multiplexing lcd displays price

Driving a segment LCD using multiplexing reduces the number of pins required to turn on or off the segments of a display. This application note discusses what a segment display is and the driving method in detail. The SDAF102NCRN01, a 3V, 7-segment custom LCD is used as an example.

Segment LCDs are constructed using two pieces of Indium Tin Oxide (ITO) glass with a twisted nematic fluid sandwiched in between. The majority of these displays are custom-made. Typical applications include measuring acidity levels in swimming pools, gases, or temperature. There are two types: static and multiplexed. A static display is a segment display with one pin for every one segment, whereas a multiplexed LCD has grouped segments, reducing the number of pins.

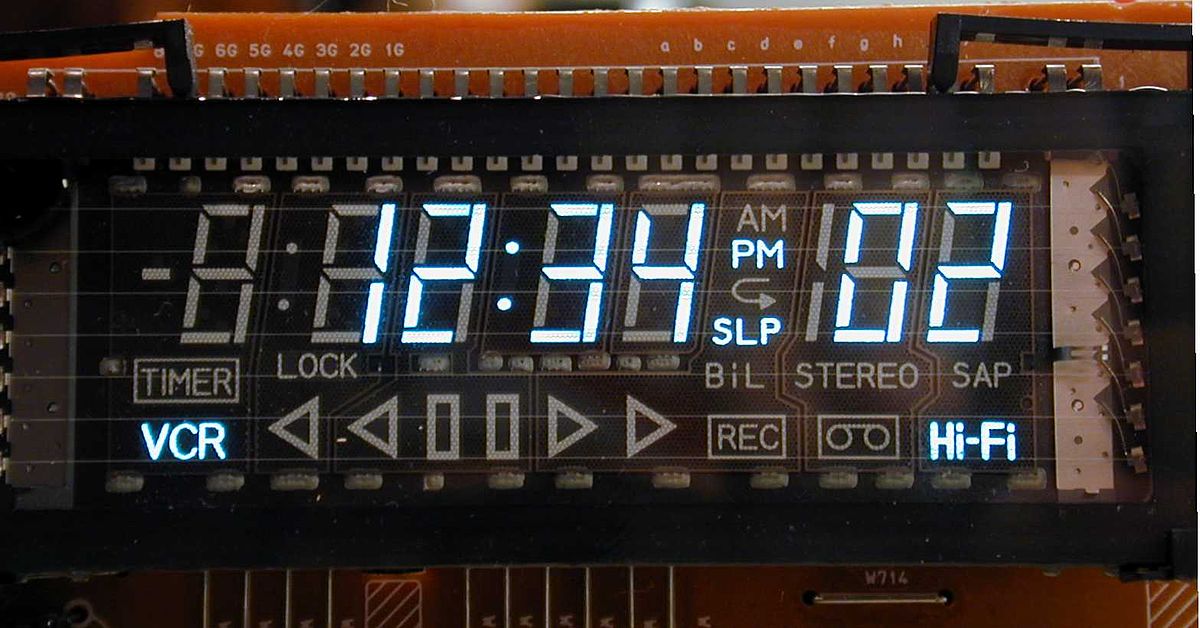

So, what is a segment? A segment is any line, dot or symbol that can be turned on and off independently. The figure below shows an example of a custom display developed by Focus LCDs.

The number of segments is dependent on what will be displayed. The most popular are seven-segment displays. In Figure 1, the digits: “0”, “8”, “4”, “7” are all seven segments. Each segment can be independently turn on or off to show a letters or number. However, the range of letters are limited. While fourteen segments have the ability to display any number and more letters.

Icons such as symbols for battery, signal strength, plus/minus and bar graphs are also considered segments. Finally, segments can also be “permanent”. This means it is always on even with no power. This is accomplished by burning the segment onto the glass. The text: “FOCUSLCDS.COM” in Figure 1 is an example.

The multiplexing technique aims to reduce the number of pins that are necessary for driving the segments of the display. This results in a simplified LCD module. In this setup, each segment control line can be connected to as many segments as there are backplanes, provided that each of the connected segments are tied to separate backplanes. This method "multiplexes" each of the segment control lines and minimizes the number of pins. The advantage of this is increased display density and reliability at the expense of complicated drive circuitry.

Segments are turned on or off using an AC voltage with no DC component (Figure 4). This means that the average voltage of the AC waveform should be equal to zero. Having a DC bias will reduce the life of the display. Also, there must be always an AC voltage on all the segments of the LCD. A sign that the LCD is degrading is when there is a loss of alignment on the edge of the characters, resulting in a distorted visual appearance.

Crosstalk, or “ghosting”, occurs when an LCD is overdriven by a combination of frequency and voltage. This appears as a partial turning on or off of a segment. To prevent inadvertent turning on or off of the segments, unused segments must be connected to its backplane (COM) pins.

One major disadvantage of multiplexed drivers is reduced contrast due to a lower duty cycle. In this case, a segment is on 25% of the time, while in static-driven displays have sharper contrast from being on 100% of the time. However, to the human eye this decrease in contrast is not noticeable.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

1TN (Twisted Nematic) is a popular LCD technology that does not require current flow for TN cells to work and uses lower operating voltages, making them suitable for portable applications.

Multiplexing (such as triplexing) reduces the number of conductors but the drive waveforms become multi-level and the contrast becomes more sensitive to temperature. You must have a display designed for the type of multiplexing you want to do.

There are also inexpensive 8-bit micros with on-chip LCD drivers with various capabilities, which I would definitely recommend (you can do a search in your favorite families of products for the presence of such a peripheral and compare capabilities to your requirements).

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

The present invention relates generally to LCD displays, and more particularly, but not by way of limitation, to a method and system for driving LCD displays.

Liquid crystal displays (LCD) are used extensively in electronic devices and displays. The LCD has become part of every day life, being included in devices have become digital in nature, such as automobile dashboards, computer monitors, radios, and watches.

Traditionally, LCDs have been used to display basic information, such as text, numbers, and symbols, mainly due to the limited capability of the LCD (i.e., on/off; black and white). However, more recently LCDs capable of displaying gray scale and color have become available. Further, technical advances in LCDs have provided the ability to use reflective polarizers within the LCDs to allow for screen printed images and colors to be selectively displayed. One such reflective polarizer is described in Ouderkirk et al., U.S. Pat. No. 5,828,488, and issued Oct. 27, 1998. An application of an LCD utilizing reflective polarizers is described in European Patent EP 0 825 477 A3, published Jun. 23, 1999, and issued to applicant Seiko.

An LCD is a passive device that does not generate light, but rather manipulates the ambient light that passes through it. There are many variations of LCD technology, but the most common of these is the field effect twisted-nematic LCD. To provide the reader with a basic understanding of LCDs and their operation, FIGS. 1 to 3B are provided and discussed hereinafter.

FIG. 1 is a layered representation of an exemplary LCD 100. The LCD 100 includes an upper polarizer 105 coupled to an upper glass layer 110. Beneath the upper glass layer 110 and coupled thereto is an (upper) electrode 115 that is generally transparent. A liquid crystal layer 120 is sandwiched between the upper electrode 115 and a lower electrode 125, which is coupled to a lower glass layer 130. A lower polarizer 135, which may be a reflective polarizer as described in EP 0 825 477 A3, as suggested above, is below the lower glass layer 130. A reflector 140 may also be located below the lower polarizer 135. Although not shown, a screen print may be located between the lower reflective polarizer 135 and the reflector 140. The screen print may show an image or simply reveal a uniform color when a segment is activated or non-activated depending on orientation of polarizers.

FIG. 2 shows selected aspects 200 of the LCD 100 that describe operability of the LCD. A light-molecule or source 205 that is oscillating (i.e., non-polarized) enters the upper polarizer 105. Because the upper polarizer 105 is polarized in a single plane, only light 210 having its direction vector in the same plane as the upper polarizer 105 passes through the upper polarizer 105, which generally results in a 50% decrease in light intensity.

Two states of the LCD are shown, (i) voltage applied and (ii) voltage not applied. In the first case, (i.e., voltage not applied), the light 215 ais rotated in polarity by 90 degrees after passing through the liquid crystal 120. By not applying a voltage, or applying a voltage below a “turn-on” threshold, to the electrodes 115 and 125, the crystalline structure 120 aof the liquid crystal 120 is twisted or rotated by 90 degrees. This 90 degree rotation causes the polarization of the light to be aligned with the lower polarizer 135 such that the light 215 apasses through the lower polarizer 135. This light 220 is reflected off of the reflector 140 and a gray-on-gray image is displayed on the LCD as viewed through the upper polarizer 105. LCDs having a 90 degree twist of the liquid crystal, which are organic molecules, are, generally, twisted nematic (TN) liquid crystals. More recently, super twisted nematic (STN) liquid crystals provide for as much as 360 degrees of twist. The STN liquid crystals provide a much higher response to an applied voltage, thereby allowing for many more segments to be integrated in a display while still producing a high contrast display.

In the second case (i.e., voltage applied), the crystalline structure 120 bof the liquid crystal 120 becomes aligned in the same direction (i.e., perpendicular to the electrodes 115 and 125) such that the light 215 bis not twisted upon exiting the liquid crystal 120. Because the lower polarizer 135 is oriented perpendicular to the polarization of the incoming light 215 b, the incoming light is blocked or absorbed by the lower polarizer 135 and is not reflected by the reflector 140. The image is seen on the LCD as being a “positive” image (i.e., black on gray) as viewed through the upper polarizer 105.

FIGS. 3A and 3B are exemplary LCDs 300 aand 300 bhaving seven segments for displaying a digit. In FIG. 3A, upper electrodes 115 a-115 gare each applied a voltage so that the digit “8” is displayed. In FIG. 3B, upper electrodes 115 d-115 fare each applied a voltage so that the digit “7” is displayed. The lower electrode 125 is considered to be a “common” so that a voltage differential is created between the segments connected to the upper electrodes 115 a-115 ghaving voltage applied thereto. It should be understood that the liquid crystal substantially sandwiched (i.e., within a segment, which is defined by common borders of the upper and lower electrodes 115 and 125) are affected by the root-mean-square (RMS) voltage applied to the electrodes 115 and 125.

Driving systems for LCDs generally include specialized circuitry that have standardized functionality. Two conventional approaches using digital circuitry have been taken by designers of driving systems for LCDs; a first approach is a fixed multiplexing approach, and a second approach is a pulse width modulation (PWM) multiplexing approach.

The fixed multiplexing approach operates on the basis of having a fixed number of lower electrodes or backplanes 125 connected to a driving system, where the driving system is configured to drive the upper and lower electrodes with predetermined voltages based on the number of backplanes to turn on and off the segments of the LCDs. A duty cycle is generated by the driving system to create an RMS voltage based on the fixed number of backplanes of the LCD. A limitation of the fixed multiplexing approach is that only two levels can be created on the LCD because the RMS voltage levels produced by the LCD driving system are fixed (i.e., on or off). Once a particular driving system (e.g., driver chip) and the number of backplanes of the LCD are selected or specified, a manufacturer of LCDs selects a liquid crystal fluid that operates within the range of the driving system. Those skilled in the art appreciate that a non-direct current (non-DC) voltage is generated by the driving system and applied to the LCD to avoid damaging the LCD.

Designers who desire gray-scale or color blends (i.e., voltage level changes) displayed on the LCD use pulse width modulation multiplexing. The pulse width modulation multiplexing approach operates on the basis of being able to drive an upper and lower electrode pair using pulse width modulation. One commercially available LCD driving system, SED1767, using conventional PWM is provided by S-MOS Systems, a Seiko Epson affiliate. This LCD driving system provides up to 16 gray-scale levels. However, this driving system requires many inputs, including gray-scale data bits to set gray-scale levels or duty cycles by the LCD driving system.

In general, the LCD driving systems used to generate various gray-scale voltage levels using conventional PWM to produce multi-level displays on LCDs are rather complex and expensive due to their unique functionality. Essentially, these specialty LCD driving systems have been developed for high-end commercial systems. Thus, consumer goods, such as watches, that are sufficiently driven by market considerations, such as price, are cost-prohibited from using LCD driving systems using conventional PWM multiplexing to generate multi-level displays (e.g., gray-scale and color) on LCDs. And, LCD driving systems operated using a fixed multiplexing approach, while inexpensive, cannot produce more than two levels on the LDC.

To overcome the problems of having to use LCD driving systems using conventional PWM multiplexing that are expensive and complex to create multi-level displays on LCDs, at least two inexpensive and relatively simple approaches are provided by the principles of the present invention. One approach (approach A) utilizes selectable or variable multiplexing, and another approach (approach B) utilizes delay signal multiplexing.

One embodiment of approach A includes a system and method for driving a liquid crystal display (LCD), having at least one segment. The system includes an LCD driver connected to at least one segment of the LCD. A processor is connected to the LCD driver. The processor may be selectively configured into any of at least two multiplexing modes, where the configured multiplexing mode initiates a signal having at least three different voltage levels for driving the at least one segment of the LCD. An external selector may be connected to the processor, where the external selector may selectively instruct the processor to achieve a particular voltage level. An internal selector may alternatively selectively configure the processor.

One embodiment of approach B includes a system and method for driving a liquid crystal display (LCD) having at least one segment including a first and second electrode. An LCD driver is coupled to the first and second electrode. A processor is coupled to the LCD driver. The processor initiates a substantially periodic signal on the first electrode and a delay signal having a time delay relative to the substantially periodic signal. The signals on the first and second electrodes form an RMS voltage to drive the segment of the LCD to any of at least three display levels. An external selector may be connected to the processor, where the external selector selectively configures the processor for selectively changing the time delay of the delay signal.

FIG. 5 is a representative LCD display with associated signals as produced by an LCD driving system utilizing selectable multiplexing according to FIGS. 4A and 4B;

Liquid crystal displays (LCD) have become pervasive in every day life as LCDs are incorporated into nearly every device imaginable. Traditionally, LCDs have been used to display information, such as time, date, radio channel, track on a compact disk, etc., to a user of the device. Recent developments of LCDs have provided for more advanced LCDs that are capable of providing multi-level or multi-state displays, including gray-scale and color. As discussed in Brewer et al., U.S. Pat. No. 5,995,456, incorporated herein by reference, various dyes and chemical compositions may be used in LCDs to provide multiple color-level displays.

The Seiko patent, previously discussed, further describes methodologies to produce colored effects in LCDs using inks (e.g., screen print) behind a reflective polarizer. The use of inks behind the reflective polarizer may be combined with various retardation film layers in or on the LCD display to produce a color change from one color (produced by the retardation film) to another color (produced by the screen printed ink). Such a combination provides a designer the ability to design an LCD with multiple color display capability.

While the LCDs have become more advanced, so too have LCD drivers to operate the LCDs. To generate gray-scale and intermediate colors, however, traditional fixed multiplexing drivers that are configured based on the number of backplanes in the LCD are no longer utilized as, once configured, provide for only two levels (i.e., on and off). More advanced drivers using a conventional PWM multiplexing driving approaches to generate intermediate voltage levels to drive the advanced LCDs are too complex and expensive to be utilized in consumer products, such as watches, clocks, garments, ornamental jewelry, and displays. Additionally, such conventional PWM multiplexing driving approaches consume power that is less than desirable for low power or battery operated applications.

The principles of the present invention provide for different driving systems to generate multi-level displays on LCDs using cost effective techniques. There are two general approaches, selectable multiplexing (approach A) and delay signal multiplexing (approach B).

The selectable multiplexing approach (approach A) utilizes multiplexing systems that are commercially available. However, the selectable multiplexing approach does not configure the multiplexing driving system to a fixed multiplexing mode based on the number of backplanes, but rather selectively configures the multiplexing system during operation. Based upon the selected multiplexing mode, a predetermined duty cycle is generated. The predetermined duty cycle generated by the selected multiplexing mode produces an RMS voltage that is applied to the LCD to create an intermediate display level. The intermediate display level may be selectively configured by an external selector, such as a push-button, or by an internal selector, such as a software routine. The simplified generation of intermediate display levels can be fixed or patterned (e.g., ramp or random).

The delay signal multiplexing approach (approach B) for driving an LCD may use a simple processor or other device to generate (i) a substantially periodic signal, and (ii) a delay signal that is time delayed relative to the substantially periodic signal. An RMS voltage is formed on a segment of the LCD to form any of at least three display levels. Similar to the multiplexing approach, the display levels of the LCD may be selectively changed using an external or internal selector. The time delay of the delay signal may include a number of different patterns, including fixed, ramped, and random, for example.

FIG. 4A is a first embodiment configuration of an LCD driving system 400 aaccording to the principles of the present invention. A microprocessor 405 ais coupled to an external memory 410 via a bus 412. The microprocessor 405 ais further coupled to an LCD driver 415 via at least one bus 420. The LCD driver 415 is connected to an LCD 425 via two buses, a COM (common) bus 430 aand a SEG (segment) bus 430 b. Other bus configurations are also possible. As shown, the LCD 425 is a single segment LCD, but could be a multi-segment LCD as understood in the art. A software program 435 may be executed or operated by the processor 405 a. The processor 405 acould be a general or specialized processor, including a digital signal processor (DSP). Further, the LCD driver 415 may be any device as known in the art for driving LCDs.

FIG. 4B is a second embodiment configuration of an LCD driving system 400 baccording to the principles of the present invention. In contrast to the LCD driving system 400 aof FIG. 4A, the memory 410 and the LCD driver 415 are embedded within the processor 405 b. Also in contrast, the LCD driving system 400 bincludes two selectors 440 aand 440 b, which are external from the processor 405 b. The selectors 440 aand 440 bmay be push-buttons, dials, knobs, wheels, contact sensors, temperature sensors, or any other type of selector that can alter the state of the computer program 435 or processor 405 b. Additionally, both LCD driving systems 405 aand 405 bcan be utilized to maintain time of day.

The configurations of the LCD driving systems 405 aand 405 bare capable of driving the LCD 425 utilizing either method A or method B as described with reference to FIGS. 5-8. However, it is contemplated that standardized or generic processors and/or drivers for the LCD may be different for the different methods being utilized to drive the LCD 125. It should be understood that the microprocessors 405 aand 405 bcould be application specific integrated circuits (ASIC) or other devices having the same or similar functionality, according to the principles of the present invention, for driving an LCD, or segments thereof, to multiple display levels.

In operation, the LCD driving systems 400 aand 400 boperate to drive the LCD 425 to multiple display levels, such as gray-scale and intermediate colors, automatically, semi-automatically, or manually. The memory maybe utilized to store the software program 435. Upon initialization or reset, the processor 405 areads the software program 435 from the memory 410 via the bus 412. The processor 405 amay thereafter execute the software program 435.

The software program 435 may include a plurality of routines for driving the LCD to multiple levels in at least one pattern, including: fixed, ramped, predetermined, random, and pseudo-random. For example, if the LCD 425 is capable of producing blue and yellow at the extreme color ends, then the ramped pattern may transition the voltage levels of the LCD 425 to display a color change from blue to yellow through various shades of green by the software program 435 being executed by the processor 405 acommanding the LCD driver 415 to change a voltage level being applied to the LCD 425. As shown, the processor 405 ahas no external inputs or selectors for configuring the processor 405 a(i.e., causing the software program 435 to change states). Therefore, the software program 435 may change states in an automatic manner as programmed. In the case of the LCD 425 being a watch face, the software program 435 may change states in a predetermined manner (e.g., synchronized to time of day), randomly, or pseudo-randomly (e.g., not in synchronization with the time of day).

The LCD driving system 400 bof FIG. 4B includes two selectors 440 a-440 bthat may be used to initiate a change of state or mode of the software program 435 manually. For example, an operator may push the selector 440 ato cause the software program 435 to change the level or color of the LCD 425 in (i) a fixed manner (e.g., blue, green, or yellow), (ii) a predetermined manner (e.g., synchronized to change once per minute or in a predetermined color order), (iii) a ramped manner (e.g., transition from blue to yellow via shades of green), and (iv) a random or pseudo-random manner (e.g., asynchronous with respect to the time of day). Additionally, the selector 440 bmay be utilized to semi-automatically selectively cause the software program 435 to drive the LCD 425 into a predetermined pattern, including either of the extreme levels or colors (e.g., blue and yellow) and any intermediate level (e.g., light-green, medium green, and dark-green) capable of being produced by the LCD driving system 400 bby the operator initiating a first action via the external selectors 405 aand 405 b.

FIG. 5 is a representative LCD display 500 with associated signals as may be produced by an LCD driving system utilizing selectable multiplexing approach (approach A) according to FIGS. 4A and 4B. The display 500 shows the connection of the common electrode COM0as related to the top and bottom segment electrodes SEGnand SEGn+1. As shown, an upper segment is selectively turned on to a selected level by, for example, applying an RMS voltage differential above a turn-on threshold between the COM0and SEGnelectrodes. A non-selected segment is created by applying an RMS voltage differential between COM0and SEGn+1electrodes that is below a turn-on threshold.

The configuration of having one common electrode, as shown in FIG. 5, is known as a direct drive configuration, a two common electrode configuration is known as a duplex configuration, a three common electrode configuration is known as a triplex multiplexing configuration, and so on. Standardized LCD driving systems based on multiplexing configurations produce predetermined common and segment driving signals. The voltage levels for the LCD driving system, Vonand Voff, are varied depending on the current multiplex configuration of the LCD driving system.

By selectively configuring the LCD driving system in a particular multiplexing mode during operation, the applied RMS voltage may be set to turn the LCD on, off, or partially on. Although the liquid crystal typically has a preconfigured rotational twist of 90 degrees up to a Voffvoltage for a given voltage threshold (e.g., 2 Vrms), if an RMS voltage less than 2V, such as 1.8 Vrms, is applied, then the liquid crystal may untwist 75 degrees, for example. By causing an untwist of the liquid crystal less than 90 degrees, an intermediate display level display may be selected. Therefore, by utilizing a fixed multiplexing LCD driving system in such a non-standardized way (i.e., selectable multiplexing), intermediate display levels may be achieved.

FIG. 6 is an exemplary flow chart 600 describing the operation of the selectable multiplexing driving system according to FIG. 5. The selectable multiplexing driving system method (method A) starts at step 605. At step 610, a multiplexing mode of at least two different multiplexing modes is selected. The multiplexing mode may be direct drive (i.e., one backplane or common electrode), duplex (i.e., two backplanes), triplex, etc. At step 615, a signal having a predetermined duty cycle based on the selected multiplexing mode is initiated to generate an RMS voltage based upon the selected multiplexing mode. The signal is applied to a segment of an LCD at step 620. It should be understood that the multiplexing mode may be selectively altered during operation to change the voltage level and corresponding color that the LCD is displaying, as discussed in conjunction with FIG. 5. The multiplexing mode may be selectively altered by a variety of mechanisms, including: an internal selector (e.g., software program) and an external selector (e.g., push-button).

FIG. 7 is a representative signal diagram 700 as produced by a delay signal multiplexing driving system (approach B) according to FIGS. 4A and 4B. A common (COM) signal 705 is substantially periodic having a 12 ms cycle. A segment (SEG) signal 710 similarly may be substantially periodic. The SEG signal 710 may be a derivative of the COM signal 705, where the SEG signal 710 is generated by simply delaying the COM signal, or be an independent signal.

By selectively altering (e.g., phase shifting or time delaying) the SEG signal 710 with respect to the COM signal 705, a resulting RMS voltage may be formed on a segment of the LCD display 425 to produce a display voltage level, which may be an end color (e.g., blue or yellow) or an intermediate color (e.g., green). The COM-SEG signal 715 is representative of the result of the two signals 705 and 710 as applied on the electrodes 430 aand 430 bof the LCD 425. As shown, the SEG signal 710 is delayed or phase shifted by t2−t1(e.g., 0.5 ms) so that a pulse 720 contains a selected duty cycle of 2*(t2−t1)/(t4−t1)*100. The selected duty cycle is maintained through t5.

At t6, the selected duty cycle is altered by delaying the SEG signal 710, which changes the duty cycle of the COM-SEG signal 715 to have a longer pulse 725. The longer pulse 725 raises the RMS voltage applied to the LCD segment, thereby selectively altering the intermediate display level (e.g., color or gray-scale) of the LCD. The time delay may be generated by a software program 435 operating within the processor 425 or an external circuit (not shown) that is either synchronous (e.g., flip-flop) or asynchronous (e.g., inverters).

FIG. 8 is an exemplary flow chart 800 describing the operation of the multiplexing driving system according to FIG. 7. At step 805, the delay signal multiplexing driving method (approach B) starts. At step 810, a substantially periodic signal is applied to the LCD. The substantially periodic signal may be applied to either the upper 115 or lower 125 electrode of a segment of the LCD 425, and the resulting differential voltage across the liquid crystal should produce the same effect as understood in the art. At step 820, a delay signal having a time delay is applied to the LCD 425. The time delay of the delay signal 710 is controlled by the LCD driving system 405 a, for example, that changes the duty cycle (i.e., RMS voltage) applied to the segment of the LCD. The time delay of the delay signal 710 may be selectively altered automatically, semi-automatically, or manually as discussed with reference to FIGS. 4A and 4B. At step 825, the method ends.

FIGS. 9A and 9B are exemplary systems 900 aand 900 bfor supporting operation of the LCD driving systems 405 aand 405 b, respectively, of FIGS. 4A and 4B. As shown, the systems 900 aand 900 bare both timekeeping devices, such as a watch or clock. However, the systems 900 aand 900 bmay also be a garment, component of a garment, jewelry, display, or any other system that is capable of utilizing the principles of the present invention.

As shown, the system 900 aincludes a single segment LCD 910. As a single segment LCD 910, there exists one common and one segment electrode (not specifically shown). The single segment LCD 910 is, in fact, the entire display dial of the timekeeping device 900 a, and can have the level of the LCD selectively altered to any level established by the selection of the LCD. For example, if the LCD is a color selectable LCD, then the display dial can be selectively set to one of the extreme colors or an intermediate color between the extreme colors. As the LCD driving system 405 autilizes an internal selector (not shown) to select the level (s) of the LCD 910, the level of the LCD 910 may be automatically selected, either time-synchronously or asynchronously. Any pattern (e.g., ramp) for changing the level of the LCD 910 may be preprogrammed.

FIG. 9B includes a multi-segment LCD 915 a, 915 b, 915 c(collectively 915), where each segment may include separate common and segment electrodes. Alternatively, a common electrode corresponding to each segment electrode may be utilized to establish the multi-segment LCD 915. By utilizing a multi-segment LCD 915, each segment may selectively display a different level so as to produce different effects for the viewer of the display. Two external selectors 440 aand 440 bmay be included on the timekeeping device 900 bto allow the operator to manually or semi-automatically alter the display. For example, the operator may push the external selector 440 ato select fixed levels for each segment of the display. Alternatively, the operator may push the external selector 440 bto selectively configure the LCD driving system 405 bto operate in an automatic mode, where the levels of the individual segments 915 a, 915 b, and 915 cof the multi-segment LCD 915 are altered, synchronously, asynchronously, time dependent, or not time dependent. It should be understood that either approach A or B for driving the LCD display 915 could be applied to systems 900 aand 900 b.

FIGS. 10A and 10B are additional exemplary systems 1000 aand 1000 bfor supporting operation of the LCD driving systems 405 aand 405 bof FIGS. 4A and 4B. Similar to FIGS. 9A and 9B, the systems 1000 aand 1000 bare both timekeeping devices, such as a watch or clock.

The system 1000 aincludes an outer ring 1005 and an LCD display 1010. The (LCD display is 1010 capable of displaying a primary color, such as red, and a secondary color, such as yellow. Alternatively, a gray scale or reflective display could be utilized. If the LCD display 1010 has a primary color of red, then to display a time element, an LCD segment may be selectively enabled to display time representative numbers, such as time in seconds, in a secondary color of yellow or an intermediate color, such as orange. For example, the number “5” 1015 ais composed of a segment of the LCD 1010. As indicated, the time in seconds is “5” seconds, which is why no other numbers around the dial, such as “10”, “15”, “20”, etc., are displayed.

In FIG. 10B, the time in seconds is equal to six seconds. As such, the number “5” 1015 bbegins to change from the secondary color (i.e., yellow) back to the primary color (i.e., red) of the LCD 1010, and the number “10” 1020 begins to turn yellow. Because six seconds is 20 percent beyond five seconds, the “5” 1015 bis approximately 80% enabled (i.e., 80% red and 20% yellow) and the number “10” is approximately 20% enabled (i.e., 20% red and 80% yellow). Other enabling and disabling techniques or synchronizations may alternatively be utilized. It should be understood that the colors of the LCD 1010 may be varied, but that the numbers representing seconds, minutes, and/or hours being transitioned on and off through intermediate levels by utilizing the principles of the present invention are the same.

Alternatively, rather than utilizing numbers (e.g., “5” 1015 a), symbols, such as a circle or some other indication, could be placed at positions representing a particular time period (e.g., seconds of a 60 second period) by placing segments of the LCD display 1010 at those locations. Yet another embodiment could have minute 1025 aand hour 1025 bhands being formed by segments of the LCD display 1010 being driven by the LCD driving system 405 aor a second LCD driving system dedicated to the minute 1015 aand hour 1015 bhands. While a traditional analog timekeeping device 1000 ais shown, a digital timekeeping device may similarly utilize the principles of the present invention.

FIGS. 11A and 11B include yet another embodiment of systems 10 aand 1100 bfor supporting operation of the LCD driving system 405 a. As shown, the systems 1100 aand 1100 bare both timekeeping devices. The LCD 1105 includes twelve segments 1105 a-1105 l. Between every other segment, a solid line is shown on the LCD 1105 to indicate to an operator or user of the timekeeping device 10 athe approximate time in seconds. The dashed lines are invisible to the operator.

To illustrate operation of the timekeeping device 1100 a, a fifth segment 1105 eis completely highlighted (i.e., colored or darkened depending upon the LCD type), which indicates that time in seconds equals 25 seconds of a 60 second cycle. In FIG. 11B, the time is equal to 29 seconds, and, expectedly, segment 1105 eis 20% highlighted and segment 1105 fis 80% highlighted. It should be understood that the LCD driving system 405 adrives each of the segments of the LCD 105 utilizing the principles of the present invention to transition the segments 1105 a-1105 lthrough intermediate display levels in a time dependent manner. It should be further understood that the segments 1105 a-11051 could be driven in a non-time dependent manner.

The PCF8576C is a peripheral device which interfaces to almost any Liquid Crystal Display (LCD) with low multiplex rates. It generates the drive signals for any static or multiplexed LCD containing up to four backplanes and up to 40 segments and can easily be cascaded for larger LCD applications. The PCF8576C is compatible with most microprocessors or microcontrollers and communicates via a two-line bidirectional I²C-bus. Communication overheads are minimized by a display RAM with auto-incremented addressing and by hardware subaddressing

There are many different display technologies such as LCD, OLED, EPD, and ECD. They are all based on fundamentally different technologies with various driving requirements. That being said, all of them share some basic ideas of how to drive them. In this article, I will explain some fundamentals in display driving. This information is relevant whether you are a professional engineer designing display applications, a hacker exploring seven segment displays for your Arduino projects, or simply if you are just interested in this topic.

There are two main categories of displays; segmented (left picture) or graphical (right picture). In a segmented display, the content on the display has to be predetermined (it can be numbers, seven segment displays, symbols, characters), while a graphical display is generic and can represent any given picture. The segmented displays are generally cheaper (even if they are custom made) while graphical displays offer more flexibility in terms of the content displayed.

Direct drive is a common driving method for segmented displays such as seven segment displays. It is a very simple option where each display segment is connected to a pin. A segment is addressed simply by setting a voltage to the targeted segment. In some cases, this type of display can be driven directly from many microcontrollers, eliminating the need for a dedicated display driver. This, in turn, reduces the cost of the overall system. This is the case for the Rdot display which can be connected to practically any MCU with accurate driving voltage. An advantage with direct drive is the possibility to address all the pixels at the same time. For LCDs, direct drive is the driving method that offers the highest contrast.

To solve the issue with an unreasonable amount of electrodes, the segments, or pixels, has to be arranged in a structure according to the figure below. This can be done with both segmented and graphical displays. For example, addressing pixel 2 (P2) is done by addressing column 2 (C2) and row 1 (R1).

In a passive matrix display, pixels are addressed row by row, this is called time multiplexing. That means that all pixels on row 1 are updated first, then all pixels on row 2, etc.. meaning that for a display with three rows, each row is only addressed ⅓ of the total time. On retro displays, it is sometimes possible to see this effect as a continuous sweeping across the screen. For LCDs, this reduces the contrast of the display which, in turn, limits the total number of rows possible. This method is often called multiplex driving for segmented displays. Passive matrix drive is a cost-effective method to drive displays as it doesn"t require any additional hardware. However, just a few display technologies have the characteristics required for passive matrix drive.

By adding transistors to the pixel, it can more easily be controlled. This is partly because transistors offer a threshold voltage which is an important feature for a display matrix to function properly. A capacitor, on the other hand, functions as an energy storage when the pixel is not addressed. In this way, all pixels can maintain their state even for a large number of rows. The Apple iMac display, for example, can in this way achieve 2880 rows without a problem. The drawback with active matrix is the high price point since the fabrication requires expensive deposition processes. For that reason, active matrix is mainly suitable for high-end displays.

There are two main display types; segmented and graphical. Direct drive is not suitable for graphical displays due to the high number of interconnections between the display and the controller. Matrix drive solves this problem with time multiplexing. There are two types of matrix drive; passive or active. Active drive is only suitable for high-end displays as it is an expensive technology. Passive matrix is a very inexpensive technology, but so far no high-resolution displays based on passive matrix have been demonstrated. Rdot will revolutionize the display industry during 2019 by introducing a passive matrix display that is both flexible and low-cost.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey