lcd panel layer thcikenss made in china

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

In order to create light and ultra-thin ultra-mobile devices, panel makers are looking to thin down their LCD and touch displays to as small a mere 0.1mm, which is a major task. In addition, when ultra-thin, transparent and flexible OLED panel technology becomes more common, mobile device designers will be able to utilize the thin panels to look even more different.

Speaking at the recent DTF 2012 Ultra Mobile & Ecosystem Forum, AU Optronics (AUO) vice president & mobile product career group general manager, Wu Dagang, first played a short film depicting the future of display technology applications. In the film, a group of students sitting at an outdoor and discussing academics. One of students takes out a display device that resembles a transparent plastic plate. Not only can the device display clear images and videos, it is also flexible and bendable. A burst of wind then blows the display device together with a pile of paper to the ground; however, because of its thin, flexible and tough material, the device doesn"t break. Another student comes to the intersection on a bicycle where the device has flown to, picks it up, clicks on the panel GPS"s navigation option and gets directions. This is the new generation of flexible displays that AUO would like to introduce.

The benefits of having a slimmer display panel are that it can increase battery capacity and battery life. The progress of existing lithium battery technology is rather slow but indispensable and its power storage capacity and supply time is proportional to the battery size. If an LCD module thickness is reduced by 25%, the leftover space will allow lithium capacity to be increased by 10%. If a smartphone has a 1,200-mAH lithium polymer battery, an extra 120mAH is equivalent to adding power enough for two hours of video watching, added Wu.

Another benefit is weight reduction. When a display panel"s LCD module thickness is reduced by 10%, the weight of the whole device can be reduced by 15%, and will further push devices to become slimmer. Aside from Apple products having a simple-to-use interface, stylish designs are also selling points. A few years ago there was more emphasis on product features and specifications, but now that emphasis has gradually transformed into daily-life applications and even into stylish design products for women.

According to statistics, 20% of mobile phones that are sent back for repair are due to screen rupture. To make display panels that are thin and not easy to break, in fact, is a challenge as the two features conflict with one another. AUO"s Slim Solution targets four main areas: OLED (organic light-emitting diode) displays, slim touch solutions, flexible and bendable solutions and slim modules. Making OLEDs is a very delicate process and the thin display technology is very forward-looking and revolutionary.

Wu further elaborated that since LCD itself cannot emit light, it needs a filter glass coupled with a reflective sheet, which will increase thickness by at least 1.5mm. OLED on the other hand is a self-luminous device that can be reduced the 1.5mm. LCD modules also have the possibility of becoming thinner. Slim touch solutions allow touch panels to reduce the two-glass structure to a one-piece structure, and then become in-cell touch that further reduces the thickness by 0.4-0.5mm.

The iPad is also becoming thinner. The first generation iPad had a thickness of 13.4mm, with a 3mm thick display panel; the second generation iPad2 saw the body thickness reduced to 8.8mm with a 2.5mm ultra-thin panel.

A display panel is composed of ITO, CF and TFT array glass on the upper layer, and film, LED/LGP components on the lower layer. First, the glass thickness has gone from 1.1mm 25 years ago all the way to 0.5mm at present and is predicted to drop to 0.3mm for tablets and 0.2mm for mobile phones in the future. In addition, light guide plates (LGPs) used in notebooks will have a thickness of 0.6mm from the present 0.8mm, whereas LGPs used in tablets will drop to 0.4mm. Notebook LED backlights will drop from 0.8mm to 0.6mm as well while tablet-use LED backlights will have a thickness of 0.4mm, a drop from 0.6mm.

In terms of touch panels, older cell phones adopted the glass-film (G/F) structure and tablets adopted a glass/glass (G/G) one. What once was G/G later became the one-glass solution (OGS) and then in-cell touch, with the sensor layer located between the CF and TFT array.

At present, AUO"s thinner G/G structure has a cover glass of 0.7-0.55mm and sensor glass of 0.4mm, reducing the overall thickness by 1.2mm, and can be used in notebooks, all-in-one PCs and tablets. OGS can be reduced to a thickness of 0.4mm and can be used in tablets and 27-inch flat-panel displays. Wu estimates that 5 to 10% of ultrabook shipments this year will have built-in touch.

Wu added that designs of flexible displays and touch screens, as well as notebooks and digital cameras that have no protective glass, must adopt in-cell touch. The technology is compatible with existing TFT panel processing and only a few more steps need to be added for producing the sensor layer. However, currently it will be more suitable for touch panels of six inches and smaller due to the noise issue of in-cell technology.

Wu also mentioned that last year the Samsung Galaxy S2 used an 8.49mm AMOLED panel to make the world"s thinnest cell phone; but this year at the CES 2012 exhibition, China-based Huawei and Japan-based Fujitsu exhibited their Ascend P1S and F-07D handsets that are 6.68mm and 6.7mm in thickness, respectively, due to AMOLED panels that were used in the designs. According to data from DisplaySearch and TSR, up to 127-201 million AMOLED panels will be shipped in 2012, and approximately 320-455 million panels by 2016.

Last year at the FPD 2011, AUO exhibited its 4.3-inch qHD (540x960, 257ppi) high-resolution AMOLED panel, its 4-inch WVGA (800x400) AMOLED with on-cell touch, and its 6-inch transparent AMOLED panel. Technology for thinning AMOLED panels has gone from 1.2 mm in the form of encapsulation glass coupled with TFT OLED glass, to 0.6mm in the single-glass type that has an encapsulation film and TFT OLED glass, and further to only 0.3mm in a bendable, water-proof and anti-shock form adopting TFT OLED films. Moreover, at the FPD 2011 AUO displayed a plastic film-designed 4-inch VGA (640x480) high-resolution flexible AMOLED display that is 0.3mm thick.

Wu concluded that AUO offers a full range of thin panels and modules, and provides a full range of 3-27 inch OGS touch panels. He also said flexible AMOLED is the future trend for smartphones, and that embedded touch technology will add to the flexibility of displays.

In recent years, with the rapid development of China"s high generation LCD panel industry, related industry chain development is also in full swing, Polaroid flat panel display as one of the most important supporting materials industry, also ushered in a rare development opportunity, and gradually localization, in this process, Shenzhen City three tiptop photoelectric Polytron Technologies Inc (hereinafter abbreviation: Sanli plays the role of forerunner spectrum), the future will continue to enjoy the huge growth space localization alternative polarizer.

As everyone knows, the polarizing film of high technical threshold, before the market dominated by several major manufacturers of LG chemistry, chemistry, etc. Sumitomo ensequence foreign monopoly. But with the transfer of the global panel business to the domestic market, the trend of polarizing industry transfer to the mainland has also been formed. For the growing domestic panel capacity, the urgent demand for the polarizing film localization is increasing.

Past industry experience shows that the rise of panel industry in a region must be accompanied by the rapid development of supporting industries in the global panel, the third panel industry transfer tide, China"s end panel manufacturing has been in the forefront to become the world"s first, and the polarizing liquid crystal panel as the most important raw materials, its development is still subject to South Korea Taiwan suppress competition rivals such as productivity advantages and technical advantages, but the trend of industrial transfer, Japanese manufacturers have basically no new production capacity, with special authorization of the technical cooperation, South Korea Taiwan polarizer manufacturers are also actively in the expansion of domestic, is particularly important for domestic manufacturers at this stage of the expansion of the window period is.

Polarizer, as one of the key raw materials of LCD panel, has been strongly supported by the national industrial policy. In recent years, the state has continuously increased its support for the flat panel display industry, especially the LCD panel industry.

At present, the domestic LCD panel production capacity has been ranked first in the world, while domestic panel makers still further accelerated the high generation panel production line construction progress, and promote domestic Polaroid demand growth, although foreign investment increase in domestic production capacity construction, but there are still a large gap between supply and demand.

According to statistics, the current domestic Polaroid accounted for less than 40% of domestic demand, to 2019 self-sufficiency rate is expected to increase to 65%, is expected to 2019 domestic demand for TFT-LCD panel factory Polaroid polarizer of about 185 million square meters, OLED needs about 9 million 580 thousand square meters, and almost all are increasing demand for capacity planning; to 2019 domestic manufacturers look at the supply of only 120 million square meters, there is a big gap between supply and demand, as one of the polarizer panel core material, the panel cost accounted for about 10%, to accelerate the localization of materials is one of the important starting point for the downstream panel manufacturers in the future to further improve the cost competitiveness, in line with industry rules - the rise of downstream upstream material substitution accelerate domestic drive. With the rapid growth of demand and the rise of domestic panel manufacturers, domestic polarizer will usher in the best opportunity for development. Three physical will take this wind, become a polarizing film industry rise directly to a high position, the leading solutions provider with international competitiveness.

Not too long ago, we’ve just got some samples of the new China Made iPhone 6 LCD Display. No doubt that this will be another option for all who are suffering from the high price of the iPhone screens. Let’s take a deep look of these screens.

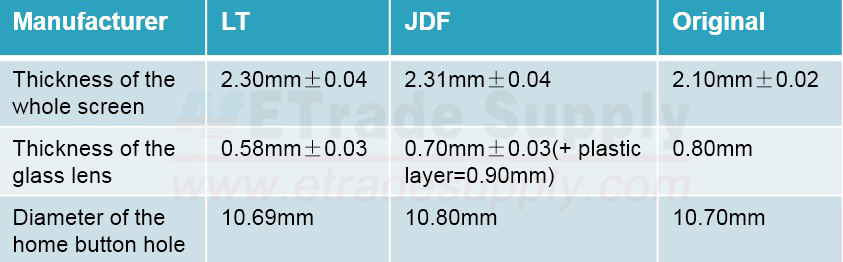

At the moment, there are two companies producing the iPhone 6 LCD screens, one is LT, the other one is JDF (no iPhone 6 screens made by TM are available now). Below are some detailed comparisons after our tests.

When taking a closer look at both of the LT and JDF iPhone 6 screens under direct light, you’ll see the digitizer textures. While for the original screen, the textures had been hidden by a special painted layer.

The glass lens of LT made iPhone 6 screen is far too thin compared with the original one, which can’t secure the display well. At the same time, thinner glass lens will make the home button stick up above the screen. While for the JDF made the screen, a plastic layer has been added to make it thicker.

► When the leading Korean players Samsung Display and LG Display exit LCD production, BOE will be the most significant player in the LCD market. Though OLED can replace the LCD, it will take years for it to be fully replaced.

► As foreign companies control evaporation material and machines, panel manufacturers seek a cheaper way to mass-produce OLED panels – inkjet printing.

When mainstream consumer electronics brands choose their device panels, the top three choices are Samsung Display, LG Display (LGD) and BOE (000725:SZ) – the first two from Korea and the third from China. From liquid-crystal displays (LCD) to active-matrix organic light-emitting diode (AMOLED), display panel technology has been upgrading with bigger screen products.

From the early 1990s, LCDs appeared and replaced cathode-ray tube (CRT) screens, which enabled lighter and thinner display devices. Japanese electronics companies like JDI pioneered the panel technology upgrade while Samsung Display and LGD were nobodies in the field. Every technology upgrade or revolution is a chance for new players to disrupt the old paradigm.

The landscape was changed in 2001 when Korean players firstly made a breakthrough in the Gen 5 panel technology – the later the generation, the bigger the panel size. A large panel size allows display manufacturers to cut more display screens from one panel and create bigger-screen products. "The bigger the better" is a motto for panel makers as the cost can be controlled better and they can offer bigger-size products to satisfy the burgeoning middle-class" needs.

LCD panel makers have been striving to realize bigger-size products in the past four decades. The technology breakthrough of Gen 5 in 2002 made big-screen LCD TV available and it sent Samsung Display and LGD to the front row, squeezing the market share of Japanese panel makers.

The throne chair of LCD passed from Japanese companies to Korean enterprises – and now Chinese players are clinching it, replacing the Koreans. After twenty years of development, Chinese panel makers have mastered LCD panel technology and actively engage in large panel R&D projects. Mass production created a supply surplus that led to drops in LCD price. In May 2020, Samsung Display announced that it would shut down all LCD fabs in China and Korea but concentrate on quantum dot LCD (Samsung calls it QLED) production; LGD stated that it would close LCD TV panel fabs in Korea and focus on organic LED (OLED). Their retreats left BOE and China Stars to digest the LCD market share.

Consumer preference has been changing during the Korean fab"s recession: Bigger-or-not is fine but better image quality ranks first. While LCD needs the backlight to show colors and substrates for the liquid crystal layer, OLED enables lighter and flexible screens (curvy or foldable), higher resolution and improved color display. It itself can emit lights – no backlight or liquid layer is needed. With the above advantages, OLED has been replacing the less-profitable LCD screens.

Samsung Display has been the major screen supplier for high-end consumer electronics, like its own flagship cell phone products and Apple"s iPhone series. LGD dominated the large OLED TV market as it is the one that handles large-size OLED mass production. To further understand Korean panel makers" monopolizing position, it is worth mentioning fine metal mask (FMM), a critical part of the OLED RGB evaporation process – a process in OLED mass production that significantly affects the yield rate.

Prior to 2018, Samsung Display and DNP"s monopolistic supply contract prevented other panel fabs from acquiring quality FMM products as DNP bonded with Hitachi Metal, the "only" FMM material provider choice for OLED makers. After the contract expired, panel makers like BOE could purchase FFM from DNP for their OLED R&D and mass production. Except for FFM materials, vacuum evaporation equipment is dominated by Canon Tokki, a Japanese company. Its role in the OLED industry resembles that of ASML in the integrated circuit space. Canon Tokki"s annual production of vacuum evaporation equipment is fewer than ten and thereby limits the total production of OLED panels that rely on evaporation technology.

The shortage of equipment and scarcity of materials inspired panel fabs to explore substitute technology; they discovered that inkjet printing has the potential to be the thing to replace evaporation. Plus, evaporation could be applied to QLED panels as quantum dots are difficult to be vaporized. Inkjet printing prints materials (liquefied organic gas or quantum dots) to substrates, saving materials and breaking free from FMM"s size restriction. With the new tech, large-size OLED panels can theoretically be recognized with improved yield rate and cost-efficiency. However, the tech is at an early stage when inkjet printing precision could not meet panel manufacturers" requirements.

Display and LGD are using evaporation on their OLED products. To summarize, OLED currently adopts evaporation and QLED must go with inkjet printing, but evaporation is a more mature tech. Technology adoption will determine a different track for the company to pursue. With inkjet printing technology, players are at a similar starting point, which is a chance for all to run to the front – so it is for Chinese panel fabs. Certainly, panel production involves more technologies (like flexible panels) than evaporation or inkjet printing and only mastering all required technologies can help a company to compete at the same level.

Presently, Chinese panel fabs are investing heavily in OLED production while betting on QLED. BOE has four Gen 6 OLED product lines, four Gen 8.5 and one Gen 10.5 LCD lines; China Star, controlled by the major appliance titan TCL, has invested two Gen 6 OLED fabs and four large-size LCD product lines.

Remembering the last "regime change" that occurred in 2005 when Korean fabs overtook Japanese" place in the LCD market, the new phase of panel technology changed the outlook of the industry. Now, OLED or QLED could mark the perfect time for us to expect landscape change.

After Samsung Display and LGD ceding from LCD TV productions, the vacant market share will be digested by BOE, China Star and other LCD makers. Indeed, OLED and QLED have the potential to take over the LCD market in the future, but the process may take more than a decade. Korean companies took ten years from panel fab"s research on OLED to mass production of small- and medium-size OLED electronics. Yet, LCD screen cell phones are still available in the market.

LCD will not disappear until OLED/QLED"s cost control can compete with it. The low- to middle-end panel market still prefers cheap LCD devices and consumers are satisfied with LCD products – thicker but cheaper. BOE has been the largest TV panel maker since 2019. As estimated by Informa, BOE and China Star will hold a duopoly on the flat panel display market.

BOE"s performance seems to have ridden on a roller coaster ride in the past several years. Large-size panel mass production like Gen 8.5 and Gen 10.5 fabs helped BOE recognize the first place in production volume. On the other side, expanded large-size panel factories and expenses of OLED product lines are costly: BOE planned to spend CNY 176.24 billion (USD 25.92 billion) – more than Tibet"s 2019 GDP CNY 169.78 billion – on Chengdu and Mianyang"s Gen 6 AMOLED lines and Hefei and Wuhan"s Gen 10.5 LCD lines.

Except for making large-size TVs, bigger panels can cut out more display screens for smaller devices like laptops and cell phones, which are more profitable than TV products. On its first-half earnings concall, BOE said that it is shifting its production focus to cell phone and laptop products as they are more profitable than TV products. TV, IT and cell phone products counted for 30%, 44% and 33% of its productions respectively and the recent rising TV price may lead to an increased portion of TV products in the short term.

Except for outdoor large screens, TV is another driver that pushes panel makers to research on how to make bigger and bigger screens. A research done by CHEARI showed that Chinese TV sales dropped by 10.6% to CNY 128.2 billion from 2018 to 2019. Large-size TV sales increased as a total but the unit price decreased; high-end products like laser TV and OLED TV saw a strong growth of 131.2% and 34.1%, respectively.

The demand for different products may vary as lifestyles change and panel fabs need to make on-time judgments and respond to the change. For instance, the coming Olympics is a new driving factor to boost TV sales; "smart city" projects around the world will need more screens for data visualization; people will own more screens and better screens when life quality improves. Flexible screens, cost-efficient production process, accessible materials, changing market and all these problems are indeed the next opportunity for the industry.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

A mil (or thou) is a unit of thickness that equals one thousandth of an inch (0.001 inches). Example: 10 mils = 0.010 inches. Mil thickness is commonly used in manufacturing in non-metric countries to measure the thickness of various thin materials, such as paint layers, thin films, foils, plastic sheets, and coatings.

Ultrasonic thickness gauges can measure paint thickness nondestructively. For example, Olympus gauges such as the 72DL PLUS instrument offer features that can calculate total paint thickness and simultaneously display paint thickness measurements of up to six individual layers. Paint thickness is expressed in mils or microns.

Automotive head-up display (HUD) systems include a projector that projects light onto the windshield. This light is then reflected into the driver"s eyes and appears as a virtual image on top of the hood of the car, at a comfortable viewing distance from the driver.1 The image source of the HUD projector, however, emits multiple rays of light at different angles from a common origin. For example, the light that is reflected into the driver"s eyes from the inner and outer air interfaces of the windshield creates the virtual image and a ghost image, respectively, and results in a double image. The windshield comprises laminated safety glass made from two layers of glass that are bonded together with one or more layers of polyvinyl butyral (PVB). Most windshields are not simple flat structures, but include slight curvatures in both the horizontal and vertical dimensions. The ghosting problem is illustrated in Figure 1(a) for standard windshields that have no wedge angle. The green and red lines show the paths of light from the image source, reflecting off the inner and outer windshield–air interfaces, respectively, into the driver"s eye to form the virtual and ghost images. The virtual and ghost images do not overlap, therefore, the image is blurred, as shown on the left of Figure 1(a).

To eliminate this ghosting effect, the angular separation between the virtual and ghost images must be less than the angular resolution of the human eye, which is about 0.2mrad. A PVB interlayer with a small, constant wedge angle is normally used to eliminate the ghost image for a driver at a defined location.2 The optimum wedge angle is dependent on the location of the driver"s eyes, as well as the mounting angle, thickness, and curvature of the windshield.3 This use of a PVB interlayer with a small wedge angle causes the virtual and ghost images to overlap, resulting in a sharp image, as shown on the left of Figure 1(b). A constant wedge angle, however, will only have an optimal effect for a single location of the driver, and taller or shorter drivers will still experience ghosting. To overcome this problem, manufacturers are starting to produce windshields with a wedge angle that varies as a function of the vertical position on the windshield.4, 5 It is therefore important to develop methods for determining the wedge angle and variations in the thickness of the windshield.

In this work, we demonstrate that low-coherence interferometry can be used to measure the windshield thickness and wedge angle profiles of a HUD system simultaneously. We have performed simultaneous measurements of the thicknesses of all the layers in laminated glass windshields (with a wedge angle) using the Lumetrics, Inc. trademarked OptiGauge II, which is a commercially available dual low-coherence all-fiber-optic interferometer. We then calculated the total thickness of the layers and the local wedge angle, as a function of the position. Our interferometer includes a superluminescent LED interferometer (with a center wavelength of 1310nm) for measurement in combination with a built-in laser interferometer for continuous distance calibration. A pair of fiber stretchers is used to vary the path length of the interferometer. Constructive interference occurs when the path lengths of the two arms of the interferometer are either equal or differ by the optical thickness—the product of the group index of refraction and the physical thickness—between any pair of optical interfaces in the sample. Further details concerning the operation and performance of the OptiGauge II are available elsewhere.6–9

We used a hand-held optical probe, which we have developed, to scan over the windshield surface while keeping all the relevant optical interfaces in focus. During these scans, the hand-held probe is kept normal to the surface of both flat and curved windshields, and at a constant distance from the surface. The distance to the surface can be adjusted so that all the optical layers of the windshield can be observed while scanning across the surface. Figure 2 shows the hand-held probe being used to measure the windshield thickness profile of a 2007 Chevrolet Corvette equipped with a factory-installed HUD system. A video of the procedure is also available.10 The optical fiber cable for our hand-held probe can be up to a few kilometers in length and is attached to our interferometer during measurement. In addition, the probe is moved manually at an approximately constant velocity from the bottom to the top of the windshield during the measurements. The distance scale in a graph of thickness versus distance is therefore only approximate. The thickness profile of each layer within the measured windshield is shown in Figure 3. The change in thickness of the PVB layer as a function of distance indicates that a small wedge angle is present, as is required for the HUD.

A snapshot of the OptiGauge II measurement screen, obtained during measurements of a five-layer acoustic HUD windshield, is shown in Figure 4. The horizontal axis shows the difference in optical path length between the arms of the interferometer and the signal peaks indicate the locations of the optical interfaces in the windshield. We made 100 repeated measurements of the thicknesses of the layers in this windshield. The standard deviations of these measurements varied from a maximum of 0.050μm—for the acoustic layer, i.e., the thinnest layer (with a thickness of 144.782μm)—to a minimum of 0.011μm for the top glass layer (with a thickness of 2125.883μm). For these measurements, the refractive index of the acoustic layer was 1.476 and that of the glass layer was 1.518.

The results of a scan in which we moved the hand-held probe from the bottom to the top of the same five-layer acoustic HUD windshield are shown in Figure 5(a). The thickness versus the approximate distance from the bottom of the windshield is shown for all the layers individually, as well as the total for the PVB interlayer. To obtain this quantitative data, we attached the hand-held probe to a transport stage. We moved this stage at a constant speed of 5mm/s, to give a spacing of 0.1mm between successive data points. The layer thickness data for the same windshield, over the region between 225mm and 525mm from the bottom edge (i.e., where the wedge angle in the PVB interlayers is constant) is given in Figure 5(b). This region of the windshield includes the location of the HUD image. We found that the wedge angle of the combined acoustic and PVB layers was 0.588mrad, as calculated from the slope of the best fit line for all the data points. The standard deviation was ±0.011mrad, as calculated from the local slopes using sets of five adjacent locations.

Figure 5.(a) Layer thickness as a function of position during a scan of the five-layer acoustic HUD windshield using the hand-held probe. (b) Quantitative partial scan of the interlayers of the acoustic HUD windshield with a constant wedge angle.

Windshields that are optimized for HUDs have very tight tolerances for uniform thicknesses of the glass layers and for wedge angles in the laminated PVB layers. Each model of car has different requirements for the wedge angles, therefore, precision metrology and quality control are required. We have demonstrated that the OptiGauge II interferometer, together with our hand-held probe coupled to a transport stage, can provide the required capability for measuring the thickness and angle profiles of individual layers in a windshield. Our next-generation probe will have built-in position encoders to provide quantitative position information during a scan, without requiring a separate transport mechanism. We also plan to assess windshields with variable wedge angles during their manufacture and assembly.

5. J. Hurlbut, D. Cashen, E. Robb, L. Spangler, J. Eckhart, Next generation PVB interlayer for improved HUD image clarity, SAE Int"l J. Passenger Cars Mech. Syst. 9, p. 360-365, 2016. doi:10.4271/2016-01-1402

As the mainstream display mode of LCD, IPS is overwhelmingly used in many fields of flat displays. However, due to the stress sensitivity of glass, the stressed light leakage is a bottleneck for achieving perfect dark state performance. The conventional scheme of using a compensation polarizer outside the cell has no effect on this light leakage. Although many studies have been conducted to overcome this limitation, the proposed methods have limited effects. Our research team has proposed a novel light leakage compensation mechanism by introducing a positive A plate that is sandwiched between the glass and the LC layer, therefore the light leakage which is caused by the combined effect of the phase retardations from the stressed glasses and the LC layer can be eliminated. In addition to theoretically analyzing the compensation principles of the novel light leakage compensation mechanism, we also use the developed positive A material to prepare light leakage compensation demos. And then the electric-optical characteristics and light leakage compensation effects of the demos are evaluated. While maintaining excellent optical and electrical characteristics, this technology effectively solves the problem of stressed light leakage of glass-based IPS, improves the dark-state image quality, and breaks the application of IPS in products such as curve products.

After decades of development, IPS (In-Plane Switching) LCD (Liquid Crystal Display) occupies a dominant position in the display field. Due to its excellent display performance, IPS is widely used in all sizes of display products, such as mobile phones, tablet computers, notebook computers, monitors, and TVs

The LL is proportional to the backlight luminance and the transmittance (Tr) of the panel. When evaluating the LL caused by stress, the backlight luminance and the φ are fixed, so the LL is proportional to Tr. At this time, the δ1 in the Tr formula becomes the retardation related to stressed glass and LC, it is proportional to the retardation of glass (δ). Therefore, LL can be derived as:

Due to the manufacturing process of CF/TFT glass and panel, and even the using process of IPS panel, it is difficult to completely avoid the stress birefringence of glass. Although some studies have proposed solutions, such as slimming of glass thickness

where σ is the stress from bending, E is Young’s modulus of glass (73,000 MPa for LCD display used glass), t is the thickness of the glass sheet and r is the radius to which the sheet is bent. In an ideal case, as the light passes through the bent glass, the in-plane retardation can be calculated by the stress-optic law shown in formula (

In this article, referring to the fundamental reason for light leakage, we have proposed a novel light leakage compensation mechanism, and a new LCD structure with an in-cell phase retarder as a solution. The basic idea of phase compensation is to introduce a positive A (+A) plate to compensate for the retardation of LC, make the stress birefringence of CF and TFT glass offset each other, and effectively eliminate light leakage. We have explained the compensation mechanisms, analyzed the electric-optical characteristics, and studied the effects of LL compensation. It is a very important point to note that, different from studies of compensation layers on improving the viewing angle

As mentioned above, our research focuses on stressed LL caused by mechanical deformation stress. When the panel is under force, due to the fixing effect of the sealant, the panel as a whole, it experiences tension on the TFT glass and compression on the CF glass as bending 1, under pure bending, these tensile and compressive stresses are equal in magnitude but opposite in direction. At the neutral axis where the transition between tensile and compressive zones occurs, the stress is zero.

The stressed LL mechanism of normal IPS is illustrated by using the Poincaré sphere2a", PI (Point 1), P2 (Point 2), P3 (Point 3), and P4 (Point 4) respectively represent the polarization state of light after passing through the polarizer, the TFT glass, the LC layer, and the CF glass. Due to the effect of phase retardation of LC, a certain level of LL occurs. When the angle between the optical axis of LC and the glass with stress birefringence is 0° or 90°, the phase retardation of the LC is invalid, and there is no light leakage. But when the angle between the optical axis of LC and the optical axis of the glass with stress birefringence is not 0° or 90°, the vertically incident light becomes linearly polarized light after passing through the TFT polarizer, due to the effect of the LC phase retardation, the polarization state after passing through the TFT glass, the LC layer, and the CF glass is changed. When passing through the CF polarizer, it cannot be completely absorbed and LL occurs. As shown in Fig. 2a", the distance from P1 (Point 1) to P4 (Point 4) is proportional to LL brightness.

Due to the combined effect of the phase retardations from the stressed glass and the LC layer, the existing IPS structure cannot eliminate the influence of glass stress. The key to solving this problem is to ensure that the light is located at P2 (as shown in Fig. 2a") before the light reaches the CF glass. We have proposed two compensation structures based on IPS mode. These compensation structures with an additional optical layer that can be matched with LC, and effectively eliminate light leakage. Although both schemes introduce a +A plate and effectively eliminate LL at a dark state, they have different structures and mechanisms.

As shown in Fig. 2b, the first new LCD structure called compensation mode 1, introduces the +A plate, which is sandwiched between the glass and LC. More specifically, the optical axis of the +A plate is perpendicular to the initial optical axis of LC, and the phase retardation of the +A plate is 350 nm, which is equal to that of the LC.Fig. 2b" illustrates the compensation principle of compensation mode 1. When receives external stress, the light from the backlight unit traverses the TFT polarizer, the effective optical axis position on the Poincaré sphere is P1, when the light (P1) successively passes through the stressed TFT glass, its polarization state is rotated from P1 to P2. And when the light (P2) passes through LC, its polarization state is rotated from P2 to P3. Then, the light (P3) successively passes through the +A plate and the stressed CF glass, whose effective optical axis positions on the Poincaré sphere are P4 and P5, respectively. The intermediate polarization state (P2) in general, is an elliptical polarization state. Due to the role of the +A plate, the polarization state (P5) on the Poincaré sphere is very near to the polarization state (P1), so the light almost can be absorbed by the CF polarizer, and the elimination of LL is achieved.

The second new LCD structure called compensation mode 2, also introduces a +A plate, but the optical axis of the +A plate is parallel to the initial optical axis of LC, the sum of the phase retardation of +A and LC is an integer multiple of a specific wavelength. Considering that the human eye has the strongest sensitivity to green light, the retardation value of +A is designed to be 200 nm, and the sum of phase retardation of +A and LC is 550 nm, that is the specific wavelength is 550 nm.

When the thickness of the glass is not equal, such as the thickness of the CF glass is 0.3t and the thickness of the TFT glass is 0.4t, the panel as a whole still has the same compressive and tensile stresses on the neutral axis, but the neutral axis is not in the middle of the CF and TFT glass. When the neutral layer is located in the TFT glass, the CF glass has compressive stress. But the TFT glass has tensile and compressive stress, as the stress birefringence δ generated by each has different directions, the δcompressive of TFT can be offset by the δtensile of TFT, and finally, the δtensile of TFT will be equal to the δcompressive of CF glass. At this time, the situation is the same as when the thickness of TFT and CF glass is equal. So when the stresses of the CF and TFT glass are not completely equal, the proposed compensation mode can still effectively reduce light leakage.

By comparing the viewing angle results in Fig. 4, the viewing angles of normal IPS and compensation mode 1 and mode 2 in the horizontal and vertical directions are almost equivalent, but for other viewing angles of compensation mode1 and mode 2 are different from the reference. This is mainly due to the effect of the +A layer. For mode 1, since the optical axis of LC and +A are perpendicular to each other, it is slightly worse than normal IPS at large viewing angles. For mode 2, the +A and LC optical axes are parallel, the difference in viewing angle is aggravated, but this has little effect, mode 1and mode 2 can still meet the viewing angle specification of 89°/89°/89°/89°.

The electric-optical characteristics of the panel are measured by DMS-1250 (Autronic Melchers Company). Figure 7 shows the V-T curves of 3.54inches demos. Because the light dispersion effect of LC and other materials was not considered in the simulation, the simulated value and the actual value cannot be completely consistent, but the trends and conclusions of the two are consistent. As can be seen from Fig. 7a, the V-T curves of normal IPS, compensation mode 1, and mode 2 basically coincides. Furthermore, it can be seen from the enlarged picture Fig. 7a", the dark state brightness of the sample is basically the same when no external force is applied, and the dark state brightness of compensation mode 1 is somewhat higher. The transmittance of normal IPS, compensation mode 1, and mode 2 are 0.099%, 0.128%, and 0.106% respectively. The transmittance curves are obtained from the brightness of the gray scales. The L0 brightness of normal IPS, compensation mode 1, and mode 2 are 0.5769nit, 0.6774nit, and 0.5526nit, respectively. Because the brightness test accuracy of the equipment is ± 0.01, the device error can be eliminated. It can be seen that the difference in brightness and transmittance is mainly caused by sample differences. The L0 brightness of ordinary IPS and mode 2 is basically the same, while the L0 brightness of mode 1 is higher.

For compensation mode 1, the dark state brightness is higher than that of the other two demos as shown in Fig. 3, so it has a lower CR. General, the light scattering of LC is an important factor to increase dark-state brightness and reduce panel CR

Since the +A plate is also horizontally arranged LC, its light scattered characteristics are similar to those of LC materials. The intensity of scattered light of the +A layer is proportional to the thickness d of the +A layer. As the retardation of +A is Δn*d, the intensity of scattered light of +A is also proportional to retardation. The CR of +A films are tested by CF Contrast Tester from Denkei. Figure 8 shows the CR of the +A films. The CR of +A decreases as the retardation increases. This is mainly because the retardation is proportional to d, the increase of d will increase the intensity of scattered light and decrease the CR of +A film.

Table Table22 are the CR of +A and panels. The retardations of compensation mode 1 and mode 2 are 350 nm and 200 nm, respectively. Due to the effect of light scattering, the CR of mode 1 (4100) is lower than that of mode 2 (6900). For mode 1, the low CR of +A is the bottleneck CR among the various optical layers of the panel and further reduces the CRpanel to 789. So it is necessary to increase the CR+A for mode 1. For mode 2, +A has a higher CR of 6900 which is almost equivalent to the color filter CR in IPS, the CRpanel remains the same as normal IPS. Based on the existing compensation materials, compensation mode 2 is recommended.

In order to verify the LL elimination effect of compensation technology on curved samples, the samples of 13.3 inches with a curvature of 2800R/2500R/2000R/1500R/1000R are prepared. And the glass thickness of normal IPS and compensation samples are 0.5t/0.5t (TFT/CF glass). The L0 brightness at the center of the panel and at the four corners of the panel are tested respectively. And the LL compensation effect of different curvatures samples are compared and analyzed. The ratio of the brightness of the four corners to the center is used to represent the LL level. The larger the ratio, the greater the brightness of the four corners, and the worse the compensation effect of LL.

In this paper, a compensation structure with excellent dark state image quality is proposed and experimentally analyzed. This technology can fundamentally improve the dark state LL even under deformation. By introducing a +A plate that is sandwiched between the glass and the homogeneous LC layer, the LL caused by the combined effect of the phase retardations from the stressed glasses and the LC layer can be eliminated. But the compensation layer for glass stressed LL must be placed between the upper and lower glass, inside the cell. The conventional scheme of using compensation polarizer outside the cell cannot achieve the compensation effect of the scheme proposed in this article. We have proposed two light leakage compensation mechanisms and structures, compensation mode 1 and mode 2. Considering the optical characteristics, especially the effect of CR of +A on the panel, we recommend the mode 2 solution. For mode 1, after the CR of +A material is improved, it is also a good light leakage improvement solution. This compensation technology is applicable for IPS modes. In addition to theoretical analysis of compensation principles, we have also developed +A materials that can meet the preparation process of IPS and prepared effective compensation demos. It is proved that the solution proposed in this paper is not only effective for reducing the local stress LL of flat panels but also effective for weakening the curved stress LL.

The LC polymer used in this research is the LIXON COAT PLC-75BT series of JNC, involving PLC-75BT01 ~ PLC-75BT07. Among them, PLC-75BT05 is recommended because of its better optical characteristics. At first, the +A material is coated on CF glass by slit coating, where the viscosity +A is 3.3 mpa•s and the coating speed is 150 mm/s. Then, put the +A glass in a vacuum chamber with a pressure of 30pa to remove the solvent. When the set pressure is reached, the glass is placed on the heating plate and kept at 90 °C for 3 min to further remove the solvent and optimize the +A alignment. After cooling to room temperature, UV cure the +A glass (500mj/cm2, 365 nm). Finally, the +A glass was placed on a hot plate at 110 °C for 30 min to fully polymerize. So far, the preparation of the +A film layer is completed.

1. Ishinabe T, et al. Optical design of R-OCB mode full-color reflective LCD with wide viewing angle and high contrast. J. Soc. Inform. Display.1998;6:243–246. doi: 10.1889/1.1985248. [CrossRef]

16. Yafeng, Y. et al. Simulation and experimental study on light leakage in ADS mode LCDs. SID Symposium Digest of Technical Papers Vol. 45, 1251–1254 (2014).

19. Jeong, H. S. et al. Liquid crystal display black light leakage correlation between VA and IPS by curvature. International Workshop on Active-matrix Flat panel Displays & Devices. IEEE, (2014).

20. Li, Z. D. et al. P-11.2: The analysis of light leakage under the large viewing angle for LCD. SID Symposium Digest of Technical Papers Vol. 50, 910–911 (2019).

36. Utsumi Y, et al. Light leakage behaviors of homogenously aligned liquid crystal layers placed between crossed polarizers. Jpn. J. Appl. Phys.2008;47:2144–2148. doi: 10.1143/JJAP.47.2144. [CrossRef]

37. Utsumi, Y. et al. Reduced light scattering intensity from liquid crystal layers for higher contrast ratio in IPS-Pro LCDs. Proc.IDW’07,17, 1749–1750 (2003).

Frequent blinking in children was associated with prolonged use of terminal devices, thickness of tear film lipid layer, and alterations in meibomian gland function.

In this study, a significant risk factor for excessive blinking in children was prolonged video device use. Some scholars have pointed out that the prolonged use of VDT is an important cause of dry eyes, and found that warming moist chamber goggles have an excellent curative effect (34). There is a time-dependent oxidative stress response in ocular surface tissue, but the VDT durations in the present study are not sufficient to discern any damage to the ocular surface. Longer periods of VDT use may cause damage to the ocular surface. Perhaps short periods of use cause the decline of MG secretion function and the thinning of TF lipid layer, which leads to the deterioration of TF stability, but not the loss of MGs.

Interestingly, studies have shown that incomplete blinking is associated with a two-fold increased risk of dry eye disease in patients with poor LLT (40). The TF lipid layer is composed of lipids secreted by meibomian glands, is located in the outermost layer of the TF, and has thickness in the range of 20–180 nm. As the lipid contact surface between the eye and the external environment, TF lipid layer can assist other TF components to inhibit tear evaporation, stabilize the air-tear surface between eye opening and blinks, and play a role in the first line of defense against bacterial invasion (41). The thickness of TF lipid layer is affected by a decrease of eyelid lipid or a change of tear composition.

Abstract: An organic light emitting diode display panel in this disclosure comprises a base substrate, an array layer disposed on the base substrate, and a planarization layer disposed on the array layer. The OLED display panel further comprises anodes disposed on the planarization layer, and a pixel definition layer located between the anodes adjacent to each other. A luminescent layer, a cathode, and an encapsulation layer are provided on the anodes. A preparation material of the pixel definition layer is a light-shading material. By the pixel definition layer made of a light-shading material, the light shading effect of the OLED display panel is greatly enhanced, and the influence of the lateral light leakage of the OLED display panel on the TFT device is prevented.

Abstract: The present invention provides a chromaticity adjustment method, a chromaticity adjustment device, and a display panel. The chromaticity adjustment method makes a chromaticity of a white image conform to a target value by adjusting a thickness of a liquid crystal layer corresponding to blue pixels. Therefore, a chromaticity deviation in the display panel can be relieved. In addition, after adjusting a thickness of a blue photoresist layer, an adjustment range of a gray scale of blue sub-pixels (B) can be reduced. While improving the chromaticity, an impact on light transmittance rate can also be reduced, and color interference can be prevented.

Abstract: The present invention provides an OLED display panel and a manufacturing method thereof. The OLED display panel comprises a display area and a bonding area defined at least at one side of the display area. The OLED display panel further comprises a substrate and a first metal layer disposed on the substrate. The first metal layer comprises a light-shielding metal disposed corresponding to the display area and a bonding metal disposed corresponding to the bonding area.

Abstract: The present invention discloses a display device and a manufacturing method thereof, including the following steps: forming a thin-film transistor array substrate, the thin-film transistor array substrate including a first surface and a second surface that are disposed opposite to each other; forming a protective layer on the first surface; forming a metal layer on the second surface by a first patterning; forming a metal member by performing a second patterning on the metal layer; forming a patterned insulating layer on the second surface; forming an electrode layer on the metal member; forming a planarization layer on the electrode layer and the insulating layer; and removing the protective layer.

Abstract: The embodiments of the present disclosure provide a manufacturing method of a display panel and the display panel. The display panel includes a display area and a non-display area. When forming electrode layers of the display panel, a halftone mask process is performed on respective electrode layers, and a heat treatment is performed on the electrode layers in the non-display area to crystallize the electrode layers. Therefore, adhesion effect between the electrode layers and a substrate are enhanced and improved. The manufacturing method of the embodiments of the present disclosure is simpler and more effective, and the adhesion effect between electrode layers and the substrate is better.

Abstract: A display panel includes at least two chip-on-film (COF) binding regions, at least one voltage signal terminal disposed between two adjacent COF binding regions, and at least one shorting bar. Each shorting bar is connected to one voltage signal terminal and two COF binding regions adjacent to the voltage signal terminal. The shorting bar includes a first closed loop line and a second closed loop line. The first closed loop line is connected to the voltage signal terminal to define a first closed loop. The second closed loop line is connected to the voltage signal terminal to define a second closed loop.

Abstract: The present disclosure relates to a top emitting AMOLED display panel, a manufacturing method thereof, and a display device. The top emitting AMOLED display panel includes a passivation layer and a protective conductive layer. The passivation layer is sandwiched between an interlayer insulating layer and a planarization layer of the top emitting AMOLED display panel; the protective conductive layer covers a metal layer and side walls of openings. The passivation layer covering the metal layer can physically protect and prevent the metal layer from oxidation, and the protective conductive layer coats the metal layer to prevent the metal layer from being etched or oxidized by anode etching solution.

Abstract: A display panel and a manufacturing method thereof are provided. The display panel includes a substrate; a light-emitting functional layer disposed on the substrate; a thin-film encapsulation layer disposed on the substrate and the light-emitting functional layer and covering the light-emitting functional layer; a drying layer disposed on the substrate and disposed around the thin-film encapsulation layer; an encapsulation cover plate disposed on the drying layer and the thin-film encapsulation layer; a curing adhesive layer disposed between the substrate and the encapsulation cover plate and disposed around the drying layer, the curing adhesive layer configured to fix the substrate and the encapsulation cover plate, and a ring-shaped groove disposed around the drying layer and provided between the drying layer and the curing adhesive layer; and an encapsulant layer disposed in the ring-shaped groove.

Abstract: The present disclosure provides a precursor solution of an indium gallium zinc oxide film and a method of preparing an indium gallium zinc oxide thin film transistor. The precursor solution is provided with an indium salt, a gallium salt, a zinc salt, a stabilizing agent, and a solvent. The stabilizing agent is ethanolamine. Use of ethanolamine helps to promote an oxidation process of the precursor solution, and reduce an oxygen vacancy concentration in the indium gallium zinc oxide film, so as to improve negative bias of a threshold voltage of a channel layer made of the indium gallium zinc oxide film in a thin film transistor.

Abstract: The present application provides a display panel and a display device. The display panel includes a plurality of light-sensing circuits and a position detection circuit. The plurality of light-sensing circuits are disposed in the display panel and are arranged in an array. Each of the plurality of light-sensing circuits includes a light-sensing transistor. The present application disposes a quantum dot layer, which can absorb interactive light and convert its light intensity signal into an electrical signal, and determines an irradiation position of the interactive light through the position detection circuit, so that an interaction with light with a longer wavelength can be realized.

Abstract: A display panel and a manufacturing method of a display panel are provided. The display panel includes a display area and a non-display area disposed on one side of the display area. A driving chip and a fanout wiring area are disposed in the non-display area. A fanout line module is disposed in the fanout wiring area. The fanout line module includes a first wiring area and a second wiring area. A first signal line connecting the data line is disposed in the first wiring area. A second signal line connecting the gate line and another first signal line connecting the data line are disposed in the second wiring area.

Abstract: The present application provides a spliced display panel. The spliced display panel includes a panel body and a cover plate, wherein the panel body includes at least a splicing seam, the cover plate includes a cover plate body and a lens assembly connected to the cover plate body, an orthographic projection of the lens assembly on a plane where the panel body is located covers at least the splicing seam, and the lens assembly includes a first convex lens and a second convex lens.

Abstract: The present invention provides a pixel driving circuit and a display panel. The pixel driving circuit includes a light emitting module and a compensation driving module which are electrically connected. The compensation driving module includes a doubled-gate driving thin film transistor, and is configured to charge a bottom gate of the doubled-gate driving thin film transistor and adjust a threshold voltage to an initial value in an initial stage. The compensation driving module receives a reference voltage to discharge the bottom gate of the doubled-gate driving thin film transistor in a threshold voltage compensation, realizing a compensation of the threshold voltage.

Abstract: A display panel and a display module are disclosed. The display panel includes at least one power adapter and at least two sub-display panels. One of the at least two sub-display panels in one row or column is electricall

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey