In most cases, this can be easily overcome by design of peripheral connection and mounting.

Optically transparent with refractive index of between 1.4 and 1.8 which is close to that of soda lime glass (commonly use as based supporting substrate of LCD)

A. LCD utilize physical phenomena of liquid crystal know as birefrigerance (which describe its properties of having two different refractive index depending on orientation) to create the light blocking and passing effect. Because of this, normally, the best viewing cone is best at a certain direction which is know as viewing angle.

The answer really depends on material selection and configuration. Because liquid crystal is primarily organic compounds, most liquid crystal material are susceptible to UV disintegration. There are some liquid crystal which are specially design for outdoor application that is more UV resistance. When use with UV blocking polarizer, the LCD can be resistance to ultra violet damage.

As previously explained, liquid crystal has two distinctive refractive index known as birefrigerance, in classical view and text book, liquid crystal used in common display application are in what we call nematic phase which is more like a glass rod which will turn when influence by electromagnetic force. Alignment layer is used to anchor the liquid crystal molecule at the glass surface forming the boundary condition for the display to work.

coating is simply a material put under the alignment material which act as a barrier layer. The main purpose is to reduce chance of ionic contamination which will deteriorate the display performance and shorten its life time. Very often, silicon dioxide is used for this purpose.

For most cases, both TN, HTN and STN utilize the phase known as nematic for display purpose. Within this phase, the liquid crystal has a "rod shape" exists within the solution which has fast response and has excellent electro-optic properties. This phase, however, only exists within a limited temperature range. The higher end of this temperature range is known as clearing point, above which, the liquid crystal lost its birefrigerance properties and cannot bend the light path anymore. Thus the polarizer will then be the only factor which affect incoming and out coming light. When the LCD is cooled down to below its clearing point, the display should be working again. The temperature for the clearing point varies greatly from material to material and you should contact our engineers regarding what you have. Normally a safe margin should be used to avoid clearing point when designing the display.

LCD displays and touch screens are in demand. They offer a sleeker, less cumbersome alternative to a mouse and keyboard or wired touch pad. And since the user can interact directly with the device’s interface, the possibilities for innovation are endless — from elevators and mobile medical equipment to industrial automation.

For many years, electronic device manufacturers generally incorporated five to seven layers of touch screen technology in the manufacture of their products — the LCD panel layers, the touch sensor layer, and the protective top cover or outer glass. Typically a touch screen is mounted on top of the LCD display and either secured with a high-performance double-sided tape, which leaves an air gap, or a silicone gel, called optical bonding, that fills air gaps and enhances readability.

Since 2012, in-cell and on-cell touch screen technologies have taken the high volume consumer segments by storm, in particular, smartphones and tablets. Born out of similar strategies of combining layers for improved functionality, in-cell technology incorporates touch sensors into the actual LCD display panel. On-cell or G2 technology moves the touch sensor to the top cover or outer glass layer.

With fewer layers, in-cell and on-cell touch screens provide designers and engineers the ability to develop much thinner devices, locate touch sensors close to the displays, create better color saturation and visual clarity, and reduce glare. All of which make users feel like they are actually touching the display and not just the outer glass layer.

Fewer layers are beneficial to a manufacturing process as well. It reduces costs by integrating the touch screen sensor as one of the layers of the LCD display, and optical bonding takes place as part of the initial production line, eliminating the need for a secondary bonding process.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey