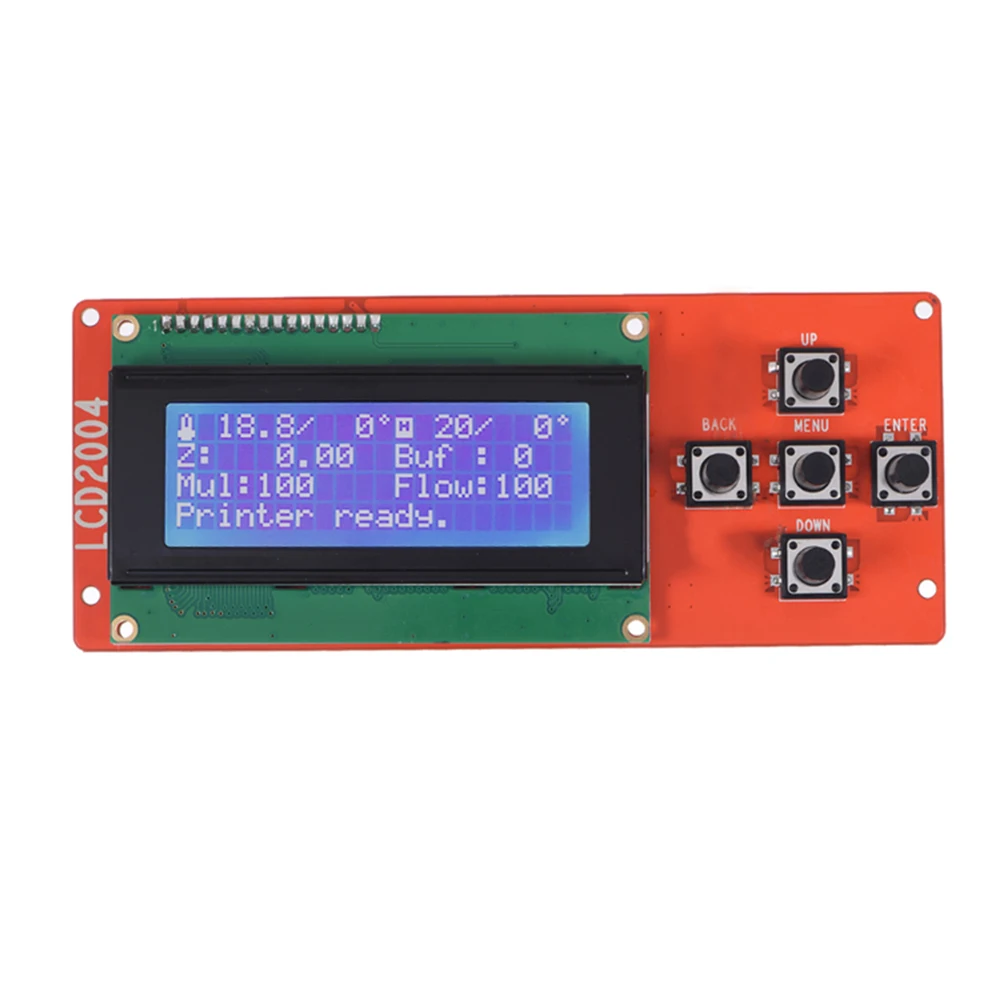

anet a8 lcd panel in stock

3. Check if it"s the issue of mainboard or lcd screen. Press the "Reset" button on the mainboard, and see if the D1 lights up on the mainboard. If the D1 indicator doesn"t lights on, it"s the mainboard that broken and need to change.

If your Anet A8 screen shows white blocks after power up, reconnect all the cables. If still not work, click the "RESET" on the mainboard. If still doesn"t work, you need to change for a new motherboard.

If you get the EZOut board you will be using this to connect aBL Touch ABL sensorto your 3D Printer. You plug this board into your LCD header on your control board and then plug the LCD cable into our board. You then have the required 5V, Ground, and Signal pins available to connect to your BL Touch Sensor with ZERO soldering. The signal pin broken out on our board is Pin 27, this will be your SERVO pin in your firmware. Includes the 10 pin extension cable so the board does not hit your control box or printer frame.

You can add on a bootloader kit above and there is a very easy to follow guide with a video on our page here: 1284p Printer Bootloader Flashing Video Guide – CR-10/Ender 2 3 5/Wanhao i3/Anet

Button covers with arrows for the anet lcd2004 lcd screen Also check out my remote Anet A8 LCD Enclosure [Here](https://www.thingiverse.com/thing:2889748)

This is an enclosure for the stock Anet A8 LCD screen. Which allows mounting the LCD off of the frame and mount it to the outside of an enclosure box or just about anywhere else you would prefer. The enclosure will have 2 options for now for the side...

Anet A8 LCD screen cover to use with this spool holder: https://www.thingiverse.com/thing:1505075 This thing was made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/aJ9Tj35IqZ2

This Is a Scooby-Doo inspired cover for the hole where the original LCD of the Anet A8 sits. It covers the LCD and the button holes. You can use the original screws....but a Little Shorter may be useful :)

This is an LCD cover that will fit Anet A8 printers with the 5 button display, and blocks most light from the screen. My A8 is in my bedroom and sometimes the screen is way too bright for me to sleep comfortably.

This is an LCD cover that will fit Anet A8 printers with the 5 button display, and blocks most light from the screen. My A8 is in my bedroom and sometimes the screen is way too bright for me to sleep comfortably.

This is a cover that will fit over the LCD screen of the Anet A8 that uses the 5 button display. It may fit models with the knob display, but I am not sure.

Two brackets used to mount the Anets LCD next to the printer in a sturdy fashion. ... One bracket replaces the panel to the right of the leftmost Z stepper motor, the other mounts to the LCD. ... The LCD is mounted with 4 short M3 screws.

......::::::[Anet A8 Rear LCD Dust Cover by Ghostjnr]::::::...... This is not a remix of the thing, it is just a helpful plastic distance between lcd board and the dust cover. ...

This is a flush mounting frame/cover for a standard Anet A8 LCD screen for custom installs . ( part LCD2004) It allows you to mount the LCD on a flat panel with the only hole needed is for the ribbon cable access . This saves a lot of time marking &...

This is a remix of the "ANet LCD cover by 3DTSUJ" and the "Anet A8 Prusa i3 Simple filament guide (Horizontal) by papinist". I couldn"t get the lcd cover into the slot on my anet so i thought i need a simpler mounting mechanism. I then looked at the...

... outside the enclusure than haveing to open every time...! Print Settings Printer: Anet A8 Rafts: No Supports: No Resolution: 0,2 Infill: 25 How I Designed This To design it i"ve used sketchup, there is also the file so you can customize it .

These sides let you position the lcd in front of the printer, and the bed will not hit it. ... *the front mount is from Keepars original file*-thank you Keepars UPDATE 5-28-19: now included is a front mount that reads "The Original Anet A8"

My Anet A8 frame is made out of clear acrylic, and I don"t like seeing the LCD circuit board though the frame. I couldn"t find a cover plate to cover it, so I cut all the bits off of the wonderful external enclosure made by ciccio92 except for the...

**Flip Case Top Upside Down Before Printing** I was looking for a 12864LCD mount for my Anet A8 but could only find variants which were separated from the printer. I don"t have space for this with my setup.... I designed this mount in Fusion 360 and it...

I was going to sleep the other night, I had an overnight print going, and I noticed the LCD on my Anet A8 was very bright, so for the time being i taped some playing cards to the LCD screen, however this was unsightly, so when i woke up the next...

The back plate that comes with the Anet A8 is poorly designed as it doesn"t take into consideration some solder joints on the back of the board. This design leaves gaps where the solder joints are so that when it gets tightened it"s not putting...

Anet A8 is a pretty famous DIY FDM 3D printer from a Chinese manufacturer Anet 3D. This machine became one of the first affordable printers on the market, quickly becoming a choice for many newcomers. Despite being released a long time ago, Anet A8 is still on the market surprisingly withstanding competition from newer machines. Is it worth purchasing though? Let’s find out.

When Anet A8 first appeared on the market, a lot of enthusiasts purchased it thanks to the affordable cost of the kit. However, the low machine price was achieved due to cutting corners here and there resulting in first versions not only requiring a lot of upgrades and attention but sometimes being downright unsafe. The main concerning factor at the time was the power cord issue causing a fire hazard, which is in combination low-quality motherboard and unstable printing bed turned some users off the Anet A8. Additionally, when purchasing the kit from Chinese suppliers and resellers, some people ended with a different model, A6, falsely advertised as A8.

The information in regards to all troubles with A8 is easy to find and access, though, people still purchase this kit. And many are able to get pretty decent prints with it as well. Anet A8, undoubtedly, requires love from the very first day of buying it. Starting from building the printer from scratch through a bit messy videos from the manufacturer to making upgrades to accommodate for a wobbly frame. In no way this is ready from the box printer.

But there are bright sides to Anet A8. The manufacturer was quick to make changes to the printer resolving some issues from the first versions. That includes upgrading to an aluminum plate under a heating bed (which was acrylic and prone to warping) with metal rails on two sides. Additionally, later orders included a different motherboard and had changes to power cords and supply (though still no “off” button). These changes went unannounced and have no special mark on the printer’s model, however, by default A8 machines now are shipped with these newer parts. And the price for Anet A8 kit dropped even lower.

One of the great advantages of A8 is being an open system, meaning that with a bit of work the printer can be adjusted to preferences or needs in terms of software and structure. And some of the first upgrades for better performance can actually be 3D printed on the A8 itself. Alternatively, some users purchase A8 as a source of parts, which they build a slightly different printer with, upgrading from light and prone to wobbling acrylic frame to a metal one.

This one is a bit advanced upgrade that will require you to purchase additional bits. However, due to A8 infamous power supply, you should consider monitoring the voltage and current.

Anet A8 is a pretty famous DIY FDM 3D printer from a Chinese manufacturer Anet 3D. This machine became one of the first affordable printers on the market, quickly becoming a choice for many newcomers. Despite being released a long time ago, Anet A8 is still on the market surprisingly withstanding competition from newer machines. Is it worth purchasing though? Let’s find out.

When Anet A8 first appeared on the market, a lot of enthusiasts purchased it thanks to the affordable cost of the kit. However, the low machine price was achieved due to cutting corners here and there resulting in first versions not only requiring a lot of upgrades and attention but sometimes being downright unsafe. The main concerning factor at the time was the power cord issue causing a fire hazard, which is in combination low-quality motherboard and unstable printing bed turned some users off the Anet A8. Additionally, when purchasing the kit from Chinese suppliers and resellers, some people ended with a different model, A6, falsely advertised as A8.

The information in regards to all troubles with A8 is easy to find and access, though, people still purchase this kit. And many are able to get pretty decent prints with it as well. Anet A8, undoubtedly, requires love from the very first day of buying it. Starting from building the printer from scratch through a bit messy videos from the manufacturer to making upgrades to accommodate for a wobbly frame. In no way this is ready from the box printer.

But there are bright sides to Anet A8. The manufacturer was quick to make changes to the printer resolving some issues from the first versions. That includes upgrading to an aluminum plate under a heating bed (which was acrylic and prone to warping) with metal rails on two sides. Additionally, later orders included a different motherboard and had changes to power cords and supply (though still no “off” button). These changes went unannounced and have no special mark on the printer’s model, however, by default A8 machines now are shipped with these newer parts. And the price for Anet A8 kit dropped even lower.

One of the great advantages of A8 is being an open system, meaning that with a bit of work the printer can be adjusted to preferences or needs in terms of software and structure. And some of the first upgrades for better performance can actually be 3D printed on the A8 itself. Alternatively, some users purchase A8 as a source of parts, which they build a slightly different printer with, upgrading from light and prone to wobbling acrylic frame to a metal one.

This one is a bit advanced upgrade that will require you to purchase additional bits. However, due to A8 infamous power supply, you should consider monitoring the voltage and current.

Since the housing is the same size as the stock frame this mod is compatible with stock lcd. The housing is 78mm wide and the stock display is 75mm wide so you have a slight tolerance on each side.

I was able to load Marlin on the SKR 1.4 and see it boot up on the LCD (woot!). I"m plugging in all the wires and encountered a couple of last (I hope) questions:

After double and triple checking wiring, I still can only get a blank blue screen. The reset button does work but nothing else. My LCD was working just fine with my last board (Anet A8 Plus stock board) so I dont think that is a problem.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey