is an lcd panel with a broken ribbon cable unfixable in stock

If that"s the case it should be fairly straight-forward. I"m guessing you already have the screen off; otherwise it wouldn"t have broken, so you probably know how to do that part.

Once the screen is off, you just have to remove the rear cover to get to where the LCD is plugged into the motherboard. Basically just take out a zillion screws, take off the back and flip it over. That whole procedure is shown in this video teardown; all you have to do is follow it up to about the 13:43 mark.

And of course you"ll need a replacement flex cable; you can find those all over the place; eBay, Amazon, AliExpress, etc. Here"s one of the first ones that came up on a search.

The newer ribbon type DMDs are notorious for being unrepairable. This is due to the carbon traces used on the display glass. If a ribbon cable gets damaged, it"s otherwise not a big deal to replace it and run jumpers. This has been tried before many times but nobody has reported they have fixed dead lines on these things. I read soldering the carbon pads on the glass could not be done.

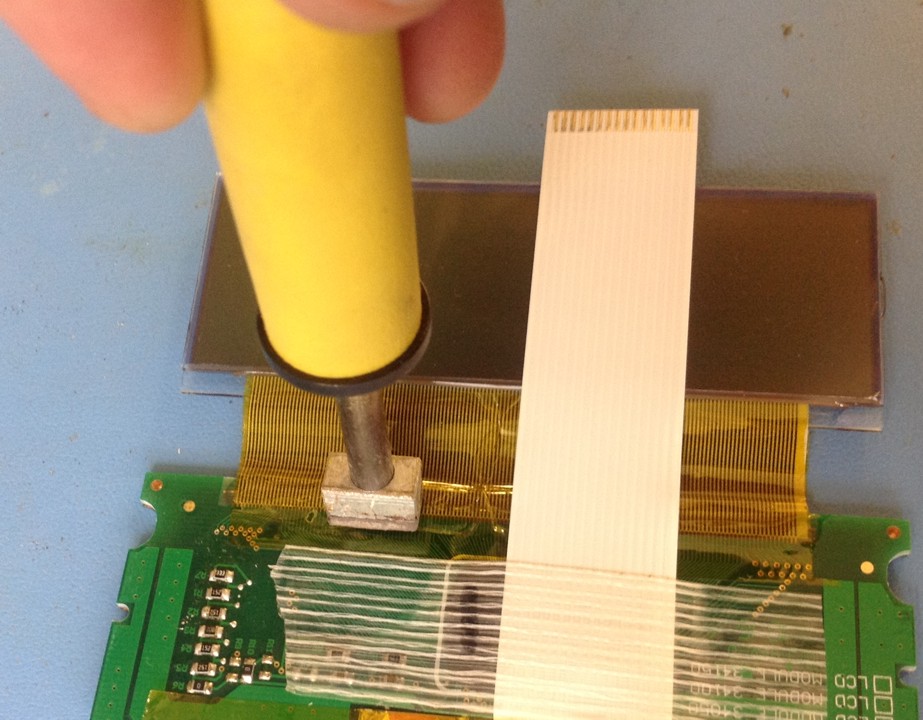

I got this one from a bulk trade and figured I would try and fix it since it"s otherwise a paperweight. I suspected the top left ribbon cable but then realized after gently flexing the cable various directions that was not the case. So I carefully used a spudger tool to separate the glass from the PCB and gently remove the row ribbon cable a little bit at a time.

I narrowed the issue down to a column driver IC in the immediate area of the affected lines. I put this under a component microscope and found all 16 legs on the ribbon cable side closest to the top of the DMD were separated from the board. A quick drag solder technique with plenty of flux cleaned that up.

Now the fabled un-fixable ribbon cable. Legend has it that many aspiring techs have tried to tackle this wild beast in the past and have failed. I dug up this quote from another thread which pinpoints exactly why:

So I tried to convince myself to leave the ribbon cable in place, as I was able to tin all 32 leads on the board without trouble. But I realized the cable was trashed at the section where it meets the board. I tried to solder but the plastic cable started melting immediately.

After scraping off what appeared to be conductive adhesive, I tried to tin the pads on the glass with solder. At first I had no luck, but with enough flux and scraping away the remaining residue I was actually able to tin one the leads. Yay!!

Now the really nerve wracking part... soldering all 32 jumper wires and crossing my fingers. I used silicone wire because of its flexibility, trying to avoid any stress on any of the carbon pads. At first this was working pretty well. But the occasional wire would become desoldered as I moved along tacking on the neighboring ones. What really killed my momentum was seeing the desoldered wires take the actual carbon pads with them. When trying to re-attach the jumpers, there was no carbon left at all to grab on to. NOOO!!

So even though I was I able to solder to the carbon pads on the glass itself, the adhesion of the carbon after 24 years on this 1996 Cherry display was compromised and it lifted right off the glass. Not sure why, maybe it was heat during operation or heat when soldering that caused it. Or maybe just a poor printing process in general. Since I knew this was a failure I removed the remaining jumpers from the glass. Some were connected well, others didn"t take much force to pull off.

As often as you use your smartphone, it’s almost inevitable that you’ll eventually drop it. You may be extremely careful, but it only takes one fumble for your phone to tumble. While iPhone screens are designed to withstand impact, you might still end up with a shattered screen.

The good news: a broken screen doesn’t mean your phone is kaput. In fact, if only the glass is broken, the fix is quick and inexpensive. The bad news: if the LCD screen is broken, you’re looking at a pricier repair.

If you’ve looked into replacement parts, you’ve likely come across two very different options: a glass screen, and an LCD screen. While the first option is cheap, the second is definitely not. Here’s the difference:

1. The glass screen is the exterior layer on your phone’s display. While it is specially engineered for durability, it’s still just glass (between layers of plastic film), which is why it’s not very pricey to replace.

Most of the time, the damage to your screen will be pretty obvious. You’ll see the spider web patterns of shattered glass across the front of your iPhone. Occasionally, however, the glass screen will be intact, and you might not realize the damage until you try to use it. Whether the damage is visible or not, it’s a good idea to run a quick diagnostic to determine the extent of it.

If you encounter any of these problems, you’re dealing with a broken LCD screen. If the glass is shattered, but the display is clear and touch capability is working, that’s a good sign. The problem is probably just the glass screen.

Whether you’re dealing with cracked glass or a broken LCD screen, you can find a quick, reliable repair service at FastPhoneRepair.com. Our qualified technicians will get your iPhone repaired and up and running again in record time and at reasonable rates.

Degradation of the fine ribbon cable in older TI graphing calculators is a familiar problem, manifesting as missing rows and columns in the LCD. Otherwise perfectly functional calculators are put to waste over two relatively short-lived ribbon cables, one of which is unreplaceable, with long-term repair methods elusive.

As the LCD is integral to the very purpose of the calculator, I was interested in correcting this common issue for the sake of correcting it. Something as trivial as "exercising" missing lines in the display would often reinvigorate them for about a day, which prompted me to investigate a more reliable repair.

Though TI does not specify the assembly method actually used, many similar ribbon cables are applied by hot press. While this entails expensive, specialized equipment, I learned to imitate the hot press process using inexpensive, readily-available components through a video on automobile instrument panel repair. Note that I modified the method since we are not able to install a new cable.

I have applied the method to seven graphing calculators exhibiting fine ribbon cable failure. In the 20 days between the repair and this writing, I observed a high degree of success across the calculators repaired.

Before continuing, check whether the fine ribbon cable is culprit. Missing or intermittently functioning lines are prime indicators of fine ribbon cable degradation. If the contents of the screen are garbled or corrupted, the coarse ribbon cable will need to be repaired first:

These are available on eBay for about US $7. The point of this is to distribute heat and pressure along the ribbon cable connection in a similar manner to a hot press. If given a choice between a tip for 30W, 45W, 60W, etc. choose 30W unless using a larger unregulated iron.

Use a soldering iron that fits this tip, which generally goes down a shaft without screw threads and is secured by a screw on the side. An iron with temperature control is preferable, though I have found that a 30 watt unregulated iron will do, if you are skilled or inclined to use one.

Install the T-tip with the silicone pad trimmed to size and allow the silicone contact surface to reach around 150 C. The 30W unregulated iron I tested reached this temperature as well.

Remove the circuit board from the calculator. Locate where the fine ribbon cable connects to the edge of the LCD glass. If there is foam padding attached, gently peel it off and set it aside. Be sure NOT to tear the ribbon cable off either end, which will ruin the chances of a successful repair.

Locate where the fine ribbon cable connects to the board. Set the LCD face down on a flat, non-abrasive surface and place the iron flat on the connection as such:

Use firm, even pressure on the connection and slowly slide the iron across the width of the cable. Take ~20-25 seconds for one pass. Do another pass. Alternate to the glass side and place the iron flat on the glass/cable connection as such:

Make two passes across the connection as before. The edge of the LCD may change color as heat is applied, but if it is turning a dark or purplish blue, move the iron faster to prevent overheating.

Now reassemble the calculator and test if the display looks good. If any defects remain, do another pass over the cable connections. There is the possibility, however, that some lines do not resolve even on the second or third attempts. These, unfortunately, will remain unrepairable.

Note: From my testing, the silicone pad is necessary to distribute heat and pressure along the cable. It will also wear out when used multiple times. Replace it when it no longer slides smoothly over the ribbon cable connection.

The TI-85 and 86 feature two ribbon cables, one on top responsible for vertical columns and one on the side for horizontal rows. Determine which one needs repair and move the side ribbon cable out of the way if necessary. I have yet to attempt a repair on the side ribbon cable, which appears more challenging to access than the top cable.

One TI-82 has one column that will start working once something is displayed on it. Despite two repair attempts, this column would not stay put when the calculator was powered off for a longer period of time.

Ideally, an economical, readily-available replacement LCD assembly without such a flawed ribbon cable would be available to prolong the useful life of TI graphing calculators. This is currently in the works as we see with KermMartian"s Surget. In the absence of a finished replacement LCD, this currently is the most effective method I have found to breathe new life into aging calculators, restoring the majority of, though not all, missing LCD lines.

Across a sample of seven calculators over 20 days, each LCD line that was repairable and repaired remained functional. The long-term viability of this repair method remains to be discovered, though it is one that vaguely emulates a common method of LCD ribbon cable assembly at the factory. In the meantime, I will take note of and post any significant changes that I notice on the calculators I have repaired using this method.

TI-80: Several missing columns and a missing row appeared. All but four columns returned to normal almost immediately. After moderate use of the screen, one column remained blank.

All calculators, except for the 0197I TI-85 (used daily), were largely unused in storage throughout the five-month period. I am not sure whether that made a significant difference.

No further repairs were attempted. Hopefully the repairs on the TI-82s and the TI-85 will continue to last a while more. I"d say this was a rather fun experiment and I will continue posting any significant developments.

Have your own thoughts to add to this or any other topic? Want to ask a question, offer a suggestion, share your own programs and projects, upload a file to the file archives, get help with calculator and computer programming, or simply chat with like-minded coders and tech and calculator enthusiasts via the site-wide AJAX SAX widget? Registration for a free Cemetech account only takes a minute.

Select a forumAnnouncements----------------Cemetech News and AnnouncementsCemetech LabsContestsGeneral Discussion----------------Technology & Calculator Open Topic-- Electronics/Hardware Development-- Calculator Hardware, Electronics, Robotics-- Calculator HelpYour Projects-- Do It YourselfGeneral Open Topic-- Politics & Rants-- Reviews-- Humour/JokesProgramming----------------Computer & Mobile-- [Comp] C and C++-- [Comp] Python, Java, and C#Calculator Programming-- TI-BASIC-- z80 & ez80 Assembly-- Casio Development & Programming-- HP Calculator News, Projects, and Support-- [TI] C and C++-- Axe & ICEWebsite Markup & Scripting1337 Programming TipsCemetech"s Projects----------------Doors CS and Doors CSESourceCoderMember Features-- TI-Freak8x-- Merthsoft-- MateoConLechuga-- JamesV-- PT_Other & Upcoming Projects-- The BASIC Elite-- mobileTunes-- CALCnet 2.2-- SuggestionsProgramming the TI-83 Plus/TI-84 PlusUsing the TI-83 Plus/TI-84 PlusWebsite-- Website Suggestions-- Website Bug ReportsCreativity----------------GraphicsMusicArtOther HobbiesPlay @ Cemetech----------------Minecraft-- Cemetech-MC 1.16-- Cemetech-MC 1.12-- Cemetech-MC 1.8FreeBuild & LEGO-- FreeBuild General-- Suggestions & Troubleshooting-- Content & Gallery-- Servers & ActivitiesUnreal TournamentOther Games

If your TV isn’t working properly, there are still a few things to consider before you give up on it. Generally, you’ll have a few warning signs that things are not exactly right.

Of course, sometimes, the TV is beyond repair and you should replace it instead. If the screen is broken or the TV doesn’t turn on no matter what you do (or if the sound stopped working completely), it’s time to check out a new set.

But, before it comes to that, let’s talk about TLC (Television Love & Care). If you start suspecting something’s not right and begin noticing imperfections on your

Few things are as off-putting as a dead pixel in the middle of your screen. Whether these dots are black or green, they’re incredibly inconvenient. Before jumping to the worst conclusion, however, you might want to make sure that it’s indeed a dead pixel, not a stuck one.

The difference is that stuck pixels usually happen because of a problem with a transistor; they often have different colours and are usually just simply out of place. If it is a dead pixel, then the TV should be sent for repairs, as, unfortunately, the issue is a difficult one to fix.

You may also want to check out if the problem is, indeed, with the screen. You’d be surprised at how often a small piece of dirt or dust can look like a dead pixel, so clean the screen before assuming you’re dealing with a big problem. Then use the screen to try games or connect it to your computer; if the pixel disappears on a specific media, then the issue could be the connection.

If the colours on your screen appear distorted, then your TV might be malfunctioning. Traditionally, this issue tends to occur gradually, meaning that you might not notice any difference at first. This is due to the common factor that one colour tends to weaken at a time; therefore, no obvious changes happen overnight.

Phantom colours are also a problem; if there are smears of bright colours in areas that should be completely white, you can be pretty sure that there’s a problem. Colour distortion is relatively simple to correct, so don’t despair! Contact a professional for advice.

If your screen starts to display bars and lines, this tends to indicate that there is an issue with a connector. This can occur when something magnetic has been placed near the TV and, in turn could mess with the picture quite considerably, even potentially de-magnetising the screen.

The issue can be due to cables that have become loose inside the screen as well, which is an easy fix, although it may require a professional because the TV may have to be opened.

This is often known as screen burn-in, although this definition is not entirely accurate. Screen burn-in is a more serious issue that involves the permanent degradation of the screen and occurs by leaving a static image on a screen for a long time.

Image retention, while frustrating, can be more easily fixed. Image retention occurs when the image sticks on the screen even when you change the channel or input different media – this tends to only appear for a few moments.

You may be able to do something about this by adjusting the levels of brightness and contrast on your TV and playing different types of content to see if the problem goes away. You can also enable your TV’s Pixel Shift feature; when this feature is turned on, images on the screen move a bit to vary the pixels used. Pixel Shift is often included in modern sets and might clean out the phantom image.

Another common problem is when the image displayed on the screen appears to be fuzzy or blurry. The smaller details tend to become lost and the quality of the picture displays poorly, very quickly taking your enjoyable movie experience to one of discomfort and stress.

This issue could occur if the signal received is a digitised standard (480p), as there’s a discrepancy between the resolution and the display. It’s also worth noting that the digital signal your TV receives can be affected by weather conditions as well, so the image can appear fuzzy and glitchy.

However, the good news is that, when this happens to modern televisions, there is a high chance of it being fixed, so you can still enjoy your TV for a long time.

If the TV is on but the picture is faded on some areas of the screen, it’ll be difficult for you to actually enjoy the content. You may try to ignore the stain-like mark but there is no denying that this will impact your experience. Faded spots are not that rare and can be accompanied by other serious issues, like your image fading to black after you’ve turned the TV on.

We offer repairs as well as a vast range of products so, if you find that your current TV is well past its sell-by date, be sure to browse our amazing

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This instructable came about from a broken LCD control module out of a modern VW Camper Van. The LCD module is part of a control unit which was virtually unreadable and a replacement for a new unit was £400+. It really was a no lose option, either have a go at fixing it or end up buying a new unit.

The fault of the LCD was that it only displayed a couple lines of output on the LCD. The symptoms are caused by poor location of the LCD ribbon in manufacture and also the poor position of the whole module in the vehicle which exposes it to heat and is subject to vibration within the vehicle. This causes the ribbon to fail eventually and is a known common fault.

The ribbon in this display actually controls the Rows of the LCD matrix and the Columns were handled by a rubber standoff connection on the longest side of the LCD. There were no problems with the rubberized connection.

Some re-work on the LCD ribbon had already been tried with a little improvement but the poor registration of the ribbon pushed me to try a new attachment.

From the photos below you can see the LCD control unit and the state of the LCD ribbon before repair. You can just make out the offset placement and poor registration of the ribbon before repair.

Do not under estimate the patience required for this repair as some delicate and nimble work is required and i cannot stress how important it is to take your time and not rush. You may only get one chance with this sort of repair.

The registrations of the LCD ribbon in this repair was difficult. It took me and my friend 20 minutes just to line up the ribbon for re-attachment. The ribbon in this case is sub 1mm pitch OR less than 25.4 thousands of an inch. You may want to try a simpler ribbon repair on an old LCD clock for example before jumping in head first with fine pitch.

Also the removal of the LCD ribbon is a delicate process as you do not want to tear what is a good ribbon or damage the carbon printed lines. Also the PCB must be respected to avoid introducing other faults and the the re-attachment may need an extra pair of hands.

You may also want to review the last step for results and lessons learned from this instructable before jumping in head first but i believe this will give a you a good insight to some important factors of LCD ribbons and possible success.

Other favorites of reworking the LCD connection that i have read here are the tinfoil on a heat gun. This has good temperature management but not so good in tight spaces. The solder iron with flat blade and tin foil is more precise but a 25 Watt iron can be too brutal on the ribbon.

1. Do you have enough spare ribbon to detach and re-attach? The more ribbon you have the more goes you may get but watch out for the mechanical caveat below.

2. Will you be mechanically constrained if you cut the ribbon. This is a tough one as some shortening of the ribbon may make it impossible to re-assemble the device!!

3. Is the Ribbon continuity visibly good, by that i mean the carbon connection lines are continuous and unbroken - Do check otherwise you may be wasting your time.

In the photos below you can see the available ribbon length was generous enough but do watch for mechanical constraints. In some cases you could find yourself not being able to lay down the LCD back down as it is too tight a radius to sit down.

The ribbon removal needs careful thought depending on your device. It would be difficult to write a complete panacea solution for every device so please use some careful judgement on your device.

You do not want to pull at the ribbon as you will most likely damage what you already have. In my instance it was best to cut the ribbon free as close to the PCB pads as possible.I used a scalpel to slice parallel to the PCB board to remove the ribbon. Do make a good job of this as you may need to preserve as much extra ribbon to re-attach the LCD module.

The LCD assembly was lifted off and put in safe place to avoid damage. The ribbon was then gently lifted and peeled back with tweezers to remove the bulk. You must not use force to remove the remainder ribbon especially if your PCB is off a cheap quality OR single sided cardboard type variety. The PCB pads can come off with the ribbon! If you have a double sided PCB of FR4

If you have a half decent PCB the connecting pads may be gold flashed (actually called Electroless Plated gold). This gold flashing is good as it provides a very good flatness to the PCB pads but they are not as mechanically strong as gold edge connectors (like you see on old PC adapter cards) which is a hard gold . The gold plate here is soft and also micrometer thin on the surface.

For either connection style you need to remove any old glue from the ribbon and remaining carbon debris from the pads. I used isopropanol on a cotton wool bud. Do not flood the PCB with cleaning fluidas you may effect electro-mechanical elements in close proximity such as switches and other items on the PCB which are not sealed against cleaning!

The PCB pads must be thoroughly cleaned and no debris must exist. Use you X10 OR x20 eyepiece here to check how clean the pads are. The PCB pads need to be pristine and nothing less.

From the photos you can see the PCB pads before cleaning through the eyepiece and the final photo shows the clean PCB pads with leftover cotton wool buds.

From the photos you can see that ribbon was trimmed with a rounded scalpel blade. The ribbon also had extra green tape which adhered to the original heel of the PCB pad connection. This gave extra mechanical stability for the ribbon but has to be peeled off to allow for re-connection. Later in this instructable i will mention about putting back extra mechanical stability for ribbon support.

If you have a fine pitch ribbon like i had this will cause you the most trouble. I needed an extra steady pair of hands to help and some patience before i got the the ribbon aligned. It took twenty minutes of nudging the PCB and ribbon to get a precise alignment. Our alignment was actually better than the original which was slightly skewed to one side.

If you do not have an extra pair of hands then i did think of using a large ball of Blu-tak to hold things in place but a second pair of hands is much better!

The trick to get good alignment is to allow some the gold pad fingers toes of the PCB to be visible just beyond the carbon lines of the ribbon. You then get the pads toes to line up with the carbon lines of the LCD ribbon.

Do not continue until you have excellent alignment of the black carbon lines of the ribbon to the PCB pads. The finer the pitch of the ribbon the better registration is required.

The photos below show how i handled the PCB and LCD and clamped the ribbon in place. The LCD display is being held by a plastic clamp above the PCB assembly. The PCB below which has components both sides is laying on some foam (try polystyrene). This allowed me to nudge the PCB under the ribbon into position. The plastic ruler acts as a LCD ribbon clamp. When you have got the registration get a steady handed friend to hold the ruler as a ribbon clamp in place so you can then apply the heat to stick the ribbon back down.

Check out the third photo and you can see what fine pitch means. There are two carbons tracks with a gap in every 1mm (25.4 thou). Now you see why it took twenty minutes to align!

You may want to skip forward to the next step to see the re-attached picture of the ribbon and to see how the alignment was achieved. You should see the gold PCB pad finger toes in line with the carbon of the ribbon

1. Do not apply so much heat you obliterate the ribbon. Yes it sounds stupid but i over cooked one side of my ribbon and got away with it. You may want to test on the bit you trimmed off elsewhere to get correct amount of heat.

2. Only tack the ribbon down my pressing the heated tip down vertically and stroking from the heel to the toe. That is to say in the same line that the carbon lines flows.

Tools for apply heating are up to you but i used a 25W Soldering iron with a wide flat tip covered in tin foil. Warning, the solder iron is too hot with tin foil so i cool it a little by dipping it into a wet sponge just before applying the heat. I used the solder iron tip method because i have more fine control but it did not have a regulated heat. If you have a good soldering iron with temperature control start low and work up to get the right heat.

Again Do not apply heat to the ribbon in one broad stroke. Work from the heel of the ribbon to the toe Or work by dabbing. By dabbing I mean hitting one spot on the ribbon with the heated tip and then lifted vertically again cooling the tip with the wet sponge before each dab.

The second photo in this step is the actual ribbon re-attached. You can see that the left hand side of the ribbon has not worked out as well as the right. I had too much heat in the solder iron. This is how i ended up cooling the solder iron with the wet sponge before applying heat.

In our case the LCD ribbon was not only glued to the PCB pads but there was some additional tape at the heel of the ribbon to hold the ribbon in place. By holding at the heel the ribbon you get some good extra mechanical support.

I did not go further with more re-work as the VW LCD module was considered a good enough result and some other time pressures intervened. It was concluded that we could read the display well enough and operate items from the controller. It was also considered as one of those quit while your ahead things!

For some people this may not be good enough but i hope that some of the steps i have listed will get people going in the correct direction when considering this. I do believe with a little more time a 100% is achievable. I took two hours to dismantle and remove the ribbon, Most of this was thinking things through... and another two hours to re-register and re-attach ribbon.

The technique for LCD ribbon removal and re-attachment are achievable certainly on simpler ribbons and fine pitch ribbons with careful preparation and thought. I hope this instructable is comprehensive enough for people to get some good results.

The ribbon is know as a "Heat Seal Connection" OR "HSC". In the industry heat and pressure are used to make this type of connection. The material comes from a family of "Anisotropic Conductive Films" OR "ACF".

The material bonds at 180 DegreeC. Direct Ribbon connection is used for economy (i.e. no fancy connectors) and for the number of connections its offers in a small footprint which would not be possible through traditional connectors.

The other end of the ribbon that joins to the LCD is terminated on the glass on Indium tin oxide (ITO) which is one of the most widely used transparent conducting oxides.

If you want more information there are many different types of LCM assemby (LCD Display plus it driving chips) to look at but these are the main ones (increasing in density):

In manufacture of these modules a machine is used for assembly which would compress HSC to the LCD Or the PCB and then apply the correct amount of heat.

very nice and complicated work but...my question is, where can I find a ribbon cable like this? I have a keyboard Technics KN2000 with a display not working because the cable was disconnected from both the glass display and the circuit board. Thank You!

I am attempting to fix a TV with vertical lines in it. Actually it was showing a black screen. I cleaned the ribbon connections and now I get an image with some multicolored vertical lines. ( good progress) . When I looked at the ends of the cable some of them were "missing" the last 1 - 2 mm of gold plating? do you think the method you used of slicing the ribbon to even the pads up is a good method? Or is there a way of replating/tinning the missing portions?

These graphite ribbon cables appear to have a layer of clear tape on either side of the graphite paths. To expose a new area of graphite paths for reconnection should the original path be damaged, the tape on one side needs to be peeled back. In my case, when I attempted to peel back the tape some of the paths fragmented and went with the peeled back tape. I suspect that in the case at hand, the peel back was not necessary and heat was used to reattach the previously exposed paths.0

My flat ribbon seems to have a plastic covering on both sides but looks just like your pictures. Must I remove the plastic covering on the attachment side before applying heat to make the connection or does the plastic stay in place and somehow act as a glue when hot?0

Attached is a picture of a screen from a Brookstone clock. I think it may be an LCD. The black pads show where a ribbon cable was connected and I see not transmission paths from the pads into the screen. How does this work? Is it really an LCD?

Are the paths in this ribbon cable covered on both sides as mine is and can you adhere the ribbon without removing any covering by applying heat? And what do I do on the LCD side where there appears to be no pads on the LCD but the ribbon cable was apparently applied in this manner?0

If this was a VW from when I use to drive them back in the 80"s, I would insert a comment here regarding "European automotive electrical systems, a love hate relationship". But since you posted "Modern" VW camper van, I"m assuming the electrical parts have little to do with "Where" the vehicle was manufactured. But back in the day (yeah, I said "Back in the day". I"m old...lol) I was having to fix something electrical on my VW"s once or twice a year on average...lol. But I loved my VW camper vans and continued to buy them. :-)0

I have two items to add, kapton tape and sil-pads used to isolate heat-sinks from semiconductor devices. With kapton tape it brings the means to secure the ribbon to the board, place the tape over the whole connection area, and kapton resists heat very well, ( try and melt it with your soldering iron). This means an average soldering iron turned down will allow heat to be applied to each joint. With experience a rework can be done in a few minutes. The bond can also be renewed on the LCD glass as well, kapton also works here. Sil-pads allow heat to be passed to the joint with some pressure applied at the same time. The sil-pad can be dragged up and down all the ribbon connections allowing uniform heating. Once the bond is resurrected the sil-pad is discarded. http://goo.gl/mpZNkm0

It"s pretty cheap and easier to solder, then you just have to clamp the cable into the connector. Maybe you are interested in reworking that to get all lines back.

Sorry, the connector on the link doesn"t match the board design... you must search for FFC, FPC connectors with the number of vias of your cable and look for the real dimensions on the datasheet.

I just thought the same way, adding aLCD flat connector... then you can swap chinese or VDO oem screens. Seems the VDO LCD(as for Audi A3-Vw golf/jetta4) have 50 pins and the ribbons is 48mm width. Then you have to look to modify the metal bracket to avoid pressure on ribbon.

i would not rule out a connector fix totally but its nice if you can fix for zero cost if possible. Also you then have to manage the mechanical constraints as well as choosing a suitable connector. Usually only the semi flexi PCB circuits ribbons go into connectors not the carbon screen printed sort so may not be so desirable.0

I think........you are a good electronics engineer ...........but I am not as you ......rather I have damaged my 3 calculator by this action.....................!..........................................but you have written very good............!0

I simply lifted the clear tape off from the top of the ribbon, then slowly stroked the ribbon contacts in turn a couple of times with the hot glue gun tip. Not hot enough to cause any damage.

My recommendation is to use a T-iron (see eBay .. about $35USD) which has the added advantage of having a heat shield that protects the insulation leading up to the solder pads.

In the photo i am only using a soldering iron covered in tin foil to heat the plastic ribbon. There is no solder used in this setup. The tin foil is there only to provide a better surface to apply heat to the ribbon (does not stick to the ribbon!!).

Actual Electrical connectivity is provided by carbon lines which are printed in the ribbon. The carbon lines only make contact via the adhesion of the ribbon.

The solder iron method technique is actually too hot and so i dip the solder iron in a sponge to cool it down before pressing down on the ribbon. If you have a temperature controlled soldering iron it would be much better.

i have an alarm clock which doesn"t have a ribbon, but instead some sort of rubbery contact strip against which the display should be pressed. You can find pics of it on google images for "lcd rubber contact strip", it seems to be called a zebra rubber. Any idea on how to glue/solder the display to that rubbery contact strip?More CommentsPost Comment

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey