diy custom lcd display free sample

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

Dr Pan: Hello, Greg. TN is the abbreviation for Twisted Nematic. The main difference between TN, HTN, STN and FSTN LCD is the view angle. From the definition, the maximum view angle of TN LCD is 90°. Take this TN positive LCD for example. The view angle is 6 o’clock direction and it can be seen very clearly in the 6 o’clock direction and the front side.

When it is a positive and reflective display, it can display without LED backlight; when it is a positive and transmissive/ transflective display, it can’t display without LED backlight, the background color is grey and the letters are black.

When it is a negative and transmissive/ transflective display, it can’t display without LED backlight, the background color is purple-black, different colors from different view angle, and the color of the letters is the color of LED backlight.

By the way, no matter it is a positive or negative display, the background color is affected by the color of LED backlight on some level. That is why the color of LED backlight is usually white.

Theoretically, we can add a blue film to TN negative LCD, it may look like this. Actually, from our experience, no one has done it before since HTN or STN negative LCD with blue background looks better with wider view angle.

TN LCD is the most commonly used since it is the cheapest. The maximum COM is 4, so it can’t display too many segments, and it can’t be used in the high end devices. But it performs very well in the simple display content: calculator and alarm clock.

One of the components the wearable watch needs is LCD screen. I have been receiving RFQs of round LCD display module since last year. Let me introduce you the 3 main ways that we make custom round display module.

It is a very common monochrome LCD screen. The pink graphic we see is the silk painting which is printed on the ITO glass. The outer clock is counting the seconds, so the black needle makes a complete turn in 60 seconds; and the inner clock is counting the minutes, so the black needle makes a complete turn in 30 minutes. In the middle of LCD screen, it is a typical 7-segment digital that could count minutes, seconds and 1/100th a second.

The LCD module includes LCD screen, IC, LED backlight (not necessary) and PCB (not necessary). The view area is only 77.0*77.0 mm, the LCD screen is 80.0*82.0 mm, but the whole COB LCD module is 94*105mm.

We use 6 DIP LEDs as the light source of LED backlight, and it needs 10 mm(8 mm at least) light shade area, check the green area of the picture above, that is why it is so big. The PCB is much bigger because there are 4 pieces of radius 1.5 mm screws to fasten the PCB and other devices together.If we put a plastic shell in front of it, it becomes a round LCD. The advantage of this methodology is that it is easiest to make, cheapest, and most stable. But the disadvantage is that the whole size of LCD module is too big. We can find a way to make it much smaller.

How can we make it so small? First, we confirm the view area 77*77 mm. Second, expand it 1.5 mm which is the minimum distance between the edge of LCD screen and view area. Third, expand it by 2.0 mm which is the distance between upper ITO glass and lower ITO glass. I marked the upper and lower ITO glasses with green lines.Fourth, expand it 1.0 mm which is the width and height of walls. Fifth, if I didn’t make a mistake, the LCD screen, LED backlight and PCB should be all round. As we know, LED backlight and PCB can be round, but not LCD screen. If LCD screen is round, what kind of connection should be used? Metal pin, zebra or conductive rubber strip can’t be installed in the round edge. Find the middle point at the bottom of LCD screen, draw a parallel line and move it up 2.5 mm, and we cut it along with the line, that is the edge of PCB. Move it up 1.0 mm and 2.0 mm, that is the edge of LCD screen. Move it up to 1.5 mm, that is the view area.

We finally get the parallel edge where conductive rubber strip or zebra can be installed. We can see that the parallel edge of LCD is only 25 mm. But how many segments do we have? 60 seconds segments + 30 minutes segments + 6*typical 7-segment digitals=132 segments. Duty is 1/4, 132/4+4=37 pieces of legs. There are 4 commonly used types of pitches for PINs: 1.27 mm, 1.5 mm, 2.0 mm, and 2.54 mm. There is no enough space (37*1.27=46.99 mm) to install PINs. But the minimum pitch of conductive rubber strip or zebra is 0.3 mm or 0.4 mm, therefore there is enough space (37*0.4=14.8 mm).

You may notice that LED backlight and PCB are the same sizes. But how can we fasten the LED backlight and PCB together? We need a plastic shell with a hole to hold all these pieces tight. Besides, there are 3 hooks in the LED backlight to hold the LCD screen. The disadvantage of this design is that it is expensive because it needs two special molds: one round LCD screen with a small semi-circle missing and a dedicated light guide plate which is to make LED backlight. And I don’t think it is very stable because all the parts are only held by the plastic shell (or cover).

Second, we extend it 2.0 mm (1.5 mm at least), see the green line in the picture above, and we get a bigger octagon which is the area of the LCD screen.

We can see that LED backlight (83.0*83.0 mm) is a little bigger than LCD screen (81.0*81.0 mm) and view area of them is exactly the same. Although we can’t fasten the LED backlight and the LCD screen together because there is no hook or screw, but there is enough space in the PCB to install the screws which can hold onto other objects. This plan C needs a plastic shell or cover as big as plan B to hold all of them together. Here I figure out some pros and cons of these plans. pricespacetechnology requirementsstylishstable

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

Orient Display is a company that specializes in manufacturing LCD displays, touch panels, OLED displays with competitive prices. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years, Orient Display factory is now the world’s leading custom LCD manufacturer in flat panel industry and is listed as a public company in China stock market. Now, Orient Display factory has 2 production lines that can produce PMOLED and AMOLED custom display modules. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. Orient Display takes around 18% market share in global automotive market and is No.1 in automotive capacitive touch screen.

Orient Display has supported customers with custom LCD displays for tens of thousands of types and models for automotive, appliances, medical, smart homes, point of sales, industrial advices, etc. Whether your design requires a small custom LCD display glass, or a fully customized LCD module, or custom monitors and displays equipped with complicated embedded control board with touch panels, our experienced engineers in North America, Europe or in China factory will assist you in designing your customized displays.

Orient Display customer service sends quotation to you (might come with technical suggestions according to your targeted applications). The time will depend on the complexity of the project and the time to source components, normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

Orient Display engineers provide custom LCD display counter-drawings for you to approve with your signature on the drawing. The drawings might be modified several times until the designs are fully achieved your technical requirements. There can be a lot of technical discussions at this stage. The time our engineers take to arrange drawings also depend on the complexity of the project. Normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

After your drawing approval, Orient Display will start to make samples or prototypes for you to test. The lead time also varies depending on the production complexity and component/material sourcing. Normally, it takes 4-6 weeks for custom LCD glass panels, 8-10 weeks for custom LCD display modules or touch panels.

After your sample / prototype approval, Orient Display is ready for production. Orient Display welcomes trial production between the prototypes to large scale production so that you have the opportunity to fully test the custom LCD display or touch panel to run well in your designed products.

Congratulations! You have accomplished the journey of the idea, design, prototype and production in the market. The journey can take from 3 months to 3 years. Whatever the voyage, Orient Display’s engineers, customer services are proud to be part of your design. Our happiness is based on your success.

Dimensions (Specification / Drawing / Sketch of the LCD, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Fully custom made TFT LCD display module can be very expensive, the NRE ranges from $80,000 to $1M depending on the size and the resolution of the LCD display and the generation of the production line the LCD display to be produced. For over 99% of our projects, we are talking about the modifications of the standard TFT LCD display. There are a lot of standard color TFT displays available in the market. You are highly likely to find one matching your requirement. If you can’t find a suitable one on our website, please check with our engineers, we have a database in factory with much more types.

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop replacement, it is great to provide files in dwg. or dxf. format.

The above information can be overwhelming. Actually, we design a lot of touch panel and LCD custom display projects without being provided detailed information. Our engineers and customer service can quickly decide the parameters based on the customer’s application. Please feel free to contact our engineers for details.

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

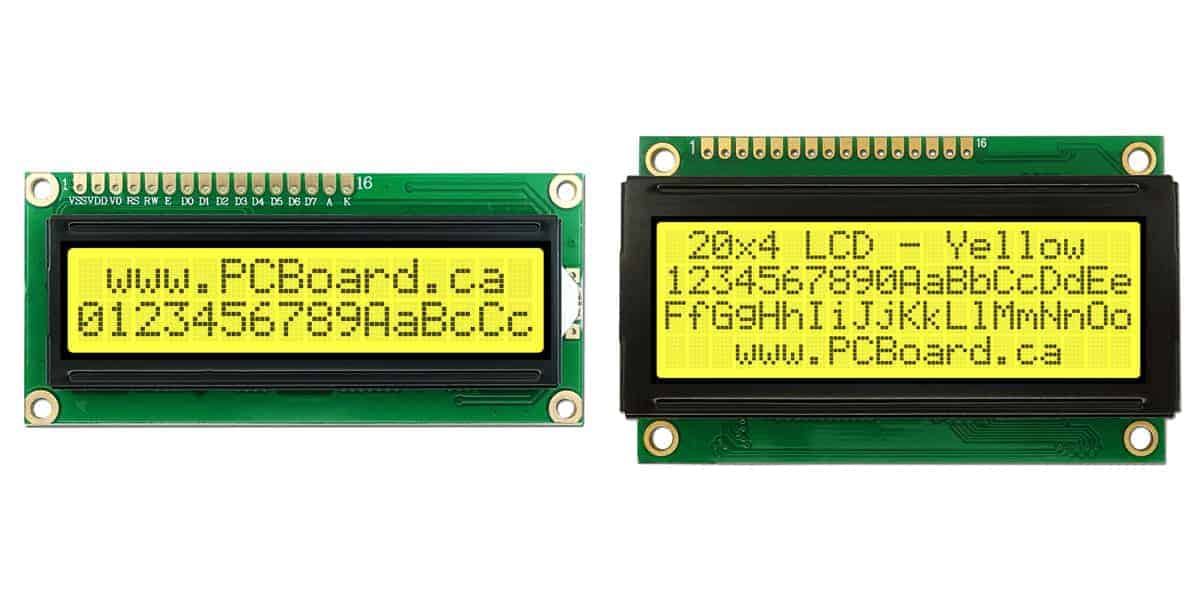

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

Next is the E pin which enables the writing to the registers, or the next 8 data pins from D0 to D7. So through this pins we are sending the 8 bits data when we are writing to the registers or for example if we want to see the latter uppercase A on the display we will send 0100 0001 to the registers according to the ASCII table. The last two pins A and K, or anode and cathode are for the LED back light.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

The first parameter in this function is a number between 0 and 7, or we have to reserve one of the 8 supported custom characters. The second parameter is the name of the array of bytes.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

Similar to the cursor() function, this will create a block-style cursor. Displayed at the position of the next character to be printed and displays as a blinking rectangle.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

A custom character allows you to display any pattern of dots on a 5×8 matrix which makes up each character. You have full control of the design to be displayed.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

Hey, great instructable. When I first saw the 2x16 display had 8 programmable characters, I was hoping large fonts or some graphics would be possible, but given the few characters, and only two lines to work with, I just assumed a big font would be impossible.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

Then, in the setup(), create a custom character using the createChar() function. This function accepts as arguments a location to allocate the char and the char variable as follows:

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

Make a positive first impression with potential clients and partners with our video business cards! Our cards combine cutting-edge technology with stunning visuals to create a one-of-a-kind LCD video business card. These visually appealing LCD business cards are great for networking events, trade shows, conferences, and more.

The LCD business card is custom printed with your design and houses a 2.4” LCD screen (resolution 320×240) available with or without speaker holes and an optional PLAY/PAUSE button. The LCD business card enables that ever vital elevator pitch to be delivered perfectly, every time. Production times are usually two weeks and the minimum order quantity – is 25 copies. Request a quotation.

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey