how to test lcd display 16x2 brands

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

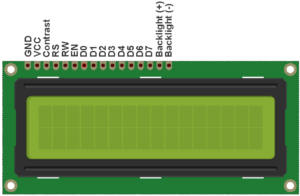

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

Sends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN(enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

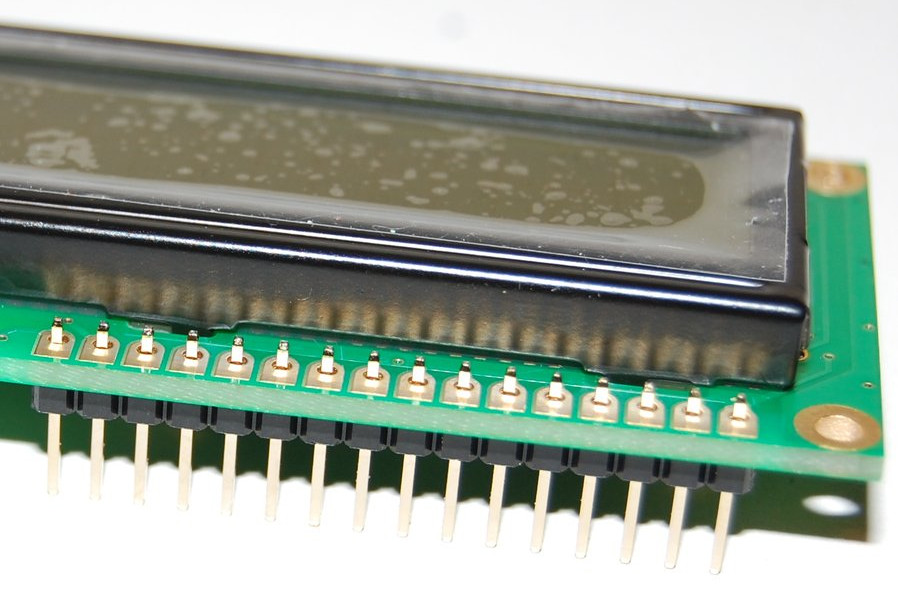

LCDs usually come without a microcontroller to control the display. To connect, you will need a strip of header pins, a potentiometer to adjust the contrast of the display, breadboard, and wires. Depending on the LCD, you may need a current limiting resistor to to limit the current to the LED backlight. You will need to solder the header pins of your choice to the display in order to plug it into your breadboard. If you have not soldered before, we recommend looking at our soldering tutorial.

While you can use any standard 16x2 alphanumeric LCD, the white on black display supplied with the kit looks übercool. The photographs in this guide are of a standard black on green display so yours may look different. The "16x2" refers to the display having two rows of sixteen characters each — other displays are available which are 8x1 or 20x4.

It is pretty straightforward to solder the header pins to the LCD module. Make sure to keep the soldering iron in contact with the joints for no more than about three seconds. There small risk of the damaging the existing components on the board with excess heat. You also need to be careful to keep the soldering iron away from the already soldered components on the board — you"re probably not yet ready to do surface mount soldering repair.

Before soldering, perform a "test fit" of parts. A test fit gives you a chance to double check if you"ve got the parts you need and ensures that they fit together. For this connection, break a row of 16x1 male headers and insert the header pins into the holes on the LCD module as shown in the image below. If you are using an RGB LED, you will need a row of 18x1 male headers.

Ensure that you don"t have one pin too many or too few in your header strip. Also make sure the black plastic strip of the header is positioned on the underside of the printed circuit board (PCB) so that you have plenty of pin length below the PCB to plug into your breadboard or a socket. The longest part of the pins should be below the PCB. The pin header provides connections that carry the data signals for controlling what the display... displays. They also carry power to the small microcontroller behind the black blob on the module and to the LED backlight if your display has one.

If you"ve done a test fit then your header should be in place. Ensure the header is aligned as parallel as possible to the edge of the board. Then solder the far left or right pin into place as shown in the image below.

Because there"s not a lot of room it is easiest to feed the solder from behind pin while the soldering iron tip is between the pins, resting on the PCB pad with the side of iron against the side of pin you"re soldering. The reason we start with just one pin is because it makes it easier to obtain the correct alignment and fix any mistakes.

If the alignment of the header isn"t quite right, carefully reheat the solder joint and move the header slightly. Don"t move the header when the solder joint is still in it"s liquid state however, or you"ll end up with a poor joint.

Once you"re happy with the alignment of the header you can solder another pin into place — we recommend soldering the pin at the opposite end of the header to the first pin you soldered. The reason for this is that once the two end pins are in place, the alignment won"t change.

Double check the alignment is still okay and if it"s not quite right you can reheat the joint and carefully move the pin. After you"ve confirmed the alignment, you can solder the remaining pins into place.

Your display module should now look like the image below. One additional detail to note is that the pin header is usually at the "top" of the display — so keep that in mind if you plan to mount it anywhere. Remember to always test the display out before mounting to a project.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Hi, I"m brand new to LCDs and Raspberry Pi GPIO. I"ve wired up a LMB162ABC 16x2 LCD that came in an Arduino Uno kit from Maker Faire. I"ve used just any open GPIO pins that I wanted figuring it doesn"t matter which ones I use as long as they are GPIO, is that correct? I want to operate in 4 bit mode so I have wired it accordingly. I get the screen to come on and the contrast variable resistor works and one row lights up solid blocks. I have tried a few python code examples and even adjusted the pins in the code to match the GPIO pins I chose and no matter what I do I cannot seem to get the dispaly to do anything (besides the solid row of blocks). Can someone please assist me with some super basic code or what I may be doing wrong? Here"s a link to a PDF of the specs for the LCD I"m using if it helps. http://www.datasheetdir.com/LMB162ABC+download

I tried Adafruit_CharLCD.py, nothing happened, wondering if the LCD it was written for was different and that"s why it"s not working...? I also posted this in the LCD screen section of the forum because I"m not really sure which area is a better fit for my issue.

I don"t see anything obviously wrong (my Python knowledge is very weak). These LCD devices are a pig to debug as you need everything correct to get any output.

Rezendes wrote:Hi, I"m brand new to LCDs and Raspberry Pi GPIO. I"ve wired up a LMB162ABC 16x2 LCD that came in an Arduino Uno kit from Maker Faire. I"ve used just any open GPIO pins that I wanted figuring it doesn"t matter which ones I use as long as they are GPIO, is that correct? I want to operate in 4 bit mode so I have wired it accordingly. I get the screen to come on and the contrast variable resistor works and one row lights up solid blocks. I have tried a few python code examples and even adjusted the pins in the code to match the GPIO pins I chose and no matter what I do I cannot seem to get the dispaly to do anything (besides the solid row of blocks). Can someone please assist me with some super basic code or what I may be doing wrong? Here"s a link to a PDF of the specs for the LCD I"m using if it helps. http://www.datasheetdir.com/LMB162ABC+download

I tried Adafruit_CharLCD.py, nothing happened, wondering if the LCD it was written for was different and that"s why it"s not working...? I also posted this in the LCD screen section of the forum because I"m not really sure which area is a better fit for my issue.

Do check the device voltage. Some 5v displays will not work at 3.3v - you can run them at 5v, but you must tie the r/w pin to 0v or you risk damaging your Pi...

If you have wiringPi, then there is some sample code there in C to drive these displays - see http://wiringpi.com/dev-lib/lcd-library/ for the details - and even if not programming in C it might be enough to double-check the wiring, display, etc.

Thanks for the replies, I have checked the physical connections a few times and they look fine. The display is 5v and I have made sure to Ground the R/W pin on the LCD. I did search and find that thread already and I have tried that code as well. I can"t imagine there are issues with all the code I have tried. I must have a physical problem... I will take some pictures of my wiring and use an ohmmeter to check each connection for sure.

I haven"t had time to take the pictures, I have checked the connections with the multimeter and everything seems fine and I think my contrast has always worked because it shows the solid row of black blocks. I will try the code you linked when I get a chance and post pictures if it"s allowed on these forums.

I am about to buy another LCD to test and make sure it"s not the LCD I have that"s the problem. The image here for the wiring of this LCD http://www.amazon.com/microtivity-IM161 ... icrotivity suggests a Diode on pins 15 and 2 pointing towards 15... Do I need that? That seems to be power to the LCD and power to the Backlight, my backlight powers up and my contrast adjustment works with the single row of solid blocks on screen... what exactly is pin 2 providing power for on the LCD?

The backlight appears to require about 4.2v and the diode is between it and the 5v supply. The diode will drop about 0.7v, so only 4.3v will get to the backlight which will be close enough to make it work without burning it out.

I already checked my connections with the multimeter though, I don"t have a diode in my setup and I"m wondering what it"s purpose is and If I Need one. Right now I"m sending 5v directly into pin 2 and 15.

1. it shows numbers and characters like #@$! in right way, but characters like "abcdefg" wrong, itshows !@#$ instead of alphabet, for example "*" for "j"

1. it shows numbers and characters like #@$! in right way, but characters like "abcdefg" wrong, itshows !@#$ instead of alphabet, for example "*" for "j"

1. it shows numbers and characters like #@$! in right way, but characters like "abcdefg" wrong, itshows !@#$ instead of alphabet, for example "*" for "j"

i use 4 bits connection and 0.0005 delay in time (same amount in sample code). i also have no pull up or pull downs, cause i don"t know which pins should be pull up or pull down (all data bits or only 4?) and with how much resistors, if you can help about this, i would be really thankful.

i use 4 bits connection and 0.0005 delay in time (same amount in sample code). i also have no pull up or pull downs, cause i don"t know which pins should be pull up or pull down (all data bits or only 4?) and with how much resistors, if you can help about this, i would be really thankful.

W.r.t. to the initialisation process, have you seen the HD44780U datasheet? (The relevant diagrams for 8-bit and 4-bit interfaces are figures 23 & 24**) Are you connecting the LCD directly to the Pi"s GPIO"s or, if it"s a 5V display, are you, like me, using level-shifters (see the links in my previous post)?

i use 4 bits connection and 0.0005 delay in time (same amount in sample code). i also have no pull up or pull downs, cause i don"t know which pins should be pull up or pull down (all data bits or only 4?) and with how much resistors, if you can help about this, i would be really thankful.

W.r.t. to the initialisation process, have you seen the HD44780U datasheet? (The relevant diagrams for 8-bit and 4-bit interfaces are figures 23 & 24**) Are you connecting the LCD directly to the Pi"s GPIO"s or, if it"s a 5V display, are you, like me, using level-shifters (see the links in my previous post)?

i use python and code is the same as this page. i don"t use level shifters for data bits (as said in link bellow), but i use . raspberry`s 5v out to power back light .i use procedure described here:

i use 4 bit, i think i have connected pins D4 to D7 right though there is no pull up or pull down resistors for D0 to D7 i don`t how should i do that. i personally have doubts about LCD`s solder too, although it shows no short circuit.

I think my second or third bit is stocked low, am i right? So pqrs: 0111 becomes 0011:0123 but 0123 stays 0123 cause it"s third bit is already 0 and make it low wont change it it was the reason a 0110 becomes ! 0010.

You"re getting "1234..." instead of "pqrs...". Initally that looks like a bit is staying low - as you suspected - and 0x01110001 "p" is getting sent as 0x00110001 "1", but then you have to remember that each character is getting sent as two lots of four bits, so "p" is 0x0111 and 0x0001. Now that still looks ok, but what about "u"? "u" is 0x0111 + 0x0111, which if that line were stuck would come out as 0x0011 and 0x0011 or "3", but it comes out as "7" 0x0011 + 0x0111. Therefore that line can"t be stuck.

You"re getting "1234..." instead of "pqrs...". Initally that looks like a bit is staying low - as you suspected - and 0x01110001 "p" is getting sent as 0x00110001 "1", but then you have to remember that each character is getting sent as two lots of four bits, so "p" is 0x0111 and 0x0001. Now that still looks ok, but what about "u"? "u" is 0x0111 + 0x0111, which if that line were stuck would come out as 0x0011 and 0x0011 or "3", but it comes out as "7" 0x0011 + 0x0111. Therefore that line can"t be stuck.

Check you connections: Most of the the problem will be your connections. Since we use a pre-tested library for our LCD displays there are very less chance for your code to be wrong. Instead concentrate on your connections make sure you have connected to the correct digital pins of the MCU.

Power up display:After making the connection when you power on the LCD, even if there is no code on the MCU you LCD should display boxes as shown below

Check your contrast pin:Another trouble maker is your contrast pin (3rd pin). Make sure this pin is connected to a potentiometer and vary the pot till you something on the screen. Because sometimes your LCD might be working just fine but your contrast level might be too low or high for you to visualize it.

Have a handy replacement:Sometimes the crude way is the best way. If you are still struggling to get it work. Try replacing it with a new LCD if the new also ones also does not work then the problem is with your code or connections. LCD displays can be easily damaged by normal reverse polarity or over voltage so having a replacement just in case is a good idea

LCD screens are useful and found in many parts of our life. At the train station, parking meter, vending machines communicating brief messages on how we interact with the machine they are connected to. LCD screens are a fun way to communicate information in Raspberry Pi Pico projects and other Raspberry Pi Projects. They have a big bright screen which can display text, numbers and characters across a 16 x 2 screen. The 16 refers to 16 characters across the screen, and the 2 represents the number of rows we have. We can get LCD screens with 20x2, 20x4 and many other configurations, but 16x2 is the most common.

In this tutorial, we will learn how to connect an LCD screen, an HD44780, to a Raspberry Pi Pico via the I2C interface using the attached I2C backpack, then we will install a MicroPython library via the Thonny editor and learn how to use it to write text to the display, control the cursor and the backlight.

2. Import four librariesof pre-written code. The first two are from the Machine library and they enable us to use I2C and GPIO pins. Next we import the sleep function from Time enabling us to pause the code. Finally we import the I2C library to interact with the LCD screen.from machine import I2C, Pin

3. Create an objecti2c to communicate with the LCD screen over the I2C protocol. Here we are using I2C channel 0, which maps SDA to GP0 and SCL to GP1.i2c = I2C(0, sda=Pin(0), scl=Pin(1), freq=400000)

4. Create a variableI2C_ADDR,which will store the first I2C address found when we scan the bus. As we only have one I2C device connected, we only need to see the first [0] address returned in the scan.I2C_ADDR = i2c.scan()[0]

5. Create an objectlcdto set up the I2C connection for the library. It tells the library what I2C pins we are using, set via the i2c object, the address of our screen, set via I2C_ADDRand finally it sets that we have a screen with two rows and 16 columns.lcd = I2cLcd(i2c, I2C_ADDR, 2, 16)

6. Create a loopto continually run the code, the first line in the loop will print the I2C address of our display to Thonny’s Python Shell.while True:

8. Write two lines of textto the screen. The first will print “I2C Address:” followed by the address stored inside the I2C_ADDR object. Then insert a new line character “\n” and then write another line saying “Tom’s Hardware" (or whatever you want it to say). Pause for two seconds to allow time to read the text.lcd.putstr("I2C Address:"+str(I2C_ADDR)+"\n")

9. Clear the screenbefore repeating the previous section of code, but this time we display the I2C address of the LCD display using its hex value. The PCF8574T chip used in the I2C backpack has two address, 0x20 and 0x27 and it is useful to know which it is using, especially if we are using multiple I2C devices as they may cause a clash on the bus.lcd.clear()

11. To flash the LED backlight, use a for loopthat will iterate ten times. It will turn on the backlight for 0.2 seconds, then turn it off for the same time. The “Backlight Test” text will remain on the screen even with the backlight off.for i in range(10):

12. Turn the backlight back onand then hide the cursor. Sometimes, a flashing cursor can detract from the information we are trying to communicate.lcd.backlight_on()

13. Create a for loopthat will print the number 0 to 19 on the LCD screen. Note that there is a 0.4 second delay before we delete the value and replace it with the next. We have to delete the text as overwriting the text will make it look garbled.for i in range(20):

Save and runyour code. As with any Python script in Thonny, Click on File >> Saveand save the file to your Raspberry Pi Pico. We recommend calling it i2c_lcd_test.py. When ready, click on the Green play buttonto start the code and watch as the test runs on the screen.

Lcd stands for liquid crystal display. Character and graphical lcd’s are most common among hobbyist and diy electronic circuit/project makers. Since their interface serial/parallel pins are defined so its easy to interface them with many microcontrollers. Many products we see in our daily life have lcd’s with them. They are used to show status of the product or provide interface for inputting or selecting some process. Washing machine, microwave,air conditioners and mat cleaners are few examples of products that have character or graphical lcd’s installed in them. In this tutorial i am going to discuss about the character lcd’s. How they work? their pin out and initialization commands etc.

Character lcd’s come in many sizes 8×1, 8×2, 10×2, 16×1, 16×2, 16×4, 20×2, 20×4, 24×2, 30×2, 32×2, 40×2 etc .Many multinational companies like Philips, Hitachi, Panasonic make their own custom type of character lcd’s to be used in their products. All character lcd’s performs the same functions(display characters numbers special characters, ascii characters etc).Their programming is also same and they all have same 14 pins (0-13) or 16 pins (0 to 15).

In an mxn lcd. M denotes number of columns and n represents number of rows. Like if the lcd is denoted by 16×2 it means it has 16 columns and 2 rows. Few examples are given below. 16×2, 8×1 and 8×2 lcd are shown in the picture below. Note the difference in the rows and columns.

On a character lcd a character is generated in a matrix of 5×8 or 5×7. Where 5 represents number of columns and 7/8 represent number of rows. Maximum size of the matrix is 5×8. You can not display character greater then 5×8 dimension matrix. Normally we display a character in 5×7 matrix and left the 8th row for the cursor. If we use the 8th row of the matrix for the character display, then their will be no room for cursor. The picture below shows the 5×8 dot matrix pixels arrangement.

To display character greater than this dimension you have to switch to graphical lcd’s. To learn about graphical lcds here is a good tutorialGraphical Lcd’s Working and Pin out.

The picture above shows the pin out of the character lcd. Almost all the character lcd’s are composed of the same pin out. Lcd’s with total pin count equal to 14 does not have back light control option. They might have back light always on or does not have a back light. 16 total pin count lcd’s have 2 extra A and K pins. A means anode and K cathode, use these pins to control the back light of lcd.

Character Lcd’s have a controller build in to them named HD44780. We actually talk with this controller in order to display character on the lcd screen. HD44780 must be properly handled and initialized before sending any data to it. HD44780 has some registers which are initialized and manipulated for character displaying on the lcd. These registers are selected by the pins of character lcd.

When we send commands to lcd these commands go to Command register and are processed their.Commands with their full description are given in the picture below.When Rs=0 command register is selected.

When we select the register Rs(Command and Data) and set Rw(read – write) and placed the raw value on 8-data lines, now its time to execute the instruction. By instruction i mean the 8-bit data or 8-bit command present on Data lines of lcd. For sending the final data/command present on the data lines we use this enable pin.Usually it remains en=0 and when we want to execute the instruction we make it high en=1 for some mills seconds. After this we again make it ground en=0.

To set lcd display sharpness use this pin. Best way is to use variable resistor such as potentiometer a variable current makes the character contrast sharp. Connect the output of the potentiometer to this pin. Rotate the potentiometer knob forward and backward to adjust the lcd contrast.

NOTE: we can not send an integer, float, long, double type data to lcd because lcd is designed to display a character only. Only the characters that are supported by the HD44780 controller. See the HD44780 data sheet to find out what characters can we display on lcd. The 8 data pins on lcd carries only Ascii 8-bit code of the character to lcd. How ever we can convert our data in character type array and send one by one our data to lcd. Data can be sent using lcd in 8-bit or 4-bit mode. If 4-bit mode is used, two nibbles of data (First high four bits and then low four bits) are sent to complete a full eight-bit transfer. 8-bit mode is best used when speed is required in an application and at least ten I/O pins are available. 4-bit mode requires a minimum of seven bits. In 4-bit mode, only the top 4 data pins (4-7) are used.

Command 0x30 means we are setting 8-bit mode lcd having 1 line and we are initializing it to be 5×7 character display.Now this 5×7 is some thing which every one should know what it stands for. usually the characters are displayed on lcd in 5×8 matrices form. where 5 is total number of columns and is number of rows.Thus the above 0x30 command initializes the lcd to display character in 5 columns and 7 rows the last row we usually leave for our cursor to move or blink etc.

The command 0x80 initialize the cursor to the first position means first line first matrix(start point) now if we add 1 in 0x80+1=0x81 the cursor moves to second matrix.

NOTE:You can send commands in hexadecimal or decimal form which one do you like the result is same because the microcontroller translate the command in 8-bit binary value and sends it to the lcd.

Character Lcd’s can be used in 4-bit and 8-bit mode.Before you send commands and data to your lcd. Lcd must first be initialized. This initialization is very important for lcd that are made by Hitachibecause they use HD44780 driver chip sets. Hd44780 Chip set first has to be initialized before using it. If you don’t initialize it properly you will see nothing on your lcd.

In 4-bit mode the high nibble is sent first before the low nibble and the En pin is toggled eachtime four bits is sent to the LCD. To initialize in 4-bit mode:

To learn more about the difference between 4-bit and 8-bit character lcd mode and operation with demo example visit the tutorial link given below. Demo examples are very easy to understand and one can make changes easily in the code. Please also give us your feed back on the post.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The LCD 16x2 are often setup to operate at 4-bit mode to save the number of GPIO pins required for interfacing with the LCD. For some reason, you seems to want to use 8-bit mode and choose to explicitly set the mode by your class instantiation. In this case, the function prototype according to the library source code would be:

Noticed that the first argument in the class instantiation specify whether you"d want to setup the display to operate at 4-bit mode or 8-bit mode, so if you want to use the 8-bit mode, the instantiation should be:

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

This is an IIC Serial 1602 LCD module. With this I2C interface LCD module, you will be able to realize data display via only 2 wires. If you already have I2C devices in your project, this LCD module actually cost no more resources at all. It is fantastic for Arduino based project.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey