lcd panel rubbing cloth made in china

G02F1/13378—Surface-induced orientation of the liquid crystal molecules, e.g. by alignment layers by treatment of the surface, e.g. embossing, rubbing or light irradiation

G02F1/133784—Surface-induced orientation of the liquid crystal molecules, e.g. by alignment layers by treatment of the surface, e.g. embossing, rubbing or light irradiation by rubbing

The present invention relates to a rubbing cloth material for manufacturing a liquid crystal panel. In the liquid crystal panel manufacturing process, alignment treatment is performed using a rubbing roller in which a rubbing cloth material having a raised pile is attached to the outer peripheral surface of a metal roller with a double-sided adhesive tape. The alignment treatment is an operation of uniformly rubbing the surface of the alignment film formed on the surfaces of the two substrates constituting the liquid crystal panel with the pile on the surface of the rubbing roller that rotates at a high speed. The object is to impart molecular orientation. Although this process is called an alignment process or a rubbing process, the present invention relates to a rubbing cloth material used in a rubbing process essential for liquid crystal panel production.

The rubbing process will be briefly described with reference to FIG. 5. In rubbing, a cloth material 2 having a pile standing on its surface is attached to the outer peripheral surface of a metal roller 1 with a double-sided adhesive tape and rotated at high speed. The surface of the alignment film formed on the surface of the substrate 5 constituting the liquid crystal panel is rubbed at high speed with the pile of the cloth material, and unidirectional molecular alignment is imparted to the surface of the alignment film. It is the purpose.

In addition, the code | symbol d in FIG. 5 is commonly called the amount of cutting, and has shown the length which the pile of a cloth material touches an alignment film (board | substrate), and influences alignment performance.

A liquid crystal display element used for a transmissive liquid crystal display panel is opposed to a TFT substrate on which a driving element (TFT) made of a thin film transistor is formed and a CF substrate on which a color filter (CF) is formed with a small gap therebetween. The liquid crystal is sealed in the gap. An ITO electrode patterned as a pixel electrode is disposed on the surface of the TFT substrate, and an alignment film is formed so as to cover the surface of the ITO electrode.

The TFT substrate and the CF substrate are arranged so that the alignment films face each other, and the alignment films on both substrates are in contact with the sealed liquid crystal. The alignment film on the TFT substrate surface and the CF substrate surface is subjected to an alignment process using a rubbing cloth material to align liquid crystal molecules. The rubbing cloth material is usually attached to the outer peripheral surface of a roller such as aluminum or stainless steel. The surface of the alignment film is rubbed with the rubbing cloth material by bringing the rubbing cloth material on the outer peripheral surface into contact with the alignment film surface while rotating the roller. As described above, when the alignment film is subjected to a rubbing treatment, ultrafine grooves are formed on the surface of the alignment film itself, or uniaxial alignment is imparted to polyimide molecules that are polymers forming the alignment film. When the liquid crystal comes into contact with the alignment film subjected to the rubbing treatment in this way, liquid crystal molecules are arranged in the direction rubbed with the rubbing cloth material, thereby realizing uniform switching characteristics of the liquid crystal by the electric field. The performance of liquid crystal alignment by rubbing affects the uniformity of display characteristics, which is the most important for a liquid crystal panel.

As the rubbing cloth material, a velvet fabric composed of a ground cloth and a pile woven in a raised state on the ground cloth is generally used. As materials for piles, those using long fibers (filaments) such as rayon and nylon and those using short fibers such as cotton are known. As the velvet fabric structure used for the rubbing cloth material, a known first pile velvet fabric as shown in FIG. 7 using cupra rayon for warp and weft of the fabric structure and viscose rayon for the pile (Patent Document) 1) is common, and a velvet structure of a V-shaped pile as shown in FIG. 8 using cotton as a pile (see Patent Document 2) is also used. These combinations are not fixed, and even if cotton is used for the pile, it is possible to weave with the first pile structure, and any structure is velvet fabric of thermoplastic synthetic fibers such as acetate fiber and polyester fiber. It can also be applied to.

In the rubbing cloth material using this type of velvet fabric, the pile is not erected vertically with respect to the ground cloth, but the direction in which the tip of the pile follows the root of the pile with respect to the rotation direction of the rubbing roller. It is known that inclining to an effective angle is an effective means for avoiding uneven alignment due to non-uniform rubbing (see Patent Document 3).

However, in the velvet structure according to the prior art, the pile cannot be inclined at an arbitrary angle with respect to the normal direction of the surface of the cloth material only by the action of the fiber weaving structure.

As a conventional method of inclining a pile of a rubbing cloth material, a velvet using rayon for a pile portion is described in detail in Patent Document 3. Specifically, a velvet cloth woven by a general manufacturing method is immersed in a glyoxal-based cellulose-reactive resin, combed with a brush in a curing machine, and then the resin is heated and cured to maintain the inclination. . This method is called resin impregnation and uses a cellulose-reactive resin, so that it is used for fibers composed of regenerated cellulose fibers other than rayon, polynosic fibers, lyocells and the like and cellulose derivatives (hereinafter referred to as cellulosic fibers). It is valid. There are some problems in providing the slope to the pile by such resin processing, and there is an urgent need to solve it in the future for higher definition and higher yield of liquid crystal panels.

Moreover, in the rubbing cloth which consists of a cotton pile, there is no effective means to incline a pile uniformly irrespective of resin impregnation.

In the above conventional resin processing method, there is a high possibility that the processing shape and the cloth characteristics will vary for each processing lot. For this reason, in the manufacturing process of the liquid crystal display panel, it was confirmed whether or not the velvet fabric of the lot can withstand use by carrying out trial rubbing in advance using the received velvet fabric and checking the orientation quality. Above, used in the manufacturing process. Even if such an arrival check is executed, the variation itself in the cloth quality itself is not improved, and it is said that unexpected rubbing failure does not end.

In addition, the conventional rayon velvet also has a problem related to the resin itself used for processing. That is, since the rubbing cloth material (velvet) is immersed in the cellulose reaction type resin, the resin adheres to the surface of each single fiber constituting the pile of the velvet. This resin tends to be relatively hard and brittle, and during rubbing, it becomes a foreign substance due to wear and drop off, and may adhere to the alignment film surface and cause defects such as display unevenness (see Non-Patent Document 1). ). Moreover, the foreign material wound in the pile may cause a damage | wound on the surface of an alignment film.

Further, the cellulose-reactive resin is an aqueous emulsion, and a rubbing cloth material using cupra as a ground yarn is very easily deformed in a state containing moisture. For this reason, the weft of the rubbing cloth material is deformed into a bow shape (commonly referred to as “boeing”), so that the so-called bend in which the weft does not intersect the warp at a right angle easily occurs.

Therefore, the present invention (1) provides a stable inclination to the pile of the rubbing cloth material of the velvet fabric, (2) reduces the elongation of the fabric, ensures the shape accuracy and the shape stability, and (3) the rubbing. The primary purpose is to suppress the generation of static electricity that naturally occurs.

In this case, without expecting the above-mentioned deviation, when the rubbing cloth is attached in parallel with the direction of the rubbing roller"s warp (weaving direction), the pile touches the minute unevenness of the object to be rubbed and vibrates. It is known that horizontal alignment spots are generated in the alignment film.

For this reason, conventionally, when cutting the rubbing cloth material from the original fabric after weaving, it has been necessary to cut it slightly obliquely from the warp direction (weaving direction) in anticipation of the above-mentioned deviation, and there is a problem that a large loss occurs in the fabric It was.

As a means for giving a stable inclination to the pile of the rubbed cloth of the velvet structure, it is desirable to devise the cloth structure itself without relying on resin processing, heat brushing, or the like. The pile of the rubbing cloth material is inclined in a certain direction with respect to the normal of the surface of the cloth material, and the inclination angle is stable in the range of 5 to 60 degrees, preferably 10 to 45 degrees. A velvet fabric that can be controlled is desired.

Further, the weaving method and processing method of the cloth is that there is no generation of foreign matter that causes scratches and contamination on the alignment film surface in the rubbing step of the liquid crystal panel manufacturing process.

In the present invention, in order to obtain a rubbing cloth material in which a pile is erected while maintaining a stable inclination, the present inventors have focused on a method for controlling the tension balance of warp in a velvet fabric.

As a means for alternately increasing or decreasing the warp tension, there is, for example, a method of supplying warp with a double beam and weaving under a condition in which the warp tension of one beam is stronger than the warp tension of the other beam. Actually, when a velvet cloth is woven by this method, the pile can be erected while being inclined in the warp direction. As another means for alternately increasing or decreasing the tension of the warp, there is a method in which highly shrinkable synthetic fibers and ordinary synthetic fibers are alternately arranged and used for the warp. In this case, an appropriate heat treatment is performed after weaving to increase the tension by shrinking the highly shrinkable synthetic fiber. Even in this method, as a result, the tension of the warp can be alternately increased and decreased, and the same effect as that of the double beam method can be obtained.

Next, as a problem to be improved for the rubbing cloth, there is a problem of dimensional stability. This is a problem of fabric stretch during rubbing. A typical velvet rubbing cloth material currently in use uses cupra rayon as a fiber material of the ground cloth. In the liquid crystal panel manufacturing process, in order to prevent electrostatic breakdown of TFT elements (thin film transistor elements), the relative humidity of the atmosphere is set high (about 60%) in order to reduce the generation of static electricity. . It is well known that in a high humidity state, the cellulosic fiber is a fiber that is easily stretched compared to a polyester fiber that is a hydrophobic synthetic fiber. In a liquid crystal display device manufactured using a substrate in which an alignment film is rubbed with a velvet fabric, linear unevenness may occur in a direction parallel to the rubbing roller. As one cause of the occurrence of this unevenness, the ease of elongation of the rubbing cloth material has been reported (see Patent Document 1).

By using a hydrophobic synthetic fiber that is difficult to stretch in a high humidity state, the elongation of the rubbing fabric material can be reduced. In addition, the occurrence of fabric bending can be reduced.

Patent Document 4 states that the rubbing cloth material easily expands and contracts due to environmental temperature and humidity and is difficult to cut with dimensional accuracy. The use of hydrophobic synthetic fibers such as polyester fibers and highly shrinkable synthetic fibers is also effective in dealing with this problem.

Static electricity generated in the rubbing process of the alignment film may destroy the TFT element of the liquid crystal panel. For this reason, it is necessary to leak the generated static electricity to the outside and prevent the accumulation of static electricity. 10 or more for one or both of the warp and weft of the woven fabric of the velvet fabric that is a rubbing fabric -2 Ωcm or more 10 0 Copper sulfide fiber sanderlon having a specific resistance value of Ωcm or less (registered trademark of Nippon Kashiwa Dyeing Co., Ltd.), 10 -2 Ωcm or more 10 6 Conductive fiber kneaded with Ωcm carbon powder, 10 0 Ωcm or more 10 6 If Beltron (registered trademark of Kanebo Co., Ltd.) having a specific resistance value of Ωcm or less is used in the ground yarn, the generated static electricity is leaked by corona discharge, and the accumulation of static electricity is reduced. In addition, coating the conductive resin mixed with carbon powder on the back side of the velvet is also effective in reducing static electricity. Furthermore, if a conductive fiber and a conductive resin are used in combination, a higher effect can be obtained.

In cutting the rubbing cloth material, it is extremely important to accurately cut the warp yarn at a desired angle (see, for example, Patent Document 5). If the base fabric structure of the rubbing cloth material is a single color, it is not easy to accurately set the cutting angle with respect to the warp. At present, the fabric is cut on the premise that the weft intersects with the warp at a right angle, but the current rubbing cloth has a lot of fabric bends. This is estimated to be one of the factors that cause the orientation characteristics to fluctuate.

Therefore, it is important that the rubbing cloth is made of a material that is not easily deformed by temperature and humidity. In order to make it easy to cut at an accurately significant angle, weaving yarns of different colors from the whole ground yarn at regular intervals to the warp, weft or both of the ground yarn of the rubbing cloth material Is effective.

As shown in FIG. 1 (a), the velvet structure is formed of a fabric structure 11 and a pile 12 woven in a standing state on the fabric structure 11. The base fabric braid 11 is woven with the wefts 13 by the warp yarns 14a, 14b, 14b ′ supplied from the double beam. In the rubbing fabric, it is important that one or both of the warp and the weft is made into a hydrophobic ligament fiber such as a polyester fiber.

The velvet structure according to the present invention is not limited to the velvet structure shown in FIG. 1, and for example, a structure such as that shown in FIGS. In the structure shown in FIGS. 2A and 2B, every two piles are inserted into the weft. In FIGS. 2 (a) and 2 (b), warps are abbreviated, but finally, as in FIG. 1, every other piece is woven with a strong and weak tension. That is, weaving is performed by supplying the warp 24a with a strong tension and the warps 24b and 24b "with a weak tension. In this structure, as shown in FIG. 11, the weft yarns C and D are crushed above the weft yarns B to form dumplings. In such a state, the pile 12 is pressed by the weft yarns A to D and given a predetermined angle of inclination in the direction along the warp direction as shown in the figure. Further, even in other velvet structures, it is possible to incline the pile by arranging the ground warp yarn of the velvet cloth material alternately with two kinds of strength and weakness.

In the structure shown in FIG. 1, as another means for alternately increasing or decreasing the warp tension, there is a method in which one warp is a heat-shrinkable fiber. That is, one warp 14a is made of heat-shrinkable fibers, and the warps 14b and 14b "are woven with a normal one beam with almost the same tension, and then heat treatment is applied to the velvet to shrink the warp 14a of heat-shrinkable fibers. Thus, the tension is higher than that of the other warps 14b and 14b ′. In this method, the fiber that thermally shrinks in the machine direction plays the role of a warp with high tension. Accordingly, the pile can be inclined by the same action as the method using the double beam. The ground yarn used in the present invention is preferably a highly shrinkable synthetic fiber, more preferably a polyester fiber having a shrinkage rate of 10% or more (130-150 ° C. dry ripening) or a boiling water shrinkage rate (BWS) of 8% or more. It is preferable that The advantage of using a highly shrinkable synthetic fiber (polyester fiber) for the ground yarn is that the ground yarn shrinks by heat treatment after weaving so that the structure can be made denser. It is known that when a gap is formed between piles in a rubbing cloth for producing a liquid crystal panel, it is known that the rubbing unevenness is generated. A major feature of this method is that a dense structure can be formed beyond the limit of weaving of the loom.

The velvet cloth material was cut into a width of 5 cm and a length of 30 cm so that the angles with respect to the warp were 0.5 degrees, 10 degrees, 15 degrees, 30 degrees, and 45 degrees, thereby preparing test pieces. The elongation in the standard state and the moisture absorption state for each angle from the warp of each sample when 5 kg tensile stress is applied to each test piece is shown. By this measurement, it is possible to know the elongation (particularly humidity dependency, anisotropy) of the fabric structure.

The sample for the comparative example is a rayon velvet using as a base yarn a cupra manufactured by Asahi Kasei Kogyo Co., Ltd., currently marketed for liquid crystal rubbing.

As a result, in the standard state, the elongation with respect to the stress of 5 kg / 5 cm does not show a large difference between the samples 1 and 2 and the comparative product until the angle from the warp is 10%. A clear difference was clearly observed between Samples 1 and 2 and the comparative control product. The elongation in the hygroscopic state was that of the samples 1 and 2 in which polyester fibers were used for the ground yarn. It is clearly less than the comparative control product, and in any case, it is shown that the sample 2 using the high shrinkage yarn for the weft is less likely to elongate than the sample 1. Therefore, it can be said that the dimensional stability as the rubbing cloth material is superior in the order of sample 2> sample 1> comparison target product in the sample 1, the sample 2, and the comparison target product.

Table 2 shows the velvet weaving conditions in which the pile of the rubbing cloth material is inclined by the velvet weave structure according to the present invention, and the pile inclination angle observed in the length direction of the fabric (angle with respect to the vertical direction of the fabric structure). It is.

The generation level of static electricity of the rubbing cloth material according to the present invention was comparatively evaluated. First, the liquid crystal alignment film was rubbed with each rubbing cloth in a state of 60% humidity. At this time, the depth of cut (d in FIG. 5) was 0.5 mm, and the amount of static electricity generated on the roller during rubbing was evaluated by measuring the charged voltage.

Sample 9 is obtained by backing a conductive resin in which carbon particles (powder) are mixed into a resin on the back surface of sample 7 in the same manner as sample 8. In Sample 9, the most remarkable effect of decreasing the charged voltage was recognized. This is because static electricity is released to the conductive resin more quickly and discharged from the entire back of the rubbing cloth material.

According to the present invention, a stable slope is imparted to the pile of the rubbed cloth material of the velvet fabric, the elongation of the fabric is reduced, the shape accuracy and the shape stability are ensured, and the generation of static electricity that is inevitably associated with the rubbing is generated. Is suppressed. Further, the present invention can form a structure that reduces the inclination of the pile in the direction parallel to the weft.

前記経糸として、張力の異なる合成繊維を組み合わせて製織したことにより構成されることを特徴とする液晶パネル製造用ラビング布材。A rubbing cloth material for producing a liquid crystal panel of a velvet woven fabric having a ground fabric composed of warps and wefts, and a pile yarn woven in the warp direction of the fabric structure,

A rubbing cloth material for producing a liquid crystal panel, characterized in that the warp yarn is formed by weaving synthetic fibers having different tensions.

前記地布組織の経糸の、地布面内の張力分布を変えることによって、地布材の表面の法線に対して経糸の方向の傾斜を前記パイルに与えたことを特徴とする液晶パネル製造用ラビング布材。A rubbing cloth material for manufacturing a liquid crystal panel according to claim 1,

Manufacturing the liquid crystal panel, wherein the pile is inclined in the direction of the warp with respect to the normal of the surface of the fabric by changing the tension distribution in the fabric surface of the warp of the fabric structure Rubbing cloth material.

前記パイル糸が、地布材の表面の法線に対して経糸の方向に傾斜し、前記パイル糸の、前記法線に対する傾斜角度が10度以上45度以下であることを特徴とする液晶パネル製造用ラビング布材。A rubbing cloth material for manufacturing a liquid crystal panel according to claim 1 or 2,

The pile yarn is inclined in the warp direction with respect to the normal line of the surface of the fabric material, and the inclination angle of the pile yarn with respect to the normal line is not less than 10 degrees and not more than 45 degrees. Rubbing cloth material for manufacturing.

前記地布組織を構成する複数の経糸のうち、所定の本数おきの経糸に、他の経糸よりも弱い張力をかけながら製織されたことを特徴とする液晶パネル製造用ラビング布材。A rubbing cloth material for manufacturing a liquid crystal panel according to claim 1 or 2,

A rubbing cloth material for manufacturing a liquid crystal panel, wherein a predetermined number of warp yarns are woven while applying a weaker tension than other warp yarns among a plurality of warp yarns constituting the base fabric structure.

前記二重ビームの一方の経糸が他方の経糸より強い張力で製織され、強い張力の経糸と弱い張力の経糸が交互に配置されることにより構成されることを特徴とする液晶パネル製造用ラビング布材。A rubbing cloth material for manufacturing a liquid crystal panel according to claim 4,

A rubbing cloth for manufacturing a liquid crystal panel, wherein one warp of the double beam is woven with a stronger tension than the other warp, and a high tension warp and a weak tension warp are alternately arranged. Wood.

前記地布組織を構成する地糸の一部に高収縮性の合成繊維を用いて製織され、当該高収縮性の合成繊維を収縮させたことを特徴とする液晶パネル製造用ラビング布材。A rubbing cloth material for manufacturing a liquid crystal panel according to claim 1 or 2,

A rubbing cloth material for manufacturing a liquid crystal panel, characterized in that a part of the ground yarn constituting the base fabric structure is woven using a high-shrinkage synthetic fiber and the high-shrinkage synthetic fiber is shrunk.

The rubbing cloth material for producing a liquid crystal panel, wherein the highly shrinkable synthetic fiber is a polyester fiber having a boiling water shrinkage of 8% or more.

前記パイル糸は、電気比抵抗値が108Ωcm以上1010Ωcm以下の合成繊維よりなる液晶パネル製造用ラビング布材。It is a rubbing cloth material for liquid crystal panel manufacture according to any one of claims 1 to 4,

The pile yarn is a rubbing cloth material for manufacturing a liquid crystal panel comprising a synthetic fiber having an electrical specific resistance value of 10 8 Ωcm or more and 10 10 Ωcm or less.

前記ラビング布材の地布組織の経糸及び緯糸のうちの少なくとも一方は、電気比抵抗値が10-2Ωcm以上106Ωcm以下の導電性合成繊維を含むことを特徴とする液晶パネル製造用ラビング布材。It is a rubbing cloth material for liquid crystal panel manufacture according to any one of claims 1 to 7,

A rubbing for manufacturing a liquid crystal panel, wherein at least one of the warp and the weft of the base fabric structure of the rubbing cloth material includes a conductive synthetic fiber having an electric specific resistance value of 10 −2 Ωcm or more and 10 6 Ωcm or less. Cloth material.

A rubbing cloth material for manufacturing a liquid crystal panel, wherein a resin containing a conductive material is applied and cured on the back side of the ground cloth structure of the rubbing cloth material.

Rubbing cloth for aligning liquid crystal and method for fabricating thereof and apparatus for fabricating thereof and method for fabricating liquid crystal display device using the same

Rubbing cloth for aligning a liquid crystal, method of manufacturing the same, apparatus for manufacturing the same and method of manufacturing a liquid crystal display using the same

About five years ago, local textile company Youngdo Velvet succeeded in developing its own rubbing cloth to break the 20 year-long monopoly of Japanese companies in the industry. A rubbing cloth is a key component for manufacturing an LCD panel, which determines the brightness and resolution of TVs, smart phones, etc. Although Youngdo Velvet had some difficulties finding customers, the Korean government encouraged LG Display to employ the product, helping it to increase its domestic market share to up to 40%.

By major item, the dependence upon imported semiconductor photocells dropped from 53.4% to 8.7% between 2002 and 2011. The percentage decreased from 90.7% to 47.4% and 90.7% to 17.7% for steel sheets for surface treatment and LCD fluorescent lamps during the same period, respectively. In the auto industry, an increasing amount of Korean companies’ parts are finding their ways into Japanese carmakers like Toyota, too.

The present invention relates to a method for fabricating a liquid crystal display (LCD) device. More particularly, the present invention relates to an apparatus and method for rubbing an alignment layer of an LCD device, in which rubbing uniformity of the alignment layer is improved.

Generally, LCD devices are widely used for clocks, calculators, monitors for PCs, notebook computers, TVs, monitors for spacecraft, PDAs, cellular phones, etc. LCD devices are used because of their characteristics and they have the advantages of low voltage driving, low power consumption, full color, thin profile, and lightness in weight.

An LCD panel may include a thin film transistor (TFT) substrate provided with a TFT array, a color filter (CF) substrate provided with a color filter array, and a liquid crystal layer formed between the two substrates. Alignment layers may be respectively provided on each surface of the TFT substrate and the CF substrate to face each other. The alignment layers determine an alignment direction of the liquid crystal layer.

The CF substrate may include a black matrix layer that prevents light from reaching the pixel regions, R/G/B color filter layers corresponding to the respective pixel regions to display various colors, and a common electrode formed on the entire surface including the color filter layers. The common electrode may be formed on the TFT substrate in an in-plan switching (IPS) mode LCD device. An alignment process may then be performed for the alignment layers of the TFT substrate and the CF substrate to arrange liquid crystal molecules.

An example of the alignment process includes a rubbing method in which a surface of an alignment layer is rubbed with a rubbing cloth. The rubbing cloth is adhered to an outer circumference of a roller. If the roller is rotated, the rubbing cloth adhered to the outer circumference of the roller contacts the surface of the alignment layer so that the surface of the alignment layer is rubbed with the rubbing cloth.

If liquid crystal molecules are arranged along a direction of the alignment layer rubbed with the rubbing cloth, it may be possible to obtain uniform display characteristics.

FIGS. 2A to 2C illustrate a related art process for rubbing an alignment layer. FIG. 2A is a perspective view illustrating an apparatus for rubbing an alignment layer, FIG. 2B is a side view illustrating an apparatus for rubbing an alignment layer, and FIG. 2C is a plan view illustrating an apparatus for rubbing an alignment layer.

As shown in FIGS. 2A to 2C, the related art apparatus for rubbing an alignment layer includes a cylindrical rubbing roller 61, a rubbing cloth 62 adhered to an outer circumference of the rubbing roller 61 using a double-sided tape, a rotary shaft 63 connected with both sides of the rubbing roller 61 and rotated along one direction while supporting the rubbing roller 61, and a rotary motor 66 connected with the rotary shaft 63 to rotate the rotary shaft 63.

The rubbing roller 61 connected with the rotary shaft 63 contacts the alignment layer 65 of the substrate 64 loaded on the stage 60 at the bottom, and forms a groove on a surface of the alignment layer 65 while being rotated by the rotary motor 66 in one direction.

That is, the related art rubbing process is performed in such a manner that the rubbing roller 61 wound with the rubbing cloth 62 is rotated to rub the surface of the alignment layer 65 using physical friction.

In order to obtain uniform display characteristics in the LCD device, it is important that the groove is uniformly formed in a wide area. The groove can uniformly be formed by rubbing the surface of the alignment layer with the rubbing cloth at uniform pressure and speed to align a high molecular chain on the surface of the alignment layer in a certain direction.

The aforementioned related art method for rubbing an alignment layer uniformly arranges the liquid crystal molecules by rubbing the alignment layer with the rubbing cloth. The related art method also uniformly displays images on the entire surface of the LCD device by arranging the alignment layer in one direction.

However, with the trend towards larger sized LCD devices, LCD devices having dimensions of 1100 mm or greater have been commercially used. Under these circumstances, the rubbing roller used for the rubbing process is contrived to have a large size.

In this case, as shown in FIG. 3, a middle portion in a longitudinal direction of the rubbing roller 61 is bent by self-load as the rubbing roller 61 of metal material has a longer cylindrical length. Also, the alignment layer 65 formed on the substrate 64 is rubbed by uneven pressure. As a result, display quality is deteriorated over the entire surface of the LCD device.

Furthermore, for the alignment process, the rubbing roller 61 is adhered with the rubbing cloth 62 using a general adhesive. Furthermore, static electricity occurs due to friction between the rubbing cloth 62 and the alignment layer 65. Friction is caused by rotation of the rubbing roller 61. For this reason, dust, dirt in the air, and/or particles generated from the rubbing cloth 62 is adsorbed into the alignment layer 65, thereby causing a pin hole.

Accordingly, the present invention is directed to an apparatus and method for rubbing an alignment layer of an LCD device, which substantially obviates one or more problems due to limitations and disadvantages of the related art.

An advantage of the present invention is to provide an apparatus and method for rubbing an alignment layer of an LCD device, in which the alignment layer is rubbed over an entire surface of a substrate at uniform pressure.

Another advantage of the present invention is to provide an apparatus and method for rubbing an alignment layer of an LCD device, in which dust and/or particle is not adsorbed into the alignment layer during the rubbing process.

To achieve these and other advantages and in accordance with the purpose of the invention, as embodied and broadly described, an apparatus for rubbing an alignment layer of an LCD device includes a rubbing means to rub the alignment layer while the rubbing means is rotated along one direction to contact a surface of the alignment layer formed on a substrate, and a liquid jet to jet liquid when the alignment layer is rubbed by the rubbing means.

In another aspect of the present invention, a method for rubbing an alignment layer of an LCD device includes forming the alignment layer on a substrate, rubbing the alignment layer by rotating a rubbing roller adhered with a rubbing cloth while moving the substrate provided with the alignment layer in one direction, and simultaneously jetting liquid using a liquid jet.

FIGS. 6A and 6B are side views illustrating a rubbing roller in an apparatus for rubbing an alignment layer of an LCD device according to a third exemplary embodiment of the present invention;

FIGS. 7A and 7B are perspective views illustrating a rubbing roller in an apparatus for rubbing an alignment layer of an LCD device according to the third exemplary embodiment of the present invention;

FIG. 9 illustrates a rubbing process performed when a middle portion of a rubbing roller bends when an alignment layer of an LCD according to an exemplary embodiment of the present invention is rubbed.

As shown in FIG. 4, the apparatus for rubbing an alignment layer of an LCD device according to a first exemplary embodiment of the present invention includes a cylindrical rubbing roller 101, a rubbing cloth 102 that may be adhered to an outer circumference of the rubbing roller 101 using a double-sided tape, a rotary shaft 103 connected with both sides of the rubbing roller 101, a rotary motor 104 connected with the rotary shaft 103, and a liquid jet 110. The rotary shaft 103 may rotate along one direction while supporting the rubbing roller 101 and the rotary motor 104 may rotate the rotary shaft 103 along one direction. The liquid jet 110 may jet liquid onto a substrate 100 during rotation of the rubbing roller 101.

Also, the rubbing roller 101 may include an inner cylinder of carbon fiber reinforcing plastic and an outer cylinder of plated stainless steel. A rubbing cloth is adhered to a surface of the plated stainless steel using a conductive adhesive.

The rubbing roller 101 connected with the rotary shaft 103 contacts the alignment layer 120 of the substrate 100 loaded on the stage 200 at the bottom. The rotary shaft 103 is rotated in one direction by the rotary motor 104 to rotate the rubbing roller 101. The rubbing cloth 102 adhered to the rubbing roller 101 forms a groove on a surface of the alignment layer 120.

The rubbing process is performed in such a manner that the rubbing roller 101 wound by the rubbing cloth 102 is rotated to rub the surface of the alignment layer 120 using physical friction.

As described above, the rubbing process is performed in such a manner that a groove is formed on the surface of the alignment layer 120 using the rubbing apparatus while the liquid is being jetted onto the entire surface of the substrate 100 using the liquid jet 110. The middle portion of the rubbing roller 101 is filled with the liquid even if it is bent. Therefore, it is possible to uniformly perform the rubbing process.

In the apparatus for rubbing an alignment of an LCD device according to a first exemplary embodiment of the present invention, the liquid jet 110 jets the liquid onto the substrate 100 provided with the alignment layer 120. In the apparatus for rubbing an alignment of an LCD device according to a second exemplary embodiment of the present invention, the liquid jet 110 jets the liquid onto the rubbing roller 101 adhered with the rubbing cloth 102.

As shown in FIG. 5, the apparatus for rubbing an alignment layer of an LCD device according to a second exemplary embodiment of the present invention includes a cylindrical rubbing roller 101, a rubbing cloth 102 that may be adhered to an outer circumference of the rubbing roller 101 using a double-sided tape, and a liquid jet 110. The liquid jet 110 jets liquid 114 onto the rubbing roller 101.

A method for rubbing an alignment layer using the aforementioned apparatus according to a second exemplary embodiment of the present invention will now be described.

The rubbing roller 101 connected with the rotary shaft 103 contacts the alignment layer 120 of the substrate 100 loaded on the stage 200 at the bottom. The rotary shaft 103 is rotated in one direction by the rotary motor 104 to rotate the rubbing roller 101. The rubbing cloth 102 adhered to the rubbing roller 101 forms a groove on a surface of the alignment layer 120.

The rubbing process is performed in such a manner that the liquid 114 is jetted onto the rubbing roller 101 provided with the rubbing cloth 102 using the liquid jet 110 when the alignment layer 120 is rubbed using the rubbing apparatus according to a second exemplary embodiment of the present invention.

As described above, the rubbing process is performed in such a manner that a groove is formed on the surface of the alignment layer 120 using the rubbing apparatus while the liquid is being jetted onto the rubbing roller 101 adhered with the rubbing cloth 102 using the liquid jet 110. The middle portion of the rubbing roller 101 is filled with the liquid 114 even if it is bent. Therefore, it is possible to uniformly perform the rubbing process.

FIGS. 6A and 6B are side views illustrating a rubbing roller in an apparatus for rubbing an alignment layer of an LCD device according to a third exemplary embodiment of the present invention, and FIGS. 7A and 7B are perspective views illustrating a rubbing roller in an apparatus for rubbing an alignment layer of an LCD device according to the third exemplary embodiment of the present invention.

In the apparatus for rubbing an alignment of an LCD device according to the first and second exemplary embodiments of the present invention, the liquid is jetted onto the substrate 100 provided with the alignment layer 120 or the rubbing roller 101 adhered with the rubbing cloth 102 through the jet nozzle 112 of the liquid jet 110. In the apparatus for rubbing an alignment of an LCD device according to a third exemplary embodiment of the present invention, the rubbing roller 101 may be provided with a plurality of holes 150 and may be directly connected with the pipe 113 to supply the liquid to the substrate 100 through the holes 150.

A method for rubbing an alignment layer using the aforementioned apparatus according to a third exemplary embodiment of the present invention will now be described.

The rubbing roller 101 connected with the rotary shaft 103 contacts the alignment layer 120 of the substrate 100 loaded on the stage 200 at the bottom. The rotary shaft 103 is rotated in one direction by the rotary motor 104 to rotate the rubbing roller 101. The rubbing cloth 102 adhered to the rubbing roller 101 forms a groove on a surface of the alignment layer 120.

The rubbing process is performed in such a manner that the cylindrical rubbing roller 101 wound by the rubbing cloth 102, which may be made of nylon, is rotated to rub the surface of the alignment layer 120 using physical friction.

The rubbing process is performed in such a manner that liquid is injected into the rubbing roller 101 provided with the plurality of holes 150 using the liquid jet 110 when the alignment layer 120 is rubbed using the rubbing apparatus according to a third exemplary embodiment of the present invention.

As described above, the rubbing process is performed in such a manner that if the liquid 114 is injected into the rubbing roller 101 using the liquid jet 110, the liquid flows toward the substrate 100 through the holes 150 formed in the rubbing roller 101 to form a groove on the surface of the alignment layer 120. The middle portion of the rubbing roller 101 is filled with the liquid 114 even if it is bent. Therefore, it is possible to uniformly perform the rubbing process.

In the aforementioned liquid jet 110, the liquid storage tank 111 may be externally supplied with N2gas. The liquid may then be supplied to the rubbing roller 101 through the pipe 113 if the pressure inside the liquid storage tank 111 reaches a maximum caused by the N2gas.

As shown in FIG. 8, the rubbing process of the alignment layer 120 formed on the substrate 100 is performed using the rubbing cloth 102 adhered to the rubbing roller 101 while the liquid 114 is being jetted onto the substrate 100. The rubbing process may determine the alignment direction of the liquid crystal.

FIG. 9 illustrates a rubbing process performed when a middle portion of a rubbing roller is bent when an alignment layer of an LCD according to an exemplary embodiment of the present invention is rubbed.

As shown in FIG. 9, if the middle portion of the rubbing roller 101 is downwardly bent by gravity, it is filled with the liquid 114 so as to obtain uniform alignment.

The rubbing process may be performed after the liquid is jetted onto the substrate or the rubbing cloth. The middle portion of the rubbing roller is filled with the liquid even if it is downwardly bent. Therefore, it is possible to uniformly perform the rubbing process and to prevent static electricity from occurring between the rubbing cloth and the alignment layer. Also, it is possible to reduce a defect caused by particles generated from the rubbing cloth.

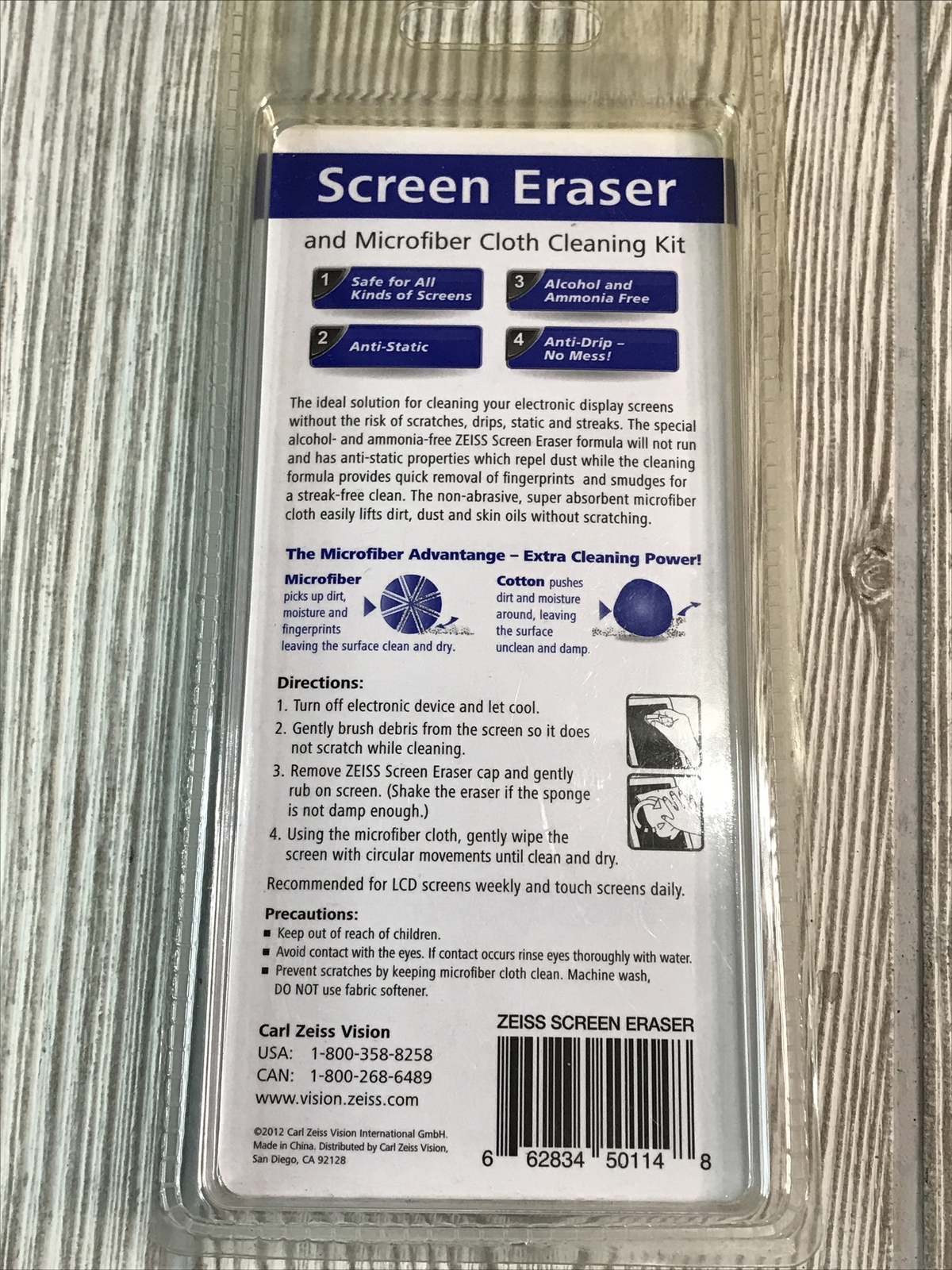

Remember when your LCD or OLED display had that brand-new, fresh-out-of-the-box shine, feel and look? You are in the right place if your display is now due for deep cleaning.

A microfiber cloth and distilled water is recommended for cleaning the display glass. Use Qtips and Isopropyl alcohol for cleaning the printed circuit board.

Although distilled water is recommended for wiping the display glass, you can use a cleanser developed explicitly for cleaning displays. However, do not spray it directly onto the display. Spray a tiny amount of the cleaner onto a microfiber cloth first to avoid getting any cleaning solution inside the display.Never spray any liquids directly onto the display.A spray is too hard to control and confine. The fluids can seep into the other display layers or surrounding components and cause irreversible liquid damage.

Only use a microfiber cloth and don"t use chemicals to clean a resistive touchscreen.Disconnect the display from the power supply and remove any screen protectors or liners.

Isopropyl alcohol (IPA) is widely used to clean printed circuit boards (PCBs). Use a Q-tip or soft small bristle brush for scrubbing a PCB, and never use a paintbrush.Gently rub a Q-tip in Isopropyl alcohol.

Cleaning soldering residue on LCD with Isopropyl alcohol and a Q-Tip.Cleaning residue around soldering elements is not necessary if Newhaven Display performed the soldering.

Liquid crystal displays (LCD) are commonly used for flat panel display. Owing to dielectric anisotropy and conductive anisotropy of liquid crystal molecules, molecular orientation of liquid crystals can be shifted under an external electronic field, such that various optical effects are produced.

An LCD panel is generally made up of two substrates, with a certain gap preserved therebetween, and a liquid crystal layer filled within the gap. Respective electrodes are formed on the two substrates, respectively, to control the orientation and orientational shift of liquid crystal molecules.

A TFT (thin film transistor) LCD panel is generally made up of a TFT array substrate and a color filter substrate, and alignment layers are usually disposed on countering sides of the respective substrate to control the alignment of a center-filled liquid crystal layer.

Conventional preparation methods of alignment layers are, for example, evaporation, rubbing and photo-alignment. For large-size panel fabrication, rubbing is still mainly used owing to its mature technology, continuous productivity and low cost.

Rubbing is performed as follows. The countering sides of the upper and lower substrates of an LCD panel are first coated with polymeric solution to form alignment layers. The alignment layers are then rubbed by a covered roller, with a definite orientation created by the directional pile of the covering cloth. By the orientation of the alignment layers, the liquid crystals on the alignment layers are aligned because of molecular actions therebetween. By controlling the rubbing direction of the roller, the liquid crystals are aligned of a certain pretilt angle, benefiting various driving modes of the LCD.

To create multiple domains (of pretilt angle) on the alignment layers, photo-alignment is generally applied, for example, as in Japan Publication Patent No. 10-142608 presented by LG Electron Inc. However, photo-alignment requires polarized light in oblique incidence, resulting in low orientation and anchoring energy. IBM has provided a fabrication method regarding a first-rubbing-latter-exposing process (Japan Publication No. 08-122792), wherein a polarized beam must be applied, and only planar alignment achievable. Even though the pretilt angle may be reduced by breaking polymer side chains in the exposure step, owing to the currently limited polarization provided by a polarizing machine (100% polarized light is hard to obtain), local exposure to the light adversely affects the orientation after rubbing. SUMMARY OF THE INVENTION

Accordingly, an object of the present invention is to provide a simple and low-cost fabrication method for an LCD with alignment layers of at least two pretilt-angle areas.

Another object of the invention is to provide a fabrication met-hod for an LCD, wherein an unpolarized electromagnetic wave beam may be applied, in normal incidence, combined with rubbing to prepare alignment layers with various pretilt-angle areas for aligning liquid crystals at various pretilt angles. Furthermore, polarized electromagnetic wave beam and oblique incidence are also applicable in the present invention.

Therefore, the invention provides a fabrication method for a liquid crystal display, which comprises providing a pair of substrates, forming alignment layers on the respective substrates, irradiating a predetermined area of at least one alignment layer with an energy beam, rubbing the alignment layer such that a first pretilt-angle area is formed in the predetermined area exposed to the energy beam, a second pretilt-angle area is formed in the area not exposed to the energy beam, bonding the pair of substrates with a preset gap therebetween, and inserting a liquid crystal layer between the substrates, wherein the liquid crystals corresponding to the first pretilt-angle area have a first pretilt angle of θ1, and hose corresponding to the second pretilt-angle area have second pretilt angle of θ2.

The invention further provides another fabrication method for a liquid crystal display, which comprises providing a pair of substrates, forming alignment layers on the respective substrates, normally irradiating a predetermined area of at least one alignment layer with an unpolarized electromagnetic wave beam, rubbing the alignment layer such that a first pretilt-angle area is formed in the predetermined area exposed to the unpolarized electromagnetic wave beam, a second pretilt-angle area is formed in the area not exposed to the unpolarized electromagnetic wave beam, bonding the pair of substrates with a preset gap therebetween, and inserting a liquid crystal layer between the substrates, wherein the liquid crystals corresponding to the first pretilt-angle area have a first pretilt angle of θ1, and those corresponding to the second pretilt-angle area have a second pretilt angle of θ2.

According to the invention, rubbing is performed after energy-beam exposure. The predetermined area of the alignment layer is exposed to the energy beam, breaking the polymer side chains to thereby reduce the pre-tilt angle of liquid crystals corresponding to the area, and the entire alignment layer is then rubbed with strong anchoring energy, forming a first pretilt angle area in the predetermined area exposed to the energy beam, and a second pretilt angle area in the rest area not exposed to the energy beam. According to the invention, energy-beam exposure is performed before rubbing, such that a linearly polarized energy beam is not required, and undesired effects of exposure on orientation are avoided. The “rubbing after exposure” method ensures overall orientation of alignment.

In the embodiment, a thin film transistor LCD is used as an example to explain the inventive fabrication method. According to the invention, the energy beam exposed on the alignment layer breaks the polymer side chains, and thus may be applied in any form, such as unpolarized electromagnetic wave beam, polarized electromagnetic wave beam, electron beam, laser beam, ion beam or plasma beam. The energy beam may be normally or obliquely incident on the alignment layers.

First, a pair of substrates 10, 20 (for an LCD panel) is provided. The substrates are, for example, glass or polymeric substrates. Thin film transistors and color filters are manufactured on respective substrates. Next, alignment layers 11, 21 including polyimide, are formed respectively on the substrates 10, 20.

In FIG. 2b, a roller 13 covered with a cloth is applied to rub the alignment layer 11, wherein areas of various pretilt angles θ1and θ2are provided. The area 11aexposed to the unpolarized UV light beam 30 forms a first pretilt angle area, while the remainder of the alignment layer 11 not exposed to the unpolarized UV light beam 30 forms a second pretilt angle area. The first pretilt angle θ1of the liquid crystals corresponding to the first pretilt angle area is between 0° and the second pretilt angle θ2, and the second pretilt angle θ2of the liquid crystals corresponding to the second pretilt angle area is between the first pretilt angle θ1and 90°. By exposing the unpolarized UV light beam 30 at a power of 500 W for 20–200 mins, the first pretilt angle θ1is reduced to 0.5°, approaching the pretilt angle of a planar aligned alignment layer.

Afterward, liquid crystals 3 are filled into the LCD panel, following the sealing of the panel, as shown in FIG. 3. Alternatively, liquid crystals 3 are formed on at least one of the substrates before the substrates are bonded.

According to the invention, rubbing is performed after energy-beam exposure. The area 11aof the alignment layer 11 is exposed to the unpolarized UV light beam 30, breaking the PI side chains to thereby reduce the pretilt angle θ1of liquid crystals corresponding to the area, and the entire alignment layer 11 is then rubbed with strong anchoring energy, forming a first pretilt angle area in the area 11a, and a second pretilt angle area in the remainder not exposed to the unpolarized UV light beam 30. According to the invention, unpolarized UV beam 30 exposure is performed before rubbing, such that a linearly polarized energy beam is no longer required, and undesired effects of exposure on orientation are avoided. The “rubbing after exposure” method ensures overall orientation of alignment.

Thus, according to the invention, an unpolarized electromagnetic wave beam, in normal incidence, combined with rubbing, prepares alignment layers with various pretilt-angle areas for aligning liquid crystals in various pretilt angles.

Furthermore, the invention exhibits advantages such as stable materials (commercial materials for alignment layers are applicable), strong anchoring energy (rubbing of a strong anchoring energy is applied in company with photo-alignment of a weak anchoring energy), simple process (only one step of exposure is required), easy alignment (suitable for normal incidence), and applications for a normal exposure machine (suitable for unpolarized energy beam). Thus, by reducing manufacture costs and simplifying processes, the inventive fabrication method for LCD is suitable for mass production.

Abstract: A rubbing apparatus including a rubbing roller including an opening portion at a region of a circumferential surface of the rubbing roller, an outlet portion connected to the opening portion and open to an outside of the rubbing roller, and a groove portion connected to the opening portion and penetrating into the rubbing roller along the opening portion; and a rubbing cloth substantially surrounding the circumferential surface of the rubbing roller.

Abstract: The present invention provides a method for attaching a protection film of a liquid crystal display module, including the following steps: (1) providing a liquid crystal display module protection film and a liquid crystal display module, wherein the liquid crystal display module protection film includes a protection film body and adhesive layers formed at edges of the protection film body and the liquid crystal display module includes a backlight module, a liquid crystal display panel disposed on the backlight module, and a front bezel disposed on the liquid crystal display panel; (2) aligning the liquid crystal display module protection film with respect to the front bezel of the liquid crystal display module; and (3) attaching the adhesive layers of the liquid crystal display module protection film to the front bezel of the liquid crystal display module so as to cover the liquid crystal display panel.

Abstract: An LCD panel, a manufacturing method and a manufacturing apparatus of the same are provided. The manufacturing method includes the following steps. The first substrate and the second substrate are combined and liquid crystal is disposed between the two substrates to form the LCD panel. The first substrate and the second substrate are fused. In the present disclosure, the interior of the combined LCD panel is isolated from the outside atmosphere by fusing the combined LCD panel. Therefore, the LCD panel can stay in the air for a long time without being damaged, thus solving the problem in the prior art that the atmosphere may break the sealant of the LCD panel in the manufacturing process of the LCD panel to cause the liquid crystal leakage.

Abstract: An input device is manufactured from a roll of a single-layer flexible transparent base sheet having a first surface and a second surface by forming a transparent electrode pattern and a wiring layer on the first surface. The transparent electrode pattern is disposed in a transparent input region, and the wiring layer extends from an end of the transparent electrode pattern into a decorative region surrounding the transparent input region. A decorative layer pattern is formed on the second surface in the decorative region, while conveying the transparent base sheet through a roll-to-roll processing. The transparent base sheet having the transparent electrode pattern and the decorative layer pattern is divided into individual units. A transparent panel having an operation surface is bonded to the second surface of each of the individual units with an optically clear adhesive layer interposed therebetween.

Abstract: The invention provides a display unit which can realize reduction in thickness and weight of the display unit by omitting a void between a touch panel and a display panel, and its manufacturing method. Whole faces of the touch panel and the display panel are directly bonded together with an adhesive layer in between. The display panel has a structure wherein a driving substrate in which organic light emitting devices are formed and a sealing substrate are bonded together with an adhesive layer in between. The touch panel has a structure wherein a lower plastic film in which a transparent electrode is formed and a touch-side plastic film in which a transparent electrode is formed are layered so that the transparent electrodes are placed opposite. The display panel is constructed with only the driving substrate, and the organic light emitting devices are sealed by the touch panel instead of the sealing substrate. Therefore, thickness and weight of the display unit can be further reduced.

Abstract: Disclosed embodiments relate to signal routings for use in a display device. The display device may include a liquid crystal display (LCD) panel having multiple pixels arranged in rows and columns. Each of the pixels includes a pixel electrode and a thin-film transistor (TFT). The LCD may include a conductive signal routing portion having a first metallic layer, a second metallic layer formed directly on the first metallic layer, and a third metallic layer formed directly on the second metallic layer. The first metallic layer may include a contact terminal. The second metallic layer when combined with the third metallic layers may decrease the resistance of the third metallic layer.

Abstract: In a flexible display panel and a fabricating method thereof, the flexible display panel includes a flexible substrate, a plurality of electro-phoretic pixel units, a plurality of electro-wetting pixel units, a transparent protective layer and a driving circuit. The electro-phoretic pixel units and the electro-wetting pixel units are formed in a first displaying area and a second displaying area of the flexible substrate respectively. The transparent protective layer is formed on the electro-phoretic pixel units and the electro-wetting pixel units, and the driving circuit is formed in the non-displaying area of the flexible substrate and electrically connected to the electro-phoretic pixel units and the electro-wetting pixel units. The flexible display panel may display static pictures through the electro-phoretic pixel units and display animation through the electro-wetting pixel units. Therefore, the flexible display panel has both the abilities for saving power and displaying animation.

Abstract: The display panel includes an opposite substrate and an array substrate. The opposite substrate includes a first substrate including a first surface and a second surface opposite to the first surface, a first wire electrode formed on the first surface, a first transparent electrode formed on the first surface and partially overlapping with the first wire electrode, and a common electrode formed on the second surface. The first wire on the first surface is formed before the first transparent electrode on the first surface. The array substrate includes a second substrate including a third surface facing the second surface, and a pixel layer formed on the third surface and facing the common electrode.

Abstract: To provide a method for producing liquid crystal display panels from a panel assembly, the display panels having a panel thickness smaller than that of the assembly, by which favorable scribe grooves can be formed, which therefore allows contribution to thin profiles and narrow frame regions of the display panels. The method includes a first scribe-formation step of forming, after a first step of thinning a TFT substrate assembly 20A and a CF substrate assembly 30A of a panel assembly 10A by etching, first scribe grooves 20b on an outer surface 20a of the TFT substrate assembly 20A along regions where seals 40 are disposed, and a second thinning step of further thinning the substrate assemblies 20A and 30A by etching, and developing the first scribe grooves 20b formed on the outer surface 20a to expose portions of the seals 40 at bottoms of the first scribe grooves 20b.

Abstract: A method of manufacturing a liquid crystal panel according to the present invention includes the steps of providing a marking pad including a marking region formed of a stack constituted only of a metal film serving as a lower layer and an ITO film serving as an upper layer on a main surface of a glass substrate, bonding a glass substrate to the glass substrate so as to be opposed to the main surface of the marking region in the marking pad at a distance therefrom, and providing marking by providing a through hole in the marking region in the marking pad by irradiating the marking region in the marking pad with laser beams through the glass substrate. Thus, the marking pad provided on the glass substrate for the liquid crystal panel can be provided with marking of high definition even though laser beams are emitted through another glass substrate for a liquid crystal panel paired with the glass substrate for the liquid crystal panel.

Abstract: A liquid crystal display panel including a first substrate, a second substrate, a liquid crystal layer, and a polymer stabilized alignment layer is provided. The second substrate is disposed opposite to the first substrate. The liquid crystal layer is disposed between the first substrate and the second substrate. The polymer stabilized alignment layer is disposed between the first substrate and the liquid crystal layer, and an average surface roughness of the polymer stabilized alignment layer is greater than or equal to 10 nm.

Abstract: A stereoscopic liquid crystal display device having a touch panel and a method for manufacturing the same, wherein a stable touch detection can be performed without influencing the operation of a neighboring display panel or an electrically-driven liquid crystal lens, are disclosed.

Abstract: A liquid crystal on silicon display panel and a method for manufacturing the same are disclosed. The method includes the following steps. First, a semiconductor substrate having a pixel region with at least one first top metal pattern and a first anti-reflection coating structure substantially disposed thereon and a circuit region with is at least one second top metal pattern and a second anti-reflection coating structure substantially disposed thereon is provided. Moreover, the circuit region surrounds the pixel region. Next, the first anti-reflection coating structure is removed. Afterward, a dielectric layer is formed on the semiconductor substrate and covering the first top metal pattern. Then, a passivation layer is formed on the dielectric layer. After that, a portion of the passivation layer and a portion of the second anti-reflection coating structure thereunder are removed to form an opening ex

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey