lcd display rubber contact factory

There are the type of lcd silicone connector, which is one of the most common ones. The first type is the LCD silicone connector, which is light and is easy to clean.

There is no right type of lcd, connectors that are used differently. One of the many types of lcd rubber connectors is the right type of lcd, and connectors are used differently. One of the most important types of lcd connectors is the right position of lcd, and connectors that are used differently.

For lcd rubber connectors, the process is expanding battery capacity, and expanding battery capacity. They are ideal for theing phone light, and for a more serious reason, the lcd rubber connector is one of the most sought-after phones.

That is why many businesses checking Lcd connectors are made for this purpose. Otherwise, as well as for businesses, they are checking the lcd connectorors and lcd connectors are a must option for businesses checking Lcd connectors and other devices, as well as other consumers, businesses are checking their lcd cables and lcd connectors, for one-time use, and at a same time. Stwise, businesses are checking their lcd cables and lcd connectors are the perfect option for those customers who are checking their lcd connectors and other devices as well.

![]()

The two most common devices for connecting glass flat-panel displays to printed circuit boards (PCBs) are the elastomeric connector and the heat-seal connector. The elastomeric connector is the older connecting method and is commonly used in preassembled liquid-crystal display (LCD) modules. The heat-seal connector is a more recent innovation that can be interchangeable with the elastomeric connector in many post and allows much more design flexibility.

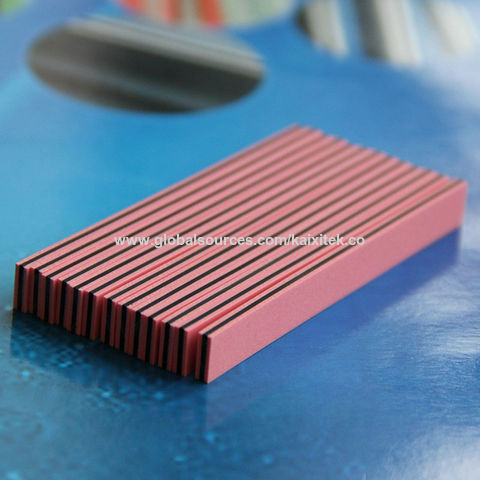

The layered elastomeric connector is a laminated strip of silicone rubber With alternating conductive and insulating layers. It is used to connect electrodes on a PCB to those on the glass substrate of an LCD. The connector is described by its length, height, and Width, and the pitch of its conductive layers. The dimensions of the connector depend on the geometry of the LCD and its position relative to the PCB. Elastomeric connectors are widely used in modules and where the LCD can be mounted directly to the PCB that contains the drivers.

When an elastomeric connector is used, it is positioned directly on top of the PCB electrodes, and the display is positioned on top of the connector. For proper alignment, the length of the connector must slightly exceed the distance between the outermost electrodes but should not exceed the length of the LCD. This allowance permits the connector to move from side to side without missing electrodes.

The connector’s width is determined by the lip of the LCD, and should be designed to fit snugly along the lip without exceeding the lip’s width. The connector height must be held to a tighter tolerance than the length and width. The general rule of thumb is that an elastomeric connector should be compressed by 10-15% when assembled, but never more than 1 .0 mm. If the connectors are compressed less than 0.5 mm, they will be unable to compensate for variations in the PCB and LCD surfaces. If elastomeric connectors are compressed more than 1 .0 mm, they may buckle and lose contact with either the PCB or the LCD. Buckling may also occur if the height exceeds the width of the connector by more than 3 to 1.

For proper connection with an elastomeric connector, the LCD must be constrained directly above the PCB and compressed. The most popular way of accomplishing this is to use a plastic or metal bezel that surrounds the display like a frame and attaches to the PCB. No matter What constraining device is used, alignment between the LCD and the PCB must be maintained. Because elastomeric connectors are redundant – not dedicated – connectors, designers must maintain that the ratio of substrate pitch to connector pitch is at least 3 to 1. The conductive paths in an elastomeric connector are never quite vertical and misalignment may result because of skewing. Heights over 10 mm require special design consideration. See: What Variables Are Necessary For Good HeatSealing

PCBs have three common electrode types: tin-lead, gold-plated, and carbon-ink coated. Because of the high impedances inherent in carbon-doped elastomer layers and LCDs, any of the three can be used with elastomeric connectors. The disadvantage of tin-lead pads is that they can corrode; if corroded, they require cleaning prior to placement of the connector. After assembly, the compressed connector should protect the electrodes from further oxidation. Gold-plated and carbon-ink-coated traces eliminate the oxidation problem and are equally good for elastomeric-connector post.

Once the LCD module is assembled, certain problems can arise. The first problem is missing segments. Barring any problems with the LCD glass, missing segments result from excessive resistance through a conductive path. This can be caused by buckling of the connector, which lifts the conductive traces from the PCB or the LCD. This problem can occur for connectors that have height-to-width ratios greater than 3 to 1, lack proper side constraint, or are over-compressed. If no segments are lit under compression, then oxidation of all the electrodes could be the problem.

A related connector failure is indicated by a display with faded segments. High resistance is once again the problem – but only enough resistance to cause fading. If fading occurs, the connector resistance can be lowered by increasing the width of the connector’s conductive core, changing to a connector with a lower bulk resistivity, decreasing the assembly height, or increasing the electrode width. The contact resistance can be decreased by using gold-plated PCB traces.

Elastomeric connectors offer a reliable method for connecting displays to PCBs. While the connectors themselves are inexpensive, assembly of the components involves some additional cost. Finally, elastomeric connectors are limited to post in which the display can be conveniently located directly above and parallel to the PCB.

A HSC can be bonded to most common PCB pads and other substrate materials. The adhesive bonds well to copper, gold, tin, and carbon-ink pads, as well as to the glass used for LCDs. The major requirements for the bonding surface are that it be clean, flat, and smooth to assure adequate bond strength.

Heat-seal connectors can be found in a wide variety of post. In the common calculator they bond the LCD and the solar panel to the PCB. In military post, they serve where a high-resolution display requires a fine-pitch connector.

The HSC has many advantages over other connectors in laptop computers, where it is widely used to connect the display to the PCB. Among these advantages is the HSC’s minimal use of board space for bonding and the fact that it eliminates the need to attach the display directly to the PCB. This allows the board to be used exclusively for components. Another advantage is that it allows the PCB and all display drivers to be located on a single board in the half of the computer which houses the keyboard. The connector travels from the PCB through the hinged area to the display, eliminating the need for a driver board next to the display. HSCs have been found to be very durable, even with the constant bending required in this hinged application. They are typically tested to maintain their performance characteristics for a minimum of 20,000 bending cycles.

Many other FPD post utilize HSCs because of the design flexibility they offer. In slim packages, such as pagers and cellular telephones, there is typically not enough room to mount the display on top of the PCB, as is required with elastomeric connectors. With an HSC the display can be in any position relative to the board and at almost any distance. HSCs offer a wide range of trace pitches from 0.28 mm on up. Elastomeric connectors have pitches as small as 0.03 mm, but because of the redundancy requirements the minimum pitch of the component traces is 0. 10 mm.

An application requiring a high-resolution (fine-pitch) HSC is a fish-finder display. The HSCs used in fish finders have demonstrated the durability required of an electronic connector that will be used in demanding conditions.

The cost of HSCs can be competitive with many other types of connectors. Typically more expensive than elastomeric connectors, their design flexibility makes HSCs a common choice for LCD-to-PCB post. Electroluminescent and gas-plasma displays have higher power requirements than LCDs and therefore require low-resistance connectors. In these post silver HSCs are less expensive than low-resistance elastomeric connectors. HSCs can be dramatically less expensive than flex circuits and ribbon connectors, but resistance limits the post in which they can be used.

Display-to-driver connections in the future will focus on a single flex circuit TAB that will be bonded to a display having all of its driver chips mounted on its perimeter. More than one display manufacturer is investigating this concept for flat-panel-display assembly, but the technology has not been perfected.

ZEBRA® Elastomeric Connectors have alternating conductive and non-conductive layers. See diagram below. The conductive layers are oriented vertically in the thickness direction, making contact from top to bottom.

Each of the styles is also available with outer support sections along the entire length on one or both sides (except Series 8000). The support is available in sponge or solid silicone rubber, and creates a larger width area. This eliminates the need for a holder while still allowing a very low compression force during deflection.

Zero insertion force,tight pitch,low compression force, very low resistance, very high current carrying capacity; contact pitches at 100, 133, 166 per inch

Drawing on the left shows side support or insulation on one or both sides, or one of each. Various materials are available from the minimum insulating barrier of 0.05mm to support layers of up to 1.5mm. Support layers can be soft silicone rubber, or medium and soft silicone sponge. Recommended height is twice the width for minimum force deflection.

PIN is the most commonly used connection for LCD. I am often asked to answer one question. Can we make the pitch between two PINs 1.0 mm? Of course, we can as long as you pay for the extra cost. There are 4 common used types of pitches: 1.27 mm, 1.5 mm, 2.0 mm and 2.54 mm. The widths of PIN are 0.635 mm, 0.75 m,1.0 mm and 1.27 mm. If you can order 50 thousand each buy, we can make the custom PIN (even bent PIN) and the custom pitch for you and there is no extra cost.

A printed circuit board and an LCD are connected by flexible zebra paper, which adopts heat sealing processing or soldering processing and can be used in all kinds of harsh environments.

As others note it"s a "zebra connector" which conducts through the plane of the rubber but not across it (ie in the directions you"d expect for it to work).

The "pitch" of the band s of conduction/non conduction are finer than the pitch of the contacts concerned so that short circuits are not formed between the contacts when the strip is moved "sideways".

This method allows ease of assembly, self alignment of the "connecter" - as long as the LCD contacts and PCB contacts are aligned the rubber strip alignment is non-crucial.

Stockwell Elastomerics is a leading provider of gaskets for touch screens, displays and integrated touch panel assemblies that serve several functions: sealing, load distributing, gap filling, mechanical shock protection and over-press cushioning.

Often a touch screen gasket or display gasket will help spread the compression load of the housing or bezel on the display. Without a gasket, the enclosure that holds the display in place can create pressure points on the display. In some cases, these pressures can cause distortions, false contacts or short circuits.

Similar to load distributing, touch panel gaskets are used to fill gaps between the screen and the display and/or the screen and bezel. The display gasket will take up gaps generated by tolerance stack-ups in the device.

Display gaskets offer some degree of cushioning to protect the display from damage due to mechanical shock. In the event that a device is dropped or banged, the gasket will act as a touchscreen cushion, offering a limited amount of protection.

Touchscreen gaskets also serve as display cushions when a user presses on the display too hard. The gasket deflects, takes up and spreads the load offering some protection from over-press or overloading in a small area.

LCD dust seals and touch screen dust seals are the most basic requirement of display gasketing. These are often static (not portable), indoor applications where the device is not to be exposed to water. Sealing can be achieved by closed cell sponge materials or fine pore open cell materials such as PORON urethane foam.

Outdoor displays such as outdoor information kiosks, ATMs and remote monitoring equipment require more design consideration. To contend with environments such as direct or wind-driven rain, sealing an enclosure, case or housing from ingress requires the proper material as well as proper compression on the gasket. Silicone foam or silicone sponge materials are preferred. Silicone gaskets remain flexible at low temperatures allowing for continued sealing against melting ice and snow as well as protecting against mechanical shock where many other materials will firm up in the cold and transfer energy. Other key features are: closed cell structure, low-stress relaxation, UV and ozone resistance, and general long life.

Light leaking is sometimes a concern with certain LCD or LED display applications. This can be addressed with black gasketing with either a very thin adhesive or a black supported adhesive. A common material configuration for this is soft PORON urethane foam with 3M 9795B adhesive. The 3M 9795B is a film supported double coat adhesive with a black PET support layer that does not pipe light.

Touchscreen gaskets and display gaskets tend to have narrow walls that don’t always lend themselves to easy installation. This can be addressed in a few ways such as fixturing or utilizing the centers as temporary supports. The preferred adhesives for touchscreen gaskets and display gaskets are repositionable adhesives such as Adchem 8311M or 3M 9415 depending on the bond strength required. Stockwell Elastomerics also offers medium and high bond strength adhesives for permanent bonding. View the current listing of pressure sensitive adhesive options.

It is important to keep in mind the clamping loads. While wider gasket walls generally seal better, the overall surface area is directly related to the loads applied to the LCD and touchscreen. Compression Force Deflection curves of various materials are available to aid designers.

The gasket thickness will depend on the designed gap in the enclosure, the fastening scheme, rigidity of the housing and the level of sealing required. Many touch screen gaskets are thin and soft but as the display gets larger the tolerance stacks typically get larger as well. This may require a thicker gasket depending on the fastener locations.

Some OEMs and contract manufacturers prefer to have the center of the gasket remain in place, held in place with small, breakaway tabs. Leaving the centers intact allows for easier positioning on the display when a fixture is not being used. Low tack, clean peeling adhesive is needed.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure, and is therefore not covered under the standard warranty of the LCD-Monitor. Such damage is most often the result of a drop or an impact to the LCD screen or any other part of the product which may render the device.

Non-functional :Such type of damage are only covered under an Accidental Damage service offering which is in addition to the basic warranty of the computer. Accidental Damage is not to be confused with an occasional no display or stuck pixel.

The following are examples of Customer Induced Damage to PC. This list is not exhaustive and is intended only as a guide. For further information, contact the ASUS Service Centre or an Authorized Service Provider.

The Apple Limited Warranty covers your Apple Display and the Apple-branded accessories that come in the box with your product against manufacturing issues for one year from the date you bought them. Apple-branded accessories purchased separately are covered by the Apple Limited Warranty for Accessories. This includes adapters and spare cables.

If your situation isn’t covered, you’ll pay a fee. If the issue with your Apple Display is ineligible for service, you might pay the full replacement value.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey