multiplexing lcd displays made in china

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

Dwin TFT LCD Module 7.0 Inch 800*480 Resolution Uart Serial HMI Touch Panel for Medical Devices Usage : Monitor LCM. Touch Screen Type : Resistive. Type : LCM. Viewing Angle : I...

Though studied extensively in the years following Reinitzer’s discovery, it wasn’t until 1927 that Vsevolod Frederiks first devised an electrically-switched light valve called the “Fréedericksz Transition”. This is the essential effect of all LCD (Liquid Crystal Display) technology. In 1936, the first practical application of the technology was patented by the Marconi Wireless Telegraph company as “The Liquid Crystal Light Valve”.

Though this type of display was not suitable for battery operation, the idea kicked off extensive application research in liquid crystals displays. Still, in the 60s, Heilmeier showed that dye molecules can be switched by liquid crystals and that this allowed an electric-field-dependent contrast effect.

In the early ’70s – almost simultaneously – Martin Schadt and Wolfgang Helfrich, as well as James Fergasson with support by Alfred Saupe, developed TN displays, which quickly found widespread application in Swiss and Japanese wrist watches.

In 1984, Terry Scheffer and J. Nehring published and patented super twisted nematic (STN) LCDs, which allowed much higher information content in passive displays.

In 1972, T. Peter Brody and his team at Westinghouse developed the first AM (Active Matrix) LCD displays, employing thin film transistors in each picture element to independently control the state of the liquid crystal in each pixel. Today, virtually all color LCD panels manufactured are of the AM type.

Twenty years later, in 1992 NEC and Hitachi became the first AM LCD manufacturers to use IPS technology. This was a breakthrough for large-screen LCDs with an acceptable visual performance for flat-panel computer screens and television applications. By the end of 2007, LCD television sales surpassed those of CRTs for the first time. Within one year, the CRT was considered obsolete for television manufacturing and just about every other practical application.

At around the same time that LCDs were overtaking CRTs in television application, Apple launched their original iPhone equipped with a revolutionary user interface (UI) primarily enabled through a projected capacitive touch screen bonded to the LCD. Today, the vast majority of smartphones and tablets employ the same TFT LCD with capacitive touch screen module integration as the central component of their user interface design.

Associated DataSupplementary Materials:Figure S1: schematic diagram of signal-conditioning circuit. (a) Hardware block schematic of the custom-made device for SARS-CoV-2 detection; (b–f) signal-conditioning circuits for (b) Peltier drive, (c) temperature sensor, (d) electric fan, (e) buzzer, and (f) indicator light. VDD and VSS represent the positive and negative power supplies, respectively. Figure S2: the custom-made portable instrument for data and setup display. (a) The home page of the instrument after starting up; (b) real-time status of the instrument; (c) real-time display during LAMP amplification with the multiplexed microwell chip; (d) amplification results displayed on the liquid crystal display. Figure S3: the top view and side view of the microwell device. Figure S4: real-time RT-LAMP amplification curves using different sets of primers on a real-time PCR instrument for 40 min at 60°C. The cyan lines were performed with the first group of primers, pink lines with the second group of primers, and black lines with the third group of primers. The targets in three different concentrations, including 107 copies/mL (low concentration, L1-L3), 108 copies/mL (middle concentration, M1-M3), and 109 copies/mL (high concentration, H1-H3), were recorded based on different sets of primers. Figure S5: the pictures of the color change in the microwells with different concentrations of ORF1ab plasmids indicate that the limit of detection of our platform achieves 1,000 copies/mL. Figure S6: simulation results of heat transfer efficiency of the unique conical shape and the tubes on the heating plate. Figure S7: quantitative data of heat transfer efficiency of the unique conical shape and the tubes on the heating plate. Figure S8: a high throughput microwell array chip with 100 microwells is applied for sample testing on the platform. (a) The high throughput chip was designed with the same dimension so that it fits the slot of the heating module on the platform; (b) the detection results are shown in the LCD display; (c) photographs of the array with 100 microwells. Table S1: LAMP primers designed for SARS-CoV-2. Table S2: the clinical samples provided by the West China Hospital. Table S3: the cost for materials and fabrication of the instrument and the microwell chip.

In this work, we developed a portable and scalable platform integrated with a multiplexed RT-LAMP microwell array biochip for rapid detection of SARS-CoV-2. The platform achieves full functions, including sample pretreatment, nucleic acid cleavage and enrichment, isothermal amplification, and colorimetric detection. On the platform, a simple laser-engraved microwell array chip was developed for multiplexed amplification of the viral RNA samples. We designed a group of six novel primers for specific identification of the conserved regions of the ORF1ab gene of SARS-CoV-2. To ascertain the rate of false results, both negative and positive controls were designed on the chip. A digital image sensing module and a liquid crystal display (LCD) were developed to detect the amplification results in each microwell. The platform achieved a low limit of detection of 1,000 copies/mL within 25 min for SARS-CoV-2 detection. Both high sensitivity (95.40%) and selectivity (95.35%) were achieved when applied this platform to test 130 clinical samples by double-blind testing at the West China Hospital, Chengdu, China. The overall performance of the platform proved its advantage as a portable and low-cost technique for rapid diagnosis of the infectious pathogens.

The setup of the platform and the microwell array-based RT-LAMP biochip is illustrated in Figure 1 (see Figure S1 for detailed circuit design and power delivery diagram). Four functional modules are designed and integrated on the platform, which implement the whole procedure including human throat swab sampling, RNA extraction, RT-LAMP amplification, and results reading (Figure 1(a), I to IV). During detection, the raw respiratory samples are collected with the aid of a swab and preserved in the sampling zone of the instrument, where the small tubes have been prefilled with virus preservation fluids. Subsequently, the collected samples are transferred with a three-channel pipette to the zone for viral inactivation and RNA extraction. The microwells prefilled with RT-LAMP buffer are applied to mix with the extracted RNAs, then initiate the isothermal amplification on the instrument under 60°C. Typically, a LAMP reaction experiences three steps, including “starting material producing step”, “cycling amplification step”, and “elongation and recycling step” [37]. A dumb-bell structure formed in the first step acts as the template for new DNA strand synthesis in the following two steps. In this work, for quick proof-of-concept, a polymethyl methacrylate (PMMA) chip with 5 × 1 microwells, including three for testing and two for control, was fabricated by laser engraving. Particularly, a conical-shaped microwell, with the top diameter of 500 μm and the bottom diameter of 3 mm, was adopted and designed (Figure 1(b), S3). The two external-control microwells are used to ascertain the rates of false-positive and false-negative results, further normalizing the output signal intensity across the devices for quantitative analysis. To achieve rapid and easy readout, we applied a colorimetric pH indicator (phenol red) in the reaction buffer. Once the amplification occurs, the pH variations lead to a color change of the buffer from pink to yellow. The color shift is proportional to the concentration of the target RNA [28]. The diagnostic result (i.e., positive (P) or negative (N) for SARS-CoV-2) in every microwell is scanned by a digital image sensor and is shown on a liquid crystal display (LCD) on the instrument. Notably, such a color change can also be visualized by the naked eye. Parameters of RT-LAMP settings, including reaction time and temperature, are set on the LCD (Figure S2).

The hardware block schematic of the custom-made device for point-of-care SARS-CoV-2 detection is shown in Figure S1. At the core of our system, we used an ARM STM32 microcontroller that could be programmed on-board through an in-circuit serial programming interface. The temperature sensor is designed to perceive the temperature of the instrument, whose specific values will be shown on the liquid crystal display. Once the temperature deviates from the set point, the corresponding drive circuit will be triggered to either heat up or cool down, thus maintaining a constant temperature. The liquid crystal display, with all sets, can realize the friendly man-machine interaction function. A digital camera and an algorithm for color intensity analysis were designed to accompany the portable instrument and to provide a user-friendly interface for data display on the LCD (Figure S2). During detection, the user will firstly turn on the instrument with a home page and a process of self-infection before work (Figure S2a). Subsequently, it will display the real-time status of the instrument (Figure S2b). Some amplification setups, including temperature and time, could be set through touch control (Figure S2c). Finally, the instrument enables the functions of LAMP reaction and detection. The data and graphs will be shown on the screen (Figure S2d). Moreover, they could be stored on the device.

Figure S1: schematic diagram of signal-conditioning circuit. (a) Hardware block schematic of the custom-made device for SARS-CoV-2 detection; (b–f) signal-conditioning circuits for (b) Peltier drive, (c) temperature sensor, (d) electric fan, (e) buzzer, and (f) indicator light. VDD and VSS represent the positive and negative power supplies, respectively. Figure S2: the custom-made portable instrument for data and setup display. (a) The home page of the instrument after starting up; (b) real-time status of the instrument; (c) real-time display during LAMP amplification with the multiplexed microwell chip; (d) amplification results displayed on the liquid crystal display. Figure S3: the top view and side view of the microwell device. Figure S4: real-time RT-LAMP amplification curves using different sets of primers on a real-time PCR instrument for 40 min at 60°C. The cyan lines were performed with the first group of primers, pink lines with the second group of primers, and black lines with the third group of primers. The targets in three different concentrations, including 107 copies/mL (low concentration, L1-L3), 108 copies/mL (middle concentration, M1-M3), and 109 copies/mL (high concentration, H1-H3), were recorded based on different sets of primers. Figure S5: the pictures of the color change in the microwells with different concentrations of ORF1ab plasmids indicate that the limit of detection of our platform achieves 1,000 copies/mL. Figure S6: simulation results of heat transfer efficiency of the unique conical shape and the tubes on the heating plate. Figure S7: quantitative data of heat transfer efficiency of the unique conical shape and the tubes on the heating plate. Figure S8: a high throughput microwell array chip with 100 microwells is applied for sample testing on the platform. (a) The high throughput chip was designed with the same dimension so that it fits the slot of the heating module on the platform; (b) the detection results are shown in the LCD display; (c) photographs of the array with 100 microwells. Table S1: LAMP primers designed for SARS-CoV-2. Table S2: the clinical samples provided by the West China Hospital. Table S3: the cost for materials and fabrication of the instrument and the microwell chip.

本发明涉及液晶显示技术领域,具体地说,涉及一种基于LTPS的传输门多路复用电路及液晶显示面板。The present invention relates to the field of liquid crystal display technology, and in particular to an LTPS-based transmission gate multiplexing circuit and a liquid crystal display panel.

为解决以上问题,本发明提供了一种基于LTPS的传输门多路复用电路及液晶显示面板,用以减少IC控制信号数量,减少IC设计难度。To solve the above problems, the present invention provides a transmission gate multiplexing circuit and a liquid crystal display panel based on LTPS, which are used to reduce the number of IC control signals and reduce the difficulty of IC design.

根据本发明的一个方面,提供了一种基于LTPS的传输门多路复用电路,包括:According to an aspect of the present invention, an LTPS-based transmission gate multiplexing circuit is provided, comprising:

反相器,其设置于所述传输门的一开关侧,使得反相前后的同一开启信号实现对所述传输门多路复用电路的控制。An inverter is disposed on a switch side of the transmission gate such that the same turn-on signal before and after the inversion performs control of the transmission gate multiplexing circuit.

根据本发明的一个实施例,通过焊盘延伸布线区域的布线传输所述同一开启信号至所述传输门多路复用电路。According to an embodiment of the present invention, the same turn-on signal is transmitted to the transfer gate multiplexing circuit through a wiring of a pad extension wiring region.

根据本发明的另一个方面,还提供了一种采用以上任一项所述传输门多路复用电路的液晶显示面板。According to another aspect of the present invention, a liquid crystal display panel using the transmission gate multiplexing circuit of any of the above is also provided.

本发明在保证传输门多路复用电路正常工作的前提下,减少了从IC侧引出的控制信号的数量,进而减少了IC侧引出控制信号线的数量。本发明有效地利用WOA区域的空余部位进行反相器的设计,用于控制信号进入到传输门多路复用电路前的反相处理,避免了WOA区域大块的空余部位,减小了由于金属刻蚀不均造成的负载效应现象。本发明提供的传输门多路复用电路走线设计,由于减少了IC侧控制信号线的输入,有效地缩短了FOUT区域的高度,减小了显示面板下边框的长度,有利于显示面板窄边框的设计。The invention reduces the number of control signals drawn from the IC side under the premise of ensuring the normal operation of the transmission gate multiplexing circuit, thereby reducing the number of control signal lines drawn from the IC side. The invention effectively utilizes the vacant part of the WOA area for the design of the inverter for controlling the inversion processing of the signal before entering the transmission gate multiplexing circuit, thereby avoiding the vacant part of the bulk of the WOA area and reducing the The load effect phenomenon caused by uneven metal etching. The transmission gate multiplexing circuit trace design provided by the invention reduces the input of the IC side control signal line, effectively shortens the height of the FOUT area, reduces the length of the lower border of the display panel, and is favorable for the display panel to be narrow. The design of the border.

图5是根据本发明的一个实施例的基于LTPS的传输门多路复用电路的驱动示意图。5 is a schematic diagram of driving of a LTPS-based transmission gate multiplexing circuit in accordance with one embodiment of the present invention.

如图5所示为根据本发明的一个实施例的基于LTPS的传输门多路复用电路的驱动示意图,以下参考图5来对本发明进行详细说明。其中,一个传输门多路复用电路对应控制像素单元中的一个子像素。FIG. 5 is a schematic diagram showing the driving of the LTPS-based transmission gate multiplexing circuit according to an embodiment of the present invention. The present invention will be described in detail below with reference to FIG. Wherein, one transmission gate multiplexing circuit corresponds to one sub-pixel in the control pixel unit.

如图5所示,该基于LTPS的传输门多路复用电路包括传输门和反相器。其中,传输门由一对具有互补结构的N型晶体管和P型晶体管构成。反相器设置于该传输门的一开关侧,使得反相前后的同一开启信号实现对传输门多路复用电路的控制。具体的,该同一开启信号在反相前直接到达传输门中的一个晶体管的开关侧,同时,该同一开启信号经反相器反相后到达传输门中的另一个晶体管的开关侧。由于N型晶体管和P型晶体管的开启电压极性相反,通过设置一反相器,可以通过控制同一开启信号实现同时打开一对N型晶体管和P型晶体,从而使得数据线信号输出端的波形正常输出。As shown in FIG. 5, the LTPS-based transmission gate multiplexing circuit includes a transmission gate and an inverter. The transfer gate is composed of a pair of N-type transistors and P-type transistors having complementary structures. The inverter is disposed on a switch side of the transmission gate such that the same turn-on signal before and after the inversion realizes control of the transmission gate multiplexing circuit. Specifically, the same turn-on signal directly reaches the switch side of one transistor in the transfer gate before inverting, and the same turn-on signal is inverted by the inverter and reaches the switch side of the other transistor in the transfer gate. Since the polarity of the turn-on voltage of the N-type transistor and the P-type transistor is opposite, by setting an inverter, it is possible to simultaneously open a pair of N-type transistors and a P-type crystal by controlling the same turn-on signal, so that the waveform of the data line signal output terminal is normal. Output.

在这种情况下,只需要3个开启信号就能控制一个像素单元中对应3个子像素的3个传输门多路复用电路。相对于图4,本发明所需的开启信号减少,有利于简化产生开启信号的IC的设计,降低IC的设计难度。In this case, only three turn-on signals are required to control the three transfer gate multiplexing circuits of the corresponding three sub-pixels in one pixel unit. Compared with FIG. 4, the required turn-on signal of the present invention is reduced, which is advantageous for simplifying the design of the IC for generating the turn-on signal and reducing the design difficulty of the IC.

在本发明的一个实施例中,该反相器设置于显示面板的阵列布线区域内,也就是将图5中的反相器设置于图1中的WOA区域。将传输门多路复用电路中的反相器设置于WOA区域内,有效利用了WOA区域的空闲部分,避免浪费WOA区域大块空余部分。由于在WOA区设置了反相器,在形成WOA区域的金属层时,使得刻蚀液的浓度降低变小,减小了由于刻蚀液浓度不均导致的金属刻蚀不均,从而减小由于金属刻蚀不均造成的Loading Effect(负载效应)现象。In one embodiment of the invention, the inverter is disposed within the array wiring area of the display panel, that is, the inverter of FIG. 5 is disposed in the WOA area of FIG. The inverter in the transmission gate multiplexing circuit is placed in the WOA area, effectively utilizing the free portion of the WOA area, avoiding wasting a large vacant portion of the WOA area. Since the inverter is disposed in the WOA region, the concentration of the etching liquid is reduced when the metal layer of the WOA region is formed, and the metal etching unevenness due to the uneven concentration of the etching liquid is reduced, thereby reducing Loading Effect due to uneven metal etching.

在本发明的一个实施例中,通过焊盘延伸布线区域的布线传输同一开启信号至传输门多路复用电路。具体的,IC产生的开启信号通过设置于FOUT区域的布线到达位于WOA区域的反相器。该开启信号经该反相器反相后到达传输门多路复用电路中的N型晶体管或P型晶体管的开关端。同时,IC产生的同一开启信号通过另一支路直接到达多路复用电路中另一晶体管的开关端。In one embodiment of the present invention, the same turn-on signal is transmitted to the transfer gate multiplexing circuit through the wiring of the pad extension wiring region. Specifically, the turn-on signal generated by the IC reaches the inverter located in the WOA area through the wiring disposed in the FOUT area. The turn-on signal is inverted by the inverter and reaches the switch terminal of the N-type transistor or the P-type transistor in the transfer gate multiplexing circuit. At the same time, the same turn-on signal generated by the IC goes directly through the other branch to the switch terminal of the other transistor in the multiplexer circuit.

当采用具有GOA结构的LTPS显示面板时,由于GOA位于显示面板的左右两侧,当采用CK信号对GOA控制时,更适合于将传输门多路复用电路中的反相器设置于两侧的WOA区域。同时,将传输门中未设置反相器的支路设置于该WOA区域中,更充分利用WOA区域中的空闲部分,减少FOUT区域中的布线设置。也就是说,FOUT区域内传输同一开启信号的一条布线延伸至WOA区域后分为两支路,其中一支路经反相器反相后到达传输门多路复用电路中一晶体管的开关侧,另一支路直接到达传输门多路复用电路中另一晶体管的开关侧。When the LTPS display panel with the GOA structure is used, since the GOA is located on the left and right sides of the display panel, when the CK signal is used to control the GOA, it is more suitable to set the inverter in the transmission gate multiplexing circuit on both sides. WOA area. At the same time, a branch in the transmission gate where no inverter is provided is disposed in the WOA area, and the idle portion in the WOA area is utilized more fully to reduce the wiring setting in the FOUT area. That is to say, a wiring that transmits the same turn-on signal in the FOUT region extends to the WOA region and is divided into two branches, one of which is inverted by the inverter and reaches the switching side of a transistor in the transmission gate multiplexing circuit. The other branch directly reaches the switching side of the other transistor in the transmission gate multiplexing circuit.

在本发明的一个实施例中,该N型晶体管和该P型晶体管为MOSFET管。具体的,采用一对具有互补结构的N型MOSFET管和P型MOSFET管制成多路复用电路中的传输门。在本发明的另一个实施例中,该N型晶体管和该P型晶体管为TFT薄膜晶体管。具体的,采用一对具有互补结构的N型TFT薄膜晶体管和P型TFT薄膜晶体管制成多路复用电路中的传输门。在液晶显示面板上,尤其是越来越多的将驱动电路采用Array制程制作在Array基板上时,优选TFT薄膜晶体管。当该传输门多路复用电路不设置在阵列基板上,或应用在其他类型的电路中,则也可以采用MOSFET管。In one embodiment of the invention, the N-type transistor and the P-type transistor are MOSFET tubes. Specifically, a pair of N-type MOSFETs and P-type MOSFETs having complementary structures are used to form a transfer gate in the multiplexer circuit. In another embodiment of the invention, the N-type transistor and the P-type transistor are TFT thin film transistors. Specifically, a pair of transmission gates in a multiplexing circuit are fabricated using a pair of N-type TFT thin film transistors having complementary structures and P-type TFT thin film transistors. On the liquid crystal display panel, especially when more and more driving circuits are fabricated on an Array substrate by an Array process, a TFT thin film transistor is preferable. The MOSFET can also be used when the pass gate multiplexing circuit is not disposed on the array substrate or in other types of circuits.

减少了IC侧信号线的输入,有效地缩短FOUT区域的高度,减小显示面板下边框的长度,有利于窄边框的设计。According to another aspect of the present invention, there is also provided a liquid crystal display panel employing the above transmission gate multiplexing circuit. The liquid crystal display panel reduces the number of CK control signal lines drawn from the IC side under the premise of ensuring the normal operation of the transmission gate multiplexing circuit. The liquid crystal display panel also effectively utilizes the vacant part of the WOA area to design the inverter for inverting processing before the CK control signal enters the transmission gate multiplexing circuit, thereby avoiding the vacant part of the WOA area and reducing the vacant part of the WOA area. Small load effect due to uneven metal etching. At the same time, the liquid crystal display panel

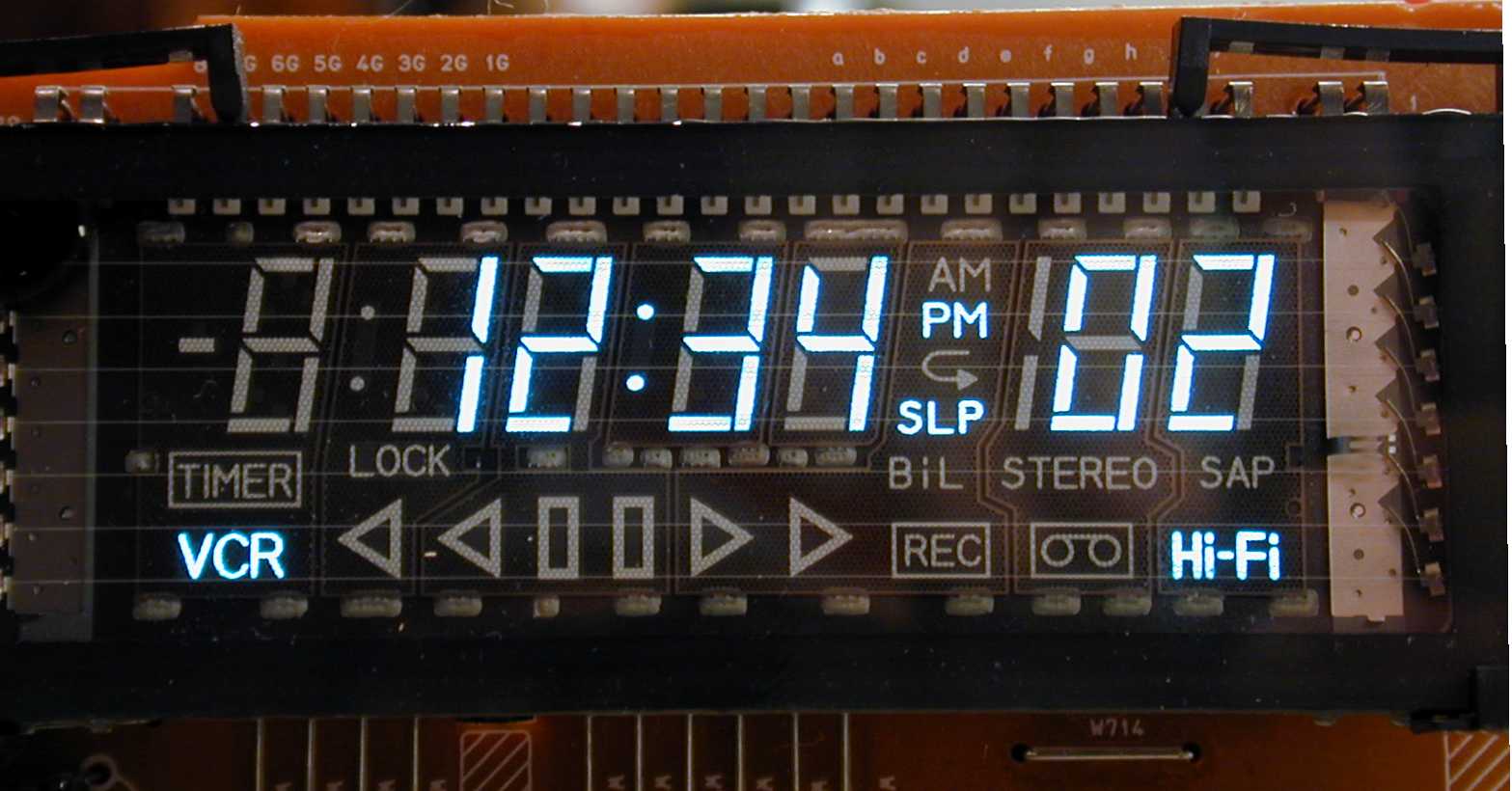

An LCD or liquid crystal display is a combination of two states of material ie, the solid & the liquid. These displays use a liquid crystal to produce a visible image. LCDs are super thin technology display screen that are used in cell phones, TVs, portable video games, laptops, computer screen, portable video games. Compared to CRT (cathode ray tube) technology, this technology permits displays to be much thinner. The LCD is composed of different layers which contain two electrodes and polarized panel filters. This technology is used to display the image in electronic devices. It is made up of active matrix or passive display grid. Most of the gadgets with LCD display uses active matrix display. There are various technologies used to make digital displays. But, we are discussing two different LCDs. The alphanumeric display and customized LCD.

The most common types of monochrome LCDs are called character display or alphanumeric display. Alphanumeric LCD displays are used to display alphabets and numbers. The 16×2 intelligent alphanumeric dot matrix displays are capable of displaying 224 different symbols and characters. Generally, alphanumeric LCDs are used widely in these applications: cellular phones, home appliances, meters, word processors, communication, medical instruments, etc.. These displays are widely used due to the following reasons:

Hardware designers and engineers favor alphanumeric LCD displays for fast developing products. These types of devices contain their own controller driver chip with a character map built into the IC. To integrate the software, the character map makes it easy for the design. When any designer or engineer wants to display or show a letter, all they need to do is to send a command requesting the capital. This is much easier than a graphics LCD module wherein each spot on the letter A needs to be addressed. This is a highly time consuming activity.

The most common structure of alphanumeric display is known as a chip on board (COB) where in the PCB (printed circuit board) is attached to the LCD glass. The name COB means that the controller driver chip is placed on the back of the PCB. This module handles vibration very well. And also the increasing holes placed on the PCB permit an easy and secure method to attach the LCD to the customer’s product.

Alphanumeric LCD displays are designed in standard configurations such as LCD display 16×2, 8×1 and 40×4. The identification of alphanumeric displays is broken down into the number of characters in each row and then the number of rows. The example of this is a 16×2, where there are 16 characters in each row, and there are two rows of these characters. This enables the alphanumeric displays to display 32characters at a time.

A character can be any letter: capital or small, any number,and punctuation mark, such as comma, period and backslash. The character table built into the microcontroller of the LCD display displays 255 different characters.Furthermore, there are many languages, so you can select a character table that displays English, German and French or any other language. Most of the alphanumeric LCD displays cannot display Chinese and Japanese languages without the use of a larger character size. This means that a 16×2 is built to display English characters, but not the Chinese;Chinese will require larger than 16×2 display.

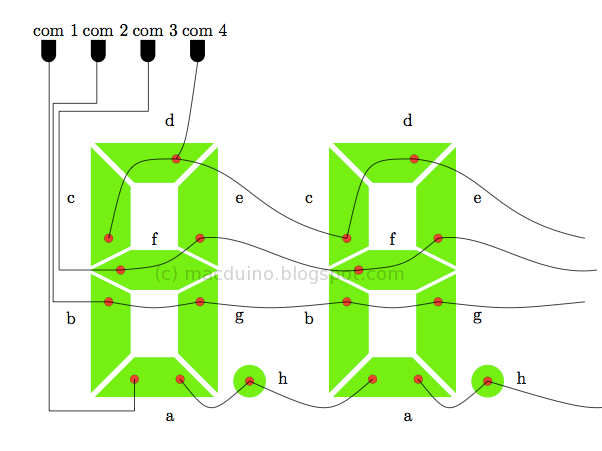

The alphanumeric displays consist of LCD displays or a set of LEDs that are connected in common anode or common cathode mode. 7 segment displays are used for only numbers in decimal and hexadecimal format.For both alphabets and numbers, the 18 segment display consisting of the 5 by 7 dot matrix is used.

Alphanumeric LCD Displays are most commonly used in test and measurement equipment, process control equipment, handheld devices, PLC’s, data loggers, PCO displays energy meters, and a host of other applications. Displaying Scrolling Messages on Alpha Numeric Displays using a PC is one of the most frequently used application of alphanumeric display.

The above block diagram can be used to display scrolling message on alphanumeric LCDs by using PC. The information can be sent through a PC that is interfaced with an 8051 microcontroller through MAX232. An external memory is connected to the microcontroller which stores the information. The endless scrolling can be displayed using alphanumeric LCD display, which is connected to a microcontroller.

In present days, different types of LCDs are used in a wide range of applications from calculators, watches, games to medical and industrial applications. One of the main advantages of LCDs over other display technologies is the display content can be modified to satisfy the exact requirements of an application. In this way, the customized LCD panels can present particular user interface information that enhances the product value and performance.

Customized LCD displays are used to display a combination of numeric, alphanumeric digits, on/off indicators,messages, graphic icons, symbols, pie charts, bar graphs, etc. The content of this panel is limited only by the imagination of the product designer. There are manyfactors that should be considered in the design of a customized LCD panel. In order to design a quotation for a customized LCD panel, the following information is necessary:LCD panel, display modes, polarisers, viewing mode, backlight requirement, operating environment, drive method, connection method, and a keypad is required if applicable.

This is all about Alphanumeric and Customized LCD displays with Applications. We all know that these LCD displays play an essential role in many applications like measurement equipment, process control equipment, handheld devices, PLC’s, Measuring device, Marine equipment, Medical equipment, Automotive display etc. This article deserves readers’ feedback, suggestions and comments. Furthermore, any doubts regarding electronics projectsreaders can post their comments in the comment section below.

I need to drive a small 4-character 7 segment display https://www.digikey.com/en/products/detail/lumex-opto-components-inc/LCD-S401M16KR/7364561. I’m looking for a small i2c or SPI driver IC that can offload the support of this display from the board’s main MCU. I suppose I could use an MSP430 and program it myself, but does TI have any existing solutions for this sort of problem?

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey