idrac lcd panel made in china

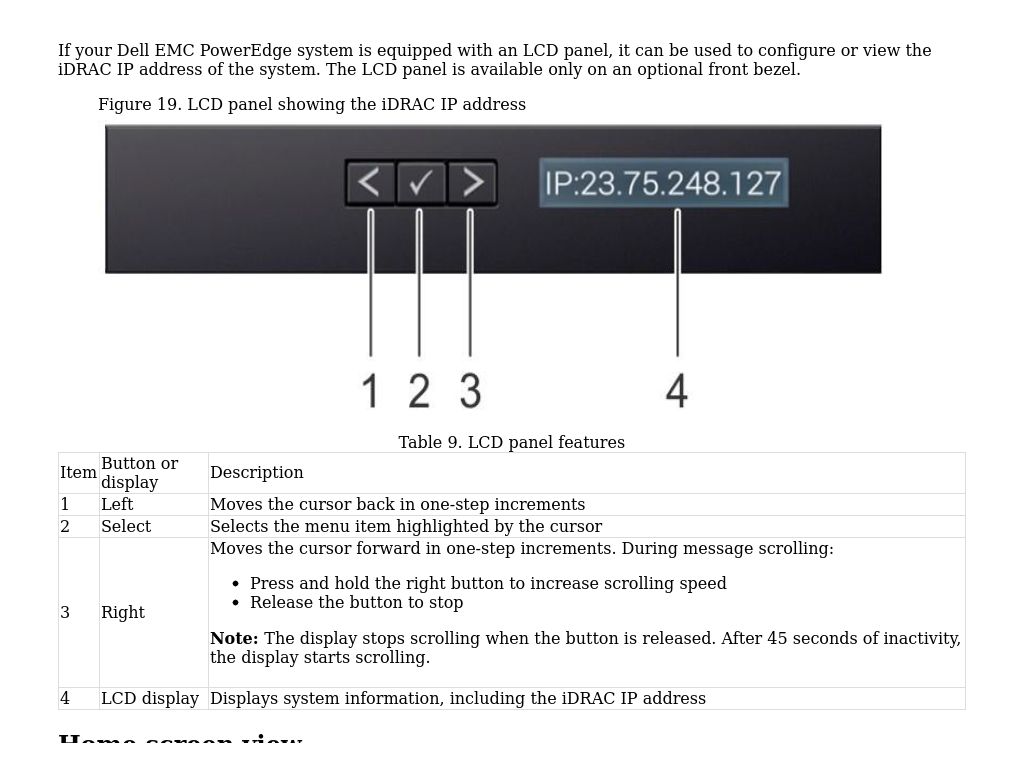

If your Dell EMC PowerEdge system is equipped with an LCD panel, it can be used to configure or view the iDRAC IP address of the system. The LCD panel is available only on an optional front bezel.

From the Setup menu, use the iDRAC option to select DHCP or Static IP to configure the network mode. If Static IP is selected, the following fields are available:

One very important consideration for choosing your blade server is the type of embedded management license you need. I’ve seen organizations attempt to save money by going with the low end license offering for systems management only to find out it doesn’t include a crucial feature. One such feature is the ability to see trends and get early warnings from a server before it alerts. In this blog post I’m going to talk about the iDRAC license options for Dell EMC blade servers including a comparison of the different license versions and why you may want them.

Dell EMC PowerEdge servers all have a dedicated systems management chip known as iDRAC 9 or integrated Dell Remote Access Controller, 9th generation. (If you are familiar with HPe ProLiant servers, the iDRAC serves a similar function as the iLO.) iDRAC provides a secure out-of-band, agent-less connection to allow for a user to manage the lifecycle of the PowerEdge server, even if the server is powered off. It also offers both a HTML 5 GUI web interface and command line interface allowing administrators to perform remote management tasks like monitoring, managing, updating, troubleshooting and remediation. Finally, iDRAC enables connectivity into other Dell Technologies datacenter management tools like OpenManage Enterprise and OpenManage Integration for VMware vCenter.

iDRAC9 v4.00.00.00 released in December of 2019 and introduced new features including a new Datacenter License – see below for details. Although there are 3 variations of the iDRAC license for Dell EMC blade servers: iDRAC9 Express, iDRAC9 Enterprise and iDRAC9 Datacenter, you really only have two to choose from. There is not an option to buy the PowerEdge server without an iDRAC9 license, therefore the Express license edition is considered the base license. All of the iDRAC9 4.00.00.00 licenses come with basic instrumentation with web GUI and API support, but here are the items available with all iDRAC9 licenses:

If you’ve read this far, congratulations. Give yourself a pat on the back and grab a nice cold one. As you can see, the list is pretty extensive for a base systems management license, so let’s next look at what the iDRAC9 Enterprise and iDRAC9 Datacenter licenses offer.

iDRAC auto certificate enrollment for SSL certificates – polls the specified Certificate Authority (CA) and authenticates the SSL certificate using the credentials provided. Can be done via the GUI, via server configuration profile or via script.

I failed to mention in the original post that the iDRAC9 Datacenter metric reports will not only deliver via the Redfish methods mentioned above, but it will also integrate into typical analytics solutions like Splunk, ElasticSearch and Grafana to name a few.

PowerEdge server lifecycle management with iDRAC9 – video by Product Manager, Doug Iler (a special thanks to him as I stole most of the above from him)

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

In the past, we had reviewed some of the based management controller (BMC) solutions from major server manufacturers, including HPE iLO 5 and Lenovo XClarity Controller (XCC). These embedded server management technologies allow a system administrator to monitor and manage servers and other network-attached equipment by remote control regardless of whether the machine is powered on or whether an operating system is installed or functional. Each of these solutions has similar functionality to the others, and each has been improved over the years to add new functions and capabilities. In this review, we take a close look at the integrated Dell Remote Access Controller (iDRAC) with Lifecycle Controller, on the current version 9, which is included in generation 14 of PowerEdge servers.

The Integrated Dell Remote Access Controller (iDRAC) has a long journey on the out-of-band management solutions. iDRAC9 is built off the features and functionality of iDRAC8, which is embedded in the previous 13th generation PowerEdge servers. iDRAC9 is designed to make system administrators more productive, allowing them to deploy, monitor, update, and manage PowerEdge servers, both locally and remotely, either from GUI or scripting.

The iDRAC controller is a piece of hardware integrated on the motherboard of the server, and as well as other BMC solutions, has its own processor, memory, network connection, and access to the system bus. The iDRAC provides remote access to the system console (keyboard and screen), allowing the system BIOS to be accessed over the Internet when the server is rebooted. Key features of iDRAC include power management, virtual media access, and remote console capabilities. These features give administrators the ability to configure a machine as if they were sitting in front of the local console.

Previous server generations and versions of iDRAC were loaded with a lot of options, and now, iDRAC9 has new features that are available only on the 14th generation Dell EMC PowerEdge servers. iDRAC9 has a brand new processor, which Dell claims to be four times faster than the previous generations, allowing all the GUI pages to change and load faster, as well as all the backend processes. Another feature is Connection View, that helps knowing where the iDRAC, as well as PCIe devices, are connected at the top rack switch, so you could know where are all cables connected without going into the server room. And System Lockdown mode, it is a secure mode that when is enabled, the system doesn’t allow any configuration changes whether wanted or unwanted into the system.

Each generation of iDRAC with Lifecycle Controller comes with a basic level of functionality. Based on the server model ordered, licensing features differ. Based on the desired level of management functionality, companies and IT administrators should decide what features fit them best.

iDRAC Basic or iDRAC Express are the standard licenses available by default on the system. iDRAC Enterprise license includes all the licensed features.

At the heart of the Dell PowerEdge servers management solution, is the embedded Lifecycle Controller (LCC). The LCC is a lightweight operating system that runs from the iDRAC to receive instructions from management systems. It also serves as a direct point for updates and helps to perform automated tasks as directed to create and maintain healthy servers.

The LCC is loaded on demand; it is not continuously running. The network configuration within the LCC allows it to access network resources for performing platform updates. Since the iDRAC can be accessed remotely, and many of the features available through the LCC are also available via the iDRAC, the LCC is commonly used for initial systems configuration. The LCC user interface provides a connection to Dell’s Internet-based firmware and software repository via FTP, eliminating the need for removable media.

Lifecycle Controller provides a graphical user interface; this allows administrators to leverage the embedded controller without having to utilize additional management tools. In order to provide a comprehensive review of Dell’s iDRAC solution, we walked through the menu and common systems management tasks of the Lifecycle Controller, using its GUI.

The LCC GUI can be accessed by pressing F2 when booting the server or from the iDRAC Web Interface, which we are going to overview below. For this review, we connect to the LCC, using the Virtual Console from iDRAC and a Java plug-in.

We need to reboot the server to access the LCC; after that, we will be directly brought to the LCC home page. From here, we can perform quick options such as updating the firmware, configure the server for iDRAC, configure RAID, or Deploy and Operating System.

Under Advanced Hardware Configuration, we can more options, System BIOS, iDRAC Settings, and Device Settings. Several configurations are going to be found under these three main options. Besides, most of these options can be performed from the iDRAC Web Interface.

For iDRAC9 is possible to update single devices using the web interface. For iDRAC7/8, the process can be carried out from the Lifecycle Controller GUI.

The main iDRAC management takes place via a web-based interface. There are multiple ways to logging in to iDRAC using the web-based interface; one could use the local iDRAC user, a Microsoft Active Directory user, or a Lightweight Directory Access Protocol (LDAP) user. Other options for log in to iDRAC, include using a smart card, Single Sign-On, remote RACADM, public key authentication, or SMCLP. With all these login options, IT administrators have extensive accessing management that increases security. During this review, we are accessing as a local user, but this access doesn’t have implications in the functionality of the GUI.

Once we log in to iDRAC, the first page we see is the dashboard, along with the main menu composed by System, Storage, Configuration, Maintenance, and iDRAC Settings located at the top of the interface. From Dashboard, we can take quick actions on the server, like graceful shutdown, identify system or turn on the system lockdown mode (shown below). Also, in the Dashboard, we have an overview of the system divided into different areas, including Health Information, System Information, Virtual Console, Recent Logs, and Notes. From the Dashboard, we can also enable the iDRAC Group Manager feature, which is available for the 14th generation of Dell Servers.

If we turn on the system lockdown mode, under the More Actions button, the GUI will show a yellow banner indicating that we are in this secure mode. Lockdown mode will keep you from making changes to the hardware configuration, improving security, and allowing to performer monitoring-only actions, for example. Lockdown mode is available from iDRAC9.

The next item in the main menu is System, which shows system details, iDRAC details, inventory, and performance logs, and we can navigate on the System sub-menu that includes Overview, Details, Inventory, Performance, and Host OS. From Overview, one can view details about the system, installed components, voltages, temperatures, and others. We start noting how depth we can go navigating in the menus, submenus, and options of this feature-rich management tool. Under Summary, essential information is displayed, such as System Information, iDRAC Detail, and many others, scrolling down. Also, we can monitor the power capacity of the system.

Under Overview, we also highlight some of the options like Front Panel, that allows viewing the live feed of the status that is currently displayed on the physical front panel LEDs.

As part of iDRAC9, we can leverage the Connection View feature, which allows us to check and troubleshoot network connections remotely. Here we can see the status and connection on switches, switches ports, and network adapters associated with the server.

Expanding on iDRAC details, we can quickly check firmware and hardware information, as well as the general configuration of the iDRAC. Below, the Asset Tracking displays the list of asset information that you have configured under the Asset Tracking page.

We move to the System Settings page. Here we can view and edit system settings such as alerts, traps, email and email server, fans, front panel, first boot device, and more parameters.

From System Update, one can update firmware for iDRAC, BIOS, and any supported device through Lifecycle Controller in a single system reboot. On this page, we can perform actions such as Manual Update, Automatic Update, or Roll Back.

The last page under Maintenance is SupportAssist; we can use this area to create SupportAssist collections. iDRAC provides an application interface for gathering platform information that enables support services to resolve platform and system problems.

We move one more time to the main menu, and here check our last item, iDRAC Settings. This last option allows to view and edit iDRAC settings such as network settings, IPMI, services, users, export and import server profile, and others. The first page we see is Overview, where we can take a glance at iDRAC details, network settings, and IP settings.

Other options under iDRAC Settings include Connectivity, to configure all network properties, and Services, useful to view or change the interface settings for local configuration, Web server, SSH, Telnet, and others.

The last page to check is Settings. From here, we can create server settings, create automated backup tasks, or import server profiles. From backup and Export, one can create a backup of the entire server configuration, including the firmware version information for the various components such as BIOS, RAID, NIC, iDRAC, and Lifecycle Controller.

With this mobile app, we can connect to the iDRAC interface of PowerEdge servers, handy to quickly troubleshoot and take actions. This app is out of the scope of this review but is worth to mention and show some of its capabilities. Below, some captures from the demo app.

In modern data centers, managing servers remotely requires powerful management tools to aid System Administrators to monitor, configure, and troubleshoot. These tools must support essential functions, including power on, power off, system updates, and other configurations. All the major server vendors provide some level of management tools, from free basic low-end tools to enterprise-class offerings. The iDRAC9, from Dell, with Lifecycle Controller, is designed to accomplish these enterprise-class management requirements.

While the iDRAC is the remote access card that gives access to the hardware status, the LCC will be useful for initial system configuration, local deployments, and firmware updates. iDRAC is embedded in every PowerEdge server, and there is no need to install extra software. Mainly, managing the iDRAC takes place in its web-based interface, which at first glance, can be truly overwhelming. The system is loaded with a lot of options that one can notice once navigating in menus and submenus. iDRAC also includes a mobile app to troubleshoot and take general actions from everywhere easily. All these tools, in the hands of system administrators, increase availability, improve productivity, and secure data center environments.

On Dell hardware, you have the option of configuring the Forge Appliance LCD, a small readout on the computer’s front panel. Use these steps to configure the LCD display for Forge:

Press Esc > Esc > Esc to exit the iDRAC Settings page and the System Setup Main Menu, then continue with instructions in Section 6.0, Installing Other Components Required by Forge.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey