lcd panel layer thcikenss pricelist

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

One of the advantages of designing a custom display is the ability to reduce your LCD display’s thickness by selecting a thin ITO glass; which is key to a thin LCD module.

The structure of the LCD is very basic, but a special glass called ITO glass is used in constructing the display. Three sides of the ITO glass are glued together with an adhesive or epoxy. Both the ITO glass and the nematic fluid used are transparent. There is a small gap of one or two millimeters between the top and bottom layer of glass. A nematic fluid is then injected between the layers. Finally, a cap is placed on the fourth side to keep the fluid from leaking out.

A polarizer is applied on both the top and bottom layer of glass. The polarizer on the top layer is always Transmissive, whereas the bottom layer can be Reflective, Transflective or Transmissive. For more details on the different types of polarizers, please read our article: LCD Polarizers.

ITO glass can be cut to custom dimensions, but smaller sized glass can add a significant cost increase to the overall cost of the LCD. The reason for the increased cost is the amount of labor and time required to add a polarizer to the small piece of glass.

Many times customers require the display to be as thin as possible; one method to achieve a thin LCD module is to select a thinner ITO glass. Keep in mind that the thinner the glass, the more expensive and the higher the fallout rate.

Note:Fallout rate does not mean failures of the LCD’s in the field; fallout is when the display fails on the manufacturing line. If the display fails in production, it is discarded before it is shipped to the customer.Once the display passes QA (Quality Assurance) it will operate normally for the life of the product.

It is possible to add a backlight to the monochrome display to make the display readable in low or no light conditions. The challenge of adding a LED backlight is that it increases the thickness of the LCD by as much as 5mm to 9mm.

In the photo above, a segmented LCD is combined with a LED backlight and backlight diffuser. A printed circuit board (PCB) is used to hold the assembly together. As the backlights name suggests, a light is placed behind the bottom layer of ITO glass.

Note: A backlight diffuser’s job function is similar to the lamp shade used on a table lamp. It disperses the light from each led to provide a more uniform appearance. Without the diffuser, there would be hot and cold spots on the display. A hot spot is where the backlight is too close to the LCD glass and it is overly bright; the area around the hot spot is dimmer and is referred to as a ‘cold spot’.

There are four methods to reduce the thickness of the LCD display/backlight combination; thereby creating a thin LCD module. However, these solutions do not apply to TFTs, VFDs, LEDs or OLEDs (Organic Light Emitting Diodes).

In the integration the backlight is sandwiched between the LCD and PCB. The LCD’s leads (pins) are then soldered to the PCB securely holding the backlight in place. This helps to create a thin LCD module.

Advantages of a PCB mounted LED backlight:The PCB combines the backlight and the LCD; this is great in applications that operating in environments of heavy vibration.

It is possible to build the PCB with only one or two layers to reduce the thickness, but current design practices call for a separate plane for power and ground. Also, a thinner board may not be as strong.

Another way to combine the LCD and the LED backlight is to use either a plastic clip to bind them together, or to use an epoxy or adhesive. There are advantages and disadvantages to both, but we suggest the plastic clip solution.

This method requires a one-time tooling fee to design and prototype a small, flexible plastic clip that holds the backlight and display together. The clip only adds a few pennies to the overall cost of the LCD combination.

This method is accomplished without any tooling cost and only adds a penny or two to the overall cost of the LCD assembly, but we do not recommend this approach.

An edge-lit display means that the LEDs are not placed behind the bottom layer of glass, but along the edge between the two layers of glass. This alone helps to create a thin LCD module.

Disadvantages to an Edge-lit display:One of the Challenges of this solution is that it increases the size of the overall display in the X and Y directions (Length and Width). Which means the sides of backlight will stick out beyond the LCD.

Side-lit displays work well for smaller size LCDs, but create hot spots around the edges if the display is too large. This is more evident with a white LED edge-lit; since white LEDs are much brighter than other colors and sometimes need to be dimmed to reduce their starkness.

EL backlights are AC (Alternating Current) driven, this requires an inverter either on the LCD or on the customers’ board. Inverters add extra cost and labor.

LEDs are DC (Direct Current) driven and do not require an inverter. Many times the voltage for the LED backlight is the same as for the LCD which means one less power supply is required.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

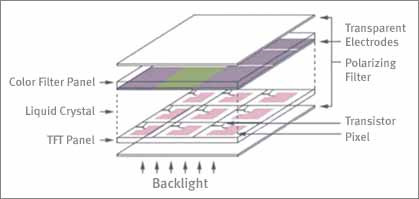

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

Our willing victim in this anatomy lesson is a Hewlett Packard LA2306x LCD monitor, manufactured way back in August 2012. At the time, it was a decent office-oriented monitor, but not the best for gaming. Like all displays, it"s basically a big grid of colored dots (picture elements or pixels) that altered many times a second give a smooth visual output from a computer.

The screen is technically classed a twisted nematic, thin film transistor, liquid crystal display (TN TFT-LCD). Don"t worry about what any of that means for now. It"s 23" in diagonal size (corner-to-corner) and the arrangement of pixels is such that there are 1920 columns and 1080 rows -- better known as the resolution of the monitor. This type of display needs a light source to make the pixels visible, and ours uses a strip of white LEDs along the bottom of the unit.

TFT-LCD panels are so heavily used that manufacturers across the world (the majority based in China and Taiwan) churn out thousands of them every single day. In a previous feature "Display Tech Compared: TN vs. VA vs. IPS, What"s the Difference?" we looked at the different types of TFT-LCD panels in detail, and we covered the difference between the 3 most popular types around:

You should definitely give that a read if you want to learn more about the differences between display panels, we won"t cover that in this article, but the unit we are using for our anatomy lesson is a TN panel, which is very common as it"s the cheapest to produce.

The ventilation slots around the back are needed, because although the monitor doesn"t use much power (42W at most), a build up of heat would damage the LCD panel. At the left of the back, there is a socket to plug in a standard main AC electricity cable, and the video inputs are on the right.

The LCD panel is at the top, lifted out of the way, so we can see the electronics used. The circuit board on the right takes the mains electricity and converts it into a range of low, direct current voltages -- the cable on the far right powers the screen, and the little one next to it is for the control buttons on the monitor.

We can see the display connectors along the top, the power and control inputs down the right, the output to the LCD panel on the bottom, and the connection to the extra USB ports on the left.

The big chip in the middle is an MStar Semiconductor LCD display driver. It takes the video output signal from the computer and works out when and how to activate all of the pixels in the panel. Every monitor will have one of these, but some are more advanced than others.

An important aspect of this chip is called the pixel clock - it determines how many pixels can be managed per second, and in this HP model, it runs at up to 165 MHz for the digital inputs and 200 MHz for the analogue one. The panel in this monitor has a total of 1920 x 1080 = 2,073,600 pixels, so with the clock running at 165 MHz, that means the pixels can be updated no faster than 79.6 times every second.

At this point, we should really talk about something called refresh rate. Before LCD panels became the norm for monitors, cathode ray tubes (CRTs) were used for the display -- these work by firing a beam of electrons (sub-atomic particles) at a layer of material that would glow when struck by the beam.

LCD panels don"t fade like this, but the drawing process still undergoes a similar pattern and return. They don"t flicker in the same way that a CRT does, but the more frequently the panel can draw out a new picture, the better the user"s experience will be.

This is why all monitor specifications include the vertical refresh rate (or typically just refresh rate) for a given resolution. The fewer the number of pixels there are to update, the quicker the panel can start over again, which is why we see higher refresh rates on small, low resolution monitors compared to big, 4K ones.

Our HP monitor remains fully functional, though prising apart LCD panels can often ruin them. So we"re going to bring out another one from HP, but this one is already dead.

This is actually the screen from a laptop, but the panel is essentially no different to that used in a monitor. The differences lie in where all the supporting electronics can be found. Let"s pull it out and flip it over:

The most obvious thing is that the panel was made by Samsung, and it"s another TFT-LCD, but we can spot the display driver chip hidden under a protective film. Given that this doesn"t work anymore, we can rip it all off and have a closer look.

The brand name of the display driver chip says WiseView, but it"s actually Samsung"s own product. There"s little else here, other than the signal input to connect the panel to the laptop (just to the right of the driver) and the multiple strips of wires that hook the chip to the screen. To the lower left of the display processor, the metal socket is for power.

The light source also controls the overall brightness of the display panel and it"s often stated in units called nits(the SI unit is candela per square metre, cd/m2, where 1 nit is the same as 1 cdm2). Our HP monitor has a maximum brightness of 250 nits, which is reasonable for its age and intended usage, whereas the Samsung panel from the laptop is 185.

The majority of LCD monitors and TVs also allow you to alter the "temperature" of the screen -- you"re not really making the panel hotter or colder, though. Instead, you"re essentially trying to replicate how sunlight appears at different times of the day. The temperature part refers to how hot the surface of the Sun would need to be in order for this light to naturally occur.

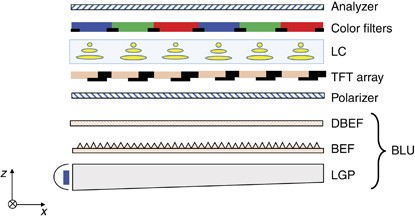

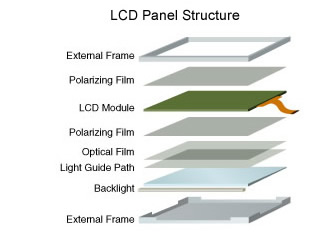

Whatever source produces the background lighting for the LCD panel, it needs to be spread across the whole screen -- in the case of our laptop corpse, this is done using a thick layer of polymer, called a light guide plate.

With all of the protective layers and side trim removed from the panel, we can now see how the screen is built. In the image above, the top is the back of the screen and would normally be covered by a layer of white plastic. The polymer layer, for scattering the background light over the panel, comprises almost half the thickness of the whole thing.

The bottom layers in the image is the liquid crystal display itself, but sandwiched in-between are several sheets of material. The first sheet diffuses the light further from the guide plate, followed by two prismatic layers to scatter that light out even more.

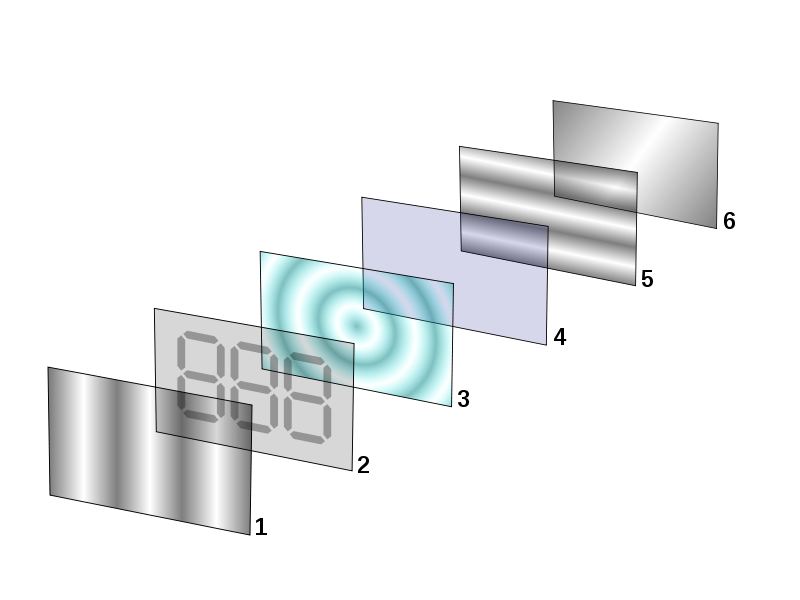

Eventually, all of this scattered and diffused light will reach the outer layers of the actual LCD screen: a composite structure of multiple sections. The first one is a thin layer made from glass, and it"s job is to polarize the light coming from the CCFL or LEDs.

The very last layer in the LCD sandwich is also glass, and it too polarizes the light. The plane of vibrations for the two glass slices are 90 degrees to each other and normally, this would completely block any light from travelling through the panel -- the screen would look almost black.

But in-between these is yet another sandwich. This one contains thousands of little pockets filled with a compound: the so-called liquid crystal. This also polarizes the light: in this particular LCD technology, the crystalline molecules form a twisted structure (hence the name twisted nematic) and it "rotates" the light to match the plane of the last polarizing layer.

The level of the voltage used determines how much light gets transmitted by the panel and since there are thousands of liquid crystal pockets, controlling all of these must require a serious amount of connections. We can see this about our case study -- for example, there are multiple traces running around the edge of the panel:

Ultimately, all of these traces form a criss-cross array of connections and hooked up to all of these are the individual pixels -- the pockets of liquid crystals. Holding the panel up to a window clearly shows them and the grid of traces:

This arrangement of sub-pixels is called a vertical strip and most widescreen monitors use this pattern. Other LCD screens, such as those found in smartphones, often use a horizontal layout or even one set at angles. It"s about how the monitor/screen is normally going to be set: i.e. portrait or landscape.

Now remember that this is TFT-LCD, a thin film transistor panel. This tells us that there is a microscopic silicon layer, so thin that light easily passes through, over all of the grid. For each sub-pixel, a single transistor is fabricated into the film, to apply the voltage to switch the crystals about.

It"s mind-boggling just how small all of these parts are. In our Samsung panel, there are 6,220,800 sub-pixels in an area less than 110 square inches (710 square centimetres). That means each sub-pixel covers an area of 0.000018 square inches (0.0011 square millimetres)! This is on a 7-year-old laptop, too -- Just imagine how small they are in a modern 4K laptop.

The very last part to the whole LCD shebang is a protective sheet, usually made from glass, that"s been coated with a thin layer of polymer to reduce reflections (known as anti-glare). This all needs to be quite tough, so it doesn"t crack easily, but also hard enough to prevent scratching.

Panels don"t have to be flat, either. Curved TVs and monitors, especially those aimed at gaming enthusiasts, often come with a degree of curvature to them. The reasoning behind this is that it"s meant to increase the sense of immersion in imagery, but this will depend a lot of where you sit and what the display is showing.

The number corresponds to the radius of the circle that the panel fits to, measured in millimetres, so 1500R would be a circle of radius 59 inches. Naturally, all of this is more expensive to manufacture, so a curved version of a standard monitor is typically sold at a higher price.

As amazing as LCD panels are, there are drawbacks to all of this wonderful tech. Starting with the background light source (or backlight, for short). You might think that it stays permanently on, because the liquid crystals block out the light, but they"re actually pulsed on and off, very rapidly to improve the perceived color quality. Unfortunately, this pulsing does make the whole screen flicker slightly, and for some people, it can be really distracting; it also adds blur to moving images. Better quality monitors try to pulse at very high rates, to reduce the issue, or synchronize the pulse with the vertical refresh (marketed as motion blur reduction).

Another issue is that the background lighting can bleed through the edges of the LCD panel and between the pixels themselves, although again, better quality monitors try to reduce this. And speaking of the pixels, most TFT-LCD panels, especially TN ones, have a limit to the number of bits to represent a color.

This is mostly due to the system used to transfer the image data. Our older Samsung laptop panel, like many others, uses a low voltage differential signal (LVDS) to transmit the red, green, and blue colors. It"s fast and needs very little power, but the one used here only offers 6 bits for a color. That"s less than 8 or 10 bits used by many graphics chips, and it results in blotchy colors and noticeable gradients.

One solution to this is something called frame rate control (FRC), where the colors are cycled between successive frames, to give the impression that there is a greater range of colors being displayed, than there actually is. Fortunately, most decent TN panels today use 8 bit LVDS, although some still use FRC to claim that the model offers "10 bit" colors.

TFT-LCD panels pretty much dominate the display industry and can be found in monitors, TVs, phones, tablets, car displays, and so on. But they"re not the only technology out there.

OLED (Organic LEDs) are better in this respect, and screens that use them can be found throughout the smartphone industry and are also popular in high end televisions. LED/OLED displays have superior color reproduction and genuine black levels compared to LCD panels -- this is because they don"t use any kind of background light. The pixels themselves emit the image and they can switch on and off much faster than a liquid crystal can twist. The downside to this is that they"re not as bright as LCD panels and they don"t last as long; as they degrade, images can be permanently "stuck on" (a problem known as burn in).

Twenty years ago, LCD monitors were still very expensive, despite a boom in sales and steep decline in prices. In this anatomy lesson, we can see why: they"re hugely complex structures, packed full of thousands of fragile and tiny components. Making these, reliably and cheaply, took decades to perfect. But perfect it they have and you can now get glorious screens, to treat your eyes, for the same price as a medium sized SSD, or low end graphics card.

With DLP technology and maximum ease of use, the Asiga MAX™ printer allows for fast, precise and efficient operation. The built-in LCD panel with touch function displays the information on the current construction process and allows interactive control of the printer. The light sensor provides consistent projector performance and uniform resin curing, the smart positioning system (SPS) ensures precise printing results. Print jobs can be stored in a queue, started from the control panel and transmitted via Ethernet or WiFi. The printer can also operate as a wireless hot spot. Thanks to the IMPRIMO® 385 nm material range and reliable DLP technology, the Asiga MAX™ can be used in all fields of dentistry. Printing jobs can be created using the Asiga Composer software, included license-free with every system.Technical data

While the main LED and LCD difference lies in the technology the TV uses to project visuals on screen, each of the two technologies responds to projections and video in a different way.

An LED TV, owing to the technology it uses, flaunts a thinner screen with sharper edges. On the other hand, the two-layer display technology adds bulk to an LCD TV.

Backlight is an important difference between LCD and LED TVs. An LED TV backlight comes in two ways: edge lighting and full array lighting. Unlike an LCD TV that uses CCFL for backlight, most LED TVs use ‘light guides’ to project pictures on the screen. For example: the latest LED Sony TV and LG TV use the edge lit with local dimming technology to present bright visuals.

When comparing LCD vs LED on the parameter of brightness, an LED TV stands out as a winner. This is because it appoints an individual dimming and backlighting system, which in comparison to LCD, makes your projections more defined, authentic, and closer to reality.

LED TVs have superior black levels and employ dynamic contrast mechanisms as compared to LCDs. Colour precision is also more defined in case of LED TV.

LCDs project clear pictures for up to 165 degrees, but projections tend to distort beyond this point. However, LED TVs are equipped to offer you better clarity at all viewing angles.

LED TVs are more energy-efficient as these models use light emitting diodes (LED) for backlighting. These TVs consume less power as compared to cold cathode fluorescent lamps (CCFL), which most LCD TVs use. This results in a power savings of up to 30%.

Owing to the technology on offer, the price of LED TVs is higher as compared to LCD TVs. For instance, to buy an LED TV that is HD Ready, you will have to spend a minimum of Rs. 10,000 and the price will go up with an increase in screen size and technology. Smart TVs, for instance, come with a higher price tag.

The best part about an LED TV is that it can perfectly fit your space, however limited or expansive it may be, courtesy its versatile size and thickness. You can buy LCDs ranging between 13 and 57 inches in size and LEDs of up to 90 inches, based on the available space.

The most common type of LCD TVs today is the flat screen; however, you can also get front projection LCDs that project an image onto a flat screen. When it comes to LEDs, the most common type is the Edge LED TV that spreads the light uniformly behind the screen. You can also find Dynamic RGB LEDs, which offer dimmer or brighter projections on certain areas, and Full-array LEDs that do not offer dimming or brightening of an individual area.

With this comparison, you must have realised that LED TVs are better than LCDs. However, when choosing a TV, understand your viewing requirement first, then choose what suits you the best. If playing games or watching films in high definition is your passion, then choose LED TVs over LCDs.

In the time to come, OLED technology is going to dominate the LED TV market. While some brands like Sony have already launched exceptional OLED TVs, more is yet to come. Unfortunately, LCD TVs will slowly vanish from the market owing to their cumbersome make and limited features.

Aluminium Composite PanelOur range of products include PVDF aluminum composite panel, Polyester coated aluminum composite panel, Signage / ATM aluminum composite panel, brush aluminium composite panel, wooden aluminum composite panel, Marble aluminium composite panel and mirror composite panel, Road Signage / Retro aluminium composite panel.

We have full devout in developing the best quality 4 mmAluminum Composite Panel. These easy to maintain panels are made from composite aluminum material and demanded widely for façade construction and wall cladding applications. Featuring assurance of superior gloss retention with minimal efforts the offered panels are fabricated in a wide range of colors and patterns as per the evolving market trends. Further, we take special consideration to the clients’ preferences and present these panels in varied dimensions at a leading price.

With the support of vast infrastructure, we are involved in developing highly demanded 4 mmPolyester Aluminium Composite Panel. The offered panels are fabricated with polyester coating and come with mill finish which is widely demanded in the industrial and commercial areas. We are sourcing the premium grade raw materials from recognized sources to present the sturdy and precisely finished panels. The offered panels are ideal for decoration at doors, walls and ceiling and can be ordered from us at a nominal price.

We have gained prominence in the domain by providing high in demand 6mm Wooden GrainAluminum Composite Panel. We have developed a modernized R&D setup to present the flawless range of aluminum panels with exquisite wooden grains. Owing to the next generation fabrication techniques the offered panels are finely finished with PVDF & PE Coating which works best for all-weather performance in both interior and exterior applications. Further, we leverage the skilled expertise of our designing experts and presenting a wide range of innovatively designed panels with mesmerizing wooden grains at a market leading price.

Incepted in the year 2014, we “Alstrom International Pvt. Ltd.” are dedicated towards providing the best in class Aluminium Composite Panel, Aluminium Partition Panel, Metlam ACP.

We are a renowned firm developing exquisitely designed Mirror Aluminum Composite Panel. We stock a vast range of composite panels that are made precisely for wall cladding applications in residential and commercial buildings. The offered product is made by high-quality aluminium composite material which is skinned with anodized aluminium mirror sheets. Developed at our modernized work set up the high-quality mirror finished ACP panels are available in gold and silver color and can be ordered at a market leading price.

Mirror aluminium composite panel is a new type of aluminium composite material skinned with anodized aluminium mirror sheets. The bottom aluminium skin is chromate treated and polyester coated.

As a prominent company, we are engaged in offering a wide range of 3 mm Aluminium Composite Panel. Our panel sheet and partition sheet is highly demanded in commercial as well as residential sectors. Offered array is manufactured by our adroit professionals using premium quality material and latest technology. To meet maximum clients" satisfaction, we provide this array in numerous specifications with customized options.

We have gained huge acceptance as a major firm of top quality Brush Aluminium Composite Panel. Our production lines are equipped with next-generation manufacturing technology that enables us to present the highly durable brush effect ACP panels for wall cladding applications. Developed by using best in class aluminum composite material the offered panels are rigorously tested for its reliable performance in the long run. Further, we stock a huge inventory of these panels in coating brush and anodized brush finish which can be ordered from us at a nominal price.

Alstrom brush aluminium composite panel comes with specially treated aluminium sheets. The surface of the aluminium skin is coating brush and anodized brush.

Made using high-quality aluminium composite panel production lines, ALSTROM brush ACP is presented long warranty and reliable performance but also offered at competitive prices.

We are a well acclaimed as reliable firm offering highly demanded ATM Polyester Aluminum Composite Panel. These are the double side polyester coated ACP panels that are ideal for exterior wall cladding applications. The offered range comes in service coating and mill finish that is widely demanded across the commercial sector. We are partnered with recognized entities and sourcing the best-suited inventory of raw materials to fabricate the elegant and finely finished panels that are accessible at a leading price.

VDF Aluminum Composite Panel consists of a polyethylene core sandwiched between two 0.25 MM aluminum skins. As its name suggests, the ACP is coated with PVDF Kynar 500 / HYLAR 5000 fluorocarbon coating in order to provide a long lasting, durable finish.

Riding on unfathomable volumes of industrial expertise, we are occupied in offering an excellent variety of Red Aluminium Composite Panel. Suitable for making the ceiling, display board, partition bunkhouse, office container, wall paneling and cubicles, these composite panels are available in various colors and patterns to choose from. Offered composite panels are praised for their simple installation, high strength and rust resistance.

With the support of vast infrastructure, we are involved in offering highly demanded 3 mmPVDF Aluminum Composite Panel. The easy to install panels are made from industry complaint grades of polyethylene core which is sandwiched between aluminum skins. Besides, the offered panels come with pollution proof fluorocarbon coating which is long lasting and works best for both residential and commercial buildings. Acclaimed widely for its maintenance-free sheen and superior chemical resistance the offered panels are accessible in varied colors and sizes at a nominal price.

Alstrom PVDF aluminium composite panel is ideal to be used for office buildings, shopping centres, industrial buildings, airports, hotels, bus stations, hospitals, schools, supermarkets, and residential buildings.

We are passionately engaged in providing an exclusive array of Bright Silver Aluminium Composite Panels. Perfect for making display board, office container, wall paneling and others, these composite panels are manufactured by our highly talented professionals using the premium grade silver, aluminium and ultra-modern machinery at par with the market established norms. Obtainable in different specifications to meet various needs of clients, these composite panels can be customized too.

We are one of the most revered firms of an impeccable assortment ofAluminium Composite Panel. These composite panels are manufactured by our professionals using high-grade aluminium in compliance with set industry norms. Used for making door, ceiling, interior, display boards, partition bunk house, office containers, wall paneling and cubicles, we offer these composite panels in various specifications as per requirements of our esteemed clients.

Owing to the years of industrial experience, we have been able to serve our valued clients with a wide range ofWhite Aluminium Composite Panel. These composite panels are available in numerous patterns, colors and other specifications. In ahead of their final dispatch, we check these composite panels on numerous parameters to confirm that these composite panels are defect free.

Made using high quality aluminium composite panel production lines, MAGIKBOND brush ACP is presented long warranty and reliable performance, but also offered at competitive prices.

We have a complete devout in offering highly demanded PVDF Aluminum Composite Panel. Owing to our modernized work setup we are fabricating the new type of composite panels that come with anodized aluminium mirror sheets. The offered product is gaining huge acclamation for its mirror finish which is thoughtfully created to match with the evolving trends in the commercial and residential sector. Further, we have developed a modernized setup for presenting industry approved grades of chrome treated and polyester coated panels. Our prestigious clients can avail the industry compliant mirror finished panels from us in golden and silver colors at a nominal price.

Nano PVDF Aluminium Composite Panel is anti-graffiti and self cleaning. It is composed of a polyethylene core sandwiched between two 0.5 MM aluminium skins. Coming with hydrophobic and lipophilic surface, the Nano-PVDF ACP features good water and dirt resistance. The protected object stays clean much longer and can be easily cleaned with pure water.

The is the most distinguished characteristic of Nano-PVDF aluminium composite panel. The lotus leaf is never polluted by dirt although coming from silt.

Due to above characteristics, the Nano PVDF composite panel is ideal for wall decoration and protection for office buildings, shopping centers, industrial buildings, airports, hotels, bus centers, hospitals, schools, supermarkets, and residential buildings, to name a few.

Fireproof Aluminium Composite Panel is a new type of composite material cored with non-combustible mineral. It has excellent fire resistance as compared with traditional aluminium composite panel. Meanwhile, Magikbond fireproof ACP conforms to German standard DIN 4102 and ASTM E 84-05 grade B-1. If you are searching for environmentally friendly building material that offers excellent fire resistance and minimal gas generation when burnt, please try MAGIKBOND fire resistant aluminium composite panel.

ALSTROM fireproof composite panel can be widely used in office buildings, Shopping centers, Industrial buildings, Airports, Hotels, Bus center, Hospitals, Schools, Supermarkets, Residential buildings

Backed by the sound experience of this industry, we have been able to offer an unmatchable assortment of Customized Aluminum Composite Panel. Offered composite panel by us is widely used for external cladding in different places like malls, restaurants and many other buildings. In order to cater to the needs of our valued clients, we offer this composite panel in a wide range of specifications. This composite panel is known for its high durability and easy installation.

Exteriors (curtain walling and wall paneling) of high rise apartments, industrial and commercial buildings, hospitals, hotels, gas stations, shopping malls, educational institutes, convention centers etc.

We have established ourselves as trustful firm of premium grade3mm/4mm/6mmFireproof Aluminium Composite Panel. The fire resistant panels are hardly flammable and demanded widely for commercial and industrial buildings. Developed by a new type of composite material cored with non-combustible mineral the offered panels are confirming to the DIN and ASTM standards. Further, the offered panels are acclaimed widely for minimum gas retention during burning and can be ordered from us in choice of dimensions at a market leading price.

We have gained much acceptance as a notable entity of best in classNano Coating Aluminum Composite Panel. The offered panels are demanded widely for its self-cleaning Features: which make it the best selling product for schools, hospitals and offices and varied industrial buildings. We have developed a state of art infrastructure and developing these panels with quality approved polyethylene core which is sandwiched between two 0.5mm aluminum skins. Further, the offered panels are tested rigorously for its Lotus effect self-cleaning properties and we are providing the maintenance free panels in varied sizes at a nominal price.

Due to above characteristics, the Nano-PVDF aluminum composite panel is ideal for wall decoration and protection for office buildings, shopping centres, industrial buildings, airports, hotels, bus centres, hospitals, schools, supermarkets, and residential buildings, to name a few.

Polyester Aluminium Composite Panel refers to ACP coated with polyester coatings. As a leading aluminium composite panel supplier, ALSTROM is supplying ACP with double side polyester coated, and ACP with one side coated with polyester and the other with service coating or mill finish.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey