lcd display rubber contact manufacturer

![]()

LCD Connectors are an industry standard for liquid crystal displays. Z-Carbon LCD Connectors consist of carbon-impregnated layers of silicone rubber separated by non-conductive silicone layers. When mated and clamped between the LCD glass and PCB, Z-Carbon LCD Connectors provide a robust and reliable connection. Due to the silicone construction of Z-Carbon LCD Connectors, they conform to the contact surfaces of the mating substrates to create a gasket-like seal that withstands environmental conditions.

In addition, the elasticity of Z-Carbon LCD Connectors provides superior performance in applications that require resilience to shock and vibration. The use of zero insertion force LCD connectors requires that line centers match on connected surfaces.The connection densities of 100, 140 and 250 connections per inch of LCD connectors provides redundant contact in most applications. This fine line spacing also reduces the potential for shorting adjacent contacts. These low-cost connectors are available in custom sizes to accommodate the specific needs of your application. If necessary, we can offer same day prototype service for sizes in our normal working range!

Stockwell Elastomerics is a leading provider of gaskets for touch screens, displays and integrated touch panel assemblies that serve several functions: sealing, load distributing, gap filling, mechanical shock protection and over-press cushioning.

Often a touch screen gasket or display gasket will help spread the compression load of the housing or bezel on the display. Without a gasket, the enclosure that holds the display in place can create pressure points on the display. In some cases, these pressures can cause distortions, false contacts or short circuits.

Similar to load distributing, touch panel gaskets are used to fill gaps between the screen and the display and/or the screen and bezel. The display gasket will take up gaps generated by tolerance stack-ups in the device.

Display gaskets offer some degree of cushioning to protect the display from damage due to mechanical shock. In the event that a device is dropped or banged, the gasket will act as a touchscreen cushion, offering a limited amount of protection.

Touchscreen gaskets also serve as display cushions when a user presses on the display too hard. The gasket deflects, takes up and spreads the load offering some protection from over-press or overloading in a small area.

LCD dust seals and touch screen dust seals are the most basic requirement of display gasketing. These are often static (not portable), indoor applications where the device is not to be exposed to water. Sealing can be achieved by closed cell sponge materials or fine pore open cell materials such as PORON urethane foam.

Outdoor displays such as outdoor information kiosks, ATMs and remote monitoring equipment require more design consideration. To contend with environments such as direct or wind-driven rain, sealing an enclosure, case or housing from ingress requires the proper material as well as proper compression on the gasket. Silicone foam or silicone sponge materials are preferred. Silicone gaskets remain flexible at low temperatures allowing for continued sealing against melting ice and snow as well as protecting against mechanical shock where many other materials will firm up in the cold and transfer energy. Other key features are: closed cell structure, low-stress relaxation, UV and ozone resistance, and general long life.

Light leaking is sometimes a concern with certain LCD or LED display applications. This can be addressed with black gasketing with either a very thin adhesive or a black supported adhesive. A common material configuration for this is soft PORON urethane foam with 3M 9795B adhesive. The 3M 9795B is a film supported double coat adhesive with a black PET support layer that does not pipe light.

Touchscreen gaskets and display gaskets tend to have narrow walls that don’t always lend themselves to easy installation. This can be addressed in a few ways such as fixturing or utilizing the centers as temporary supports. The preferred adhesives for touchscreen gaskets and display gaskets are repositionable adhesives such as Adchem 8311M or 3M 9415 depending on the bond strength required. Stockwell Elastomerics also offers medium and high bond strength adhesives for permanent bonding. View the current listing of pressure sensitive adhesive options.

It is important to keep in mind the clamping loads. While wider gasket walls generally seal better, the overall surface area is directly related to the loads applied to the LCD and touchscreen. Compression Force Deflection curves of various materials are available to aid designers.

The gasket thickness will depend on the designed gap in the enclosure, the fastening scheme, rigidity of the housing and the level of sealing required. Many touch screen gaskets are thin and soft but as the display gets larger the tolerance stacks typically get larger as well. This may require a thicker gasket depending on the fastener locations.

Some OEMs and contract manufacturers prefer to have the center of the gasket remain in place, held in place with small, breakaway tabs. Leaving the centers intact allows for easier positioning on the display when a fixture is not being used. Low tack, clean peeling adhesive is needed.

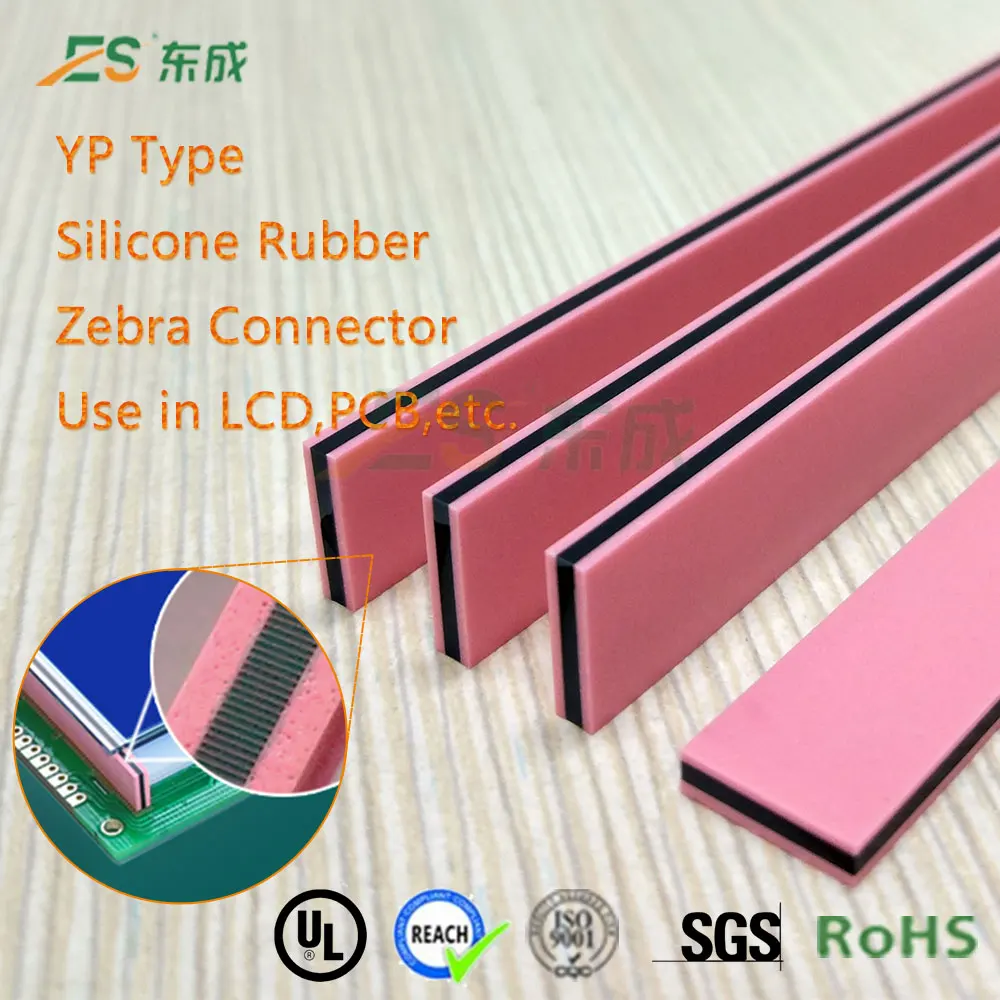

As others note it"s a "zebra connector" which conducts through the plane of the rubber but not across it (ie in the directions you"d expect for it to work).

The "pitch" of the band s of conduction/non conduction are finer than the pitch of the contacts concerned so that short circuits are not formed between the contacts when the strip is moved "sideways".

This method allows ease of assembly, self alignment of the "connecter" - as long as the LCD contacts and PCB contacts are aligned the rubber strip alignment is non-crucial.

Find the different lcd strips wholesale and at great prices on Alibaba.com. LED strips offer a full range of colors and varieties of LED, for example, C9 and C9 LED strips wholesale are a great option when you get in bulk with the wholesale price!. Alibaba.com offers LED strips with a wide range of options and varieties of LED strips wholesale for a great price. However, LED strips also offer several features such as color temperature, input voltage, and LED efficiency all the same, depending on your customers ’ needs and preferences.

Real lcd zebra strips can hold many light as long as they can be used. The price of lcd zebra strips depends on the size and the budget of the customers.

Find the best lcd zebra lights wholesale, Alibaba.com has a wide variety of options to choose from, including bulk led zebra lights for sale, LED zebra lights for sale, and more wholesale from Alibaba. The price of lcd zebra lights for sale depends on the size, the model, and the size of the zebra lights that you want to achieve.

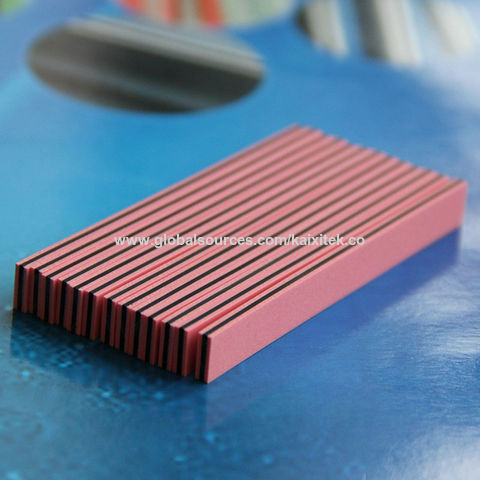

ZEBRA® Elastomeric Connectors have alternating conductive and non-conductive layers. See diagram below. The conductive layers are oriented vertically in the thickness direction, making contact from top to bottom.

Each of the styles is also available with outer support sections along the entire length on one or both sides (except Series 8000). The support is available in sponge or solid silicone rubber, and creates a larger width area. This eliminates the need for a holder while still allowing a very low compression force during deflection.

Zero insertion force,tight pitch,low compression force, very low resistance, very high current carrying capacity; contact pitches at 100, 133, 166 per inch

Drawing on the left shows side support or insulation on one or both sides, or one of each. Various materials are available from the minimum insulating barrier of 0.05mm to support layers of up to 1.5mm. Support layers can be soft silicone rubber, or medium and soft silicone sponge. Recommended height is twice the width for minimum force deflection.

PIN is the most commonly used connection for LCD. I am often asked to answer one question. Can we make the pitch between two PINs 1.0 mm? Of course, we can as long as you pay for the extra cost. There are 4 common used types of pitches: 1.27 mm, 1.5 mm, 2.0 mm and 2.54 mm. The widths of PIN are 0.635 mm, 0.75 m,1.0 mm and 1.27 mm. If you can order 50 thousand each buy, we can make the custom PIN (even bent PIN) and the custom pitch for you and there is no extra cost.

A printed circuit board and an LCD are connected by flexible zebra paper, which adopts heat sealing processing or soldering processing and can be used in all kinds of harsh environments.

Elastomeric connectors, also known by the registered trademark ZEBRA connectors,elastomer matrix to produce overall anisotropic conductive properties. The original version consisted of alternating conductive and insulating layers of silicone rubber, cut crosswise to expose the thin layers. They provide high-density redundant electrical paths for high reliability connections. One of the first applications was connecting thin and fragile glass liquid crystal displays (LCDs) to circuit boards in electronic devices, as little current was required.

A "matrix" version consists of short, fine, metallic wires, 300 to 2,000 per square centimeter, aligned parallel but not touching each other, embedded in a rubber sheet.

http://tmsearch.uspto.gov USPTO Reg. No. 1017912, LAYERED ELECTRICAL CONTACTS AND CONNECTORS, Filed October 10, 1974 by Technical Wire Products Inc, Cranford, NJ, USA; first used in commerce Apr 26, 1974; renewed Sept 11, 2005; last listed owner Fuji Polymer Industries Ltd Chiyoda Nogoya-shi Aichi-ken Japan

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

![]()

The two most common devices for connecting glass flat-panel displays to printed circuit boards (PCBs) are the elastomeric connector and the heat-seal connector. The elastomeric connector is the older connecting method and is commonly used in preassembled liquid-crystal display (LCD) modules. The heat-seal connector is a more recent innovation that can be interchangeable with the elastomeric connector in many post and allows much more design flexibility.

The layered elastomeric connector is a laminated strip of silicone rubber With alternating conductive and insulating layers. It is used to connect electrodes on a PCB to those on the glass substrate of an LCD. The connector is described by its length, height, and Width, and the pitch of its conductive layers. The dimensions of the connector depend on the geometry of the LCD and its position relative to the PCB. Elastomeric connectors are widely used in modules and where the LCD can be mounted directly to the PCB that contains the drivers.

When an elastomeric connector is used, it is positioned directly on top of the PCB electrodes, and the display is positioned on top of the connector. For proper alignment, the length of the connector must slightly exceed the distance between the outermost electrodes but should not exceed the length of the LCD. This allowance permits the connector to move from side to side without missing electrodes.

The connector’s width is determined by the lip of the LCD, and should be designed to fit snugly along the lip without exceeding the lip’s width. The connector height must be held to a tighter tolerance than the length and width. The general rule of thumb is that an elastomeric connector should be compressed by 10-15% when assembled, but never more than 1 .0 mm. If the connectors are compressed less than 0.5 mm, they will be unable to compensate for variations in the PCB and LCD surfaces. If elastomeric connectors are compressed more than 1 .0 mm, they may buckle and lose contact with either the PCB or the LCD. Buckling may also occur if the height exceeds the width of the connector by more than 3 to 1.

For proper connection with an elastomeric connector, the LCD must be constrained directly above the PCB and compressed. The most popular way of accomplishing this is to use a plastic or metal bezel that surrounds the display like a frame and attaches to the PCB. No matter What constraining device is used, alignment between the LCD and the PCB must be maintained. Because elastomeric connectors are redundant – not dedicated – connectors, designers must maintain that the ratio of substrate pitch to connector pitch is at least 3 to 1. The conductive paths in an elastomeric connector are never quite vertical and misalignment may result because of skewing. Heights over 10 mm require special design consideration. See: What Variables Are Necessary For Good HeatSealing

PCBs have three common electrode types: tin-lead, gold-plated, and carbon-ink coated. Because of the high impedances inherent in carbon-doped elastomer layers and LCDs, any of the three can be used with elastomeric connectors. The disadvantage of tin-lead pads is that they can corrode; if corroded, they require cleaning prior to placement of the connector. After assembly, the compressed connector should protect the electrodes from further oxidation. Gold-plated and carbon-ink-coated traces eliminate the oxidation problem and are equally good for elastomeric-connector post.

Once the LCD module is assembled, certain problems can arise. The first problem is missing segments. Barring any problems with the LCD glass, missing segments result from excessive resistance through a conductive path. This can be caused by buckling of the connector, which lifts the conductive traces from the PCB or the LCD. This problem can occur for connectors that have height-to-width ratios greater than 3 to 1, lack proper side constraint, or are over-compressed. If no segments are lit under compression, then oxidation of all the electrodes could be the problem.

A related connector failure is indicated by a display with faded segments. High resistance is once again the problem – but only enough resistance to cause fading. If fading occurs, the connector resistance can be lowered by increasing the width of the connector’s conductive core, changing to a connector with a lower bulk resistivity, decreasing the assembly height, or increasing the electrode width. The contact resistance can be decreased by using gold-plated PCB traces.

Elastomeric connectors offer a reliable method for connecting displays to PCBs. While the connectors themselves are inexpensive, assembly of the components involves some additional cost. Finally, elastomeric connectors are limited to post in which the display can be conveniently located directly above and parallel to the PCB.

A HSC can be bonded to most common PCB pads and other substrate materials. The adhesive bonds well to copper, gold, tin, and carbon-ink pads, as well as to the glass used for LCDs. The major requirements for the bonding surface are that it be clean, flat, and smooth to assure adequate bond strength.

Heat-seal connectors can be found in a wide variety of post. In the common calculator they bond the LCD and the solar panel to the PCB. In military post, they serve where a high-resolution display requires a fine-pitch connector.

The HSC has many advantages over other connectors in laptop computers, where it is widely used to connect the display to the PCB. Among these advantages is the HSC’s minimal use of board space for bonding and the fact that it eliminates the need to attach the display directly to the PCB. This allows the board to be used exclusively for components. Another advantage is that it allows the PCB and all display drivers to be located on a single board in the half of the computer which houses the keyboard. The connector travels from the PCB through the hinged area to the display, eliminating the need for a driver board next to the display. HSCs have been found to be very durable, even with the constant bending required in this hinged application. They are typically tested to maintain their performance characteristics for a minimum of 20,000 bending cycles.

Many other FPD post utilize HSCs because of the design flexibility they offer. In slim packages, such as pagers and cellular telephones, there is typically not enough room to mount the display on top of the PCB, as is required with elastomeric connectors. With an HSC the display can be in any position relative to the board and at almost any distance. HSCs offer a wide range of trace pitches from 0.28 mm on up. Elastomeric connectors have pitches as small as 0.03 mm, but because of the redundancy requirements the minimum pitch of the component traces is 0. 10 mm.

An application requiring a high-resolution (fine-pitch) HSC is a fish-finder display. The HSCs used in fish finders have demonstrated the durability required of an electronic connector that will be used in demanding conditions.

The cost of HSCs can be competitive with many other types of connectors. Typically more expensive than elastomeric connectors, their design flexibility makes HSCs a common choice for LCD-to-PCB post. Electroluminescent and gas-plasma displays have higher power requirements than LCDs and therefore require low-resistance connectors. In these post silver HSCs are less expensive than low-resistance elastomeric connectors. HSCs can be dramatically less expensive than flex circuits and ribbon connectors, but resistance limits the post in which they can be used.

Display-to-driver connections in the future will focus on a single flex circuit TAB that will be bonded to a display having all of its driver chips mounted on its perimeter. More than one display manufacturer is investigating this concept for flat-panel-display assembly, but the technology has not been perfected.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey