boe the largest lcd panel maker made in china

BOE Technology Group Co., Ltd., or Jingdongfang (Chinese: 京东方科技集团股份有限公司), is a Chinese electronic components producer founded in April 1993. Its core businesses are interface devices, smart IoT systems and smart medicine and engineering integration.LCD, OLEDs and flexible displays.

In April 1993, Beijing Oriental Electronics Group Co., Ltd was founded by Wang Dongsheng. In 1997, it listed B shares on the Shenzhen Stock Exchange. In 2001, Beijing Oriental Electronics was renamed BOE Technology Group Co., Ltd. BOE acquired SK Hynix"s STN-LCD and OLED businesses for US$22.5 million.flat-panel display businesses for US$380 million.

In 2009, BOE Energy Technology Co., Ltd was founded to enter the photovoltaics industry. In 2010, BOE acquired Suzhou Gaochuang Electronics" Taipei Display Research Center and AIO Manufacturing Plant.

In 2011, BOE established a Japan branch and R&D center in Tokyo. In 2012, BOE established an American branch and R&D center in Santa Clara in Silicon Valley, California. In 2014, BOE established a subsidiary in Frankfurt, Germany. In 2015, BOE acquired OASIS International Hospital.

In 2017, BOE established its Middle East Branch in Dubai and set up a subsidiary based in São Paulo, Brazil. BOE also announced its plan to build a hospital in Chengdu which will be opened in late 2020. BOE announced a long-term agreement with Universal Display Corporation, UDC will supply phosphorescent OLED materials to BOE.LG Display still lead in terms of area shipment.

In 2018, BOE acquired SES-imagotag for €200 million.Kopin Corporation and Olightek for OLED micro-displays manufacturing.Huawei Mate 20 Pro is the first flagship tier smartphone with an AMOLED sourced from BOE (also sourced from LG Display).

In 2019, BOE formed a joint venture with Rohinni for MicroLED and mini LED backlighting manufacturing.Hisense announced its U9E TVs featuring dual LCD panels which Hisense said exceeds OLED TVs in brightness, color gamut and color accuracy. Its panels are produced by BOE.Huawei Mate X scheduled for release in Q4 2019 reportly has a foldable OLED from BOE.Samsung Displays.flat-panel display producer.Huawei to research cameras under OLEDs.LG Display and Tianma as OLED supplier for LG Electronics smartphones in 2020.Apple beginning in 2021 for the iPhone.

On February 1, 2022, the company announced they had developed the world’s fastest gaming monitor with a 500Hz refresh rate. The prototype 27-inch monitor has a resolution of 1080p.

In 2021, WIPO’s annual World Intellectual Property Indicators report ranked BOE Technology"s number of patent applications published under the PCT System as 7th in the world, with 1,892 patent applications being published during 2020.

BOE has manufacturing facilities located in Beijing, Hefei, Chengdu, Chongqing, Fuzhou, Mianyang, Wuhan, Kunming, Suzhou, Ordos and Gu"an. BOE has global marketing and R&D centers in 19 countries, such as Japan, South Korea, Singapore, the United States, Germany, the United Kingdom, France, Switzerland, India, Russia, Brazil and Dubai.

BOE Technology Group Co., Ltd., also known as Jingdongfang, is a China-based electronics and semiconductor company with its headquarters located in Beijing, China. Being an electronics company, BOE Technology exactly knows how much effort it takes to stay strong among great competition from its peers. And, it is tougher to be popular and stay relevant, when the big names from foreign countries are your competitors. BOE Technology is one of the biggest examples of how local products can also be the best, and how buying local products can help the country’s economy, too.

BOE Technology is among the leading electronics company in China and expertise in electronics health care, the internet of things, and photovoltaics, such that it produces products like interface devices, smart medicine, smart IoT systems as well as engineering integration-related products. BOE Technology is also famous as the largest supplier of LCD, OED, and flexible/foldable displays. The company also manufactures and sells fingerprint sensors, optoelectronic sensors, and solar panels.

The sudden rise in revenues helped BOE Technology list the B shares on the Shenzhen Stock Exchange, in 1997. The company was then renamed BOE Technology Group Co., Ltd. in 2001. It made its first acquisition in the same year, where it bought the LCD and OLED businesses of

BOE Technology put the foundation of the BOE Energy Technology Co., Ltd and entered the photovoltaic business in 2009. The company expanded overseas when it opened its branch and an R&D center in Tokyo, Japan (2011) and Santa Clara in Silicon Valley, California (2012). In 2015 and 2016, BOE Technology opened offices in Frankfurt Germany, and New Delhi, India, respectively. In the following years, the company expanded to Dubai, Brazil, Indonesia, South Africa, etc.

Yashica is a Software Engineer turned Content Writer, who loves to write on social causes and expertise in writing technical stuff. She loves to watch movies and explore new places. She believes that you need to live once before you die. So experimenting with her life and career choices, she is trying to live her life to the fullest.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

SHANGHAI - China"s BOE Technology Group, one of the world"s largest display manufacturers, plans to build a massive new factory in Beijing, as it looks to next-generation technology for new revenue streams.

BOE will invest 29 billion yuan ($4 billion) in the 600,000 sq. meter factory, according to Sunday"s announcement, with an eye toward expanding into markets for new technologies, such as panels for virtual reality (VR) devices, and a new type of high-end panel called mini-LED.

BOE, China’s largest display company, was listed as a major panel supplier in Samsung Electronics’ business report. BOE has filled the vacancy created by Samsung Display’s phased reduction of large LCD panels for TVs.

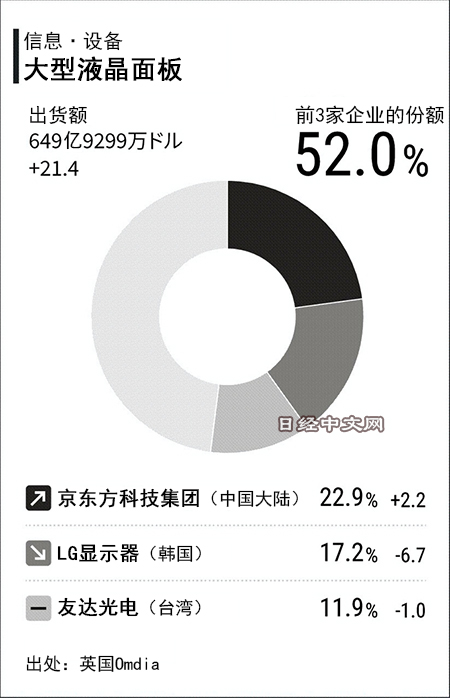

The business report, which was registered with the Financial Supervisory Service’s electronic disclosure system, listed three major display panel suppliers for the company"s consumer electronics (CE) sector in 2021 -- BOE and CSOT of China and AUO of Taiwan. BOE was newly added as a major supplier. BOE surpassed LG Display in 2018 to become the world’s No. 1 LCD manufacturer.

Samsung Display decided in early 2021 to stop producing large LCD panels beginning from 2022. The decision was made to speed up its transition to next-generation QD-OLED panels as the profitability of the LCD business fell significantly due to a price war with Chinese companies.

It stopped the operation of L7 at Asan Campus in South Chungcheong Province, which had produced large LCD panels, in March 2021. An 8th-generation LCD production line at the Suzhou plant in China was sold in April 2021. However, it is still operating some of its large LCD production facilities at Asan Campus at the request of Samsung Electronics. Samsung Display is considering shutting down these facilities within June 2022.

Industry insiders say that Samsung Display"s withdrawal from the LCD business has weakened Samsung Electronics" bargaining power in negotiations with Chinese vendors.

Samsung Electronics’ price burden for TV panels has nearly doubled over the past year. The Samsung Electronics business report says that the company spent 10,582.3 billion won on purchasing display panels in 2021. This was an increase of 94.2 percent from the previous year (5,448.3 billion won). The main factor behind the increase is a rise in LCD panel prices. Samsung Electronics explained that prices of TV panels rose about 39 percent on year in 2021.

Industry insiders say one solution is to accelerate a shift to OLED-based TVs. Chinese panel makers are investing aggressively to develop large OLED panel technologies, but they have not yet reached the volume production stage.

Samsung Electronics is negotiating with Samsung Display and LG Display over the release of OLED TVs. LG Display is the only company that mass produces large OLED panels. It can produce 10 million TV panels annually. Samsung Display started mass production of large OLED panels at the end of 2021. The two Korean OLED panel makers adopt white (W) and blue (B) light sources, respectively.

LCD manufacturers are mainly located in China, Taiwan, Korea, Japan. Almost all the lcd or TFT manufacturers have built or moved their lcd plants to China on the past decades. Top TFT lcd and oled display manufactuers including BOE, COST, Tianma, IVO from China mainland, and Innolux, AUO from Tianwan, but they have established factories in China mainland as well, and other small-middium sizes lcd manufacturers in China.

China flat display revenue has reached to Sixty billion US Dollars from 2020. there are 35 tft lcd lines (higher than 6 generation lines) in China,China is the best place for seeking the lcd manufacturers.

The first half of 2021, BOE revenue has been reached to twenty billion US dollars, increased more than 90% than thesame time of 2020, the main revenue is from TFT LCD, AMoled. BOE flexible amoled screens" output have been reach to 25KK pcs at the first half of 2021.the new display group Micro LED revenue has been increased to 0.25% of the total revenue as well.

Established in 1993 BOE Technology Group Co. Ltd. is the top1 tft lcd manufacturers in China, headquarter in Beijing, China, BOE has 4 lines of G6 AMOLED production lines that can make flexible OLED, BOE is the authorized screen supplier of Apple, Huawei, Xiaomi, etc,the first G10.5 TFT line is made in BOE.BOE main products is in large sizes of tft lcd panel,the maximum lcd sizes what BOE made is up to 110 inch tft panel, 8k resolution. BOE is the bigger supplier for flexible AM OLED in China.

As the market forecast of 2022, iPhone OLED purchasing quantity would reach 223 million pcs, more 40 million than 2021, the main suppliers of iPhone OLED screen are from Samsung display (61%), LG display (25%), BOE (14%). Samsung also plan to purchase 3.5 million pcs AMOLED screen from BOE for their Galaxy"s screen in 2022.

Technology Co., Ltd), established in 2009. CSOT is the company from TCL, CSOT has eight tft LCD panel plants, four tft lcd modules plants in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou and in India. CSOTproviding panels and modules for TV and mobile

three decades.Tianma is the leader of small to medium size displays in technologyin China. Tianma have the tft panel factories in Shenzhen, Shanhai, Chendu, Xiamen city, Tianma"s Shenzhen factory could make the monochrome lcd panel and LCD module, TFT LCD module, TFT touch screen module. Tianma is top 1 manufactures in Automotive display screen and LTPS TFT panel.

Tianma and BOE are the top grade lcd manufacturers in China, because they are big lcd manufacturers, their minimum order quantity would be reached 30k pcs MOQ for small sizes lcd panel. price is also top grade, it might be more expensive 50%~80% than the market price.

Panda electronics is established in 1936, located in Nanjing, Jiangshu, China. Panda has a G6 and G8.6 TFT panel lines (bought from Sharp). The TFT panel technologies are mainly from Sharp, but its technology is not compliance to the other tft panels from other tft manufactures, it lead to the capacity efficiency is lower than other tft panel manufacturers. the latest news in 2022, Panda might be bougt to BOE in this year.

Established in 2005, IVO is located in Kunsan,Jiangshu province, China, IVO have more than 3000 employee, 400 R&D employee, IVO have a G-5 tft panel production line, IVO products are including tft panel for notebook, automotive display, smart phone screen. 60% of IVO tft panel is for notebook application (TOP 6 in the worldwide), 23% for smart phone, 11% for automotive.

Besides the lcd manufacturers from China mainland,inGreater China region,there are other lcd manufacturers in Taiwan,even they started from Taiwan, they all have built the lcd plants in China mainland as well,let"s see the lcd manufacturers in Taiwan:

Chimei Innolux Corporation was the successor company, and it initially preserved the Chimei name. In order to differentiate itself from the ChiMei brand, the company was renamed "Innolux Corporation" in December 2012.

Innolux"s 14 plants in Taiwan possess a complete range of 3.5G, 4G, 4.5G, 5G, 6G, 7.5G, and 8.5G-8.6G production line in Taiwan and China mainland, offering a full range of large/medium/small LCD panels and touch-control screens.including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch-control solutions,full range of TFT LCD panel modules and touch panels, including TV panels, desktop monitors, notebook computer panels, small and medium-sized panels, and medical and automotive panels.

AUO is the tft lcd panel manufacturers in Taiwan,AUO has the lcd factories in Tianma and China mainland,AUOOffer the full range of display products with industry-leading display technology,such as 8K4K resolution TFT lcd panel, wide color gamut, high dynamic range, mini LED backlight, ultra high refresh rate, ultra high brightness and low power consumption. AUO is also actively developing curved, super slim, bezel-less, extreme narrow bezel and free-form technologies that boast aesthetic beauty in terms of design.Micro LED, flexible and foldable AMOLED, and fingerprint sensing technologies were also developed for people to enjoy a new smart living experience.

Hannstar was found in 1998 in Taiwan, Hannstar display hasG5.3 TFT-LCD factory in Tainan and the Nanjing LCM/Touch factories, providing various products and focus on the vertical integration of industrial resources, creating new products for future applications and business models.

driver, backlight etc ,then make it to tft lcd module. so its price is also more expensive than many other lcd module manufacturers in China mainland.

Maclight is a China based display company, located in Shenzhen, China. ISO9001 certified, as a company that more than 10 years working experiences in display, Maclight has the good relationship with top tft panel manufacturers, it guarantee that we could provide a long term stable supply in our products, we commit our products with reliable quality and competitive prices.

Maclight products included monochrome lcd, TFT lcd module and OLED display, touch screen module, Maclight is special in custom lcd display, Sunlight readable tft lcd module, tft lcd with capacitive touch screen. Maclight is the leader of round lcd display. Maclight is also the long term supplier for many lcd companies in USA and Europe.

If you want tobuy lcd moduleorbuy tft screenfrom China with good quality and competitive price, Maclight would be a best choice for your glowing business.

China’s BOE Technology Group, one of the world’s largest display manufacturers, plans to build a massive new factory in Beijing, as it looks to next-generation technology for new revenue streams.

BOE will invest RMB 29 billion (USD 4 billion) in the 600,000-square-meter factory, according to Sunday’s announcement, with an eye toward expanding into markets for new technologies, such as panels for virtual reality (VR) devices, and a new type of high-end panel called mini-LED.

This technology is said to produce more vivid images by reducing the size of the light-emitting diodes that illuminate the display from behind. The factory will have the capacity to produce 50,000 panels per month.

The facility will be overseen by a company established by BOE. Construction will begin next year, with production slated to start in 2025 and full capacity being reached the year after.

Slowing demand in the domestic market for TVs, computers, and smartphones that use the company’s displays pushed BOE into the red during the July-September period. Its net loss of RMB 1.3 billion (USD 179 million) for the quarter was a significant drop from the RMB 7.2 billion (USD 989 million) profit the company reported for the same period a year earlier.

Sales slumped 27% to RMB 41.1 billion (USD 5.6 billion), weighed down by falling prices for liquid-crystal displays. BOE holds the world’s largest market share for LCD panels.

With sales also sluggish for the company’s organic light-emitting diode displays, which it had been focusing on in recent years, BOE is urgently trying to find new markets to tap into.

(Yicai Global) June 13 -- BOE Technology Group, TCL China Star Optoelectronics Technology and other big Chinese liquid crystal display manufacturers are reducing output starting from this month to try and stop a freefall in prices caused by a global glut.

Panel makers are cutting production by 16 percent on average from this month, Rong Chaoping, senior researcher at market research firm AVC Revo, told Yicai Global. Television panel makers are expected to ship 3.6 million less panels than last month.

Panel makers will reduce capacity by between 15 and 20 percent this month, said Wu Rongbing, chief analyst at Chinese semiconductor intelligence service Omdia.

TCL China Star intends to continue with its production cuts until September, while Beijing-based BOE and HKC Optoelectronics Technology have not yet decided how long they will reduce output, Rong said. None of the three companies responded when contacted by Yicai Global.

LCD TV display shipments from China’s five largest panel manufacturers accounted for 68.5 percent of the global market in April, a new high, and they were expected to exceed 70 percent this year, according to Omdia.

But there is much less demand for notebook computers, monitors and TVs now that fewer people are working from home as the Covid-19 pandemic wanes and amid pressure from global inflation. This is driving prices down, said Li Yaqin, general manager of market research firm Sigmaintell.

The global panel industry is expected to slash production by about 20 percent this year, according to Beijing-based Sigmaintell. It is the first time since 2013 that the worldwide sector has implemented such a large-scale and wide-ranging cut in manufacturing. But it should help to slow the fall in prices, Li said.

“Tumbling prices are squeezing profits,” Li said. “The price of a TV panel is now below cost price and that of some data panels is also below the manufacturing cost.”

The price of small and medium-sized TV displays has more than halved since the highest point last year, and that of large-sized screens have fallen by more than 40 percent, according to AVC Revo.

“Panel makers are facing rising liquidity pressure and bigger losses as prices are now below cost price, so the display industry is likely to undergo another big reshuffle,” Rong said.

Excess supply will ease in the third quarter once output is cut, and prices will start to pick up and then flatten out, Li said. Demand for consumer electronic products is shrinking by far more than expected so it is too early to tell whether prices will rebound in the second half, she added.

Panel prices are likely to stop dropping this month or next as output falls, Wu said. Whether prices will start to pick up soon depends on when demand improves.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Everdisplay Optronics (Shanghai) Co.,Ltd.(EDO) is a company dedicated to production of small-to-medium AMOLED display and research of next generation technology. The company currently has generation 4.5 OLED line.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Established in 2013, Eternal Material Technology is committed to the research, development and manufacturing of electronic materials and providing technical services. EMT is leading the industry with its products of OLED and color photoresist materials.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

► When the leading Korean players Samsung Display and LG Display exit LCD production, BOE will be the most significant player in the LCD market. Though OLED can replace the LCD, it will take years for it to be fully replaced.

► As foreign companies control evaporation material and machines, panel manufacturers seek a cheaper way to mass-produce OLED panels – inkjet printing.

When mainstream consumer electronics brands choose their device panels, the top three choices are Samsung Display, LG Display (LGD) and BOE (000725:SZ) – the first two from Korea and the third from China. From liquid-crystal displays (LCD) to active-matrix organic light-emitting diode (AMOLED), display panel technology has been upgrading with bigger screen products.

From the early 1990s, LCDs appeared and replaced cathode-ray tube (CRT) screens, which enabled lighter and thinner display devices. Japanese electronics companies like JDI pioneered the panel technology upgrade while Samsung Display and LGD were nobodies in the field. Every technology upgrade or revolution is a chance for new players to disrupt the old paradigm.

The landscape was changed in 2001 when Korean players firstly made a breakthrough in the Gen 5 panel technology – the later the generation, the bigger the panel size. A large panel size allows display manufacturers to cut more display screens from one panel and create bigger-screen products. "The bigger the better" is a motto for panel makers as the cost can be controlled better and they can offer bigger-size products to satisfy the burgeoning middle-class" needs.

LCD panel makers have been striving to realize bigger-size products in the past four decades. The technology breakthrough of Gen 5 in 2002 made big-screen LCD TV available and it sent Samsung Display and LGD to the front row, squeezing the market share of Japanese panel makers.

The throne chair of LCD passed from Japanese companies to Korean enterprises – and now Chinese players are clinching it, replacing the Koreans. After twenty years of development, Chinese panel makers have mastered LCD panel technology and actively engage in large panel R&D projects. Mass production created a supply surplus that led to drops in LCD price. In May 2020, Samsung Display announced that it would shut down all LCD fabs in China and Korea but concentrate on quantum dot LCD (Samsung calls it QLED) production; LGD stated that it would close LCD TV panel fabs in Korea and focus on organic LED (OLED). Their retreats left BOE and China Stars to digest the LCD market share.

Consumer preference has been changing during the Korean fab"s recession: Bigger-or-not is fine but better image quality ranks first. While LCD needs the backlight to show colors and substrates for the liquid crystal layer, OLED enables lighter and flexible screens (curvy or foldable), higher resolution and improved color display. It itself can emit lights – no backlight or liquid layer is needed. With the above advantages, OLED has been replacing the less-profitable LCD screens.

Samsung Display has been the major screen supplier for high-end consumer electronics, like its own flagship cell phone products and Apple"s iPhone series. LGD dominated the large OLED TV market as it is the one that handles large-size OLED mass production. To further understand Korean panel makers" monopolizing position, it is worth mentioning fine metal mask (FMM), a critical part of the OLED RGB evaporation process – a process in OLED mass production that significantly affects the yield rate.

Prior to 2018, Samsung Display and DNP"s monopolistic supply contract prevented other panel fabs from acquiring quality FMM products as DNP bonded with Hitachi Metal, the "only" FMM material provider choice for OLED makers. After the contract expired, panel makers like BOE could purchase FFM from DNP for their OLED R&D and mass production. Except for FFM materials, vacuum evaporation equipment is dominated by Canon Tokki, a Japanese company. Its role in the OLED industry resembles that of ASML in the integrated circuit space. Canon Tokki"s annual production of vacuum evaporation equipment is fewer than ten and thereby limits the total production of OLED panels that rely on evaporation technology.

The shortage of equipment and scarcity of materials inspired panel fabs to explore substitute technology; they discovered that inkjet printing has the potential to be the thing to replace evaporation. Plus, evaporation could be applied to QLED panels as quantum dots are difficult to be vaporized. Inkjet printing prints materials (liquefied organic gas or quantum dots) to substrates, saving materials and breaking free from FMM"s size restriction. With the new tech, large-size OLED panels can theoretically be recognized with improved yield rate and cost-efficiency. However, the tech is at an early stage when inkjet printing precision could not meet panel manufacturers" requirements.

Display and LGD are using evaporation on their OLED products. To summarize, OLED currently adopts evaporation and QLED must go with inkjet printing, but evaporation is a more mature tech. Technology adoption will determine a different track for the company to pursue. With inkjet printing technology, players are at a similar starting point, which is a chance for all to run to the front – so it is for Chinese panel fabs. Certainly, panel production involves more technologies (like flexible panels) than evaporation or inkjet printing and only mastering all required technologies can help a company to compete at the same level.

Presently, Chinese panel fabs are investing heavily in OLED production while betting on QLED. BOE has four Gen 6 OLED product lines, four Gen 8.5 and one Gen 10.5 LCD lines; China Star, controlled by the major appliance titan TCL, has invested two Gen 6 OLED fabs and four large-size LCD product lines.

Remembering the last "regime change" that occurred in 2005 when Korean fabs overtook Japanese" place in the LCD market, the new phase of panel technology changed the outlook of the industry. Now, OLED or QLED could mark the perfect time for us to expect landscape change.

After Samsung Display and LGD ceding from LCD TV productions, the vacant market share will be digested by BOE, China Star and other LCD makers. Indeed, OLED and QLED have the potential to take over the LCD market in the future, but the process may take more than a decade. Korean companies took ten years from panel fab"s research on OLED to mass production of small- and medium-size OLED electronics. Yet, LCD screen cell phones are still available in the market.

LCD will not disappear until OLED/QLED"s cost control can compete with it. The low- to middle-end panel market still prefers cheap LCD devices and consumers are satisfied with LCD products – thicker but cheaper. BOE has been the largest TV panel maker since 2019. As estimated by Informa, BOE and China Star will hold a duopoly on the flat panel display market.

BOE"s performance seems to have ridden on a roller coaster ride in the past several years. Large-size panel mass production like Gen 8.5 and Gen 10.5 fabs helped BOE recognize the first place in production volume. On the other side, expanded large-size panel factories and expenses of OLED product lines are costly: BOE planned to spend CNY 176.24 billion (USD 25.92 billion) – more than Tibet"s 2019 GDP CNY 169.78 billion – on Chengdu and Mianyang"s Gen 6 AMOLED lines and Hefei and Wuhan"s Gen 10.5 LCD lines.

Except for making large-size TVs, bigger panels can cut out more display screens for smaller devices like laptops and cell phones, which are more profitable than TV products. On its first-half earnings concall, BOE said that it is shifting its production focus to cell phone and laptop products as they are more profitable than TV products. TV, IT and cell phone products counted for 30%, 44% and 33% of its productions respectively and the recent rising TV price may lead to an increased portion of TV products in the short term.

Except for outdoor large screens, TV is another driver that pushes panel makers to research on how to make bigger and bigger screens. A research done by CHEARI showed that Chinese TV sales dropped by 10.6% to CNY 128.2 billion from 2018 to 2019. Large-size TV sales increased as a total but the unit price decreased; high-end products like laser TV and OLED TV saw a strong growth of 131.2% and 34.1%, respectively.

The change in TV sales responded to a lifestyle change since the 4G era: people are getting more and more used to enjoy streaming services on portable devices like tablets and smartphones. The ‘disappearing living room" is a phenomenon common for the young generation in Chinese tier-1 cities.

Millions of young white-collars support the co-leasing business in China and breed the six-billion-dollar Ziroom, a unicorn company that provides rental and real estate management services. As apartments can be leased by single rooms instead of the whole apartment, living rooms become a public area while tenants prefer to stay in their private zones – it hints that the bedroom is too small to fit in a TV.

Besides the tier-1 cities" "disappearing living rooms," the mobile Internet gives another reason to explain the declining TV sale in China. Various streaming services and high-speed networks allow people to watch programs wherever and whenever they would like to. However, the change in life does not imply TV will disappear. For families, the living room is still a place for family members to gather and have fun. The growth of high-end TV sales also tells the "living room" economy.

The demand for different products may vary as lifestyles change and panel fabs need to make on-time judgments and respond to the change. For instance, the coming Olympics is a new driving factor to boost TV sales; "smart city" projects around the world will need more screens for data visualization; people will own more screens and better screens when life quality improves. Flexible screens, cost-efficient production process, accessible materials, changing market and all these problems are indeed the next opportunity for the industry.

It is the first time that China took over the No. 1 spot in the display market, which Korea has always been a leader in. The title of “the strongest country in display market” is lost after 17 years. It would not be possible to reclaim the No. 1 spot if Korea cannot find a way to expand investment in next-generation displays such as organic light emitting diodes (OLED).

According to market research firm Omdia, China recorded $64.8 billion in sales including LCD and OLED in the global display market last year. China took over Korea’s No. 1 spot with a market share of 41.5%. Korea"s market share fell 8.3 points (p) to 33.2%. This is the first time since 2004, in 17 years, that Korea had to hand over the No. 1 spot. Korea had a 9.4 p advantage in market share over China up until 2019.

China overtook Korea and seized power in the LCD market by offering a low-priced products. BOE, China"s largest panel manufacturer, has become the world"s largest LCD manufacturer with help of the subsidy from the Chinese government. LCD sales was $28.6 billion last year, accounting for 26.3% of the total LCD market. The sales of Chinese companies such as BOE, CSOT, Tianma, and Visionox increased significantly as demand for TV and information technology (IT) devices increased with the prolonged COVID 19 and increased price of LCD panel.

After taken over in the LCD market, Korea is focusing on the highly-valued OLED market. Samsung Display and LG Display are transforming their LCD production lines to OLED. Korea is the No. 1 with 82.3% of the global OLED market shares according to Omdia, and China’s market share only accounts for16.6%.

China"s dominance is expected to continue for some time because the large display market such as TVs and laptops still depends on LCD. Only when Korea starts to reduce OLED panel prices by mass producing OLED, then Korea can replace the LCD market led by China.

Samsung Display and LG Display were not able to make a decision on investment plans for large OLED plants due to problems with yield and investment funds. Samsung and LG are expected to invest more than KRW 7 trillion in OLED facilities this year according to the industry. Mass production from these companies is expected to begin in the second half of next year even when new and expanding existing investments are made this year.

China has also started to narrow the gap with Korea in OLED industry. BOE and other companies have commercialized OLED for small and medium-sized displays such as mobile, laptop, and tablet. Following LCD market, China is threatening Korea in OLED market as well as China expands OLED market share mainly in the Chinese smartphone market.

Critics are pointing out that Korea needs to expand in OLED market and develop new technologies in order to maintain the OLED gap with China. Korea must take control over the large TV panel market, which has a large technological gap with China, and create a new form factor with new technologies such as flexible, rollable, and bendable panels.

Some criticizes that R&D support and interest are required even if Korean government does not provide subsidies like the Chinese. It is daunting that the government seems to have lost interest in the display industry by giving support for the government’s national talent developing project, and cutting the support for the next-generation display field.

An official from the display industry said, “With the government-led industrial promotion policy and copious domestic market, China is making an effort to solidify its leading position in the display industry. There is a neglect on display industry in Korea since the display promotion policy is almost non-existent compared to semiconductors and batteries.”

One of China’s largest LCD panel makers BOE Technology will partner with the government of Wuhan to build a 46 billion yuan ($7 billion) production facility, reflecting the country’s ongoing efforts to create a world-class industry to compete with counterparts in South Korea and Taiwan.

BOE Technology Group Co. Ltd. will partner with the Wuhan city government and a local fund also based in Hubei province to build the plant for leading-edge 10.5-generation liquid crystal displays, the main component used to make large TVs and video screens.

The Wuhan government and the fund will initially invest up to 20 billion yuan in the project, while BOE will provide 6 billion yuan. The remainder of the 46 billion yuan investment will be split among the three parties in a manner to be determined later. The production line is expected to begin operation in 2019, with initial monthly capacity of 120,000 panels, mostly for LCDs of 65 inches and larger.

Beijing has made development of the country’s panel industry a strategic part of its national plan, providing strong support for such developments. The central Chinese city of Wuhan has emerged as one center for such production, becoming the first to host production lines from BOE and the country’s other top two players, TCL Corp. and Tianma Microelectronics Co. Ltd.

But experts warn that the highly cyclical LCD panel industry may need to brace for a supply glut as a slew of new projects get built in China. Many 10.5- and 11th-generation production lines are now under development in China alone, and most are expected to begin operations in 2018 and 2019. Between 2011 and 2016, BOE and TCL benefitted from a combined total of more than 12 billion yuan in support from local governments and Beijing, company documents show.

China’s efforts to boost the industry also come as organic light-emitting diode (OLED) displays are increasingly popular, which could challenge demand for LCD panels over the longer term. OLED displays have the advantage of greater flexibility than LCDs, and can even be bent and folded.

“China should pay attention to the possibility of the LCD technology being disrupted and ramp up effects on research of non-LCD technologies” Guan Xudong, a professor from the College of Information Sciences and Technology at Peking University in a recent interview with China Electronics News.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

China’s BOE Technology Group (京東方) replaced Taiwan-based flatpanel maker Innolux Corp (群創) to become the third-largest TV screen supplier in the world last month, according a report by market information advisory firm TrendForce Corp (集邦科技).

The strong showing made by BOE reflected the Chinese firm’s improvement in its yield rate, which boosted its TV panel shipments last month, the report said, adding that BOE bucked the downturn of global TV screen shipments in the month.

Last month, BOE shipped 3.24 million TV panels, up 1.2 percent from a month earlier, while Innolux, which felt the pinch of the impact resulting from a magnitude 6.4 earthquake in southern Taiwan last month, shipped 2.66 million TV screens, down 21.9 percent from a month earlier.

In addition to the damage caused by the earthquake, Trendforce said, Innolux witnessed its production fall due to fewer working days during the Lunar New Year holiday last month.

BOE was the only one among the top six TV panel suppliers in the world to record a month-on-month increase in shipments last month. International TV panel shipments fell 8.7 percent last month from a month earlier to 17.88 million units, TrendForce said.

LG Display Co of South Korea retained its position as the world’s largest TV panel supplier last month, when the South Korean firm shipped 3.83 million TV screens, down 8.1 percent from a month earlier.

TrendForce said that LG cut its production last month to shield itself from losses since prices of 32-inch TV screens had fallen to a level closer to their production costs at a time of an international supply glut.

Samsung Display Co, a subsidiary of South Korea’s Samsung Group came in second last month, unchanged from a month earlier, after shipping 3.38 million TV panels, down 1.8 percent month-on-month, TrendForce said.

The smaller decline of Samsung Display’s sales showed that buyers shifted their orders from Innolux to the South Korean firm after the earthquake, TrendForce added.

China Star Optoelectronics Technology Co (華星光電) took fifth position after shipping 2.29 million TV panels last month, down 8.9 percent from a month earlier, on the back of slow season effects, the research report said.

Taiwan’s AU Optronics Corp (AUO, 友達) shipped 1.76 million TV screens last month, down 8.1 percent from a month earlier, to rank as the sixth-largest supplier in the world, unchanged from January, TrendForce said.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Attendees visit the booth of TV panel maker Shenzhen China Star Optoelectronics Technology during an international exhibition in Shanghai on July 11, 2019. [Photo by Lyu Liang/For China Daily]

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

The pandemic will accelerate reshuffling in the display industry as supply has surpassed demand in the past few years and competition has become very fierce, he added.

"The outbreak has caused a periodic drop in demand in the global display market and sped up the restructuring of the entire industry. Chinese enterprises are in a favorable position, and I believe that they will further enhance their competitiveness," Li said.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

"China"s semiconductor display industry has made large advances in the past decade, changing the display industry"s global competitive landscape. China has transformed into the world"s largest consumer market and manufacturing base for display terminals, with huge market potential," said BOE Vice-President Zhang Yu.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan ($6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Chen Lijuan, an analyst at Sigmaintell, said panel manufacturers should not just invest in production lines, but also pay more attention to the establishment of the whole supply chain, including raw materials, equipment and technology.

Bian Zheng, deputy director of research at AVC Revo, a unit of market consultancy firm AVC, said China will have a 51 percent market share in global TV shipments in 2020, while South Korea will have 25 percent, adding that large-screen TV panels will bolster healthy development of the industry.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

Li Yaqin, general manager of Sigmaintell, said 65-inch TVs will become the mainstream in people"s living rooms in the future, but OLED TVs will not be able to immediately spur customer purchases at this time though the future trend is for higher-tech options.

Latest research from Omdia has found that Chinese display maker BOE has led the market in shipments of large area TFT LCD displays in December 2021, both in units and total area shipped. This accounts for nearly one-third of whole unit shipments, as the industry set new records for shipments for the month and year.

Pandemic restrictions impacted demand for and spending across home entertainment products with display shipments of TV and IT devices experiencing a growth surge. The total of large area TFT display shipments rose to a record 89.4 million square meters in December, reflecting a 4 percent month-on-month increase over November, as well as 5 percent Year on Year growth (YoY), Omdia reported in its latest Large Area Display Market Tracker.

For the full year, large area TFT LCD shipments increased with 9 percent YoY by units and 4 percent YoY by area, reaching 962.7 million units and 228.8 million square meters shipped in 2021, both historical highs and marking the first time the industry has ever shipped more than 900 million units in a year.

Among display makers, China"s BOE took the largest shares for both units and total area shipped in 2021. BOE took 31.5 percent for units shipped and 26.2 percent for area shipped, marking the first time one maker has captured over 31 percent market share for whole unit shipments and 26 percent share for whole area shipments in large area TFT LCD history.

Beyond BOE, Innolux took 15.4 percent market share for large area TFT LCD unit shipments, followed by LG Display with 13.4 percent in 2021. For total area shipped, China Star took 15.8 percent as second largest maker after BOE, followed by LG Display in third with 11.9 percent in 2021.

Strong demand particularly for mobile PC LCD during the pandemic increased notebook PC LCD unit shipments in 2021, rising 26 percent YoY. Tablet PC LCD unit shipments also rose 7 percent YoY last year. On the other hand, the LCD TV display segment saw unit shipments fall 4 percent YoY due to a slowdown in demand in 3Q21. But ongoing LCD TV size migration in favor of larger screens meant that total LCD TV display area shipped increased 2 percent YoY in 2021 despite the drop in unit shipments.

Large area TFT LCD revenue increased 34 percent YoY in 2021 and reached US$85.2 billion, also setting a record and the first time large area TFT LCD revenue has ever exceeded $80 billion. Strong demand and size migration to larger screens during COVID-19 pandemic combined with display price hikes up until 3Q21 to drive the high revenue number.

In the large area OLED segment, strong consumer demand for high-end TVs and notebook PCs drove surging demand for OLED TV and notebook PC OLED, which saw 66 percent YoY and 418 percent YoY increases in units shipped last year, respectively. Overall large area OLED achieved a historical high for unit shipments, hitting 23.7 million units shipped in 2021, a 37 percent YoY increase over 2020.

YoonSung Chung, senior research manager for large area displays and supply chain at Omdia, commented: "Display makers waited for results from Black Friday sales to set their early 2022 sales and pricing strategies. However, results seem to fall short of expectations for LCD TVs. LCD TV display buyers will price LCD TV displays more aggressively in the coming months.

"While demand for IT displays is weakening, panel makers’ supply plans are ambitious. Unless panel makers adjust their fab utilisation, price erosions could imminently worsen for large area display applications, including monitor and notebook PC LCDs. Omdia expects the LCD TV panel prices to reach the price bottom in 1H 2022 and then gradually rebound based on the market demand recovery."

In addition, BOE will invest inTFT liquid crystal (thin film transistor liquid crystal) technology, which has superior contrast ratio and refresh rate to conventional displays, in order to differentiate it from other manufacturers. At the time of writing the article, TFT LCD, which is widely used in mobile phones, PCs, and handheld game consoles, was originally a technology developed in the United States, but it was Japanese and Korean companies that succeeded in commercializing it. It is said that these companies have solidified their superiority in the industry by acquiring innovative and excellent patents.

First, in 2001, Hynix semiconductors weresold to BOE for STN LCDs , which were not strategically important, and for the OLED business, which was at the prototype stage at the time. And a year later, the TFT LCD business was sold for $ 350 million (about 43 billion yen at the rate at that time), in which comprehensive intellectual property and patents related to 4th and 5th generation TFT LCDs were sold. Was included.

BOE, which absorbed the display technology and capabilities of Hynix Semiconductor, built a state-of-the-art LCD factory with the financial support of the Beijing Municipal Government, as well as to build a distribution network and capabilities in the international market. It strengthened its power by acquiring a 26% stake inTPV Technology , a major monitor manufacturer in Hong Kong. As a result, in 2006, it became the ninth largest TFT LCD manufacturer in the world.

BOE"s core business is display technology, which owns a factory that includes a state-of-the-art 10.5th generation TFT LCD production line and the only 6th generation flexibleAMOLED display factory in China. In addition, it is investing a large amount of research and development to continuously improve the product, and has obtained more than 70,000 patents so far, such as applying for 9655 patents in 2019. That.

As a unique version of Moore "s Law, which discusses long-term trends in semiconductors, founder Wang advocated the law that "if the price of the display does not change, the product performance needs to double every 36 months." We pushed ahead with technological development. As a result, we are the third-largest patented company in the industry in terms of OLED technology, after Samsung Display and LG Display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey